ASTM D6296-98(2013)

(Test Method)Standard Test Method for Total Olefins in Spark-ignition Engine Fuels by Multidimensional Gas Chromatography

Standard Test Method for Total Olefins in Spark-ignition Engine Fuels by Multidimensional Gas Chromatography

SIGNIFICANCE AND USE

5.1 The quantitative determination of olefins in spark-ignition engine fuels is required to comply with government regulations.

5.2 Knowledge of the total olefin content provides a means to monitor the efficiency of catalytic cracking processes.

5.3 This test method provides better precision for olefin content than Test Method D1319. It also provides data in a much shorter time, approximately 20 min following calibration, and maximizes automation to reduce operator labor.

5.4 This test method is not applicable to M85 or E85 fuels, which contain 85 % methanol and ethanol, respectively.

SCOPE

1.1 This test method provides for the quantitative determination of total olefins in the C4 to C10 range in spark-ignition engine fuels or related hydrocarbon streams, such as naphthas and cracked naphthas. Olefin concentrations in the range from 0.2 to 5.0 liquid-volume % or mass %, or both, can be determined directly on the as-received sample whereas olefins in samples containing higher concentrations are determined after appropriate sample dilution prior to analysis.

1.2 This test method is applicable to samples containing alcohols and ethers; however, samples containing greater than 15 % alcohol must be diluted. Samples containing greater than 5.0 % ether must also be diluted to the 5.0 % or less level, prior to analysis. When ethyl-tert-butylether is present, only olefins in the C4 to C9 range can be determined.

1.3 This test method can not be used to determine individual olefin components.

1.4 This test method can not be used to determine olefins having higher carbon numbers than C10.Note 1—Precision was determined only on samples containing MTBE and ethanol.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6296 −98 (Reapproved 2013)

Standard Test Method for

Total Olefins in Spark-ignition Engine Fuels by

Multidimensional Gas Chromatography

This standard is issued under the fixed designation D6296; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method provides for the quantitative determi- 2.1 ASTM Standards:

nation of total olefins in the C to C range in spark-ignition D1319 Test Method for Hydrocarbon Types in Liquid Petro-

4 10

engine fuels or related hydrocarbon streams, such as naphthas leum Products by Fluorescent Indicator Adsorption

and cracked naphthas. Olefin concentrations in the range from D4052 Test Method for Density, Relative Density, and API

0.2 to 5.0 liquid-volume % or mass %, or both, can be Gravity of Liquids by Digital Density Meter

determined directly on the as-received sample whereas olefins D4307 Practice for Preparation of Liquid Blends for Use as

in samples containing higher concentrations are determined Analytical Standards

after appropriate sample dilution prior to analysis. D4815 Test Method for Determination of MTBE, ETBE,

TAME, DIPE, tertiary-Amyl Alcohol and C to C Alco-

1 4

1.2 This test method is applicable to samples containing

hols in Gasoline by Gas Chromatography

alcohols and ethers; however, samples containing greater than

D5599 Test Method for Determination of Oxygenates in

15 % alcohol must be diluted. Samples containing greater than

Gasoline by Gas Chromatography and Oxygen Selective

5.0 %ethermustalsobedilutedtothe5.0 %orlesslevel,prior

Flame Ionization Detection

to analysis. When ethyl-tert-butylether is present, only olefins

in the C to C range can be determined.

4 9 3. Terminology

1.3 Thistestmethodcannotbeusedtodetermineindividual

3.1 Definitions of Terms Specific to This Standard:

olefin components.

3.1.1 trap, n—a device utilized to selectively retain specific

portions (individual or groups of hydrocarbons or oxygenates)

1.4 This test method can not be used to determine olefins

of the test sample and to release the retained components by

having higher carbon numbers than C .

increasing the trap temperature.

NOTE 1—Precision was determined only on samples containing MTBE

and ethanol. 3.2 Acronyms:

3.2.1 ETBE—ethyl-tert-butylether.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.2.2 MTBE—methyl-tert–butylether.

standard.

4. Summary of Test Method

1.6 This standard does not purport to address all of the

4.1 A reproducible 0.2-µL volume of a representative

safety concerns, if any, associated with its use. It is the

sample, or a dilution thereof, is introduced into a computer

responsibility of the user of this standard to establish appro-

controlled gas chromatographic system consisting of a series

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee D02 on the ASTM website.

