ASTM D2672-96a

(Specification)Standard Specification for Joints for IPS PVC Pipe Using Solvent Cement

Standard Specification for Joints for IPS PVC Pipe Using Solvent Cement

SCOPE

1.1 This specification covers the socket produced for solvent cement joints on both pressure and non-pressure IPS pipe. It also covers the testing of the joints on both pressure and non-pressure pipe, and includes requirements for socket dimensions, burst pressure, and joint tightness tests of the solvent cemented joints. The tests described are not intended for routine quality control, but rather to evaluate the performance characteristics of the joint.

Note 1-On dual marked Schedule 40 DWV and potable water pipe, the socket bells must conform to the dimensional and physical requirements for pressure socket bells.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only. Note 2-Changes in ground, water, or air temperature will produce expansion or contraction forces in PVC piping, and these will result in longitudinal shear stresses in the solvent cement joints. These stresses must be considered in the design and operation of the system. Note 3-See Methods D618 for information relating to this specification.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2672 – 96a

Standard Specification for

Joints for IPS PVC Pipe Using Solvent Cement

This standard is issued under the fixed designation D 2672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 618 Practice for Conditioning Plastics for Testing

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

1.1 This specification covers the socket produced for sol-

sure of Plastic Pipe, Tubing, and Fittings

vent cement joints on both pressure and non-pressure IPS pipe.

D 1600 Terminology for Abbreviated Terms Relating to

It also covers the testing of the joints on both pressure and

Plastics

non-pressure pipe, and includes requirements for socket di-

D 1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

mensions, burst pressure, and joint tightness tests of the solvent

tic Pipe, Schedules 40, 80, and 120

cemented joints. The tests described are not intended for

D 2122 Test Method for Determining Dimensions of Ther-

routine quality control, but rather to evaluate the performance

moplastic Pipe and Fittings

characteristics of the joint.

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

NOTE 1—On dual marked Schedule 40 DWV and potable water pipe, 3

Pressure-Rated Pipe (SDR Series)

the socket bells must conform to the dimensional and physical require-

D 2564 Specification for Solvent Cements for Poly(Vinyl

ments for pressure socket bells.

Chloride) (PVC) Plastic Piping Systems

1.2 The text of this specification references notes, footnotes,

D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

and appendixes which provide explanatory material. These 3

tic Drain, Waste and Vent Pipe and Fittings

notes and footnotes (excluding those in tables and figures) shall

D 2855 Practice for Making Solvent-Cemented Joints with

not be considered as requirements of the specification.

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

1.3 The values stated in inch-pound units are to be regarded

F 412 Terminology Relating to Plastic Piping Systems

as the standard. The values given in parentheses are for

F 512 Specification for Smooth-Wall Poly(Vinyl Chloride)

information only.

(PVC) Conduit and Fittings for Underground Installation

F 656 Specification for Primers for Use in Solvent Cement

NOTE 2—Changes in ground, water, or air temperature will produce

expansion or contraction forces in PVC piping, and these will result in Joints of Poly(Vinyl Chloride) (PVC) Plastic Pipe and

longitudinal shear stresses in the solvent cement joints. These stresses

Fittings

must be considered in the design and operation of the system.

2.2 NSF Standard:

NOTE 3—See Practice D 618 for information relating to this specifica-

Standard No. 14 for Plastic Piping Components and Related

tion.

Materials

1.4 The following safety hazards caveat pertains only to the

3. Terminology

test method portion, Section 10, of this specification. This

standard does not purport to address all of the safety concerns,

3.1 Definitions—Definitions are in accordance with Termi-

if any, associated with its use. It is the responsibility of the user

nology F 412 and abbreviations are in accordance with Termi-

of this standard to establish appropriate safety and health

nology D 1600, unless otherwise specified.

practices and determine the applicability of regulatory limita-

4. Materials

tions prior to use.

4.1 General—PVC plastics used to make the pipe, which

2. Referenced Documents

are belled under this specification, are designated in PVC

2.1 ASTM Standards:

product standards referencing this standard.

4.2 Solvent cements must conform to the requirements of

Specification D 2564.

1 2

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Annual Book of ASTM Standards, Vol 08.01.

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. Annual Book of ASTM Standards, Vol 08.04.

