ASTM A1056-08

(Specification)Standard Specification for Cast Iron Couplings Used for Joining Hubless Cast Iron Soil Pipe and Fittings

Standard Specification for Cast Iron Couplings Used for Joining Hubless Cast Iron Soil Pipe and Fittings

SCOPE

1.1 This specification covers the materials and testing of cast iron couplings for joining hubless cast iron soil pipe and fittings for sizes 1½ to 10 in.

1.2 It is the purpose of this specification to furnish information as to the characteristics of a particular sleeve type coupling when applied to cast iron soil pipe and fittings manufactured in accordance with Specification A 888, latest revision, and CISPI Designation 301, latest revision.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1056 −08

StandardSpecification for

Cast Iron Couplings Used for Joining Hubless Cast Iron Soil

Pipe and Fittings

This standard is issued under the fixed designation A1056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2240 Test Method for Rubber Property—Durometer Hard-

ness

1.1 This specification covers the materials and testing of

E8 Test Methods for Tension Testing of Metallic Materials

cast iron couplings for joining hubless cast iron soil pipe and

2.2 ANSI Standards:

fittings for sizes 1 ⁄2 to 10 in.

ANSI B18.2.1 Square and Hex Bolt and Screws Inch Series

1.2 It is the purpose of this specification to furnish informa-

ANSI B18.1.2 Square and Hex Nuts (Inch Series)

tionastothecharacteristicsofaparticularsleevetypecoupling 4

2.3 CISPI Standard:

when applied to cast iron soil pipe and fittings manufactured in

CISPI-301 Specification for Hubless Cast Iron Soil Pipe and

accordance with Specification A888, latest revision, and CISPI

Fittings for Sanitary and Storm Drain, Waste and Vent

Designation 301, latest revision.

Piping Applications

1.3 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

3.1 Definitions:

conversions to SI units that are provided for information only

3.1.1 Definitions of the following terms used in this speci-

and are not considered standard.

fication are found in Terminology A644: elastomeric, durom-

1.4 The following precautionary caveat pertains only to the

eter and dynamic.

test method portion, Section 8, of this specification. This

3.2 Definitions of Terms Specific to This Standard:

standard does not purport to address all of the safety concerns,

3.2.1 center stop, n—an integral part of the gasket centered

if any, associated with its use. It is the responsibility of the user

on the axial length of the gasket intended to limit the insertion

of this standard to establish appropriate safety and health

depth of the pipe and/or fitting to be coupled.

practices and determine the applicability of regulatory limita-

3.2.2 clamp assembly, n—that portion of the coupling ex-

tions prior to use.

cluding the gasket, nuts and bolts.

2. Referenced Documents

3.2.3 coupling, n—the complete assembly.

3.2.4 fitting, n—parts of a pipeline other than straight pipes,

2.1 ASTM Standards:

valves, or couplings.

A48/A48M Specification for Gray Iron Castings

A644 Terminology Relating to Iron Castings

3.2.5 gasket, n—the elastomeric portion of the coupling.

A888 Specification for Hubless Cast Iron Soil Pipe and

3.2.6 joint, n—the point of assembly consisting of the

Fittings for Sanitary and Storm Drain, Waste, and Vent

coupling and the joined pipes or fittings, or both.

Piping Applications

3.2.7 manufacturer of the clamp assembly, n— the entity

C564 Specification for Rubber Gaskets for Cast Iron Soil

that casts the clamp assembly.

Pipe and Fittings

3.2.8 manufacturer of the coupling, n—the entity that as-

sembles the components of the coupling such as the gasket and

the clamp assembly.

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.75 on Gaskets and

3.2.9 manufacturer of the gasket, n—theentitythatproduces

Coupling for Plumbing and Sewer Piping.

the elastomeric portion of the coupling.

