ASTM C717-00

(Terminology)Standard Terminology of Building Seals and Sealants

Standard Terminology of Building Seals and Sealants

SCOPE

1.1 This standard covers terms, related standard definitions, and descriptions of terms used or likely to be used in standard test methods, specifications, guides, and practices (related to building seals and sealants) consistent with the scope and areas of interest of ASTM Committee C24.

1.2 Definitions and descriptions of terms are written to ensure that building seals and sealants standards are properly understood and interpreted.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 717 – 00

Standard Terminology of

Building Seals and Sealants

This standard is issued under the fixed designation C 717; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 883 Terminology Relating to Plastics

D 1079 Terminology Relating to Roofing, Waterproofing,

1.1 This standard covers terms, related standard definitions,

and Bituminous Material

and descriptions of terms used or likely to be used in standard

D 1565 Specification for Flexible Cellular Materials—

test methods, specifications, guides, and practices (related to

Vinyl Chloride Polymers and Copolymers (Open-Cell

building seals and sealants) consistent with the scope and areas

Foam)

of interest of ASTM Committee C-24.

D 1566 Terminology Relating to Rubber

1.2 Definitions and descriptions of terms are written to

D 2102 Test Method for Shrinkage of Textile Fibers

ensure that building seals and sealants standards are properly

(Bundle Test)

understood and interpreted.

E 631 Terminology of Building Constructions

2. Referenced Documents

2.2 ACI (American Concrete Institute) Standard:

301-72 (1975) Specifications to Structural Concrete for

2.1 ASTM Standards:

Buildings

C 509 Specification for Elastomeric Cellular Preformed

Gasket and Sealing Material

3. Significance and Use

C 542 Specification for Lock-Strip Gaskets

3.1 Definitions:

C 716 Specification for Installing Lock-Strip Gaskets and

2 3.1.1 Terms and their related standard definitions in Section

Infill Glazing Materials

4 are intended for use uniformly and consistently in all building

C 790 Guide for Use of Latex Sealants

seals and sealants test methods, specifications, guides, and

C 797 Practices and Terminology for Use of Oil- and

practices. The purpose of such use is to promote a clear

Resin-Based Putty and Glazing Compounds

understanding and interpretation of the standards in which they

C 898 Guide for Use of High Solids Content, Cold Liquid-

are used.

Applied Elastomeric Waterproofing Membrane with Sepa-

3.1.2 Definitions of terms are written in the broadest sense

rate Wearing Course

possible, consistent with the intended meaning. Definitions

C 957 Specification for High-Solids Content, Cold Liquid-

have not been limited to a specific technical field when they

Applied Elastomeric Waterproofing Membrane with Inte-

can have a multi-field application.

gral Wearing Surface

3.1.3 The definition of a term that can have different

C 961 Test Method for Lap Shear Strength for Hot-Applied

meanings in different technical fields is preceded by a phrase

Sealants

limiting it to the specific field intended, that is, “in building

C 964 Guide for Lock-Strip Gasket Glazing

construction.”

C 981 Guide for Design of Built-Up Bituminous Membrane

3.2 Description of Terms:

Waterproofing Systems for Building Decks

3.2.1 Descriptions of Terms are special purpose definitions

C 1021 Practice for Laboratories Engaged in the Testing of

intended to provide a precise understanding and interpretation

Building Sealants

of the seals and sealants standards in which they are used.

C 1127 Guide for Use of High Solids Content, Cold Liquid-

3.2.2 A specific description of a term is applicable to the

Applied Elastomeric Waterproofing Membrane with an

2 standard or standards in which the term is described and used.

Integral Wearing Surface

3.2.3 Each standard in which a term is used, in a specially

C 1193 Guide for Use of Joint Sealants

defined manner, should list the term and its description under

the subheading, descriptions of terms.

This terminology is under the jurisdiction of ASTM Committee C-24 on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.01

Annual Book of ASTM Standards, Vol 08.01.

on Terminology of Building Seals and Sealants.

Annual Book of ASTM Standards, Vol 04.04.

The boldface designations refer to the original source of the definition and the Annual Book of ASTM Standards, Vol 09.01.

ASTM Technical Committee having jurisdiction. Annual Book of ASTM Standards, Vol 07.01.

