ASTM F1664-08(2018)

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) and Other Conforming Organic Polymer-Coated Steel Tension Wire Used with Chain-Link Fence

Standard Specification for Poly(Vinyl Chloride) (PVC) and Other Conforming Organic Polymer-Coated Steel Tension Wire Used with Chain-Link Fence

ABSTRACT

This specification deals with poly(vinyl chloride), PVC and other conforming organic polymer-coated steel tension wire for use with chain-link fence. Tension wire, produced from three classes of wire coatings, is covered as follows: Class 1, consisting of a polymer coating extruded over zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire; Class 2a, consisting of a polymer coating extruded and adhered to zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire; and Class 2b, consisting of a polymer coating fused and adhered to zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire. Materials shall be tested and the individual grades shall conform to specified values of wire size, breaking strength, metallic coating weight, PVC coating thickness, polymer-coated tension wire properties, and coil length.

SCOPE

1.1 This specification covers PVC and other conforming organic polymer-coated steel tension wire for use with chain link fence. PVC and other organic polymer coatings hereinafter will be designated as polymer coating.

1.2 Tension wire, produced from three classes of wire coatings, is covered as follows:

1.2.1 Class 1, consisting of a polymer coating extruded over zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire;

1.2.2 Class 2a, consisting of a polymer coating extruded and adhered to zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire; and

1.2.3 Class 2b, consisting of a polymer coating fused and adhered to zinc-coated or aluminum-coated or zinc-5 % aluminum-mischmetal alloy-coated steel wire.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1664 −08 (Reapproved 2018)

Standard Specification for

Poly(Vinyl Chloride) (PVC) and Other Conforming Organic

Polymer-Coated Steel Tension Wire Used with Chain-Link

Fence

This standard is issued under the fixed designation F1664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.1 This specification covers PVC and other conforming

A428/A428M Test Method for Weight [Mass] of Coating on

organic polymer-coated steel tension wire for use with chain

Aluminum-Coated Iron or Steel Articles

linkfence.PVCandotherorganicpolymercoatingshereinafter

D1499 Practice for Filtered Open-Flame Carbon-Arc Expo-

will be designated as polymer coating.

sures of Plastics

1.2 Tension wire, produced from three classes of wire

F552 Terminology Relating to Chain Link Fencing

coatings, is covered as follows:

F934 Specification for Standard Colors for Polymer-Coated

1.2.1 Class 1, consisting of a polymer coating extruded over

Chain Link Fence Materials

zinc-coated or aluminum-coated or zinc-5 % aluminum-

G152 Practice for Operating Open Flame Carbon Arc Light

mischmetal alloy-coated steel wire;

Apparatus for Exposure of Nonmetallic Materials

1.2.2 Class 2a, consisting of a polymer coating extruded

G153 Practice for Operating Enclosed Carbon Arc Light

and adhered to zinc-coated or aluminum-coated or zinc-5 %

Apparatus for Exposure of Nonmetallic Materials

aluminum-mischmetal alloy-coated steel wire; and

1.2.3 Class 2b, consisting of a polymer coating fused and

3. Terminology

adhered to zinc-coated or aluminum-coated or zinc-5 %

3.1 Definitions—For definitions of terms such as fabric

aluminum-mischmetal alloy-coated steel wire.

(chain-link fence), tension wire, PVC, and polymer coating,

1.3 The values stated in inch-pound units are to be regarded

see Terminology F552.

as the standard. The values given in parentheses are for

information only.

4. Ordering Information

1.4 This international standard was developed in accor-

4.1 Orders for tension wire purchased in accordance with

dance with internationally recognized principles on standard-

this specification shall include the following information:

ization established in the Decision on Principles for the

4.1.1 Quantity (expressed in number of coils);

Development of International Standards, Guides and Recom-

4.1.2 Class of coating to be applied to metallic-coated steel

mendations issued by the World Trade Organization Technical

wire;

Barriers to Trade (TBT) Committee.