Current edition approved Sept. 10, 1996. Published November 1996. Originally Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor,

published as D 2672 – 68. Last previous edition D 2672 – 96. MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2672

4.3 Primers must conform to the requirements of Specifica- determined in accordance with 10.3.

tion F 656.

5.2.2 Joint Tightness—The (bell) socket joint on non-

pressure pipe shall not leak when tested in accordance with

5. Requirements

10.4.

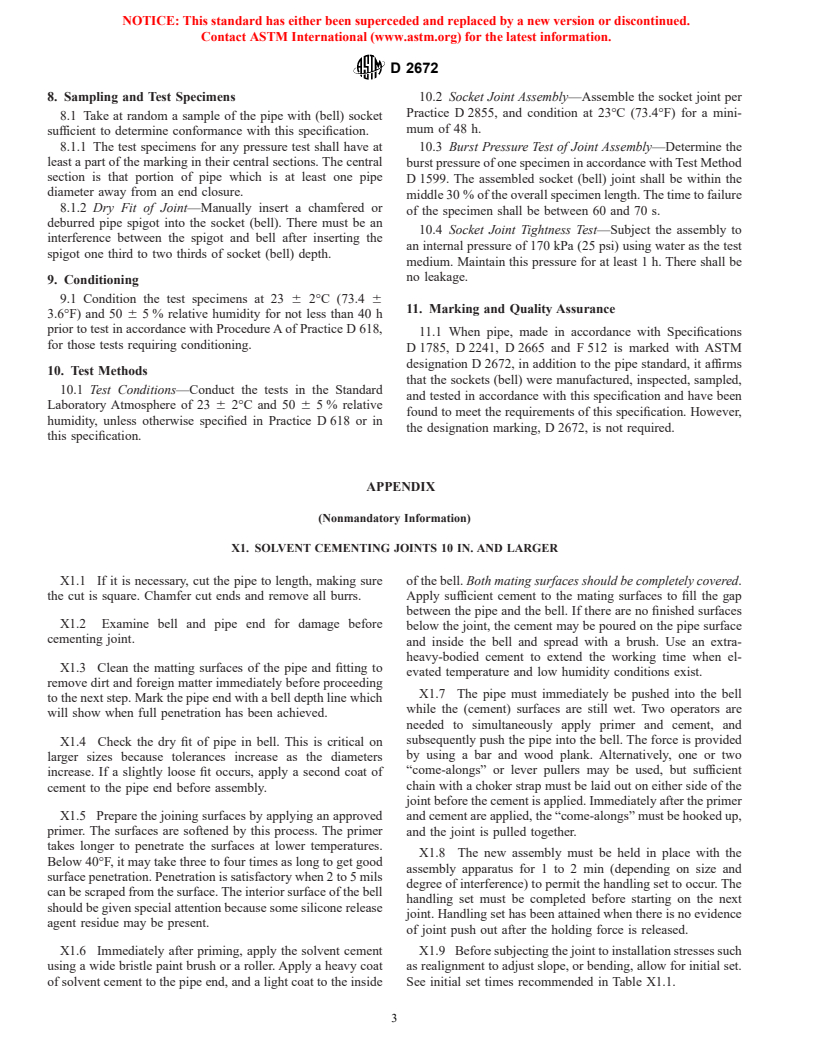

5.1 Bell Socket Dimensions and Tolerances:

5.1.1 Diameters and Length—The diameter, lengths, and

6. Workmanship

tolerances of the bell sockets shall be as shown in Table 1 when

6.1 Each socket (bell) is required to be uniform in depth,

measured in accordance with Test Method D 2122.

circular in cross section concentric with the pipe, and to have

5.1.2 Wall Thicknesses—The minimum wall thicknesses of

an end as square as commercially practicable.

the sockets (bell) shall not be less than 90 % of the minimums

shown for the pressure pipe in the applicable ASTM specifi-

7. Retest and Rejection

cation. For non-pressure pipe, the integral socket (bell) shall be

considered satisfactory when formed from pipe which meets 7.1 If the results of any test(s) do not meet the requirements

the minimum wall thickness requirements of the applicable of this specification, the test(s) shall be conducted again only

ASTM specification when measured in accordance with Test by agreement between the purchaser and the seller. Under such

Method D 2122. agreement, minimum requirements shall not be lowered, nor

5.2 Joint Tests: tests omitted, substituted, changed, or modified, nor shall

5.2.1 Burst Pressure—The minimum burst pressures for specification limits be changed. If upon retest, failure occurs,

pipe and (bell) socket on pressure pipe shall be as given for the quantity of product represented by the test(s) does not meet

pressure pipe in the applicable ASTM specification when the requirements of this specification.

