ASTM D6205-98

(Practice)Standard Practice for Calibration of the James Static Coefficient of Friction Machine

Standard Practice for Calibration of the James Static Coefficient of Friction Machine

SCOPE

1.1 This practice covers the testing of the James Machine for reprocucibility and repeatability of static coefficient of friction, relative to a standard reference interface consisting of the working surfaces of Borco board and standard leather shoe sole material. The practice provides basis data on the stability of the James Machine to ensure accurate static coefficient of friction determinations over time and repeated use and for determining if the James Machine is mechanically calibrated and properly aligned.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6205–98

Standard Practice for

Calibration of the James Static Coefficient of Friction

Machine

This standard is issued under the fixed designation D 6205; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Chrome Tanned, Impregnated, and Soles

1.1 This practice covers the testing of the James Machine

3. Terminology

for reproducibility and repeatability of static coefficient of

3.1 Definitions: For general definitions, see Test Method

friction, relative to a standard reference interface consisting of

2 D 2047 and Terminology D 2825.

theworkingsurfacesofBorco boardandstandardleathershoe

3.1.1 James Static Coeffıcient of Friction (JSCOF),

sole material. The practice provides basis data on the stability

n—static coefficient of friction as measured by the James

of the James Machine to ensure accurate static coefficient of

machine in accordance with Test Method D 2047.

friction determinations over time and repeated use and for

3.2 Definitions of Terms Specific to This Standard:

determining if the James Machine is mechanically calibrated

3.2.1 Borco, n—special 5-ply vinyl drawing board cover.

and properly aligned.

3.2.2 reference surface, Borco standard leather system,

1.2 This standard does not purport to address all of the

n—working interface of the set consisting of the white side of

safety concerns, if any, associated with its use. It is the

the Borco material, mounted as described in this practice, and

responsibility of the user of this standard to establish appro-

the standard leather shoe sole material, mounted on a precision

priate safety and health practices and determine the applica-

shoe pad as described in this practice.

bility of regulatory limitations prior to use.

3.2.3 standard test sequence, n—seriesofnotlessthaneight

2. Referenced Documents consecutive James Static Coefficient of Friction (JSCOF)

determinations made on the Borco/standard leather system in

2.1 ASTM Standards:

accordance with this practice.

D 2047 Test Method for Static Coefficient of Friction of

Polish-Coated Floor Surfaces as Measured by the James

4. Summary of Practice

Machine

4.1 The performance of the James Machine, in the standard

D 2825 Terminology Relating to Polishes and Related Ma-

3 configuration for the determination of James Static Coefficient

terials

of Friction (JSCOF), is tested relative to a standard working

E 29 Practice for Using Significant Digits in Test Data to

4 interface consisting of the surface of white Borco material in

Determine Conformance with Specifications

4 contact with a standard leather shoe pad. The static coefficient

E 178 Practice for Dealing with Outlying Observations

4 of friction values generated provide a basis to establish the

E 456 Terminology Relating to Quality Statistics

reproducibility and repeatability of the mechanical configura-

2.2 Federal Specification:

tion of the James Machine and determine whether the machine

KK-L-165C Leather, Cattlehide, Vegetable Tanned and

remains within the calibration limits.

5. Significance and Use

5.1 This practice is used to calibrate the James Machine for

determination of static coefficient of friction of polish surfaces

This practice is under the jurisdiction of ASTM Committee D-21 on Polishes

and is the direct responsibility of Subcommittee D21.06 on Slip Resistance.

in accordance with Test Method D 2047. Over considerable

Current edition approved Jan. 10, 1998. Published July 1998.

time and repeated use the James Machine tends to become

Borco is a registered trademark for a Danish product imported into the United

somewhat mechanically out of calibration, giving self-evident

States by Sierra Group, a division of Wallace Leisure Products, Inc.Available from

Papyro-TexA/S, DK-2730, Herlev, Denmark; distributed in NorthAmerica through

drafting and office supply stores under the trade names “Borco,” “Vyco,” and

“Altex” board covers.

