ASTM E81-96(2011)

(Test Method)Standard Test Method for Preparing Quantitative Pole Figures

Standard Test Method for Preparing Quantitative Pole Figures

SIGNIFICANCE AND USE

Pole figures are two-dimensional graphic representations, on polar coordinate paper, of the average distribution of crystallite orientations in three dimensions. Data for constructing pole figures are obtained with X-ray diffractometers, using reflection and transmission techniques.

Several alternative procedures may be used. Some produce complete pole figures. Others yield partial pole figures, which may be combined to produce a complete figure.

SCOPE

1.1 This test method covers the use of the X-ray diffractometer to prepare quantitative pole figures.

1.2 The test method consists of several experimental procedures. Some of the procedures (1-5) permit preparation of a complete pole figure. Others must be used in combination to produce a complete pole figure.

1.3 Pole figures (6) and inverse pole figures (7-10) are two-dimensional averages of the three-dimensional crystallite orientation distribution. Pole figures may be used to construct either inverse pole figures (11-13) or the crystallite orientation distribution (14-21). Development of series expansions of the crystallite orientation distribution from reflection pole figures (22, 23) makes it possible to obtain a series expansion of a complete pole figure from several incomplete pole figures. Pole figures or inverse pole figures derived by such methods shall be termed calculated. These techniques will not be described herein.

1.4 Provided the orientation is homogeneous through the thickness of the sheet, certain procedures (1-3) may be used to obtain a complete pole figure.

1.5 Provided the orientation has mirror symmetry with respect to planes perpendicular to the rolling, transverse, and normal directions, certain procedures (4, 5, 24) may be used to obtain a complete pole figure.

1.6 The test method emphasizes the Schulz reflection technique (25). Other techniques (3, 4, 5, 24) may be considered variants of the Schulz technique and are cited as options, but not described herein.

1.7 The test method also includes a description of the transmission technique of Decker, et al (26), which may be used in conjunction with the Schulz reflection technique to obtain a complete pole figure.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E81 −96 (Reapproved 2011)

Standard Test Method for

Preparing Quantitative Pole Figures

ThisstandardisissuedunderthefixeddesignationE81;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the use of the X-ray diffracto-

responsibility of the user of this standard to establish appro-

meter to prepare quantitative pole figures.

priate safety and health practices and determine the applica-

1.2 The test method consists of several experimental proce-

bility of regulatory limitations prior to use.

dures. Some of the procedures (1-5) permit preparation of a

complete pole figure. Others must be used in combination to

2. Summary of Test Method

produce a complete pole figure.

2.1 The test method consists of characterizing the distribu-

1.3 Pole figures (6) and inverse pole figures (7-10) are two

tion of orientations of selected lattice planes with respect to

dimensional averages of the three-dimensional crystallite ori-

sample-fixed coordinates (6). The distribution will usually be

entation distribution. Pole figures may be used to construct

obtained by measurement of the intensity of X rays diffracted

either inverse pole figures (11-13) or the crystallite orientation

by the sample. In such measurements the detector and associ-

distribution (14-21). Development of series expansions of the

ated limiting slits are fixed at twice the appropriate Bragg

crystallite orientation distribution from reflection pole figures

angle,andthediffractedintensityisrecordedastheorientation

(22, 23) makes it possible to obtain a series expansion of a

of the sample is changed (1-6, 25, 26, 27).After the measured

completepolefigurefromseveralincompletepolefigures.Pole

data have been corrected, as necessary, for background,

figuresorinversepolefiguresderivedbysuchmethodsshallbe

defocusing,andabsorption,andnormalizedtohaveanaverage

termed calculated. These techniques will not be described

value of unity, the results may be plotted in stereographic or

herein.

equal-area projection.

1.4 Provided the orientation is homogeneous through the

2.2 The geometry of the Schulz (25) reflection method is

thickness of the sheet, certain procedures (1-3) may be used to

illustrated in Fig. 1. Goniometers employing this geometry are

obtain a complete pole figure.

commerciallyavailable.ThesourceofXraysisindicatedby L.

1.5 Provided the orientation has mirror symmetry with

Slit S1 limits divergence of the incident beam in the plane of

respect to planes perpendicular to the rolling, transverse, and

projection. Slit S2 limits divergence perpendicular to the plane

normal directions, certain procedures (4, 5, 24) may be used to

of projection. The sample, indicated by crosshatching, may be

obtain a complete pole figure.

tilted about the axis FF', which is perpendicular to the

1.6 The test method emphasizes the Schulz reflection tech- diffractometer axis and lies in the plane of the sample. The tilt

nique (25). Other techniques (3, 4, 5, 24) may be considered angle was denoted φ by Schulz (25). The sample position

variants of the Schulz technique and are cited as options, but shown in Fig. 1 corresponds to φ=0 deg, for which approxi-

not described herein.

