ASTM B111-98(2004)

(Specification)Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

SCOPE

1.1 This specification covers seamless tube and ferrule stock of copper and various copper alloys up to 3 1/8in, inclusive, in diameter, for use in surface condensers, evaporators, and heat exchangers. Tubes for this application are normally made from the following coppers or copper alloys: Copper orCopperAlloy UNS No.3Previously UsedDesignationType of MetalC10100OFEOxygen-free electronicC10200OF Oxygen-free without residual de-oxidantsC10300. . . Oxygen-free, extra low phosphorusC10800. . . Oxygen-free, low phosphorusC12000DLPA Phosphorized, low residual phosphorusC12200DHPA Phosphorized, high residual phos-phorusC14200DPAA Phosphorized, arsenicalC19200. . . Phosphorized, 1 % ironC23000. . . Red BrassC28000. . . Muntz MetalC44300. . . Admiralty Metals, B, C, and DC44400C44500C60800. . . Aluminum BronzeC61300. . .C61400. . . Aluminum Bronze, DC68700. . . Aluminum Brass, BC70400. . . 95-5 Copper-NickelC70600. . . 90-10 Copper-NickelC71000. . . 80-20 Copper-NickelC71500. . . 70-30 Copper-NickelC71640. . . Copper-nickel-iron-manganeseC72200. . . . . .ADesignations listed in Classification B 224.

Note 1--A complete metric companion to Specification B111has been developed -- B111M; therefore no metric equivalents are presented in this specification.

Note 2--Warning-- Mercury is a definite health hazard in use and disposal. (See 12.1.)

1.2 The following safety hazards caveat pertains only to the test methods portion, Section 18, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 111 – 98 (Reapproved 2004)

Standard Specification for

Copper and Copper-Alloy Seamless Condenser Tubes and

Ferrule Stock

This standard is issued under the fixed designation B 111; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE 2— Warning—Mercury is a definite health hazard in use and

1. Scope*

disposal. (See 12.1.)

1.1 This specification covers seamless tube and ferrule

1.2 The following safety hazards caveat pertains only to the

stock of copper and various copper alloys up to 3 ⁄8 in.,

test methods portion, Section 18, of this specification: This

inclusive, in diameter, for use in surface condensers, evapora-

standard does not purport to address all of the safety concerns,

tors, and heat exchangers. Tubes for this application are

if any, associated with its use. It is the responsibility of the user

normally made from the following coppers or copper alloys:

of this standard to establish appropriate safety and health

Copper or

Copper Previously practices and determine the applicability of regulatory limita-

Alloy Used

tions prior to use.

UNS No. Designation Type of Metal

2. Referenced Documents

C10100 OFE Oxygen-free electronic

A

C10200 OF Oxygen-free without residual deoxidants

2.1 The following documents of the issue in effect on date

C10300 . . . Oxygen-free, extra low phosphorus

of material purchase form a part of this specification to the

C10800 . . . Oxygen-free, low phosphorus

A

C12000 DLP Phosphorized, low residual phosphorus extent referenced herein:

A

C12200 DHP Phosphorized, high residual phosphorus

2.2 ASTM Standards:

A

C14200 DPA Phosphorized, arsenical

B 153 Test Method for Expansion (Pin Test) of Copper and

C19200 . . . Phosphorized, 1 % iron

C23000 . . . Red Brass Copper-Alloy Pipe and Tubing

C28000 . . . Muntz Metal

B 154 Test Method for Mercurous Nitrate Test for Copper

C44300 . . . Admiralty Metals, B, C, and D

and Copper Alloys

C44400

C44500 B 170 Specification for Oxygen-Free Electrolytic Copper—

C60800 . . . Aluminum Bronze

Refinery Shapes

C61300 . . . . . .

B 224 Classification of Coppers

C61400 . . . Aluminum Bronze, D

C68700 . . . Aluminum Brass, B

E 8 Test Methods for Tension Testing of Metallic Materials

C70400 . . . 95-5 Copper-Nickel

E 29 Practice for Using Significant Digits in Test Data to

C70600 . . . 90-10 Copper-Nickel

Determine Conformance with Specifications

C71000 . . . 80-20 Copper-Nickel

C71500 . . . 70-30 Copper-Nickel

E 53 Test Methods for Determination of Copper in Unal-

C71640 . . . Copper-nickel-iron-manganese

loyed Coppers by Gravimetry

C72200 . . . . . .

E 54 Test Methods for Chemical Analysis of Special

A

Designations listed in Classification B 224.

Brasses and Bronzes

NOTE 1—A complete metric companion to Specification B 111 has been

E 62 Test Methods for Chemical Analysis of Copper and

developed—B 111M; therefore, no metric equivalents are presented in this

Copper Alloys (Photometric Methods)

specification.