Current edition approved June 1, 2008. Published June 2008. DOI: 10.1520/

A1056-08.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Cast Iron Soil Pipe Institute (CISPI), 5959 Shallowford Rd.,

the ASTM website. Suite 419, Chattanooga, TN 37421, http://www.cispi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1056−08

4. Materials and Manufacture 4.2 All cast iron parts shall be made of a minimum class 25

cast iron and shall show compliance to this requirement using

4.1 Physical properties of gaskets shall comply with Speci-

test methods contained in Specification A48/A48M.

fication C564 and the dimensions, material specifications,

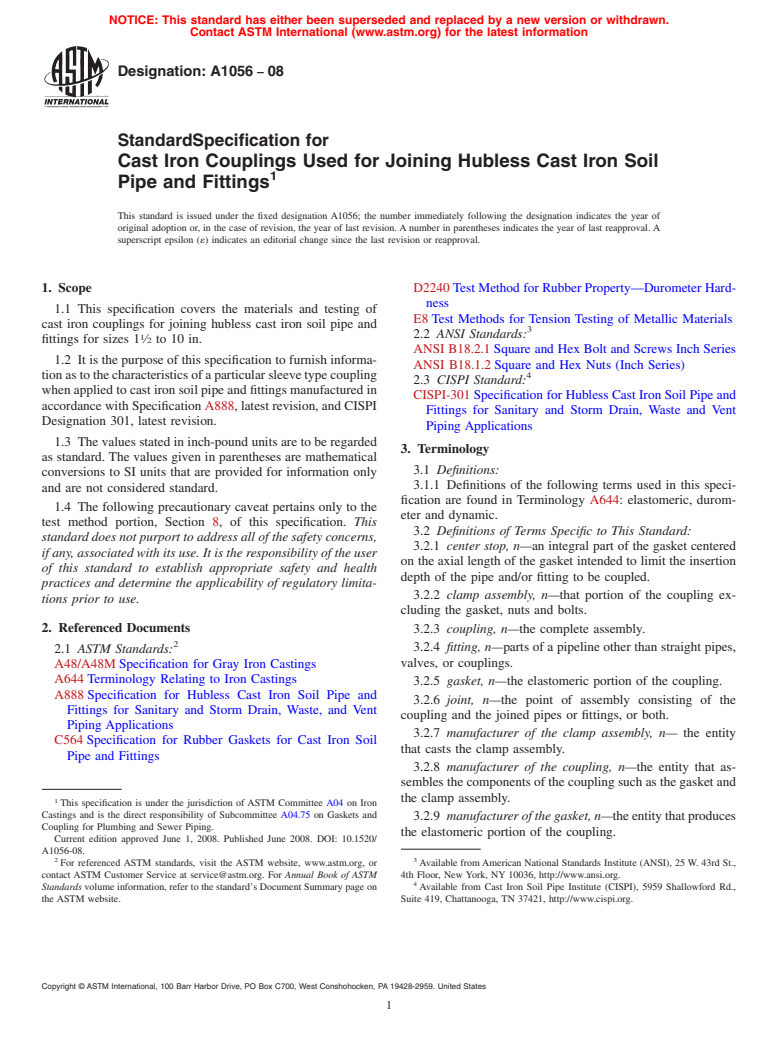

physical and chemical properties as shown in Fig. 1, Fig. 2,

Table 1, and Table 2.

Dimensions in. (mm)

1 ⁄2 (38.100) 2 (50.800) 3 (76.200) 4 (101.600) 5 (127.000) 6 (152.400) 8 (203.200) 10 (254.000)

A 2.125 2.125 2.125 2.125 3.000 3.000 4.000 4.000

(53.975) (53.975) (53.975) (53.975) (76.200) (76.200) (101.600) (101.600)

B 1.531 1.969 2.969 4.000 4.969 5.969 7.969 10.085

(38.887) (50.013) (75.413) (101.600) (126.213) (151.613) (202.413) (256.159)

C 1.937 2.344 3.344 4.406 5.344 6.344 8.344 10.460

(49.200) (59.538) (84.938) (111.912) (135.737) (161.138) (211.938) (265.684)

