ASTM D4819-96(2005)

(Specification)Standard Specification for Flexible Cellular Materials Made From Polyolefin Plastics

Standard Specification for Flexible Cellular Materials Made From Polyolefin Plastics

ABSTRACT

This specification applies to flexible closed-cell materials made from polyolefin plastics and blends of polyolefin plastics. Two types of flexible, closed-cell polyolefin foams are covered: type I - closed cell foams made with polyolefin plastics and either chemically or radiation crosslinked, and type II - closed cell foams made with polyolefin plastics that are non-crosslinked. Cellular polyolefin foams furnished under this specification shall be manufactured from any resin or blend of resins that are members of the polyolefin family together with added compounding materials. Unless otherwise specified, the color of cellular polyolefin foams shall be natural.

SCOPE

1.1 This specification applies to flexible closed-cell materials made from polyolefin plastics and blends of polyolefin plastics as defined in Section .

1.2 Extruded or molded shapes too small to permit the cutting of standard test specimens are difficult to classify or test by standard test methods and will usually require special testing procedures or the use of standard test sheets.

1.3 In case of conflict between the provisions of this specification and those of detailed specifications for a particular product, the latter shall take precedence. These detailed specifications for the flexible closed-cell polyolefin plastic foams should state the particular test or tests desired.

1.4 In cases involving referee decisions, SI units shall be used.

1.5 This specification does not contain test procedures or values for all the suffix letters listed in and . Where the procedure is not described in this specification or special limits are desired, or both, the test procedures and values must be arranged between the purchaser and the supplier.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4819 −96(Reapproved 2005)

Standard Specification for

Flexible Cellular Materials Made From Polyolefin Plastics

This standard is issued under the fixed designation D4819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D624 Test Method for Tear Strength of Conventional Vul-

canized Rubber and Thermoplastic Elastomers

1.1 This specification applies to flexible closed-cell materi-

D1596 Test Method for Dynamic Shock Cushioning Char-

als made from polyolefin plastics and blends of polyolefin

acteristics of Packaging Material

plastics as defined in Section 3.

D2863 Test Method for Measuring the Minimum Oxygen

1.2 Extruded or molded shapes too small to permit the

Concentration to Support Candle-Like Combustion of

cuttingofstandardtestspecimensaredifficulttoclassifyortest

Plastics (Oxygen Index)

by standard test methods and will usually require special

D3575 Test Methods for Flexible Cellular Materials Made

testing procedures or the use of standard test sheets.

From Olefin Polymers

E96/E96M Test Methods for Water Vapor Transmission of

1.3 In case of conflict between the provisions of this

specification and those of detailed specifications for a particu- Materials

F355 TestMethodforImpactAttenuationofPlayingSurface

lar product, the latter shall take precedence. These detailed

specifications for the flexible closed-cell polyolefin plastic Systems and Materials

foams should state the particular test or tests desired.

2.2 Motor Vehicle Safety Standard:

MVSS-302 Flammability of Vehicle Interior Materials—

1.4 In cases involving referee decisions, SI units shall be

Passenger Cars, Multipurpose Passenger Vehicles, Trucks

used.

and Buses

1.5 This specification does not contain test procedures or

2.3 UL Standard:

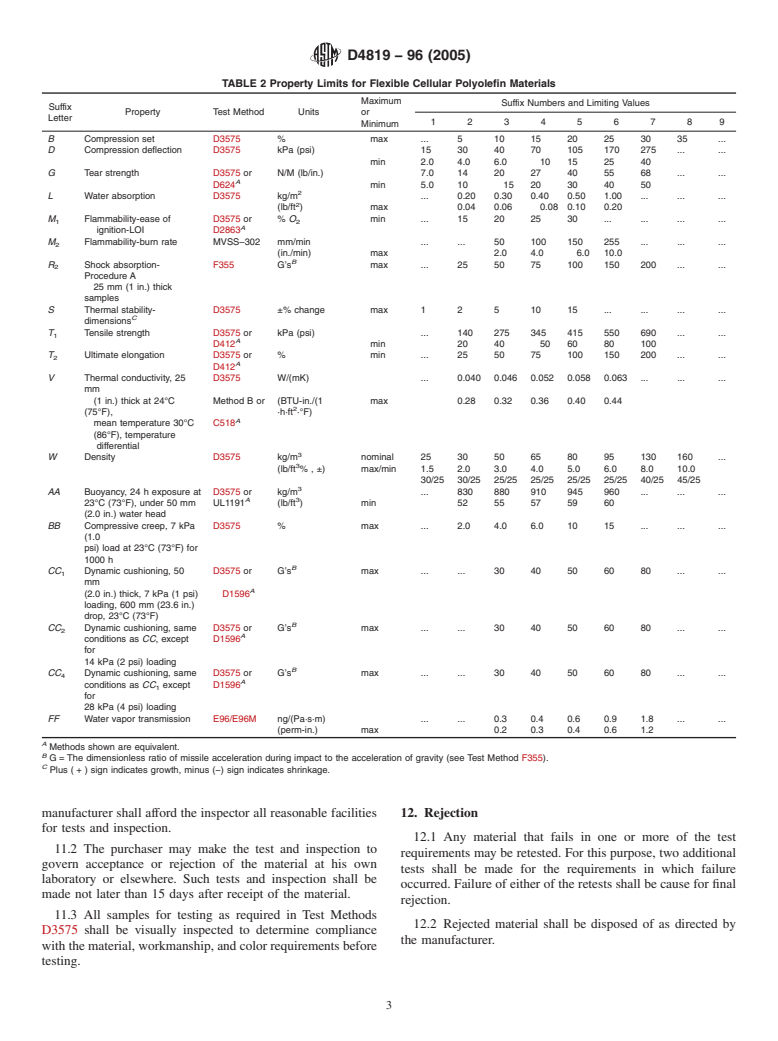

values for all the suffix letters listed in Table 1 and Table 2.