4.1.3 Color of coating;

4.1.4 Selection of type of metallic coating on the steel wire

2. Referenced Documents

substrate, which shall be the choice of the producer unless

2.1 ASTM Standards:

otherwise specified;

A90/A90M Test Method for Weight [Mass] of Coating on

4.1.5 Core diameter of wire or minimum wire breaking

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

strength, or both;

4.1.6 Packaging requirements; and

4.1.7 Certification, if required.

This specification is under the jurisdiction ofASTM Committee F14 on Fences

and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and

4.2 Any tests required other than those covered specifically

Wire Accessories.

in this specification must be stipulated by the purchaser in the

Current edition approved March 1, 2018. Published March 2018. Originally

approvedin1995.Lastpreviouseditionapprovedin2013asF1664–08(2013).DOI: order or contract.

10.1520/F1664-08R18.

NOTE 1—Atypical ordering description is as follows: 20 coils polymer-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

coated steel tension wire, Class 2b coating, olive green color, 7-gage

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on (0.177-in. (4.50 mm)) core wire, in 1000-ft (305-m) coils, certified to this

the ASTM website. specification.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1664−08 (2018)

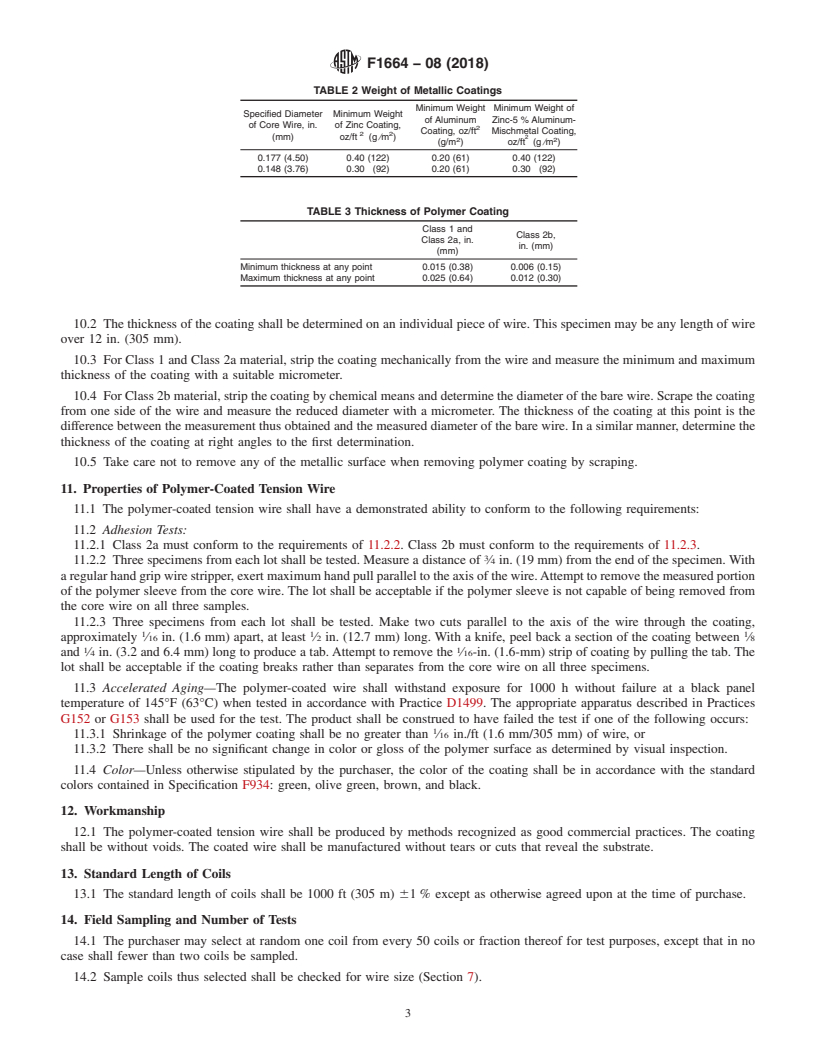

TABLE 2 Weight of Metallic Coatings

5. Materials

Minimum Weight Minimum Weight of

5.1 Base Metal—The base metal shall be steel of such Specified Diameter Minimum Weight

of Aluminum Zinc-5 % Aluminum-

of Core Wire, in. of Zinc Coating,

qualityandpuritythat,whendrawntothesizeofwirespecified

Coating, oz/ft Mischmetal Coating,

2 2

(mm) oz/ft (g ⁄m ) 2

2 2

(g/m ) oz/ft (g ⁄m )