E 75 Test Methods for Chemical Analysis of Copper-Nickel

and Copper-Nickel-Zinc Alloys

E 112 Test Methods for Determining Average Grain Size

This specification is under the jurisdiction of ASTM Committee B05 on Copper

E 243 Practice for Electromagnetic (Eddy Current) Exami-

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube. nation of Copper and Copper-Alloy Tubes

Current edition approved May 1, 2004. Published May 2004. Originally

e1

approved in 1937. Last previous edition approved in 1998 as B 111 – 98 .

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-111 in Section II of the Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

The UNS system for copper and copper alloys (see Practice E 527) is a simple

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

expansion of the former standard designation system accomplished by the addition

Standards volume information, refer to the standard’s Document Summary page on

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

the ASTM website.

composition variations of the base alloy.

Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 111 – 98 (2004)

E 255 Practice for Sampling Copper and Copper Alloys for 4. Ordering Information

the Determination of Chemical Composition

4.1 Orders for material under this specification shall include

E 478 Test Methods for Chemical Analysis of Copper

the following information:

Alloys

4.1.1 Quantity of each size (number of pieces and number of

E 527 Practice for Numbering Metals and Alloys (UNS)

feet),

4.1.2 Material (Section 1),

3. Terminology

4.1.3 Form (tube or ferrule stock),

3.1 Definitions:

4.1.4 Temper (Section 7),

3.1.1 lengths, n—straight pieces of the product.

4.1.5 Whether tension test is required (Section 7),

3.1.1.1 specific, n—straight lengths that are uniform in

4.1.6 Whether a pressure test is to be used instead of the

length, as specified, and subject to established length toler-

eddy current test (see 13.1),

ances.

4.1.7 Dimensions, the diameter, wall thickness, whether

3.1.2 tube, seamless, n—a tube produced with a continuous

minimum or nominal wall, and length (see Section 14),

periphery in all stages of the operations.

4.1.8 Whether cut ends of the tube are to be deburred (see

3.1.2.1 tube, condenser, n—See tube, heat exchanger.

15.1),

3.1.2.2 tube, ferrule, n—a tube from which metal rings or

4.1.9 If the product is to be subsequently welded (see Table

collars (ferrules) are made for use in installing condenser tubes.

1 and Footnotes G and H).

3.1.2.3 tube, heat exchanger, n—a tube manufactured to

4.1.10 Specification number and year of issue,

special requirements as to dimensional tolerances, finish, and

4.1.11 Certification, if required (see 22.1), and

temper for use in condensers and other heat exchangers.

4.1.12 Mill test report, if required (see 24.1).

3.2 Description of Term Specific to This Standard:

3.2.1 capable of—the test need not be performed by the 4.2 When material is purchased for agencies of the U.S.

producer of the material. However, should subsequent testing government, this shall be specified in the contract or purchase

order, and the material shall conform to the Supplementary

by the purchaser establish that the material does not meet these

requirements, the material shall be subject to rejection. Requirements as defined herein.

