ASTM D8335-20

(Guide)Standard Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials

Standard Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials

SIGNIFICANCE AND USE

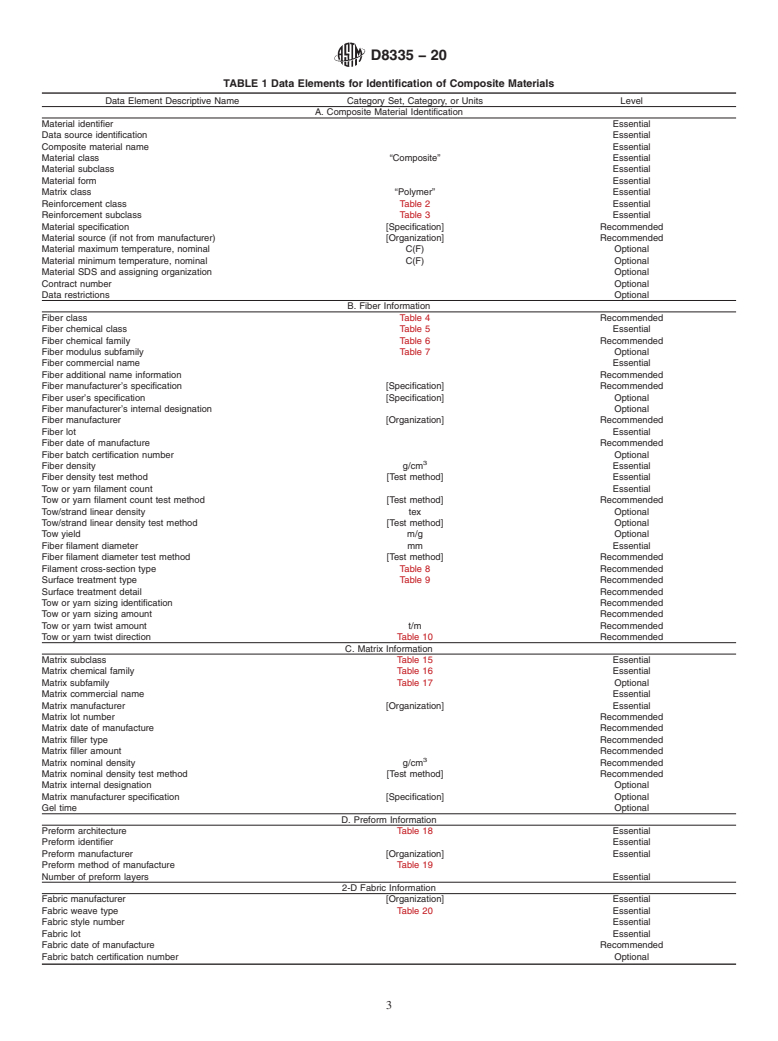

4.1 This guide provides the recommended data elements for the identification of fiber-reinforced composite materials and the information which is considered essential to uniquely describe a fiber, filler, or core material.

4.2 The intent of this guide is to provide sufficient detail that values are known for the material parameters that may influence test results or material property values.

4.3 This guide is for material identification and description only. It does not include the recommended data elements for mechanical test data or other specific types of test data. Such items are covered by separate formats to be referenced in material specifications or other test standards.

4.4 Composite materials are defined as two or more materials that are combined on a macroscale. There is a gray area between composites and other material classes. Two examples of this gray area between polymer matrix composites and plastics are toughened polystyrene and liquid crystal polymer. Appendix X1 contains a table, which provides guidelines for distinguishing between reinforced polymers and polymer matrix composites.

4.5 Composite materials consist of a matrix phase and one or more discrete reinforcements. Reinforcements may be interpreted broadly to include any macroscale second material, including fibers, particulates, precipitated particles, or structured domains of the parent material. The reinforcements covered in this guide include fibers and such particulates and precipitated particles that can be described adequately as filler within the matrix. The reinforcements may be polymers, metals, ceramics, or other materials. Sandwich constructions are covered by this guide via identification of the core material. These guidelines are suitable for the identification of composites in simple shapes of constant thickness; for example, plates or tubes. For complex structures, additional information relevant to a specific application may be required.

4.6 Classification of ...

SCOPE

1.1 This guide establishes essential and desirable identification elements for fiber-reinforced composite materials and for fibers, fillers, and core materials, matrices, preforms, prepregs, processes, and parts used in these composite materials. This guide is intended for preparing test reports, databases, and material documents.