D 1.531 1.969 2.969 4.000 4.969 5.969 7.969 10.085

(38.887) (50.013) (75.413) (101.600) (126.213) (151.613) (202.413) (256.159)

E 1.037 2.250 3.250 4.313 5.250 6.250 8.250 10.366

(26.340) (57.150) (82.550) (109.550) (133.350) (158.750) (209.550) (263.296)

F 1.937 2.344 3.344 4.406 5.344 6.344 8.344 10.460

(49.200) (59.538) (84.938) (111.912) (135.737) (161.138) (211.938) (265.684)

G 2.125 2.531 3.531 4.594 5.532 6.532 8.532 10.650

(53.975) (64.287) (89.687) (116.688) (140.513) (165.913) (216.713) (270.510)

H 2.219 2.625 3.625 4.684 5.626 6.626 8.626 10.744

(56.363) (66.675) (92.075) (118.974) (142.900) (168.300) (219.100) (272.898)

J 2.313 2.719 3.719 4.781 5.720 6.720 8.720 10.838

(58.750) (69.063) (94.463) (121.437) (145.288) (170.688) (221.488) (275.285)

NOTE 1—Dimensional Tolerances to be RMA Class 3 (see Table 1).

FIG. 1Rubber Gasket

A1056−08

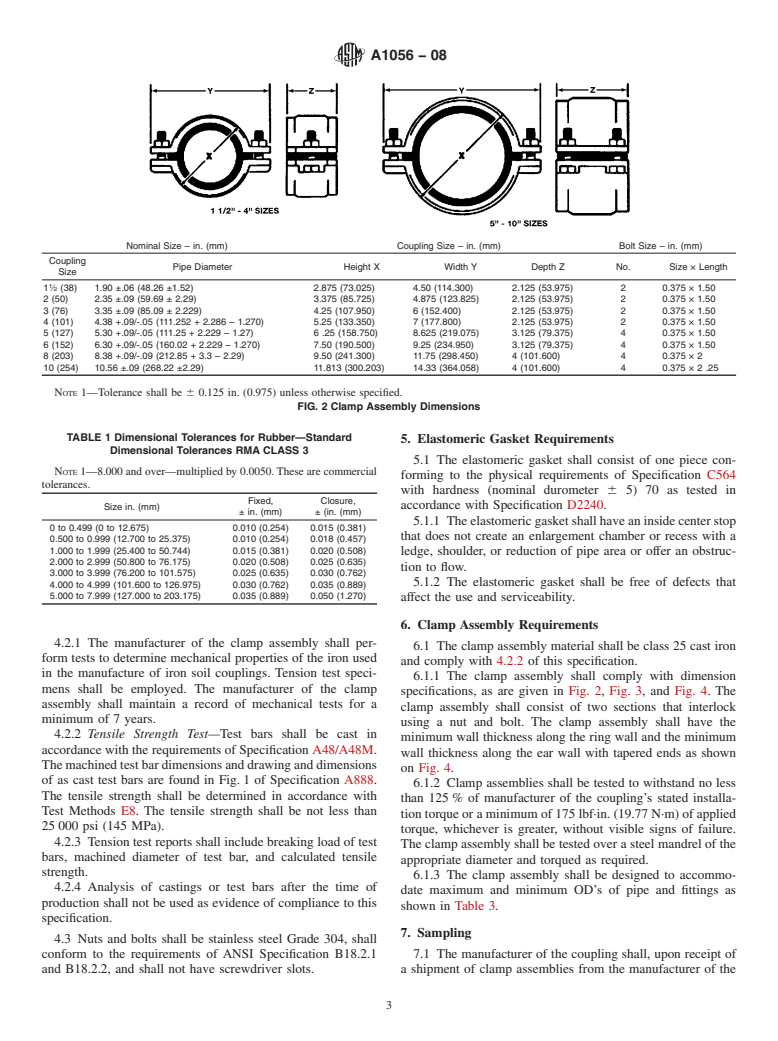

Nominal Size – in. (mm) Coupling Size – in. (mm) Bolt Size – in. (mm)

