ASTM E1952-06

(Test Method)Standard Test Method for Thermal Conductivity and Thermal Diffusivity by Modulated Temperature Differential Scanning Calorimetry

Standard Test Method for Thermal Conductivity and Thermal Diffusivity by Modulated Temperature Differential Scanning Calorimetry

SIGNIFICANCE AND USE

Thermal conductivity is a useful design parameter for the rate of heat transfer through a material.

The results of this test method may be used for design purposes, service evaluation, manufacturing control, research and development, and hazard evaluation. (See Practice E 1231.)

SCOPE

1.1 This test method describes the determination of thermal determination of thermal conductivity of homogeneous, non-porous solid materials in the range of 0.10 to 1.0 W/(K m) by modulated temperature differential scanning calorimeter. This range includes many polymeric, glass, and ceramic materials. Thermal diffusivity, which is related to thermal conductivity through specific heat capacity and density, may also be derived. Thermal conductivity and diffusivity can be determined at one or more temperatures over the range of 0 to 90 C.

1.2 SI units are the standard. The values given in parentheses are provided for information purposes only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1952 – 06

Standard Test Method for

Thermal Conductivity and Thermal Diffusivity by Modulated

1

Temperature Differential Scanning Calorimetry

This standard is issued under the fixed designation E1952; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E473 Terminology Relating to Thermal Analysis and Rhe-

ology

1.1 This test method describes the determination of thermal

E967 Test Method for Temperature Calibration of Differen-

determination of thermal conductivity of homogeneous, non-

tial Scanning Calorimeters and Differential Thermal Ana-

porous solid materials in the range of 0.10 to 1.0W/(K • m) by

lyzers

modulated temperature differential scanning calorimeter. This

E968 Practice for Heat Flow Calibration of Differential

range includes many polymeric, glass, and ceramic materials.

Scanning Calorimeters

Thermal diffusivity, which is related to thermal conductivity

E1142 Terminology Relating to Thermophysical Properties

throughspecificheatcapacityanddensity,mayalsobederived.

E1231 Practice for Calculation of Hazard Potential Figures-

Thermal conductivity and diffusivity can be determined at one

of-Merit for Thermally Unstable Materials

or more temperatures over the range of 0 to 90 °C.

1.2 SI units are the standard. The values given in parenthe-

3. Terminology

ses are provided for information purposes only.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 Specific technical terms used in this document are

safety concerns, if any, associated with its use. It is the

defined in Terminologies E473 and E1142.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 modulated temperature differential scanning

bility of regulatory limitations prior to use.

calorimeter—a version of differential scanning calorimetry

2. Referenced Documents thatprovidesasinusoidallyvaryingtemperatureprogramtothe

2

test specimen in addition to the traditional isothermal or

2.1 ASTM Standards:

temperature ramp programs. Results from analysis shall in-

clude apparent and specific heat capacity.

1

This test method is under the jurisdiction of Committee E37 on Thermal

4. Summary of Test Method

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

4.1 The heat capacity of a test specimen may be determined

rimetry and Mass Loss.

Current edition approved Dec. 1, 2006. Published January 2007. Originally using the modulated temperature approach in which an oscil-

approved in 1998. Last previous edition approved in 2001 as E1952 – 01. DOI:

latory or periodically repeating temperature program (around

10.1520/E1952-06.

an average temperature) is imposed upon a test specimen

The process described in this test method is covered by a patent (Marcus, S. M.

producing an oscillatory (periodic) heat flow into or out of the

and Reading, M., U. S. Patent 5 335 993, 1994) held by TA Instruments, Inc., 109

Lukens Drive, New Castle DE 19720. Interested parties are invited to submit

specimen. The heat capacity of the test specimen may be

information regarding the identification of acceptable alternatives to this patented

obtained from the amplitude of the resultant heat flow divided

method to the Committee on Standards, ASTM Headquarters, 100 Barr Harbor

by the amplitude of the oscillatory (periodic) temperature that

Drive, West Conshohocken PA 19428-2959. Your comments will receive careful

produces it. Specific heat capacity is obtained by normalizing

considerations at a meeting of the responsible technical committee which you may

attend.

the heat capacity to specimen mass.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.1 The accuracy of the heat capacity thus obtained

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

depends upon experimental conditions. When a thin test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specimen encapsulated in a specimen pan of high thermal

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1952 – 06

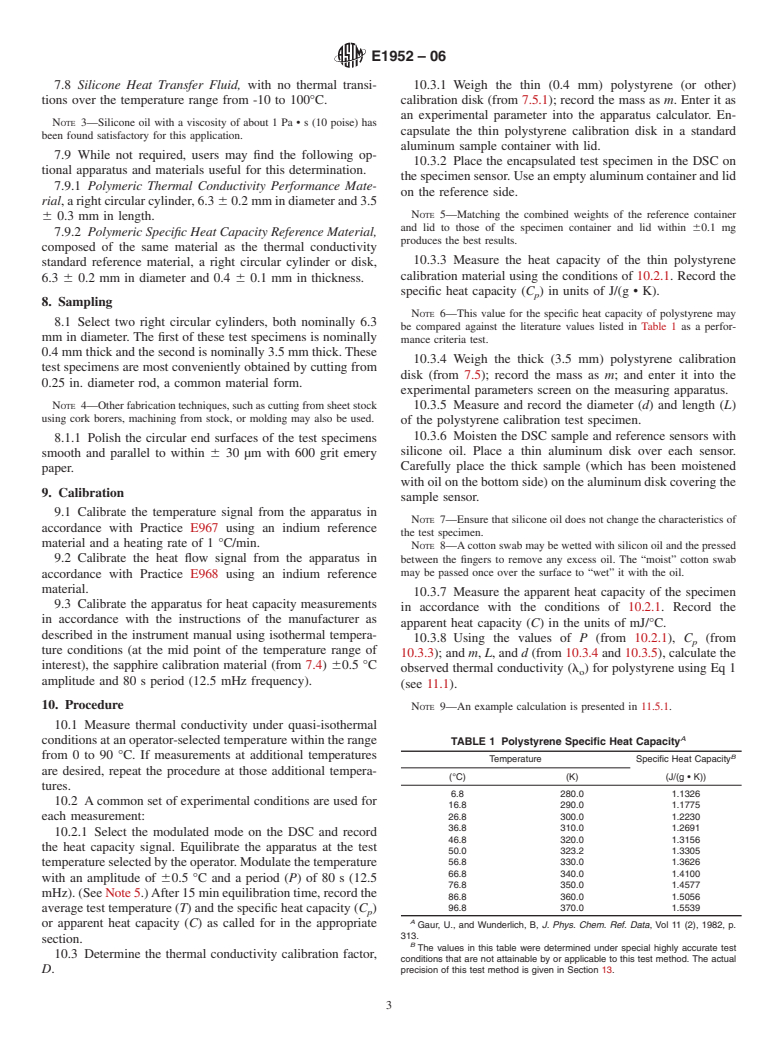

conductivity is treated with temperature oscillations of long environment of inert nitrogen purge gas at a rate of 50

period (low frequency), the test specimen is assumed to mL/min6 10 mL/min.

achieve a uniform temperature distribution and the resultant 7.1.2 A Temperature Controller, capable of executin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.