ASTM C1354-96(2004)

(Test Method)Standard Test Method for Strength of Individual Stone Anchorages in Dimension Stone

Standard Test Method for Strength of Individual Stone Anchorages in Dimension Stone

SIGNIFICANCE AND USE

This test method is intended to provide information from which applicable design data can be determined for a given anchor used to support a dimension stone panel. The strength of a limited length of anchor may be related to a longer length of support when the flexibility of the support is properly considered by the designer. Refer to Guide C 1242.

SCOPE

1.1 This test method provides procedures for determining the ultimate strength of an assembly consisting of stone with mechanical anchor (anchorage). Load is applied, separately, perpendicular to the surface of the panel and parallel to the surface of the panel. This test is intended to represent the interaction of the anchor with the stone panel. However, influence of the backup structure on the strength of the assemblies is not included.

1.2 This method is applicable to stone panels supported by mechanical anchors.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1354–96 (Reapproved2004)

Standard Test Method for

Strength of Individual Stone Anchorages in Dimension

Stone

This standard is issued under the fixed designation C 1354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope loads from the stone to the building structure, either directly or

through an intermediate structure.

1.1 This test method provides procedures for determining

3.1.2 anchorage, n—assembly consisting of a stone panel

the ultimate strength of an assembly consisting of stone with

with a mechanical anchor.

mechanical anchor (anchorage). Load is applied, separately,

3.1.3 panel, n—cut stone with large face dimensions in

perpendicular to the surface of the panel and parallel to the

relationtoitsthickness,forplacementinabuildingstructureor

surface of the panel. This test is intended to represent the

frame assembly.

interaction of the anchor with the stone panel. However,

influence of the backup structure on the strength of the

4. Summary of Test Method

assemblies is not included.

4.1 Test specimens consisting of a stone panel sample and a

1.2 This method is applicable to stone panels supported by

mechanical anchor are fabricated in the same manner and of

mechanical anchors.

the same materials as their intended construction uses. The

1.3 The values stated in SI units are to be regarded as the

mechanical anchor is connected to a test support.Atest load is

standard.

applied perpendicular or parallel to the face of the stone panel.

1.4 This standard does not purport to address all of the

The test load is applied gradually using a calibrated test

safety concerns, if any, associated with its use. It is the

machine; load is increased until the stone or the mechanical

responsibility of the user of this standard to establish appro-

anchor fails.

priate safety and health practices and determine the applica-

4.2 The load at failure and mode of failure of each test

bility of regulatory limitations prior to use.

specimenisobservedandrecorded.Thetestasdescribedabove

2. Referenced Documents is repeated five times for each combination of stone and anchor

to be tested and for each direction of load to be tested.

2.1 ASTM Standards:

C 1242 Guide for Design, Selection, and Installation of

5. Significance and Use

Exterior Dimension Stone Anchors and Anchoring Sys-

5.1 This test method is intended to provide information

tems

from which applicable design data can be determined for a

E 4 Practices for Force Verification of Testing Machines

given anchor used to support a dimension stone panel. The

E 575 Practice for Reporting Data from Structural Tests of

strengthofalimitedlengthofanchormayberelatedtoalonger

Building Constructions, Elements, Connections, and As-

length of support when the flexibility of the support is properly

semblies

considered by the designer. Refer to Guide C 1242.

3. Terminology

6. Testing Machine

3.1 Definitions:

6.1 The testing machine shall conform to the requirements

3.1.1 anchor, n—in general, a metal shape inserted into a

of Practices E 4.

slot or hole in the stone panel that provides for the transfer of

6.2 The load from the testing machine shall be applied

through appropriate devices (a lubricated ball-and-socket or a

lubricated universal joint) to apply direct tension to the test

This test method is under the jurisdiction of ASTM Committee C18 on

specimen without bending.

Dimension Stone and is the direct responsibility of Subcommittee C18.01.