Coupling

Pipe Diameter Height X Width Y Depth Z No. Size × Length

Size

1 ⁄2 (38) 1.90 ±.06 (48.26 ±1.52) 2.875 (73.025) 4.50 (114.300) 2.125 (53.975) 2 0.375 × 1.50

2 (50) 2.35 ±.09 (59.69 ± 2.29) 3.375 (85.725) 4.875 (123.825) 2.125 (53.975) 2 0.375 × 1.50

3 (76) 3.35 ±.09 (85.09 ± 2.229) 4.25 (107.950) 6 (152.400) 2.125 (53.975) 2 0.375 × 1.50

4 (101) 4.38 +.09/-.05 (111.252 + 2.286 – 1.270) 5.25 (133.350) 7 (177.800) 2.125 (53.975) 2 0.375 × 1.50

5 (127) 5.30 +.09/-.05 (111.25 + 2.229 – 1.27) 6 .25 (158.750) 8.625 (219.075) 3.125 (79.375) 4 0.375 × 1.50

6 (152) 6.30 +.09/-.05 (160.02 + 2.229 – 1.270) 7.50 (190.500) 9.25 (234.950) 3.125 (79.375) 4 0.375 × 1.50

8 (203) 8.38 +.09/-.09 (212.85 + 3.3 – 2.29) 9.50 (241.300) 11.75 (298.450) 4 (101.600) 4 0.375 × 2

10 (254) 10.56 ±.09 (268.22 ±2.29) 11.813 (300.203) 14.33 (364.058) 4 (101.600) 4 0.375×2.25

NOTE 1—Tolerance shall be 6 0.125 in. (0.975) unless otherwise specified.

FIG. 2Clamp Assembly Dimensions

TABLE 1 Dimensional Tolerances for Rubber—Standard

5. Elastomeric Gasket Requirements

Dimensional Tolerances RMA CLASS 3

5.1 The elastomeric gasket shall consist of one piece con-

NOTE 1—8.000 and over—multiplied by 0.0050. These are commercial

forming to the physical requirements of Specification C564

tolerances.

with hardness (nominal durometer 6 5) 70 as tested in

Fixed, Closure,

Size in. (mm) accordance with Specification D2240.

± in. (mm) ± (in. (mm)

5.1.1 Theelastomericgasketshallhaveaninsidecenterstop

0 to 0.499 (0 to 12.675) 0.010 (0.254) 0.015 (0.381)

that does not create an enlargement chamber or recess with a

0.500 to 0.999 (12.700 to 25.375) 0.010 (0.254) 0.018 (0.457)

1.000 to 1.999 (25.400 to 50.744) 0.015 (0.381) 0.020 (0.508)

ledge, shoulder, or reduction of pipe area or offer an obstruc-

2.000 to 2.999 (50.800 to 76.175) 0.020 (0.508) 0.025 (0.635)

tion to flow.

3.000 to 3.999 (76.200 to 101.575) 0.025 (0.635) 0.030 (0.762)

5.1.2 The elastomeric gasket shall be free of defects that

4.000 to 4.999 (101.600 to 126.975) 0.030 (0.762) 0.035 (0.889)

5.000 to 7.999 (127.000 to 203.175) 0.035 (0.889) 0.050 (1.270)

affect the use and serviceability.

6. Clamp Assembly Requirements

4.2.1 The manufacturer of the clamp assembly shall per-

6.1 The clamp assembly material shall be class 25 cast iron

form tests to determine mechanical properties of the iron used

and comply with 4.2.2 of this specification.

in the manufacture of iron soil couplings. Tension test speci-

6.1.1 The clamp assembly shall comply with dimension

mens shall be employed. The manufacturer of the clamp

specifications, as are given in Fig. 2, Fig. 3, and Fig. 4. The

assembly shall maintain a record of mechanical tests for a

clamp assembly shall consist of two sections that interlock

minimum of 7 years.

using a nut and bolt. The clamp assembly shall have the

4.2.2 Tensile Strength Test—Test bars shall be cast in

minimum wall thickness along the ring wall and the minimum

accordance with the requirements of Specification A48/A48M.

wall thickness along the ear wall with tapered ends as shown

Themachinedtestbardimensionsanddrawinganddimensions

on Fig. 4.

of as cast test bars are found in Fig. 1 of Specification A888.