Current edition approved June 10, 2000. Published June 2000. Originally Annual Book of ASTM Standards, Vol 04.11.

published as C 717 – 72. Last previous edition C 717 – 99. Available from American Concrete Institute, P.O. Box 19150 Redford Station,

Annual Book of ASTM Standards, Vol 04.07. Detroit, MI 48219.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 717

4. Terminology

4.1 Terms and Definitions:

adhesive failure, n—in building construction, failure of the

bond between the sealant, adhesive, or coating and the

substrate surface.

back bedding, n—See bedding.

back putty, n—See bedding.

back-up material—See sealant backing.

band aid sealant joint, n—Use bridge sealant joint (pre-

ferred term).

bead, n—in building construction, in sealants and glazing, a

strip of applied sealant, glazing compound, or putty.

bed, v—in building construction in glazing, to apply a bead of

sealant between a lite of glass or a panel and the stationary

stops or sight bars of the sash or frame.

bed, n—See bedding.

bedding, n—in building construction in glazing, a bead of

sealant applied between a lite of glass or a panel and the

stationary stop or sight bar of the sash or frame. It is usually

the first bead to be applied when setting glass or panels.

bicellular sealant backing, n—a flexible and very compress-

ible extruded shape (usually cylindrical), with a surface skin,

that is composed of both open and closed cell material.

bite, n—in building construction in glazing, the dimensional

depth by which the framing system (such as frames, stops,

sash, or lock-strip gaskets) overlaps the edge of the glass or

panel.

bloom, n—in building construction, a substance formed by

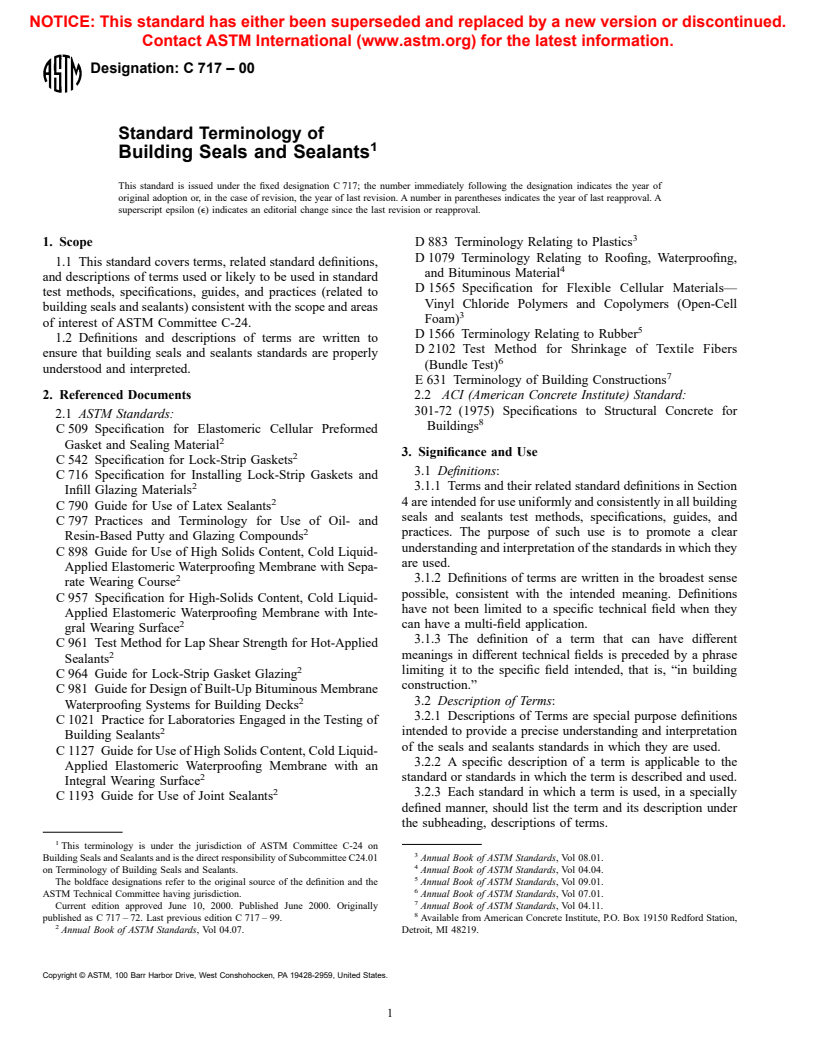

FIG. 1 Bridge Sealant Joint

blooming.

blooming, v—in building construction, movement or diffusion

many cells (either open, closed, or both) dispersed through

of a component such as a plasticizer, monomer, unreacted

the mass. D 1565; D1566; D-11

polymer or other formulation ingredient to a sealant, coating,

chalk, n—in building construction, a powder formed by

or membrane surface.

chalking

bond breaker—in building construction, a material to prevent

DISCUSSION—The powder is not necessarily white.

adhesion at a designated interface.

bridge sealant joint, n—in building construction, a joint

chalking, v—in building construction, formation of a powder

where sealant is applied over the joint to the face of

on the surface of a sealant, coating, or membrane that is

substrates that are in approximately the same plane (see Fig.

caused by the disintegration of the polymer or binding

1).

medium due to weathering.

