ASTM E1709-00

(Test Method)Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer

Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer

SCOPE

1.1 This test method covers measurement of the retroreflective properties of sign materials such as traffic signs and symbols (vertical surfaces) using a portable retroreflectometer that can be used in the field. The portable retroreflectometer is a hand-held instrument with a defined standard geometry that can be placed in contact with sign material to measure the retroreflection in a standard geometry. The measurements can be compared to minimum requirements to determine the need for replacement. Entrance and observation angles specified in this test method are those used currently in the United States and may differ from the angles used elsewhere in the world.

1.2 This test method is intended to be used for the field measurement of traffic signs but may be used to measure the performance of materials before placing the sign in the field or before placing the sign material on the sign face.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1709 – 00

Standard Test Method for

Measurement of Retroreflective Signs Using a Portable

Retroreflectometer

This standard is issued under the fixed designation E 1709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 coeffıcient of retroreflection, R , n—of a plane retrore-

A

flecting surface, the ratio of the coefficient of luminous

1.1 This test method covers measurement of the retroreflec-

intensity (R ) of a plane retroreflecting surface to its area (A),

I

tive properties of sign materials such as traffic signs and

−1 −2

expressed in candelas per lux per square metre (cd · lx ·m ).

symbols (vertical surfaces) using a portable retroreflectometer

3.2.2 datum axis, n—a designated half-line from the retrore-

that can be used in the field. The portable retroreflectometer is

flector center perpendicular to the retroreflector axis.

a hand-held instrument with a defined standard geometry that

3.2.3 entrance angle, b, n—the angle between the illumi-

can be placed in contact with sign material to measure the

nation axis and the retroreflector axis.

retroreflection in a standard geometry. The measurements can

3.2.4 entrance half-plane, n—The half plane that originates

be compared to minimum requirements to determine the need

on the line of the illumination axis and contains the retrore-

for replacement. Entrance and observation angles specified in

flector axis.

this test method are those used currently in the United States

3.2.5 instrument standard, n—working standard used to

and may differ from the angles used elsewhere in the world.

standardize the portable retroreflectometer.

1.2 This test method is intended to be used for the field

3.2.6 observation angle, a, n—the angle between the illu-

measurement of traffic signs but may be used to measure the

mination axis and the observation axis.

performance of materials before placing the sign in the field or

3.2.7 observation half-plane, n—The half plane that origi-

before placing the sign material on the sign face.

nates on the line of the illumination axis and contains the

1.3 This standard does not purport to address all of the

observation axis.

safety concerns, if any, associated with its use. It is the

3.2.8 orientation angle, v , n—the angle in a plane perpen-

s

responsibility of the user of this standard to establish appro-

dicular to the retroreflector axis from the entrance half-plane to

priate safety and health practices and to determine the

the datum axis, measured counter-clockwise from the view-

applicability of regulatory limitations prior to use.

point of the source.

2. Referenced Documents

3.2.9 portable retroreflectometer, n—a hand-held instru-

ment that can be used in the field or in the laboratory for

2.1 ASTM Standards:

measurement of retroreflectance.

E 284 Terminology of Appearance

3.2.9.1 Discussion—In this test method, “portable retrore-

E 808 Practice for Describing Retroreflection

flectometer” refers to a hand-held instrument that can be placed

E 809 Practice for Measuring Photometric Characteristics

in contact with sign material to measure the retroreflection in a

of Retroreflectors

standard geometry.

E 810 Test Method for Coefficient of Retroreflection or

3.2.10 presentation angle, g, n—the dihedral angle from the

Retroreflective Sheeting

entrance half-plane to the observation half-plane, measured

3. Terminology

counter-clockwise from the viewpoint of the source.

3.2.11 retroreflection, n—a reflection in which the reflected

3.1 The terminology used in this test method generally

rays are returned preferentially in directions close to the

agrees with that used in Terminology E 284.

opposite of the direction of the incident rays, this property

3.2 Definitions—The delimiting phrase “in retroreflection”

being maintained over wide variations of the direction of the

applies to each of the following definitions when used outside

incident rays.

the context of this or other retroreflection standards.