mateparafocusingconditionsexistatthedetectorslit,S3.With

theapplicationofadefocusingcorrection,thismethodisuseful

1.7 The test method also includes a description of the

over a range of colatitude φ from 0 deg to approximately 75

transmission technique of Decker, et al (26), which may be

deg.

used in conjunction with the Schulz reflection technique to

2.2.1 Tilting the sample about FF ', so as to reduce the

obtain a complete pole figure.

distance between L and points in the sample surface above the

plane of projection, causes X rays diffracted from these points

to be displaced to the left of the center of S3, while X rays

This test method is under the jurisdiction of ASTM Committee E04 on

diffracted from points in the sample surface below the plane of

Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray

projection are displaced to the right of the center of S3. The

and Electron Metallography.

Current edition approved Oct. 1, 2011. Published December 2011. Originally

displacementisequalto2Dtanφcosθ,where Disthedistance

approvedin1949.Lastpreviouseditionapprovedin2007asE81–96(2007).DOI:

aboveorbelowtheplaneofprojection.Theintegrated,ortotal,

10.1520/E0081-96R11.

diffracted intensity is influenced only slightly by tilting the

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this test method. sample (28). Insofar as possible, the detector slit shall be of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E81 − 96 (2011)

3. Significance and Use

3.1 Pole figures are two-dimensional graphic

representations, on polar coordinate paper, of the average

distributionofcrystalliteorientationsinthreedimensions.Data

for constructing pole figures are obtained with X-ray

diffractometers, using reflection and transmission techniques.

3.2 Several alternative procedures may be used. Some

produce complete pole figures. Others yield partial pole

figures, which may be combined to produce a complete figure.

4. Apparatus

4.1 Source of X Rays—A beam of characteristic X rays of

substantially constant intensity is required. Characteristic Ka-

FIG. 1 Geometry of Reflection Method.

lpha radiation of chromium, iron, cobalt, nickel, copper,

molybdenum, and silver have all been used successfully,

depending on the chemical composition of the specimen.

Insofar as possible, the radiation selected shall provide suffi-

sufficient width to include the defocused line profile corre-

cient angular dispersion to permit the resolution of peaks to be

sponding to the maximum sample tilt for which measurements

measured, and shall not produce excessive fluorescence in the

are to be made. Because of interferences from neighboring

sample. Linear absorption coefficients (29) for selected ele-

diffraction peaks and physical limitations on sample size and

mentsaregiveninTable2.Lowerenergyradiation(Cr,Fe,Co,

detectorslitwidth,itisnecessarytolimitverticaldivergenceof

Ni, Cu) is generally preferred for reflection pole figure mea-

the incident beam.Awidely used pole figure goniometer with

surements as it provides greater angular dispersion. Higher

a focal spot to the center of the sample distance of 172 mm

energy radiation (Mo, Ag) is generally preferred for transmis-

employs a 0.5-mm slit located 30 mm from the center of the

sion measurements.

sampleforthispurpose.Measuredintensitiesmaybecorrected

4.2 Slits—Suitableslitsshallbeprovidedtolimithorizon-tal

for defocusing by comparison with intensities diffracted by a

(in the plane of projection of Figs. 1 and 2) and vertical

randomly oriented specimen of similar material, or byemploy-

(perpendicular to the plane of projection of Figs. 1 and 2)

ing the theoretically calculated corrections (28).

divergenceoftheincidentbeam.Horizontaldivergencesof1to

2.3 The geometry of the transmission technique of Decker,

3 deg for reflection and 0.5 deg for transmission are typical.

et al (26) is shown in Fig. 2. In contrast to the reflection

Vertical divergences of 0.2 deg for reflection and 1 deg for

method, X rays diffracted from different points in the sample

transmission are typical. Insofar as possible, the receiving slit

diverge,makingtheresolutionofadjacentpeaksmoredifficult.

shall be of sufficient width to include the diffracted peak.

Theratioofthediffractedintensityatα=−5,−10,···,−70deg,

Receiving slits corresponding to 1 deg 2−theta are typical.