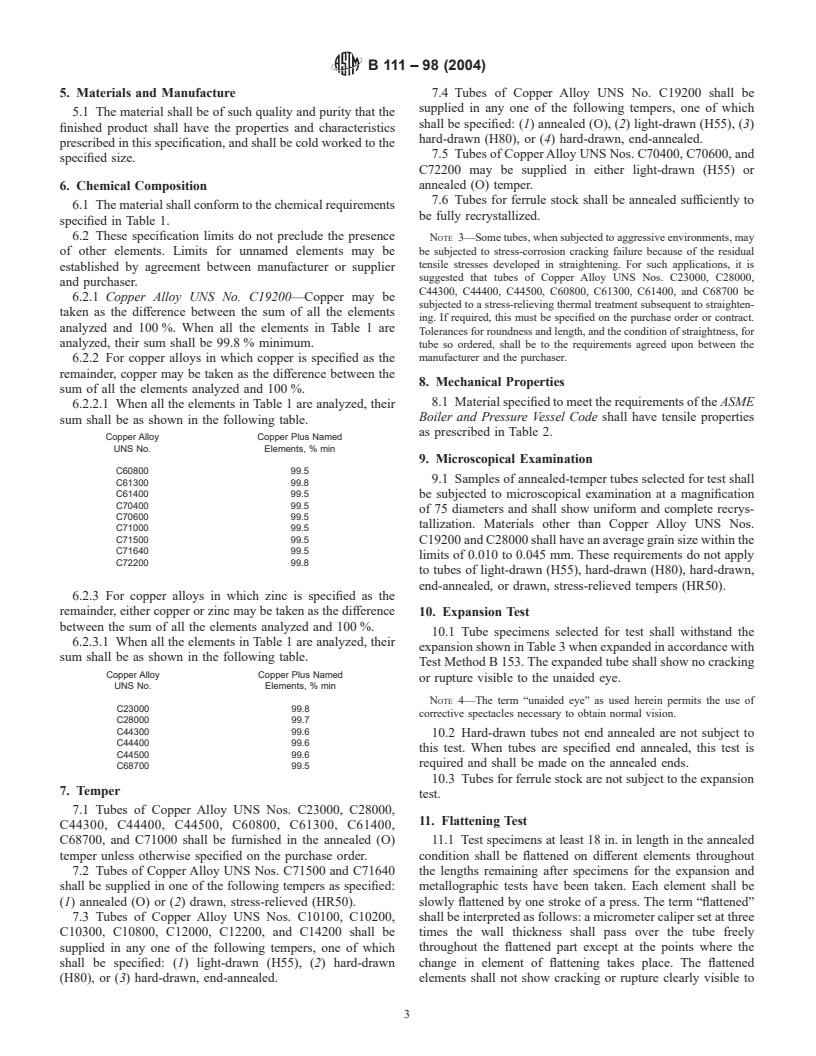

TABLE 1 Chemical Requirements

Composition, %

Copper or

Copper

Other

Nickel, Lead,

A

Alloy UNS

Copper Tin Aluminum Iron Zinc Manganese Arsenic Antimony Phosphorus Chromium Named

incl Cobalt max

No.

Elements

B C

C10100 99.99 min . . . . . . . . . 0.0010 . . . 0.0001 max . . . . . . . . . 0.0003 max . . .

D

C10200 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

C10300 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.001–0.005 . . . . . .

E

C10800 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.005–0.012 . . . . . .

C12000 99.90 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004–0.012 . . . . . .

C12200 99.9 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.040 . . . . . .

C14200 99.40 min . . . . . . . . . . . . . . . . . . . . . 0.15–0.50 . . . 0.015–0.040 . . . . . .

C19200 98.7 min . . . . . . . . . . . . 0.8–1.2 . . . . . . . . . . . . 0.01–0.04 . . . . . .

C23000 84.0–86.0 . . . . . . . . . 0.05 0.05 max remainder . . . . . . . . . . . . . . . . . .

C28000 59.0–63.0 . . . . . . . . . 0.30 0.07 max remainder . . . . . . . . . . . . . . . . . .

C44300 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

C44400 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . 0.02–0.10 . . . . . . . . .

C44500 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . . . . 0.02–0.10 . . . . . .

C60800 remainder . . . 5.0–6.5 . . . 0.10 0.10 max . . . . . . 0.02–0.35 . . . . . . . . . . . .

F,G

C61300 remainder 0.20–0.50 6.0–7.5 0.15 max 0.01 2.0–3.0 0.10 max 0.20 max . . . . . . 0.015 max . . .

C61400 remainder . . . 6.0–8.0 . . . 0.01 1.5–3.5 0.20 max 1.0 max . . . . . . . . . . . . . . .

C68700 76.0–79.0 . . . 1.8–2.5 . . . 0.07 0.06 max remainder . . . 0.02–0.10 . . . . . . . . . . . .

C70400 remainder . . . . . . 4.8–6.2 0.05 1.3–1.7 1.0 max 0.30–0.8 . . . . . . . . . . . . . . .

H H H H

C70600 remainder . . . . . . 9.0–11.0 0.05 1.0–1.8 1.0 max 1.0 max . . . . . . .

H H H H

C71000 remainder . . . . . . 19.0–23.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . .

H H H H

C71500 remainder . . . . . . 29.0–33.0 0.05 0.40–1.0 1.0 max 1.0 max . . . . . . .

H H H H

C71640 remainder . . . . . . 29.0–32.0 0.05 1.7–2.3 1.0 max 1.5–2.5 . . . . . . .

H H H H

C72200 remainder . . . . . . 15.0–18.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . 0.30–0.70

A

Copper (including silver).

B

This value is exclusive of silver and shall be determined by difference of “impurity total” from 100 %. “Impurity total” is defined as the sum of sulfur, silver, lead, tin,

bismuth, arsenic, antimony, iron, nickel, mercury, zinc, phosphorus, selenium, tellurium, manganese, cadmium, and oxygen present in the sample.

C

Impurity maximums in ppm for C10100 shall be: antimony 4, arsenic 5, bismuth 1, cadmium 1, iron 10, lead 5, manganese 0.5, mercury 1, nickel 10, oxygen 5,

phosphorus 3, selenium 3, silver 25, sulfur 15, tellurium 2, tin 2, and zinc 1.

D

Oxygen in C10200 shall be 10 ppm max.

E

Copper plus sum of named elements shall be 99.95 % min.

F

Silicon shall be 0.10 % max.