UL1191 Standard for Components for Personal Flotation

Where the procedure is not described in this specification or

Devices

special limits are desired, or both, the test procedures and

values must be arranged between the purchaser and the

3. Terminology

supplier.

3.1 Definitions:

1.6 The values stated in SI units are to be regarded as the

3.1.1 blend—mixture of polyolefin plastic(s) with other

standard. The values given in parentheses are for information

polymer(s) in which at least 51 mass % is the polyolefin

only.

plastic(s).

NOTE 1—There is no similar or equivalent ISO standard.

3.1.2 polyolefin plastics—material based on polymers made

by the polymerization of olefins or copolymerization of olefins

2. Referenced Documents

with other polymers, the polyolefin being at least 51 mass %.

2.1 ASTM Standards:

3.1.3 resin—solid, semi-solid, or pseudo-solid organic ma-

C518 Test Method for Steady-State Thermal Transmission

terial that has an indefinite and often high molecular weight,

Properties by Means of the Heat Flow Meter Apparatus

exhibits a tendency to flow when subject to stress, usually has

D412 Test Methods forVulcanized Rubber andThermoplas-

a softening or melting range, and usually fractures conchoid-

tic Elastomers—Tension

ally.

4. Classification (Types, Suffix Letters, and Suffix

This specification is under the jurisdiction of ASTM Committee D20 on

Numbers)

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

Plastics.

4.1 Types—This specification covers two types of flexible,

Current edition approved March 1, 2005. Published March 2005. Originally

closed-cell polyolefin foams designated as follows:

approved in 1988. Last previous edition approved in 1996 as D4819 - 96. DOI:

10.1520/D4819-96R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Department of Transportation, Washington, DC.

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), Corporate Progress, 333

the ASTM website. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4819−96 (2005)

TABLE 1 Suffix Letter Designations

5. Ordering Information

A Heat resistance

5.1 When ordering, the product shall be described by

B Compression set under constant deflection

showing the type and suffix letters and number designations as

C Ozone or weather resistance

D Compression deflection

described in Section 4.

E Oil resistance

5.2 Minimum recommended properties for either type of

F Low temperature

G Tear resistance

foam shall include requirements for Compression Deflection

H Flex resistance

(Suffix D), Tensile Strength (Suffix T ), and Ultimate Elonga-

I Not assigned

J Abrasion resistance tion (Suffix T ).

K Adhesion capability

5.3 The properties selected and values set shall be selected

L Water absorption

M Flammability resistance

to ensure the required performance of the end product.

N Impact resistance

5.4 Specialrequirementsshallbelisted.Testproceduresand

O Electrical properties

P Staining resistance

limits shall be established by negotiation between the pur-

Q Not assigned

chaser and the supplier. Each special requirement shall be

R Resilience

listed as Z suffix letters followed by numerical subscripts.

R Shock absorption

S Thermal stability

T Tensile strength

6. Materials and Manufacture

T Ultimate elongation

U Not assigned

6.1 Cellular polyolefin foams furnished under this specifi-

V Thermal conductivity

cation shall be manufactured from any resin or blend of resins

W Density

that are members of the polyolefin family together with added

X Not assigned

Y Not assigned

compounding materials of such a nature and quality that the

Z Special requirements

finished product complies with this specification. In permitting

AA Buoyancy

choice in use of those materials by the producer, it is not

BB Compressive creep

CC Dynamic cushioning

intended to imply that the different resins are equivalent with

DD Open cell

respect to all physical properties. Special characteristics other

EE Not assigned

than those prescribed in this specification that may be desired

FF Water vapor transmission

for specific applications shall be listed in the product specifi-

cations, as they may influence the choice of the type of resin or

other materials used.

6.2 All materials and workmanship shall be in accordance

4.1.1 Type I—Closed cell foams made with polyolefin

with good commercial practice and the resulting cellular

plastics and either chemically or radiation crosslinked.

polyolefin shall be free from defects affecting serviceability.

4.1.2 Type II—Closed cell foams made with polyolefin

7. Color

plastics that are non-crosslinked.

7.1 Unless otherwise specified, the color of cellular poly-

4.2 Suffıx Letters—Suffix letters shall be added to the type

olefin foams shall be natural. The foam shall contain no

designation (4.1) singly or in combination to indicate the

colorants.

necessary requirements.

4.2.1 The significance of the approved suffix letters is given

8. Physical Properties

in Table 1.

8.1 The polyolefin foams shall conform to the requirements

4.2.2 Frequently used suffix letters for polyolefin foams are

given in the classification (see Section 4) and described in

given in Table 2. Where more than one test method exists for

Table 2 togethe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.