tothediffractedintensityatα=0deg,calculatedinaccordance

4.3 Specimen Holder—Reflection Method:

with the expression given by Decker, et al (26) for linear

4.3.1 The specimen holder for the reflection method shall

absorption thickness product, µt,=1.0, 1.4, ···, 3.0, and, for

preferably employ the Schulz reflection geometry illustrated in

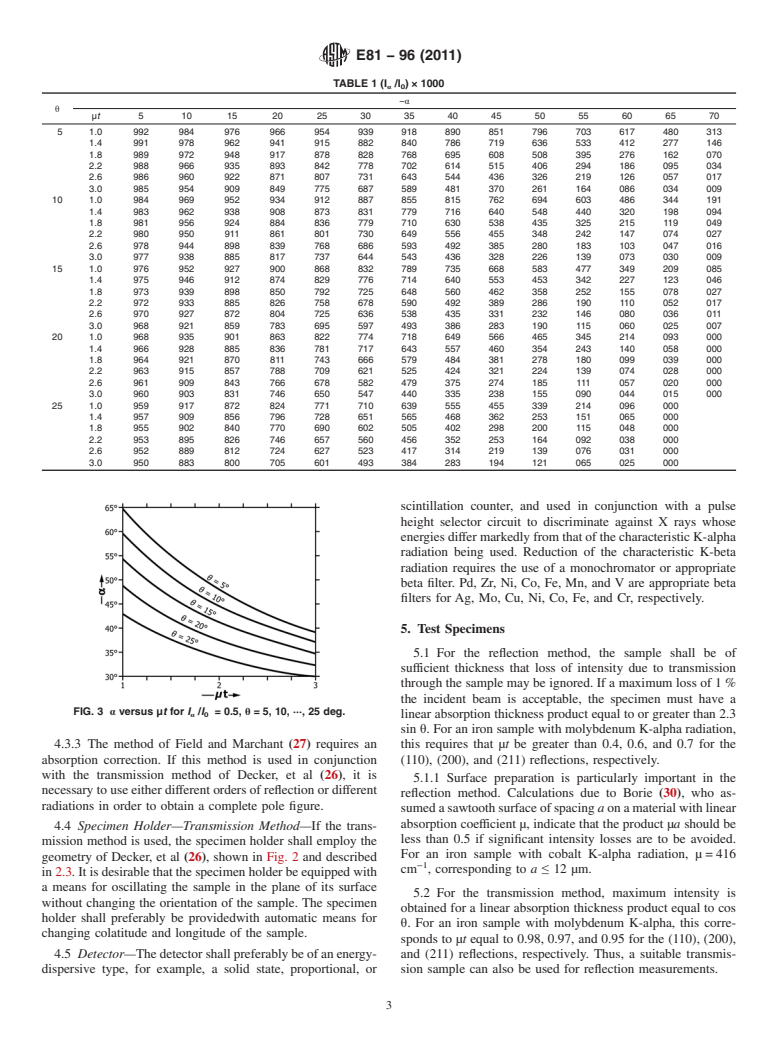

θ=5, 10,··· , 25 deg is given in Table 1. These data may be

Fig. 1 and described in 2.2. It is desirable that the specimen

used as a guide to determine the useful range of α for a given

holder be equipped with a means for oscillating the sample in

µt andθ. If, for example, I /I is restricted to values≥ 0.5, one

α 0

the plane of its surface without changing the orientation of the

arrives at the series of curves shown in Fig. 3.

sample.Itisalsodesirablethatthemagnitudeoftheoscillation

be variable. The specimen holder shall preferably be provided

with automatic means for changing colatitude and longitude of

the sample.

4.3.2 Alternative reflection geometries include those of

Bakarian (1),FieldandMarchant (27),andJetterandBorie (2).

The method of Bakarian requires machining a number of

cylindrical specimens whose axes are perpendicular to the

sheet normal direction. Each specimen provides intensity data

alongoneparalleloflongitude.ThemethodofJetterandBorie

entails the preparation of a spherical specimen. In the methods

ofBakarianandofJetterandBorie,thesampleshall,insofaras

possible, be prepared from homogeneous material. These

methods have the advantage that intensity data need not be

corrected for absorption or defocusing. They do not permit

oscillation of the sample. Equipment is not currently commer-

FIG. 2 Geometry of Transmission Method. cially available for these methods.

E81 − 96 (2011)