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of The sole source of supply of apparatus known to the committee at this time, the

Subcommittee D02.04.0L on Gas Chromatography Methods. AC FTO Analyzer, is AC Analytical Controls, Inc., 3494 Progress Dr., Bensalem,

Current edition approved Oct. 1, 2013. Published October 2013. Originally PA19020. If you are aware of alternative suppliers, please provide this information

approved in 1998. Last previous edition approved in 2008 as D6296 – 98(2008). to ASTM Headquarters. Your comments will receive careful consideration at a

DOI: 10.1520/D6296-98R13. meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6296−98 (2013)

FIG. 1Typical Flow Diagram and Component Configuration

of columns, traps, and switching valves operating at various 5.2 Knowledge of the total olefin content provides a means

temperatures. The valves are actuated at predetermined times to monitor the efficiency of catalytic cracking processes.

to direct portions of the sample to appropriate columns and

5.3 This test method provides better precision for olefin

traps. The sample first passes through a polar column that

content than Test Method D1319. It also provides data in a

retains C + hydrocarbons, all aromatics, C + olefins, and

12 11

much shorter time, approximately 20 min following

some alcohols, all of which are subsequently backflushed to

calibration, and maximizes automation to reduce operator

vent. The fraction eluting from the polar column, which

labor.

contains C and lower boiling saturated hydrocarbons as well

5.4 This test method is not applicable to M85 or E85 fuels,

asdeceneandlowerboilingolefins,entersanether/alcoholtrap

which contain 85 % methanol and ethanol, respectively.

where the ethers and alcohols are selectively retained and also

subsequently backflushed. The fraction eluting from the ether/

6. Interferences

alcohol trap, which consists of C and lower boiling saturated

hydrocarbons and the olefins, enters an olefin trap. The olefins 6.1 Some types of sulfur-containing compounds are irre-

versibly absorbed in the olefin and oxygenate traps ultimately

are selectively retained while the saturated hydrocarbons elute,

pass through a nonpolar column, and are detected by a flame reducingthetrapcapacity.However,avarietyofspark-ignition

engine fuels have been analyzed without significant perfor-

ionization detector (FID). When the saturated hydrocarbons

have completely eluted to the FID, the nonpolar column oven mance deterioration of these traps.

is cooled and the olefins, which have been retained on the

6.2 Commercial dyes used to distinguish between grades

olefin trap, are desorbed by heating.The desorbed olefins enter

andtypesofspark-ignitionenginefuelshavenotbeenfoundto

and elute from the nonpolar column, which is temperature

interfere with this test method.

programmed to separate the olefins by boiling point, and are

6.3 Commercial detergent additives utilized in spark-

detected by the FID.

ignition engine fuels have not been found to interfere with this

NOTE 2—Separation of olefins by boiling point is necessary for the

test method.

calculation of the volume % of the olefins because the density of low

6.4 Dissolved water in spark-ignition engine fuels has not

boiling olefins differs from that of high boiling olefins and, therefore, a

density correction must be applied.

been found to interfere with this test method. Free water must

be removed using anhydrous sodium sulfate or other drying

4.2 Quantitation of the detected olefin peak areas to provide

agent to permit injection of accurate sample volumes.

volume % or mass %, or both, is accomplished through the use

of an external standard followed by the application of flame

7. Apparatus

ionization detector response factors. The quantitation also

takes into consideration the baseline compensation, sample

7.1 Thecompletesystemusedtoobtaintheprecisiondatais

dilution, and density corrections.

comprised of a computer controlled gas chromatograph, auto-

mated sample injector, computer software, and specific hard-

5. Significance and Use

ware modifications. These modifications include columns,

5.1 The quantitative determination of olefins in spark- traps, and valves which are described as follows and in Section

ignition engine fuels is required to comply with government 8. Fig. 1 illustrates a typical flow diagram and component

regulations. configuration. Other configurations, components, or conditions

D6296−98 (2013)