3.2.12 rotation angle, e, n—the angle in a plane perpendicu-

lar to the retroreflector axis from the observation half-plane to

This test method is under the jurisdiction of ASTM Committee E12 on Color the datum axis, measured counter-clockwise from the view-

and Appearance and is the direct responsibility of Subcommittee E12.10 on

point of the source.

Retroreflection.

3.3 Definitions of entrance angle components b and b ,as

1 2

Current edition approved July 10, 2000. Published September 2000. Originally

e1

well as other geometrical terms undefined in this test method,

published as E 1709 – 95. Last previous edition E 1709 – 95a .

Annual Book of ASTM Standards, Vol 06.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1709

may be found in Practice E 808. shall be portable, with the capability of being placed at various

locations on the signs. The retroreflectometer shall be con-

4. Summary of Test Method

structed so that placement on the sign will preclude stray light

4.1 This test method involves the use of commercial por-

(daylight) from entering the measurement area of the instru-

table retroreflectometers for determining the retroreflectivity of

ment and affecting the reading.

highway signing materials.

6.2 Instrument Standard, or standards of desired color(s)

4.2 The entrance angle shall be nominally −4°.

and material(s).

4.3 The observation angle shall be 0.2°.

6.3 Light Source Requirements:

4.4 The portable retroreflectometer uses a instrument stan-

6.3.1 The projection optics shall be such that the illumi-

dard for standardization.

nance at any point over the measurement area shall be within

4.5 After standardization, the retroreflectometer is placed in

10 % of the average illuminance.

contact with the sign to be tested, ensuring that only the desired

6.3.2 The aperture angle of the source as determined from

portion of the sign is within the measurement area of the

the center of the measurement area shall be not greater than

instrument.

0.1°.

4.6 The reading displayed by the retroreflectometer is re-

corded. The retroreflectometer is then moved to another

6.4 Receiver Requirements:

position on the sign, and this value is recorded. A minimum of

6.4.1 The receiver shall have sufficient sensitivity and range

four readings will be taken and averaged for each retroreflec-

to accommodate coefficient of retroreflection values from 0.1

−1 −2

tive color on the sign to be tested.

to 1999.9 cd· lx ·m .

6.4.2 The combined spectral distribution of the light source

5. Significance and Use

and the spectral responsivity of the receiver shall match the

5.1 Measurements made by this test method are related to

combined spectral distribution of CIE Illuminant A and the

the night time brightness of retroreflective traffic signs approxi-

V(l) spectral luminous efficiency function according to the

mately facing the driver of a mid-sized automobile equipped

following criterion: For any choice of plano-parallel colored

with tungsten filament headlights at about 200 m distance.

absorptive filter mounted in front of a white retroreflective

5.2 Retroreflective material used on traffic signs degrades

sample, the ratio of the R measured with the filter to the R

A A

with time and requires periodic measurement to ensure that the

measured without the filter shall be within 10 % of the

performance of the retroflection provides adequate safety to the

Illuminant A luminous transmittance of an air space pair of two

driver.

such filters.

5.3 The quality of the sign as to material used, age, and wear

6.4.3 The instrument may be either a “point instrument” or

pattern will have an effect on the coefficient of retroreflection.

an “annular instrument”, depending on the shape of the

These conditions need to be observed and noted by the user.