and coated with an organic polymer, the finished wire shall be

0.177 (4.50) 0.40 (122) 0.20 (61) 0.40 (122)

of uniform quality and have properties and characteristics as

0.148 (3.76) 0.30 (92) 0.20 (61) 0.30 (92)

prescribed in this specification.

5.2 Wireusedforthemanufactureoftensionwireshallmeet

the requirements of this specification. The polymer coating

9.4 Theweightofthealuminumcoatingshallbedetermined

shall be formulated and produced properly to conform to the

by the method contained in Test Method A428/A428M after

requirements of this specification.

stripping the polymer coating as outlined in Section 10.

6. Manufacture

10. Thickness of PVC Coating

6.1 Class 1 polymer-coated wire shall have the coating

10.1 The thickness of the coating shall be in accordance

extruded onto wire that conforms to the requirements as given

with Table 3.

in Table 1.

10.2 The thickness of the coating shall be determined on an

6.2 Class 2a polymer-coated wire shall have the coating

individual piece of wire. This specimen may be any length of

extrudedandadheredtowirethatconformstotherequirements

wire over 12 in. (305 mm).

as given in Table 1.

10.3 For Class 1 and Class 2a material, strip the coating

6.3 Class 2b polymer-coated wire shall have the coating

mechanically from the wire and measure the minimum and

fused and adhered to wire that conforms to the requirements as

maximum thickness of the coating with a suitable micrometer.

given in Table 1.

10.4 For Class 2b material, strip the coating by chemical

means and determine the diameter of the bare wire. Scrape the

7. Size of Wire

coating from one side of the wire and measure the reduced

7.1 The permissible variation from the specified diameter of

diameterwithamicrometer.Thethicknessofthecoatingatthis

the core wire, 0.177 in. (4.50 mm) 7 gage or 0.148 in. (3.76

point is the difference between the measurement thus obtained

mm) 9 gage, shall be 60.005 in. (0.13 mm).

and the measured diameter of the bare wire. In a similar

manner, determine the thickness of the coating at right angles

8. Breaking Strength

to the first determination.

8.1 Tension wire shall meet the minimum breaking strength

10.5 Take care not to remove any of the metallic surface

indicated in Table 2 when tested in accordance with

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1664 − 08 (Reapproved 2013) F1664 − 08 (Reapproved 2018)

Standard Specification for

Poly(Vinyl Chloride) (PVC) and Other Conforming Organic

Polymer-Coated Steel Tension Wire Used with Chain-Link

Fence

This standard is issued under the fixed designation F1664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers PVC and other conforming organic polymer-coated steel tension wire for use with chain link fence.

PVC and other organic polymer coatings hereinafter will be designated as polymer coating.

1.2 Tension wire, produced from three classes of wire coatings, is covered as follows:

1.2.1 Class 1, consisting of a polymer coating extruded over zinc-coated or aluminum-coated or zinc-5 % aluminum-

mischmetal alloy-coated steel wire;

1.2.2 Class 2a, consisting of a polymer coating extruded and adhered to zinc-coated or aluminum-coated or zinc-5 %

aluminum-mischmetal alloy-coated steel wire; and

1.2.3 Class 2b, consisting of a polymer coating fused and adhered to zinc-coated or aluminum-coated or zinc-5 %

aluminum-mischmetal alloy-coated steel wire.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A428/A428M Test Method for Weight [Mass] of Coating on Aluminum-Coated Iron or Steel Articles

D1499 Practice for Filtered Open-Flame Carbon-Arc Exposures of Plastics

F552 Terminology Relating to Chain Link Fencing

F934 Specification for Standard Colors for Polymer-Coated Chain Link Fence Materials

G152 Practice for Operating Open Flame Carbon Arc Light Apparatus for Exposure of Nonmetallic Materials

G153 Practice for Operating Enclosed Carbon Arc Light Apparatus for Exposure of Nonmetallic Materials

3. Terminology

3.1 Definitions—For definitions of terms such as fabric (chain-link fence), tension wire, PVC, and polymer coating, see

Terminology F552.