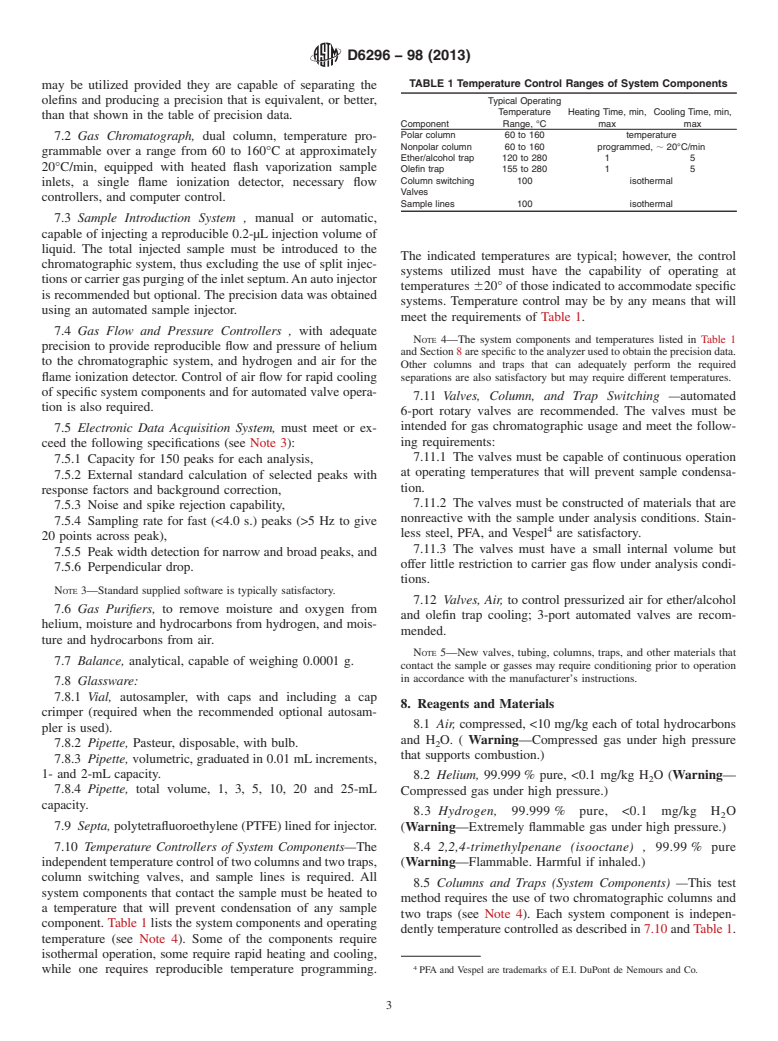

TABLE 1 Temperature Control Ranges of System Components

may be utilized provided they are capable of separating the

olefins and producing a precision that is equivalent, or better, Typical Operating

Temperature Heating Time, min, Cooling Time, min,

than that shown in the table of precision data.

Component Range, °C max max

Polar column 60 to 160 temperature

7.2 Gas Chromatograph, dual column, temperature pro-

Nonpolar column 60 to 160 programmed, ; 20°C/min

grammable over a range from 60 to 160°C at approximately

Ether/alcohol trap 120 to 280 1 5

20°C/min, equipped with heated flash vaporization sample

Olefin trap 155 to 280 1 5

Column switching 100 isothermal

inlets, a single flame ionization detector, necessary flow

Valves

controllers, and computer control.

Sample lines 100 isothermal

7.3 Sample Introduction System , manual or automatic,

capable of injecting a reproducible 0.2-µL injection volume of

liquid. The total injected sample must be introduced to the

The indicated temperatures are typical; however, the control

chromatographic system, thus excluding the use of split injec-

systems utilized must have the capability of operating at

tionsorcarriergaspurgingoftheinletseptum.Anautoinjector

temperatures 620° of those indicated to accommodate specific

is recommended but optional. The precision data was obtained

systems. Temperature control may be by any means that will

using an automated sample injector.

meet the requirements of Table 1.

7.4 Gas Flow and Pressure Controllers , with adequate

NOTE 4—The system components and temperatures listed in Table 1

precision to provide reproducible flow and pressure of helium

andSection8arespecifictotheanalyzerusedtoobtaintheprecisiondata.

to the chromatographic system, and hydrogen and air for the

Other columns and traps that can adequately perform the required

flame ionization detector. Control of air flow for rapid cooling separations are also satisfactory but may require different temperatures.

of specific system components and for automated valve opera-

7.11 Valves, Column, and Trap Switching —automated

tion is also required.

