ASTM C1092-94

(Specification)Specification for Glass Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer Pipe (Withdrawn 1995)

Specification for Glass Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer Pipe (Withdrawn 1995)

General Information

Standards Content (Sample)

AMERICAN SOCIETY FOR TESTING AND MA TERI/

1916 Race St. Philadelphia, Pa 19103

~~l~ Designation: C 1092 - 94

Reprinted from the Annual Book of AS™ Standards. Copyright AS™

If not listed in the current combined index, will appear in the next ed~ion.

Standard Specification for

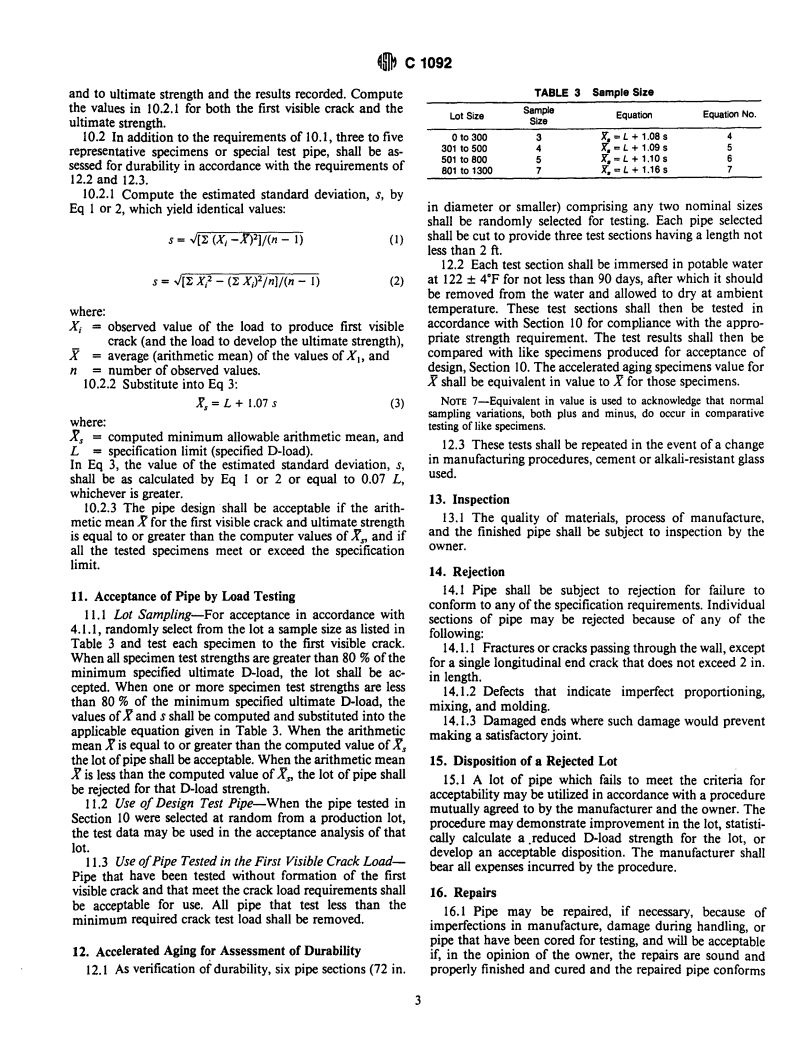

Glass Reinforced Concrete D-Load Culvert, Storm Drain, and

1

Sewer Pipe

This standard is issued under the fixed designation C 1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (t) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Basis of Acceptance

1.1 This specification covers concrete pipe reinforced with 4.1 The acceptability of the pipe design shall be deter

substantially continuous inner and outer layers of alkali mined in accordance with Section 10. After the pipe design

resistant glass rovings and is designed for specific D-loads has been accepted, or if the pipe design has been accepted

and intended to be used for conveyance of sewage, industrial previously in accordance with Section 10, the basis of

wastes, and storm water and for the construction of culverts. acceptance shall be as described in 4.1.1.

4.1.1 Acceptance on the basis of pipe load and material

NOTE 1-A complete metric companion to Specification C 1092 is

tests and inspection of manufactured pipe for defects shall be

being developed-C 1092M; therefore, no metric equivalents are pre

determined in accordance with Sections 5, 6, 9, and 11.

sented in this specification.

NoTE 2-faperience has shown that the successful performance of

NOTE 3-It is necessary that samples be selected at random. For

this product depends upon the proper selection of the pipe strength, the

guidance see Practice E 105.

type of bedding and backfill, the care in the field construction work, and

4.2 Age for Acceptance-Pipe shall be considered ready

provision for adequate inspection at the construction site. This specifi

for acceptance when they conform to the requirements.

cation does not include requirements for bedding, backfill, the relation

ship between earth cover load and the strength designation of pipe, or

5. Design and Manufacturing Data

durability under unusual environmental conditions. These requirements

should be included in the project specification.

5.1 The manufacturer shall provide the following infor

mation regarding the pipe:

2. Referenced Documents 5.1.l Pipe strength, design strength, and minimum ulti

mate strength.

2.1 ASTM Standards:

NOTE 4-The relationship of the ultimate D-load strength to the

C 31 Practice for Making and Curing Concrete Test

design D-load strength shall not be less than 1.5 times the design

2

Specimens in the Field

strength.

2

C 33 Specification for Concrete Aggregates

5.1.2 Physical Characteristics-Diameter, wall thickness,

C 39 Test Method for Compressive Strength of Cylin

2

laying length, and joint details.

drical Concrete Specimens

5.1.3 Design concrete strengths; minimum f c equals

C 42 Test Method for Obtaining and Testing Drilled

2 5000 psi.

Cores and Sawed Beams of Concrete

3 5.1.4 Glass Reinforcement:

C 150 Specification for Portland Cement

5.1.4.1 Type of alkali-resistant glass reinforcement, and

C 309 Specification for Liquid Membrane-Forming Com

2 applicable specification, and

pounds for Curing Concrete

5.1.4.2 Placement, placement tolerances, spacing and

C 497 Test Methods for Concrete Pipe, Manhole Sec

4

cross-sectional area of glass reinforcement (strands per foot).

tions, or Tile

3 5.1.5 Manufacturing and curing process.

C 595 Specification for Blended Hydraulic Cements

C 822 Terminology Relating to Concrete Pipe and Re

6. Materials and Manufacture

4

lated Products

5

6.1 Materials:

E 105 Practice for Probability Sampling of Materials

6.1.1 Cement-Portland cement shall conform to the

requirements of· Specification C 150, or shall be either

3. Terminology

Portland blast-furnace slag cement or Portland-pozzolan

3.1 Definitions-For definitions of terms relating to con

cement conforming to the requirements of Specification

crete pipe, see Terminology C 822.

c 595.

6.1.2 Aggregates-Aggregates shall conform to the re

quirements of Specification C 33, except that the require

1 This specification is under the jurisdiction of ASTM Committee C-13 on

ment for gradation shall not apply.

Concrete Pipe and is the direct responsibility of Subcommittee Cl 3.07 on

6.1.3 Admixtures and Blends-Admixtures and blends

Acceptance Specifications and Precast Concrete Box Sections.

Current edition approved July 15, 1994. Published September 1994. Originally shall not be used.

published as C 1092 - 88. Last previous edition C 1092 - 88.

6.1.4 Glass Reinforcement-The alkali-resistant glass fi

2 Annual Book of ASTM Standards, Vol 04.02.

bers shall contain a minimum of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.