Current edition approved Oct. 1, 2004. Published November 2004. Originally

7. Support Frame and Loading Device

approved in 1996. Last previous edition approved in 1996 as C 1354 – 96.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 The support frame (excluding the anchor to be tested)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shall have sufficient strength to not yield while supporting

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. maximum applied load. In addition, the support frame shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1354–96 (2004)

FIG. 1A Edge of Panel Supported by Tab Inserted into Kerf in Edge of Panel

FIG. 1B Edge of Panel Supported by Pin Installed into Hole Drilled into Edge of Panel

FIG. 1 Setup for Testing Connection in Edge of Sample—Test Procedure A

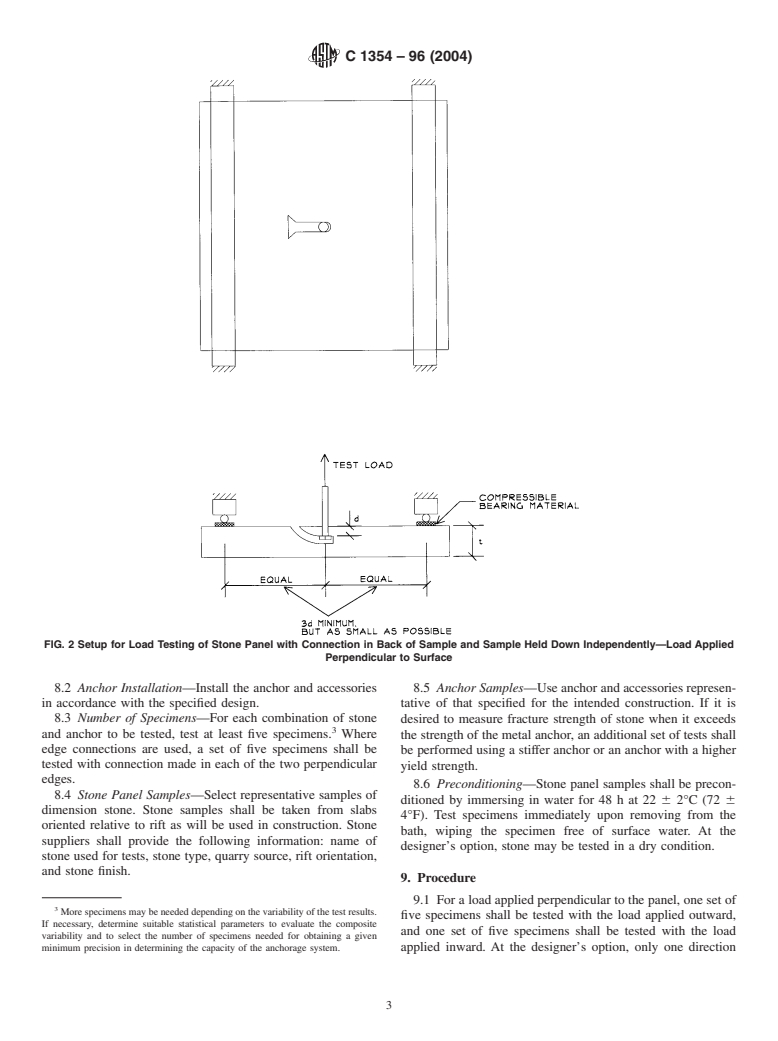

sufficiently stiff to limit deflection to less than 1 mm (0.04 in.) sample of anchor. The stone sample may be held down by

at maximum test load and to limit rotation to less than 2°. independent anchors as shown in Fig. 2 or by the device used

7.2 For load perpendicular to the surface of the stone panel: to apply load as shown in Fig. 3.

7.2.1 A rubber pad or a setting gypsum bed shall be used 7.3 For load parallel to the surface of the stone panel:

between the stone and the loading or restraint surface to avoid 7.3.1 Thestonepanelsampleisrestrainedintheplaneofthe

concentration of stress in the surface of the stone sample. panel while a test load is applied parallel to the plane of the

7.2.2 A frame to support a stone sample with anchor in the panel as shown in Fig. 4. The area beneath the anchor shall be

side edge of the stone is shown in Fig. 1. Fig. 1 represents kept unsupported to prevent restraint of spalls that may

outward loading on a single stone panel. At the designer’s artificially increase the strength. The surface between the

option, two stone panels can be tested on a single split anchor. loading plate and the stone panel sample shall be lubricated.

7.2.2.1 The test specimen is supported at one end by the

8. Test Specimens

anchor.Theanchorshallbeattachedtothesupportframeinthe

same way it will be attached to the backup structure in 8.1 Anchorage System—The anchorage system shall be

construction. The sample of stone is supported at the opposite representative of the type to be used in field construction and

end by a 25 mm (1 in.) diameter rod. shallincludetheanchortobeusedandallaccessoriesnormally

7.2.2.2 The load from the testing machine is applied to the required to attach the anchor to the backup structure. If sealant,

stone sample through a 25 mm (1 in.) diameter rod, located as epoxy, or other form of kerf filler is specified to be used in field

close as possible to the anchor that supports the stone but at a construction, the bond between the sealant, epoxy, or other

distance not less than the thickness

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.