1.2 These guidelines are specific to fiber-reinforced polymer-matrix composite materials. Composite materials, which also contain particulates or precipitated particles, are also included, provided they can be described adequately as a filler in the matrix.

1.3 The materials covered by this guide include fibers, both continuous and discontinuous, and fillers of various geometries which are used as reinforcements in composite materials, as well as core materials used in sandwich composites, matrices both thermoset and thermoplastic, fiber preforms, prepreg product forms, manufacturing processes, and generic part forms. Cores may be foam, honeycomb, or naturally occurring materials such as balsa wood. These materials are distinguished from bulk materials by the importance of their specialized geometric forms to their properties. This difference is reflected in the use of geometry, along with chemistry, as a primary basis for classification. Additional data elements that are considered desirable, but not essential, are also defined. The purpose is to allow the meaningful comparison of data from different sources.

1.4 Data elements in this guide are relevant to test data, data as obtained in the test laboratory and historically recorded in laboratory notebooks. Property data, data that have been analyzed and reviewed, may only need a subset of these data elements.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practi...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D8335 −20

Standard Guide for

Identification of Fiber-Reinforced Polymer-Matrix Composite

1

Materials

This standard is issued under the fixed designation D8335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This guide establishes essential and desirable identifica-

1.6 This international standard was developed in accor-

tion elements for fiber-reinforced composite materials and for

dance with internationally recognized principles on standard-

fibers, fillers, and core materials, matrices, preforms, prepregs,

ization established in the Decision on Principles for the

processes, and parts used in these composite materials. This

Development of International Standards, Guides and Recom-

guide is intended for preparing test reports, databases, and

mendations issued by the World Trade Organization Technical

material documents.

Barriers to Trade (TBT) Committee.

1.2 These guidelines are specific to fiber-reinforced

polymer-matrix composite materials. Composite materials,

2. Referenced Documents

which also contain particulates or precipitated particles, are

2

2.1 ASTM Standards:

also included, provided they can be described adequately as a

D1600 Terminology forAbbreviatedTerms Relating to Plas-

filler in the matrix.

tics

1.3 The materials covered by this guide include fibers, both

D3878 Terminology for Composite Materials

continuous and discontinuous, and fillers of various geometries

D6507 Practice for Fiber Reinforcement Orientation Codes

which are used as reinforcements in composite materials, as

for Composite Materials

well as core materials used in sandwich composites, matrices

IEEE/ASTM SI 10 American National Standard for Metric

both thermoset and thermoplastic, fiber preforms, prepreg

Practice

3

product forms, manufacturing processes, and generic part

2.2 Other Document:

forms. Cores may be foam, honeycomb, or naturally occurring

CMH-17 Composite Materials Handbook-17, Revision G or

materials such as balsa wood. These materials are distin-

latest

guished from bulk materials by the importance of their

specialized geometric forms to their properties. This difference

3. Terminology

is reflected in the use of geometry, along with chemistry, as a

3.1 Definitions—Terminology in accordance with Terminol-

primary basis for classification. Additional data elements that

ogy D3878 shall be used where applicable.

areconsidereddesirable,butnotessential,arealsodefined.The

3.2 Definitions of Terms Specific to This Standard:

purpose is to allow the meaningful comparison of data from

3.2.1 data element, n—one individual piece of information

different sources.

used in describing a material or to record test results.

1.4 Data elements in this guide are relevant to test data, data

3.2.1.1 Discussion—For example, a variable name, test

as obtained in the test laboratory and historically recorded in

parameter, and so forth.

laboratory notebooks. Property data, data that have been

3.2.2 essential data element, n—a data element in a record

analyzed and reviewed, may only need a subset of these data

which must be completed in order to make the record mean-

elements.

ingful in accordance with the pertinent guidelines or standard.

1.5 This standard does not purport to address all of the

3.2.2.1 Discussion—Data elements are considered essential

safety concerns, if any, associated with its use. It is the

iftheyarerequiredtomakeacomparisonofpropertydatafrom

responsibility of the user of this standard to establish appro-

different sources meaningful. A comparison of data from

1 2

This guide is under the jurisdiction of ASTM Committee D30 on Composite For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Materials and is the direct responsibility of Subcommittee D30.01 on Editorial and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Resource Standards. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2020. Published August 2020. DOI: 10.1520/ the ASTM website.

3

D8335-20. Available from www.cmh17.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8335−20

different sources may still be possible if essential infor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.