DISCUSSION—Not to be confused with joints in bridges.

DISCUSSION—Chalk on a light color sealant is often white, however a

darker color can also exhibit chalking.

building seal—See seal.

butt glazing, n—in building construction, a glazing system closed cell, n—a cell totally enclosed by its walls and hence

wherein butt joints are formed between lites and filled with

not interconnecting with other cells. D 883; D-20

a glazing sealant. closed cell material, n—a cellular material in which substan-

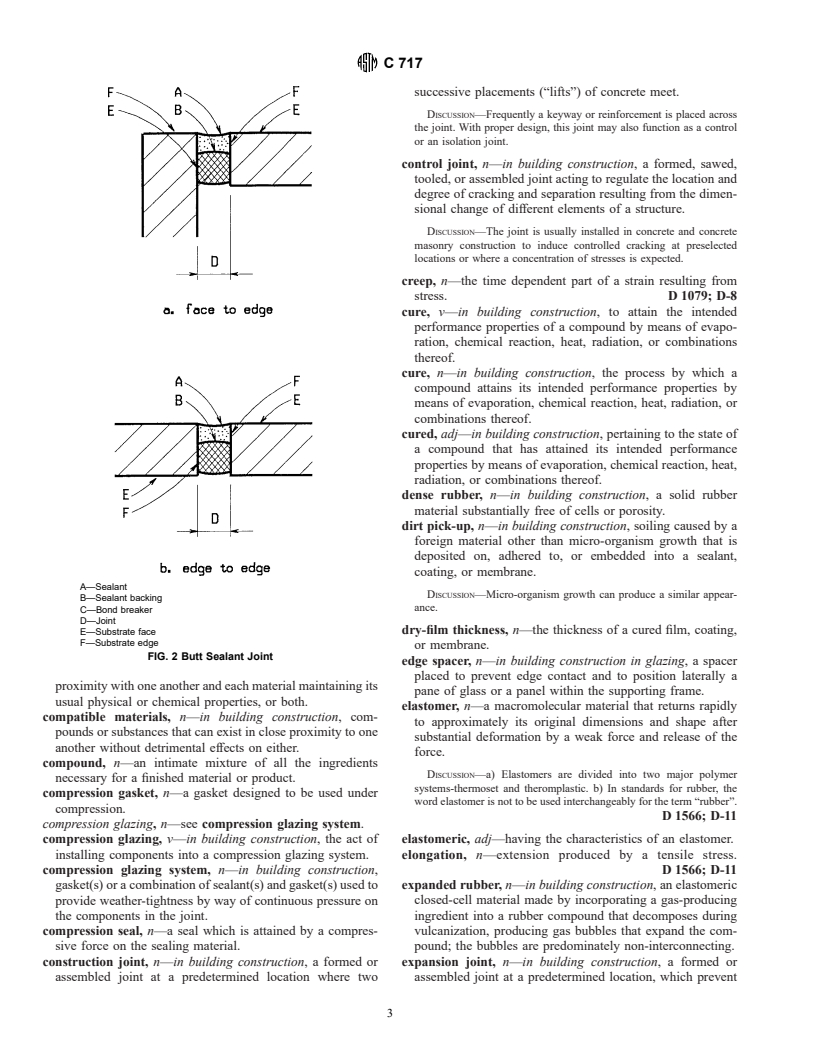

butt joint, n—See butt sealant joint. (See Fig. 2.)

tially all cells in the mass are closed cells.

butt sealant joint, n—in building construction, a joint where closed cell sealant backing, n—in building construction,a

sealant is applied within the joint between approximately flexible and somewhat compressible extruded shape (usually

parallel substrate surfaces that are face-to-edge or edge-to- cylindrical), with a surface skin, that is composed of closed

edge. (See Fig. 2.) cell material.

caulk, v—in building construction, to install or apply a sealant cohesive failure, n—in building construction, failure charac-

across or into a joint, crack, or crevice. terized by rupture within the sealant, adhesive, or coating.

caulk, n—See sealant. cold joint, n—a plane of weakness in concrete caused by an

caulking, n—See sealant. interruption or delay in the placing operation, which permits

caulking compound, n—See sealant. the first batch to start setting before the next batch is placed,

cell, n—a single small cavity surrounded partially or com- resulting in little or no bond between the two batches.

pletely by walls. D 1566; D-11 compatibility, n—in building construction, the capability of

cellular material, n—a generic term for materials containing two or more materials to be placed in contact or close

C 717

successive placements (“lifts”) of concrete meet.

DISCUSSION—Frequently a keyway or reinforcement is placed across

the joint. With proper design, this joint may also function as a control

or an isolation joint.

control joint, n—in building construction, a formed, sawed,

tooled, or assembled joint acting to regulate the location and

degree of cracking and separation resulting from the dimen-

sional change of different elements of a structure.