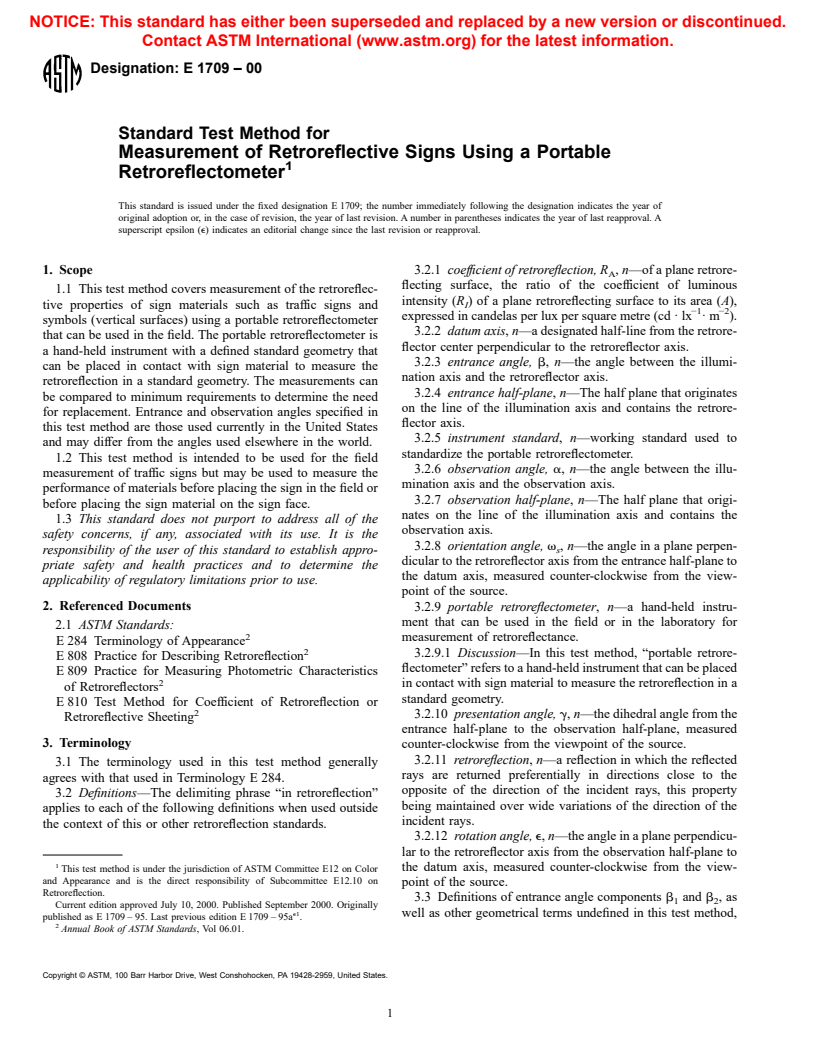

receiver aperture (see Fig. 1). Point and annular instruments

5.4 This test method is not intended for use for the mea-

make geometrically different measurements of R , which may

surement of signs when the instrument entrance and observa- A

produce values differing on the order of 10 %. Both measure-

tion angles differ from those specified herein.

ments are valid for most purposes, but the user should learn the

6. Apparatus

type of instrument from its specifications sheet and be aware of

certain differences in operation and interpretation. For both

6.1 Portable Retroreflectometer—The retroreflectometer

FIG. 1 Annular and Point Aperture Instrument Angles

E 1709

a range instrument with presentation angle (g) varying between

–180° and +180°. For the denoted –4° entrance angle the range

instrument would include the b and b settings indicated in

1 2

Table 1. Table 1 includes the setting b =–4°; b =0°, among

1 2

others. There is no definite rotation angle (e) for the annular

instrument. All values from –180° to +180° are subsumed in

the measurement.