G

When the product is for subsequent welding applications and is so specified by the purchaser, chromium shall be 0.05 % max, cadmium 0.05 % max, zinc 0.05 % max,

and zirconium 0.05 % max.

H

When the product is for subsequent welding applications, and so specified by the purchaser, zinc shall be 0.50 % max, lead 0.02 % max, phosphorus 0.02 % max,

sulfur 0.02 % max, and carbon 0.05 % max.

B 111 – 98 (2004)

5. Materials and Manufacture 7.4 Tubes of Copper Alloy UNS No. C19200 shall be

supplied in any one of the following tempers, one of which

5.1 The material shall be of such quality and purity that the

shall be specified: (1) annealed (O), (2) light-drawn (H55), (3)

finished product shall have the properties and characteristics

hard-drawn (H80), or (4) hard-drawn, end-annealed.

prescribed in this specification, and shall be cold worked to the

7.5 Tubes of Copper Alloy UNS Nos. C70400, C70600, and

specified size.

C72200 may be supplied in either light-drawn (H55) or

annealed (O) temper.

6. Chemical Composition

7.6 Tubes for ferrule stock shall be annealed sufficiently to

6.1 The material shall conform to the chemical requirements

be fully recrystallized.

specified in Table 1.

6.2 These specification limits do not preclude the presence

NOTE 3—Some tubes, when subjected to aggressive environments, may

of other elements. Limits for unnamed elements may be be subjected to stress-corrosion cracking failure because of the residual

tensile stresses developed in straightening. For such applications, it is

established by agreement between manufacturer or supplier

suggested that tubes of Copper Alloy UNS Nos. C23000, C28000,

and purchaser.

C44300, C44400, C44500, C60800, C61300, C61400, and C68700 be

6.2.1 Copper Alloy UNS No. C19200—Copper may be

subjected to a stress-relieving thermal treatment subsequent to straighten-

taken as the difference between the sum of all the elements

ing. If required, this must be specified on the purchase order or contract.

analyzed and 100 %. When all the elements in Table 1 are

Tolerances for roundness and length, and the condition of straightness, for

analyzed, their sum shall be 99.8 % minimum. tube so ordered, shall be to the requirements agreed upon between the

manufacturer and the purchaser.

6.2.2 For copper alloys in which copper is specified as the

remainder, copper may be taken as the difference between the

8. Mechanical Properties

sum of all the elements analyzed and 100 %.

8.1 Material specified to meet the requirements of the ASME

6.2.2.1 When all the elements in Table 1 are analyzed, their

Boiler and Pressure Vessel Code shall have tensile properties

sum shall be as shown in the following table.

as prescribed in Table 2.

Copper Alloy Copper Plus Named

UNS No. Elements, % min

9. Microscopical Examination

C60800 99.5

9.1 Samples of annealed-temper tubes selected for test shall

C61300 99.8

C61400 99.5

be subjected to microscopical examination at a magnification

C70400 99.5

of 75 diameters and shall show uniform and complete recrys-

C70600 99.5

tallization. Materials other than Copper Alloy UNS Nos.

C71000 99.5

C71500 99.5 C19200 and C28000 shall have an average grain size within the

C71640 99.5

limits of 0.010 to 0.045 mm. These requirements do not apply

C72200 99.8

to tubes of light-drawn (H55), hard-drawn (H80), hard-drawn,

end-annealed, or drawn, stress-relieved tempers (HR50).

6.2.3 For copper alloys in which zinc is specified as the

remainder, either copper or zinc may be taken as the difference

10. Expansion Test

between the sum of all the elements analyzed and 100 %.

10.1 Tube specimens selected for test shall withstand the

6.2.3.1 When all the elements in Table 1 are analyzed, their

expansion shown in Table 3 when expanded in accordance with

sum shall be as shown in the following table.

Test Method B 153. The expanded tube shall show no cracking

Copper Alloy Copper Plus Named

or rupture visible to the unaided eye.

UNS No. Elements, % min

NOTE 4—The term “unaided eye” as used herein permits the use of

C23000 99.8

corrective spectacles necessary to obtain normal vision.

C28000 99.7

C44300 99.6

10.2 Hard-drawn tubes not end annealed are not subject to

C44400 99.6

this test. When tubes are specified end annealed, this test is

C44500 99.6

required and shall be made on the annealed ends.

C68700 99.5

10.3 Tubes for ferrule stock are not subject to the expansion

7. Temper

test.

7.1 Tubes of Copper Alloy UNS Nos. C23000, C28000,

11. Flattening Test

C44300, C44400, C44500, C60800, C61300, C61400,

C68700, and C71000 shall be furnished in the annealed (O) 11.1 Test specimens at least 18 in. in length in the annealed

temper unless otherwise specified on the purchase order. condition shall be flattened on different elements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.