DISCUSSION—The joint is usually installed in concrete and concrete

masonry construction to induce controlled cracking at preselected

locations or where a concentration of stresses is expected.

creep, n—the time dependent part of a strain resulting from

stress. D 1079; D-8

cure, v—in building construction, to attain the intended

performance properties of a compound by means of evapo-

ration, chemical reaction, heat, radiation, or combinations

thereof.

cure, n—in building construction, the process by which a

compound attains its intended performance properties by

means of evaporation, chemical reaction, heat, radiation, or

combinations thereof.

cured, adj—in building construction, pertaining to the state of

a compound that has attained its intended performance

properties by means of evaporation, chemical reaction, heat,

radiation, or combinations thereof.

dense rubber, n—in building construction, a solid rubber

material substantially free of cells or porosity.

dirt pick-up, n—in building construction, soiling caused by a

foreign material other than micro-organism growth that is

deposited on, adhered to, or embedded into a sealant,

coating, or membrane.

A—Sealant

DISCUSSION—Micro-organism growth can produce a similar appear-

B—Sealant backing

ance.

C—Bond breaker

D—Joint

dry-film thickness, n—the thickness of a cured film, coating,

E—Substrate face

F—Substrate edge

or membrane.

FIG. 2 Butt Sealant Joint

edge spacer, n—in building construction in glazing, a spacer

placed to prevent edge contact and to position laterally a

proximity with one another and each material maintaining its

pane of glass or a panel within the supporting frame.

usual physical or chemical properties, or both.

elastomer, n—a macromolecular material that returns rapidly

compatible materials, n—in building construction, com-

to approximately its original dimensions and shape after

pounds or substances that can exist in close proximity to one

substantial deformation by a weak force and release of the

another without detrimental effects on either.

force.

compound, n—an intimate mixture of all the ingredients

DISCUSSION—a) Elastomers are divided into two major polymer

necessary for a finished material or product.

systems-thermoset and theromplastic. b) In standards for rubber, the

compression gasket, n—a gasket designed to be used under

word elastomer is not to be used interchangeably for the term “rubber”.

compression.

D 1566; D-11

compression glazing, n—see compression glazing system.

compression glazing, v—in building construction, the act of elastomeric, adj—having the characteristics of an elastomer.

elongation, n—extension produced by a tensile stress.

installing components into a compression glazing system.

compression glazing system, n—in building construction, D 1566; D-11

gasket(s) or a combination of sealant(s) and gasket(s) used to expanded rubber, n—in building construction, an elastomeric

provide weather-tightness by way of continuous pressure on closed-cell material made by incorporating a gas-producing

the components in the joint. ingredient into a rubber compound that decomposes during

compression seal, n—a seal which is attained by a compres- vulcanization, producing gas bubbles that expand the com-

sive force on the sealing material. pound; the bubbles are predominately non-interconnecting.

construction joint, n—in building construction, a formed or expansion joint, n—in building construction, a formed or

assembled joint at a predetermined location where two assembled joint at a predetermined location, which prevent

C 717

the transfer of forces across the joint as a result of movement are approximately perpendicular to each other (see Fig. 3).

or dimensional change of different elements of a structure or flow, v—in building construction, the deformation of a tape

building.

sealant under stress.

expansion joint seal, n—in building construction, a seal or fluid migration, n—in building construction, accumulation of

sealant system that provides an elastic, compressible, or

a fluid from a sealant, coating, or membrane on or in an

flexible barrier to the passage of gases, liquids, or solids. adjacent material.

face glazing, n—the method of glazing in which a rabbeted

DISCUSSION—Migration of a non-fluid component can also occur.

glazing recess, with no removable stop, is used and a

triangular bead of compound is applied to the face of the lite

four-side structural sealant glazing, n—in building construc-

and extended onto the recess.

tion, a glazing system wherin all sides of a rectangular-

fillet bead joint, n—Use fillet sealant joint (preferred term).

shaped lite or panel are structural sealant glazed.

(See Fig. 3.)

gasket, n—any preformed, deformable device designed to be

fillet sealant joint, n—in building construction, a joint where

placed between two adjoining parts to provide a seal.

sealant is applied over the joint to the face of substrates that

glazing, v—in building construction, the installation of glass or

other materials in prepared openings.

gun-grade, n—in building construction, a material of a suit-

able viscosity to extrude through the nozzle of a hand- or

power-operated device.

hardness, n—the resistance to indentation as measured under

specified conditions. D 1566; D-11

hydrostatic pressure, n—a state of stress in which all the

principal stresses are equal (and there is no shear stress), as

in a liquid at rest; the product of the unit weight of the liquid

and the difference in elevation between the given

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.