6.4.3.4 For the annular instrument the “up” marking shall be

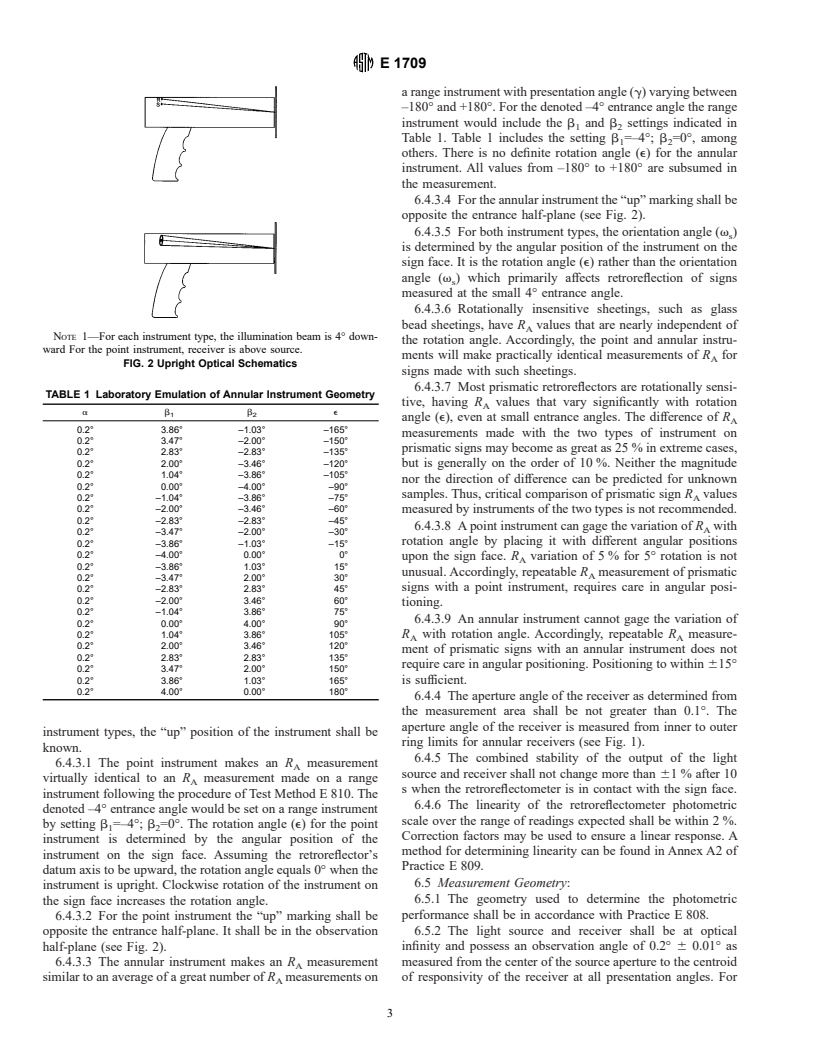

opposite the entrance half-plane (see Fig. 2).

6.4.3.5 For both instrument types, the orientation angle (v )

s

is determined by the angular position of the instrument on the

sign face. It is the rotation angle (e) rather than the orientation

angle (v ) which primarily affects retroreflection of signs

s

measured at the small 4° entrance angle.

6.4.3.6 Rotationally insensitive sheetings, such as glass

bead sheetings, have R values that are nearly independent of

A

NOTE 1—For each instrument type, the illumination beam is 4° down-

the rotation angle. Accordingly, the point and annular instru-

ward For the point instrument, receiver is above source.

ments will make practically identical measurements of R for

A

FIG. 2 Upright Optical Schematics

signs made with such sheetings.

6.4.3.7 Most prismatic retroreflectors are rotationally sensi-

TABLE 1 Laboratory Emulation of Annular Instrument Geometry

tive, having R values that vary significantly with rotation

A

ab b e

1 2

angle (e), even at small entrance angles. The difference of R

A

0.2° 3.86° –1.03° –165°

measurements made with the two types of instrument on

0.2° 3.47° –2.00° –150°

prismatic signs may become as great as 25 % in extreme cases,

0.2° 2.83° –2.83° –135°

0.2° 2.00° –3.46° –120° but is generally on the order of 10 %. Neither the magnitude

0.2° 1.04° –3.86° –105°

nor the direction of difference can be predicted for unknown

0.2° 0.00° –4.00° –90°

samples. Thus, critical comparison of prismatic sign R values

0.2° –1.04° –3.86° –75° A

0.2° –2.00° –3.46° –60° measured by instruments of the two types is not recommended.