3 5

Annual Book of ASTM Standards, Vol 15.04. Available from Standardization Documents Order Desk, Bldg 4 Section D, 700

Annual Book of ASTM Standards, Vol 14.02. Robbins Ave., Philadelphia, PA 19111-5094, Atten: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6205–98

anomalous JSCOF readings. The periodic accumulation and 6.1.6 Test Table not Level—This problem is usually caused

comparison of data generated by this practice provides an by normal wear of the table transport guides, but it may also

indication of when the machine is no longer within the result from an impact on the table or improper use of the test

calibration limits and can no longer be expected to provide table for storage. A test table which is not level will result in

accurate and reliable data. abnormal JSCOF readings. The deviation from accurate

JSCOF readings will depend on the magnitude and direction of

the deviation of the test table from level.

6. Interferences (Troubleshooting)

6.1.7 Excess Play or Movement in the Strut Rack Gear—

6.1 Deviations in calibration data and anomalies in machine

This results from wear in the strut rack and pinion gear

reproducibility and repeatability are due to the following

assembly, loss of lubricant, or use of an improper lubricant in

interferences:

the gear box. Care must be taken that there is enough freedom

6.1.1 Contamination of the Test Surfaces—These are most

in the movement of the strut rack gear so that the vertical

commonly due to fingerprints or other soils on the working

motion of the strut rack gear is not impeded. Excess play in a

leather surface or the working surface of the Borco board, or

direction either parallel or perpendicular to the plane of normal

the presence of residual materials on the Borco board from use

motion of the strut (or in any direction perpendicular to the

of an improper cleaning solution. Generally, contamination of

vertical motion of the strut rack gear) will result in low JSCOF

the working surfaces will result in low JSCOF readings.

readings.

6.1.2 Irregular Test Table Transport—This problem is most

6.1.8 Test Table Travel is not Orthogonal to the Plane of

common on James Machines that derive test table transport

Strut Motion—This is usually caused by excessive movement

from manual cranking, which may not be smooth and uniform,

in the strut rack gear assembly in a direction perpendicular to

but it may also be caused by grit and dirt in the drive

the plane of normal strut motion (see 6.1.7), binding or

mechanism or on the transport guides of the test table. Test

excessive movement in at least one of the upper strut pivots

table movement that is not smooth and uniform will provide

(see 6.1.4), or normal wear or misalignment of the test table

low JSCOF readings.

transport guides (see 6.1.6). This problem results in low

6.1.3 Improper Rate of Test Table Transport—Even when

JSCOF readings, since the slipping motion of the shoe pad on

uniform, the use of an improper rate of test table transport will

the test surface is compounded by a skewing action (greater

result in changes in the JSCOF. This is most often seen in

lateral forces are applied at the interface than are recorded by

manually cranked test table transports, where the rate of travel

the linear table displacement shown on the JSCOF chart).

is difficult to judge subjectively. Many motor driven test tables

6.1.9 Chart Board (or JSCOF Chart) is not in a Plane

have an electrical motor speed control which adjusts the rate of

Parallel to the Plane of the Strut Motion—This problem is

table travel, and this can be inadvertently moved out of

usuallyduetoaheavyimpactonthechartboard,butitcanalso

adjustment.Too rapid a rate of travel will result in high JSCOF

be due to the use of a pad of JSCOF charts (rather than an

readings, and too slow a rate of travel will result in low

individual sheet) attached to the chart board. The magnitude

readings.

and sign of deviations in JSCOF readings that result from this

6.1.4 Wear or Binding—Wear or binding at the following

problem depend on the magnitude and direction of the devia-

bearing surfaces will result in deviations from calibration and

tion of the chart board references planes from a parallel

loss of machine repeatability: upper strut pivot, upper strut ball

configuration with respect to the plane of strut motion.

bearings,backplate,strutrackandpiniongearassembly,lower

6.1.10 Warped, or “Out of True” Back Plate, Chart Board,

strut pivot, and shoe pad cups for lower strut pivots. These

Strut Arm, or Strut Rack Gear—Though this problem can be

problems are most often the result of the normal, repeated use

the result of heavy impact, it is most commonly the result of

of the James Machine, but they can also be caused by heavy

not maintaining the James Machine in a controlled temperature

impacts, improper use, improper periodic cleaning and lubri-

environment. The James Machine is a complex assembly of

cation, or inadequate protection of the machine from dirt.Wear

parts that are rigidly held in alignment by bead welds or bolts.