TABLE 1 Tapered Sockets for Bell-End Pipe, in. (mm)

A B C

A

Socket Entrance Diameter, in. (mm) Socket Bottom Diameter, in. (mm) Socket Length, in. (mm), min

Pipe Size,

Tolerance on Maximum Tolerance on Maximum

in.

Nominal Nominal Non-Pres-

Nominal Out-of- Nominal Out-of- Pressure

C

Diameter Diameter sure

B B

Diameter Round Diameter Round

1 8 0.417 (10.59) 60.004 (60.10) 0.024 (0.61) 0.401 (10.18) 60.004 (60.10) 0.024 (0.61) 0.500 (12.70) . . .

/

1 4 0.552 (14.02) 60.004 (60.10) 0.024 (0.61) 0.536 (13.61) 60.004 (60.10) 0.024 (0.61) 0.500 (12.70) . . .

/

3 8 0.687 (17.45) 60.004 (60.10) 0.024 (0.61) 0.671 (17.04) 60.004 (60.10) 0.024 (0.61) 0.750 (19.05) . . .

/

1 2 0.848 (21.54) 60.004 (60.10) 0.024 (0.61) 0.836 (21.23) 60.004 (60.10) 0.024 (0.61) 1.000 (25.40) 1.000 (25.40)

/

3 4 1.058 (26.87) 60.004 (60.10) 0.028 (0.71) 1.046 (26.57) 60.004 (60.10) 0.028 (0.71) 1.250 (31.75) 1.000 (25.40)

/

1 1.325 (33.65) 60.005 (60.13) 0.030 (0.76) 1.310 (33.27) 60.005 (60.13) 0.030 (0.76) 1.500 (38.10) 1.000 (25.40)

11 4 1.670 (42.42) 60.005 (60.13) 0.034 (0.86) 1.655 (42.04) 60.005 (60.13) 0.034 (0.86) 1.750 (44.45) 1.250 (31.75)

/

11 2 1.912 (48.56) 60.006 (60.15) 0.036 (0.91) 1.894 (48.11) 60.006 (60.15) 0.036 (0.91) 2.000 (50.80) 1.375 (34.92)

/

2 2.387 (60.63) 60.006 (60.15) 0.036 (0.91) 2.363 (60.02) 60.006 (60.15) 0.036 (0.91) 2.250 (57.15) 1.750 (44.45)

21 2 2.889 (73.38) 60.007 (60.18) 0.044 (1.12) 2.861 (72.67) 60.007 (60.18) 0.044 (1.12) 2.500 (63.50) 2.000 (50.80)

/

3 3.516 (89.31) 60.008 (60.20) 0.046 (1.17) 3.484 (88.49) 60.008 (60.20) 0.046 (1.17) 3.250 (82.55) 2.875 (73.02)

31 2 4.016 (102.01) 60.008 (60.20) 0.046 (1.17) 3.984 (101.19) 60.008 (60.20) 0.046 (1.17) 3.500 (88.90) 3.125 (79.37)

/

4 4.518 (114.76) 60.009 (60.23) 0.048 (1.22) 4.482 (113.84) 60.009 (60.23) 0.048 (1.22) 4.000 (101.60) 3.375 (85.72)

5 5.583 (141.81) 60.010 (60.25) 0.080 (2.03) 5.543 (140.79) 60.010 (60.25) 0.080 (2.03) 4.000 (101.60) 4.000 (101.60)

6 6.647 (168.83) 60.011 (60.28) 0.082 (2.08) 6.603 (167.72) 60.011 (60.28) 0.082 (2.08) 6.000 (152.40) 5.000 (127.00)

8 8.655 (219.84) 60.015 (60.38) 0.120 (3.05) 8.598 (218.39) 60.015 (60

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.