4. Ordering Information

4.1 Orders for tension wire purchased in accordance with this specification shall include the following information:

4.1.1 Quantity (expressed in number of coils);

This specification is under the jurisdiction of ASTM Committee F14 on Fences and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and Wire

Accessories.

Current edition approved March 1, 2013March 1, 2018. Published March 2013March 2018. Originally approved in 1995. Last previous edition approved in 20082013 as

F1664 – 08.F1664–08(2013). DOI: 10.1520/F1664-08R13.10.1520/F1664-08R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1664 − 08 (2018)

4.1.2 Class of coating to be applied to metallic-coated steel wire;

4.1.3 Color of coating;

4.1.4 Selection of type of metallic coating on the steel wire substrate, which shall be the choice of the producer unless otherwise

specified;

4.1.5 Core diameter of wire or minimum wire breaking strength, or both;

4.1.6 Packaging requirements; and

4.1.7 Certification, if required.

4.2 Any tests required other than those covered specifically in this specification must be stipulated by the purchaser in the order

or contract.

NOTE 1—A typical ordering description is as follows: 20 coils polymer-coated steel tension wire, Class 2b coating, olive green color, 7-gage (0.177-in.

(4.50 mm)) core wire, in 1000-ft (305-m) coils, certified to this specification.

5. Materials

5.1 Base Metal—The base metal shall be steel of such quality and purity that, when drawn to the size of wire specified and

coated with an organic polymer, the finished wire shall be of uniform quality and have properties and characteristics as prescribed

in this specification.

5.2 Wire used for the manufacture of tension wire shall meet the requirements of this specification. The polymer coating shall

be formulated and produced properly to conform to the requirements of this specification.

6. Manufacture

6.1 Class 1 polymer-coated wire shall have the coating extruded onto wire that conforms to the requirements as given in Table

1.

6.2 Class 2a polymer-coated wire shall have the coating extruded and adhered to wire that conforms to the requirements as given

in Table 1.

6.3 Class 2b polymer-coated wire shall have the coating fused and adhered to wire that conforms to the requirements as given

in Table 1.

7. Size of Wire

7.1 The permissible variation from the specified diameter of the core wire, 0.177 in. (4.50 mm) 7 gage or 0.148 in. (3.76 mm)

9 gage, shall be 60.005 in. (0.13 mm).

8. Breaking Strength

8.1 Tension wire shall meet the minimum breaking strength indicated in Table 2 when tested in accordance with Test Methods

and Definitions A370.

8.2 Specimens to establish conformance with this requirement shall comprise individual pieces from a coil of the tension wire.

The specimens shall be of sufficient length so as to be gripped firmly in the testing machine. The polymer coating may be removed

from the sample by chemical or mechanical means before testing.

9. Weight of Metallic Coatings

9.1 The weight of the metallic coating shall conform to Table 1.

9.2 The weight of the coating shall be determined on an individual piece of wire over 12 in. (305 mm).

9.3 The weight of the zinc or zinc-5 % aluminum mischmetal alloy coating shall be determined by the method contained in Test

Method A90/A90M after stripping the polymer coating as outlined in Section 10.

9.4 The weight of the aluminum coating shall be determined by the method contained in Test Method A428/A428M after

stripping the polymer coating as outlined in Section 10.

10. Thickness of PVC Coating

10.1 The thickness of the coating shall be in accordance with Table 3.

TABLE 1 Breaking Strength of Metallic-Coated Core Wire

Specified Diameter of Core Wire, Minimum Breaking Strength,

in. (mm) lbf (N)

0.177 (4.50) 1950 (8670)

0.148 (3.76) 1290 (5740)

F1664 − 08 (2018)

TABLE 2 Weig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.