resulting in excessive play in the bearing surfaces will results

Since many of the parts are constructed of different metals,

in lower JSCOF readings. Sporadic binding of the bearing

temperature changes (and the different coefficients of thermal

surfaces and pivot points will result in loss of machine

expansion) will result in very large forces being applied to the

reproducibility and repeatability. Consistent binding of the

joints or to the components themselves. This can result in a

bearing or pivot surfaces can result in high JSCOF readings.

distortion or warping of the parts, particularly those which are

6.1.5 Test Table not Flat—Test tables are warped out of

large or have at least one long dimension.

flatness by either heavy impacts onto the table, storage of

heavy items on the edges of the test table, or storage of the

7. Apparatus

JamesMachinewiththeweightandstrutintheuprightposition 6,7

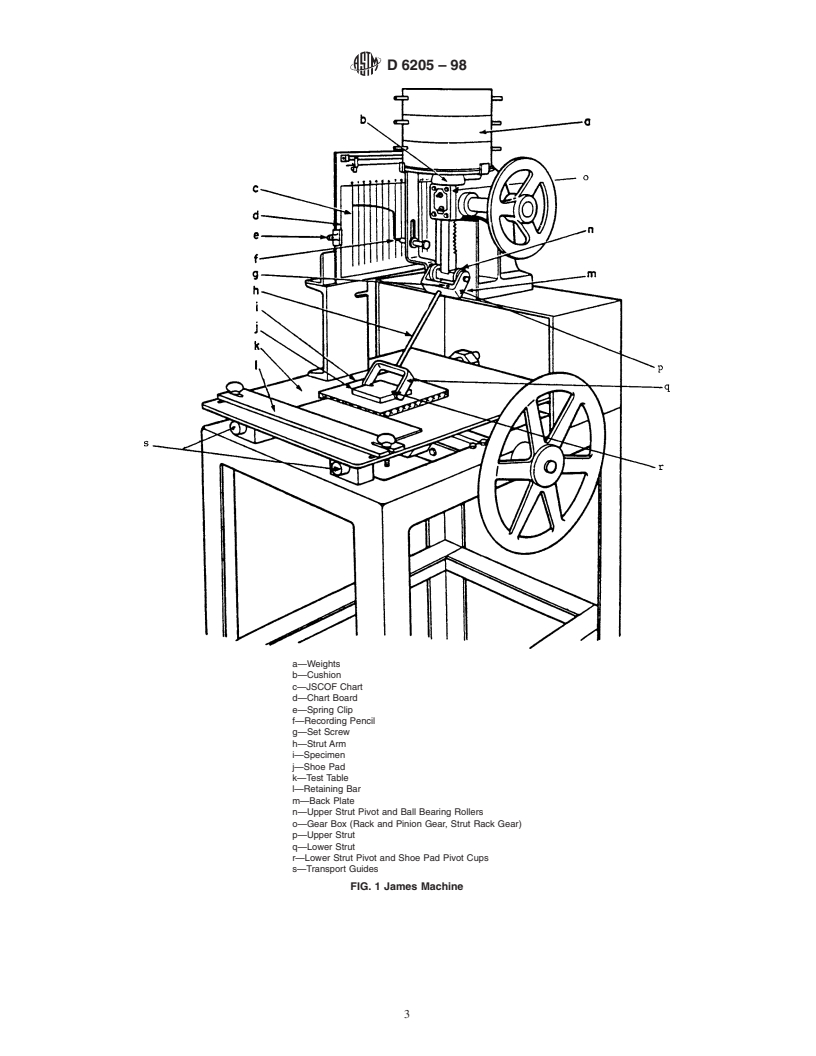

7.1 James Machine —See Fig. 1.

resting on the test table. This practice does not test for flatness

of the test table, and this property must be independently

assessed, either visually or by use of a machinist’s dial gage

ThesolesourceofsupplyoftheJamesMachineknowntothecommitteeatthis

attached to the strut rack gear to test the traversing test table.

time is Quadra, Inc., 1833 Oakdale Ave., Racine, WI 53405; (414)-637-6525.