TABLE 1 (I /I ) × 1000

α 0

−α

θ

µt 5 10 15 20 25303540455055606570

5 1.0 992 984 976 966 954 939 918 890 851 796 703 617 480 313

1.4 991 978 962 941 915 882 840 786 719 636 533 412 277 146

1.8 989 972 948 917 878 828 768 695 608 508 395 276 162 070

2.2 988 966 935 893 842 778 702 614 515 406 294 186 095 034

2.6 986 960 922 871 807 731 643 544 436 326 219 126 057 017

3.0 985 954 909 849 775 687 589 481 370 261 164 086 034 009

10 1.0 984 969 952 934 912 887 855 815 762 694 603 486 344 191

1.4 983 962 938 908 873 831 779 716 640 548 440 320 198 094

1.8 981 956 924 884 836 779 710 630 538 435 325 215 119 049

2.2 980 950 911 861 801 730 649 556 455 348 242 147 074 027

2.6 978 944 898 839 768 686 593 492 385 280 183 103 047 016

3.0 977 938 885 817 737 644 543 436 328 226 139 073 030 009

15 1.0 976 952 927 900 868 832 789 735 668 583 477 349 209 085

1.4 975 946 912 874 829 776 714 640 553 453 342 227 123 046

1.8 973 939 898 850 792 725 648 560 462 358 252 155 078 027

2.2 972 933 885 826 758 678 590 492 389 286 190 110 052 017

2.6 970 927 872 804 725 636 538 435 331 232 146 080 036 011

3.0 968 921 859 783 695 597 493 386 283 190 115 060 025 007

20 1.0 968 935 901 863 822 774 718 649 566 465 345 214 093 000

1.4 966 928 885 836 781 717 643 557 460 354 243 140 058 000

1.8 964 921 870 811 743 666 579 484 381 278 180 099 039 000

2.2 963 915 857 788 709 621 525 424 321 224 139 074 028 000

2.6 961 909 843 766 678 582 479 375 274 185 111 057 020 000

3.0 960 903 831 746 650 547 440 335 238 155 090 044 015 000

25 1.0 959 917 872 824 771 710 639 555 455 339 214 096 000

1.4 957 909 856 796 728 651 565 468 362 253 151 065 000

1.8 955 902 840 770 690 602 505 402 298 200 115 048 000

2.2 953 895 826 746 657 560 456 352 253 164 092 038 000

2.6 952 889 812 724 627 523 417 314 219 139 076 031 000

3.0 950 883 800 705 601 493 384 283 194 121 065 025 000

scintillation counter, and used in conjunction with a pulse

height selector circuit to discriminate against X rays whose

energiesdiffermarkedlyfromthatofthecharacteristicK-alpha

radiation being used. Reduction of the characteristic K-beta

radiation requires the use of a monochromator or appropriate

beta filter. Pd, Zr, Ni, Co, Fe, Mn, and V are appropriate beta

filters for Ag, Mo, Cu, Ni, Co, Fe, and Cr, respectively.

5. Test Specimens

5.1 For the reflection method, the sample shall be of

sufficient thickness that loss of intensity due to transmission

through the sample may be ignored. If a maximum loss of 1%

the incident beam is acceptable, the specimen must have a

FIG. 3 α versus µt for I /I = 0.5, θ = 5, 10, ···, 25 deg.

α 0

linear absorption thickness product equal to or greater than 2.3

sin θ. For an iron sample with molybdenum K-alpha radiation,

4.3.3 The method of Field and Marchant (27) requires an this requires that µt be greater than 0.4, 0.6, and 0.7 for the

absorption correction. If this method is used in conjunction (110), (200), and (211) reflections, respectively.

with the transmission method of Decker, et al (26),itis

5.1.1 Surface preparation is particularly important in the

necessarytouseeitherdifferentordersofreflectionordifferent

reflection method. Calculations due to Borie (30), who as-

radiations in order to obtain a complete pole figure.

sumedasawtoothsurfaceofspacing aonamaterialwithlinear

absorption coefficient µ, indicate that the product µa should be

4.4 Specimen Holder—Transmission Method—If the trans-

less than 0.5 if significant intensity losses are to be avoided.

mission method is used, the specimen holder shall employ the

For an iron sample with cobalt K-alpha radiation, µ=416

geometry of Decker, et al (26), shown in Fig. 2 and described

−1

cm , corresponding to a ≤ 12 µm.

in2.3.Itisdesirablethatthespecimenholderbeequippedwith

a means for oscillating the sample in the plane of its surface

5.2 For the transmission method, maximum intensity is

without changing the orientation of the sample. The specimen

obtained for a linear absorption thickness product equal to cos

holder shall preferably be providedwith automatic means for

θ. For an iron sample with molybdenum K-alpha, this corre-

changing colatitude and longitude of the sample.

sponds to µt equal to 0.98, 0.97, and 0.95 for the (110), (200),

4.5 Detector—Thedetectorshallpreferablybeofanenergy- and (211) reflections, respectively. Thus, a suitable transmis-

dispersive type, for example, a solid state, proportional, or sion sample can also be used for reflection measurements.

E81 − 96 (2011)

−1

TABLE 2 Linear Absorption Coefficient µ (cm ) for Selected Wavelengths and Elements

K-alpha Radiation

Ag Mo Cu Ni Co Fe Cr

λ 0.5608 0.7107 1.5418 1.6591 1.7902 1.9373 2.2909

Absorber

6 C 0.90 1.41 10.4 12.8 15.9 20.0 32.6

12 Mg 3.69 7.15 67.2 83.0 104 130 211

13 Al 7.15 13.9 131 162 202 253 410

22 Ti 55.4 109 936 1134 1386 1696 2570 K

24 Cr 114 224 1869 2258 2739 3329 574

25 Mn 131 257 2115 2545 3072 424 539

26 Fe 155 303 2424 2912 416 523 850

27 Co 194 378 2786 436 544 684 1112

28 Ni 214 415 407 503 627 789

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.