0.2° –2.83° –2.83° –45°

6.4.3.8 A point instrument can gage the variation of R with

A

0.2° –3.47° –2.00° –30°

rotation angle by placing it with different angular positions

0.2° –3.86° –1.03° –15°

0.2° –4.00° 0.00° 0°

upon the sign face. R variation of 5 % for 5° rotation is not

A

0.2° –3.86° 1.03° 15°

unusual. Accordingly, repeatable R measurement of prismatic

A

0.2° –3.47° 2.00° 30°

signs with a point instrument, requires care in angular posi-

0.2° –2.83° 2.83° 45°

0.2° –2.00° 3.46° 60°

tioning.

0.2° –1.04° 3.86° 75°

6.4.3.9 An annular instrument cannot gage the variation of

0.2° 0.00° 4.00° 90°

0.2° 1.04° 3.86° 105° R with rotation angle. Accordingly, repeatable R measure-

A A

0.2° 2.00° 3.46° 120°

ment of prismatic signs with an annular instrument does not

0.2° 2.83° 2.83° 135°

require care in angular positioning. Positioning to within 615°

0.2° 3.47° 2.00° 150°

0.2° 3.86° 1.03° 165° is sufficient.

0.2° 4.00° 0.00° 180°

6.4.4 The aperture angle of the receiver as determined from

the measurement area shall be not greater than 0.1°. The

aperture angle of the receiver is measured from inner to outer

instrument types, the “up” position of the instrument shall be

ring limits for annular receivers (see Fig. 1).

known.

6.4.5 The combined stability of the output of the light

6.4.3.1 The point instrument makes an R measurement

A

source and receiver shall not change more than 61 % after 10

virtually identical to an R measurement made on a range

A

s when the retroreflectometer is in contact with the sign face.

instrument following the procedure of Test Method E 810. The

6.4.6 The linearity of the retroreflectometer photometric

denoted –4° entrance angle would be set on a range instrument

scale over the range of readings expected shall be within 2 %.

by setting b =–4°; b =0°. The rotation angle (e) for the point

1 2

Correction factors may be used to ensure a linear response. A

instrument is determined by the angular position of the

method for determining linearity can be found in Annex A2 of

instrument on the sign face. Assuming the retroreflector’s

Practice E 809.

datum axis to be upward, the rotation angle equals 0° when the

6.5 Measurement Geometry:

instrument is upright. Clockwise rotation of the instrument on

6.5.1 The geometry used to determine the photometric

the sign face increases the rotation angle.

performance shall be in accordance with Practice E 808.

6.4.3.2 For the point instrument the “up” marking shall be

opposite the entrance half-plane. It shall be in the observation 6.5.2 The light source and receiver shall be at optical

half-plane (see Fig. 2). infinity and possess an observation angle of 0.2° 6 0.01° as

6.4.3.3 The annular instrument makes an R measurement measured from the center of the source aperture to the centroid

A

similar to an average of a great number of R measurements on of responsivity of the receiver at all presentation angles. For

A

E 1709

annular receivers, the observation angle is taken as the angular standard shall be used and a correction factor shall be applied

distance when area A and area B are equal (see Fig. 1). to the readings obtained by use of the white standard. To

6.5.3 The entrance angle of the light source shall be −4°6 determine this correction factor, carry out the following steps:

1°. 8.1.3.1 Standardize the instrument using a white standard,

8.1.3.2 Without changing the instrument settings, note the

7. Standardization

reading for a selected prephotometered standard similar in

7.1 The retroreflectometer shall be standardized using an color, material, and type to the sign material to be tested,

instrument standard consisting of a separate panel or disc of a

8.1.3.3 Obtain a correction factor by dividing the known

material with a known R value. The calibration values shall be

retroreflectance of the selected prephotometered standard by

A

maintained by checking against other standards or by labora-

the reading noted in 8.1.3.2, and

tory recalibration

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.