Lack of adequate test table flatness will result in poor repro-

Machine shop-drawings for the construction of the James machine are available

ducibility of data as a function of the test specimen (tile)

from Chemical Specialities Manufacturers Association, 1913 Eye Street, NW,

placement on the table. Washington, DC 20006; (202)-872-8110.

D6205–98

a—Weights

b—Cushion

c—JSCOF Chart

d—Chart Board

e—Spring Clip

f—Recording Pencil

g—Set Screw

h—Strut Arm

i—Specimen

j—Shoe Pad

k—Test Table

l—Retaining Bar

m—Back Plate

n—Upper Strut Pivot and Ball Bearing Rollers

o—Gear Box (Rack and Pinion Gear, Strut Rack Gear)

p—Upper Strut

q—Lower Strut

r—Lower Strut Pivot and Shoe Pad Pivot Cups

s—Transport Guides

FIG. 1 James Machine

D6205–98

,

7 8

7.2 Standard Reference Leather —Leather sole material pad when the strut is in the full upright position and the test

conforming to Federal Specification KK-L-165C (Type 1, table is in the start position. The shoe pad stop end shall be

Class 6). constructed so that it contacts only the machined shoe pad and

7.3 Leather/Shoe Pad Assembly—Reference leather not the leading edge of the leather. See Fig. 2. The shoe pad

mounted on the machined shoe pad. stop prevents slippage of the shoe pad during movement of the

7.4 Borco Board —drafting and drawing board working test table during calibration of the James Machine.

surface cover. 7.10 Drafting Tape.

,

7 9

7.5 Reference Surface —Aluminum plate, 30.48 by 30.48 7.11 Machinist’s Square.

by 0.3175 cm (12 by 12 by 0.125 in.), which has been

machinedflat,towhich30.48by30.48cm(12by12in.)Borco 8. Test Surface

board has been mounted, white side up.

8.1 For James Machine calibration the test surface assembly

,

7 10

7.6 JSCOF Chart.

will consist of the working interface between the standard

7.7 Cleaner Solution—Alcohol and water-based cleaner

reference leather, mounted on the shoe pad, and the mounted

that does not leave a non-volatile residue, such as household

Borco board reference surface.

window glass cleaner, or equivalent.

8.2 The test surfaces shall not be altered, adulterated, or

7.8 Cleaning Cloth—Clean, lint-free, absorbent cloth or

contaminated in any matter, except for the cleaning procedure

white paper towel.

which begins each test sequence. When not in use, the

7.9 Shoe Pad Stop—Metal block, approximately 15 cm (6

referencesurfaceandleather/shoepadassemblyshallbestored

in.) wide and long enough to fit between the James Machine

in individual, sealed, dust-proof plastic bags, and protected

test table retaining bar and the leading edge of the metal shoe

from impacts, contamination, and scratches.

9. Procedure

If you aware of alternative suppliers, please provide this information toASTM

9.1 Preliminary:

Headquarters.Your comments will receive careful consideration at a meeting of the

9.1.1 Remove the reference surface from its protective

responsible technical committee, which you may attend.

Thesolesourceofsupplyofstandardreferenceleatherknowntothecommittee plastic bag.

at this time is Parsons Tanning Co., 333 Skokie Blvd., Suite 105, Northbrook, IL

9.1.2 Clean the bottom aluminum surface and the Borco

60062. RequestType 1, Class 6. Precut leather, ready to mount on the test shoe pad,

surface with cleaning solution and a clean, lint-free cloth or

isavailablefromChemicalSpecialitiesManufacturersAssociation,1913EyeStreet,

soft paper towel. Wipe dry and set the clean reference surface

NW, Washington, DC 20006; (202)-872-8110.

The sole source of supply of a mounted reference surface known to the

asideinadust-freeenvironmenttothoroughlydry(donotheat)

committee at this time isTechnical Products Co., 264 ParkAvenue, North Caldwell,

for a minimum of 30 min before using it in the test procedure.

NJ 07006.

10 Do not touch the cleaned reference surface or allow it to

The sole source of supply of a JSCOF Chart known to the committee at this

contact other objects.

time is Chemical Specialities Manufacturers Association, 1913 Eye Street, NW,

Washington, DC 20006; (202)-872-8110.

9.1.3 Remove the leather /shoe pad assembly from i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.