6-port rotary valves are recommended. The valves must be

intended for gas chromatographic usage and meet the follow-

7.5 Electronic Data Acquisition System, must meet or ex-

ing requirements:

ceed the following specifications (see Note 3):

7.11.1 The valves must be capable of continuous operation

7.5.1 Capacity for 150 peaks for each analysis,

at operating temperatures that will prevent sample condensa-

7.5.2 External standard calculation of selected peaks with

tion.

response factors and background correction,

7.11.2 The valves must be constructed of materials that are

7.5.3 Noise and spike rejection capability,

nonreactive with the sample under analysis conditions. Stain-

7.5.4 Sampling rate for fast (<4.0 s.) peaks (>5 Hz to give

less steel, PFA, and Vespel are satisfactory.

20 points across peak),

7.11.3 The valves must have a small internal volume but

7.5.5 Peak width detection for narrow and broad peaks, and

offer little restriction to carrier gas flow under analysis condi-

7.5.6 Perpendicular drop.

tions.

NOTE 3—Standard supplied software is typically satisfactory.

7.12 Valves, Air, to control pressurized air for ether/alcohol

7.6 Gas Purifiers, to remove moisture and oxygen from

and olefin trap cooling; 3-port automated valves are recom-

helium, moisture and hydrocarbons from hydrogen, and mois-

mended.

ture and hydrocarbons from air.

NOTE 5—New valves, tubing, columns, traps, and other materials that

7.7 Balance, analytical, capable of weighing 0.0001 g.

contact the sample or gasses may require conditioning prior to operation

in accordance with the manufacturer’s instructions.

7.8 Glassware:

7.8.1 Vial, autosampler, with caps and including a cap

8. Reagents and Materials

crimper (required when the recommended optional autosam-

8.1 Air, compressed, <10 mg/kg each of total hydrocarbons

pler is used).

and H O. ( Warning—Compressed gas under high pressure

7.8.2 Pipette, Pasteur, disposable, with bulb. 2

that supports combustion.)

7.8.3 Pipette, volumetric, graduated in 0.01 mLincrements,

1- and 2-mL capacity.

8.2 Helium, 99.999 % pure, <0.1 mg/kg HO(Warning—

7.8.4 Pipette, total volume, 1, 3, 5, 10, 20 and 25-mL

Compressed gas under high pressure.)

capacity.

8.3 Hydrogen, 99.999 % pure, <0.1 mg/kg H O

7.9 Septa, polytetrafluoroethylene (PTFE) lined for injector.

(Warning—Extremely flammable gas under high pressure.)

7.10 Temperature Controllers of System Components—The

8.4 2,2,4-trimethylpenane (isooctane) , 99.99 % pure

independenttemperaturecontroloftwocolumnsandtwotraps, (Warning—Flammable. Harmful if inhaled.)

column switching valves, and sample lines is required. All

8.5 Columns and Traps (System Components) —This test

system components that contact the sample must be heated to

method requires the use of two chromatographic columns and

a temperature that will prevent condensation of any sample

two traps (see Note 4). Each system component is indepen-

component. Table 1 lists the system components and operating

dently temperature controlled as described in 7.10 and Table 1.

temperature (see Note 4). Some of the components require

isothermal operation, some require rapid heating and cooling,

while one requires reproducible temperature programming. PFA and Vespel are trademarks of E.I. DuPont de Nemours and Co.

D6296−98 (2013)

TABLE 2 Set Up Mixtures TABLE 3 Calibration Standard 1 Containing MTBE

Mixture Approximate Component Density, kg/L Mass % Volume %

No. Component Concentrations, mass % Pentene 0.6452 1.00 1.09

1 methyl-tert-butylether (MTBE) 5 Hexene 0.6763 1.00 1.04

isooctane 95 Heptene 0.7009 1.00 1.00

Octene 0.7186 1.00 0.98

2 ethyl-tert-butylether (ETBE) 5 Nonene 0.7329 1.00 0.96

isooctane 95 Decene 0.7440 1.00 0.94

Undecane 0.7438 1.00 0.94

Dodecane 0.7521 1.00 0.93

Isooctane 0.6985 87.00 87.41

MTBE 0.7451 5.00 4.71

Refer to Fig. 1 for the location of the components in the

Total 100.00 100.00

system. The following list of columns and traps contains

guidelines that are to be used to judge suitability.

8.5.1 Polar Column— At a temperature of 160°C, this

column must retain all aromatic components in the sample and

elute all nonaromatic components boiling below 200°C, which

components, are shown in Table 3 and Table 4. Calibration

includes decene and lower boiling olefins, within 2 min after

Standard 1 is used for all samples except those that contain

sample injection.

ETBE and Calibration Standard 2 is used for samples contain-

8.5.1.1 This column mu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.