6.1.2 Clamp assemblies shall be tested to withstand no less

The tensile strength shall be determined in accordance with

than 125 % of manufacturer of the coupling’s stated installa-

Test Methods E8. The tensile strength shall be not less than

tion torque or a minimum of 175 lbf·in. (19.77 N·m) of applied

25 000 psi (145 MPa).

torque, whichever is greater, without visible signs of failure.

4.2.3 Tension test reports shall include breaking load of test

The clamp assembly shall be tested over a steel mandrel of the

bars, machined diameter of test bar, and calculated tensile

appropriate diameter and torqued as required.

strength.

6.1.3 The clamp assembly shall be designed to accommo-

4.2.4 Analysis of castings or test bars after the time of

date maximum and minimum OD’s of pipe and fittings as

production shall not be used as evidence of compliance to this

shown in Table 3.

specification.

7. Sampling

4.3 Nuts and bolts shall be stainless steel Grade 304, shall

conform to the requirements of ANSI Specification B18.2.1 7.1 The manufacturer of the coupling shall, upon receipt of

and B18.2.2, and shall not have screwdriver slots. a shipment of clamp assemblies from the manufacturer of the

A1056−08

TABLE 2 Rubber Gasket Physical Requirements

NOTE 1—Material: The sealing sleeve shall be made from an elastomeric compound that meets the requirements of Specification C564.

NOTE2—PhysicalTests:Thetestspecimensshallbeobtainedfromfinishedsleevesandtestedpursuanttothemethodsdescribedinthefollowingtable.

Physical Tests,

Test ASTM Method

Min or Max Requirements

Tensile Strength 1500 psi (105.49 kg/cm) min D412

Elongation 250 min D412

Durometer (Shore A) 70±5at76±5 D2240

Accelerated Aging 15 % max tensile and 20 % max elongation deterioration, 10 points max; increase in hardness, D573

all determinations after oven aging for 96 h at 158°F (70°C)

Compression Set 25 % max after 22 h at 158°F (70°C) D395 Method B

Oil Immersion 80 % max volume change after immersion in ASTM oil no. IRM903 for 70 h at 212°F (100°C) D471

Ozone Cracking No visible cracking at 2 times magnification of the gasket after 100 h. Exposure in 1.5 ppm D1149

ozone concentration at 100°F (37.778°C). Testing and inspection to be on gasket which is loop

mounted to give approximately 20 % elongation of outer surface

Tear Resistance Die C; 150 lb (68.089 mm) min per in. (25.400 mm) of thickness D624

Water Absorption 20 % max by weight after 7 days at 158°F (70°C) D471

Style 1 Style 2

Nominal Pipe Size

AB C D

1 ⁄2 1.0625 3.7600 — —

2 1.0625 4.1875 — —

3 1.0625 5.1875 — —

4 1.0625 6.3437 — —

5 — — 2.0625 7.5937

6 — — 2.0625 8.6250

8 — — 1.6562 10.875

10 — — 1.6562 13.315

NOTE 1—Tolerance shall be 6 0.125 in. (0.975) unless otherwise specified.

FIG. 3Bolt Hole Layout Dimensions

clamp assemblies, take a random sampling of couplings 8.1.1.1 A test apparatus such as the one shown in Fig. 5 is

manufactured therefrom and subject them to the tests specified

suggested. Other testing apparatuses that provide restraint to

in Section 8. If a coupling fails any of the tests, then the entire

the assembly shall also be permitted. Close the outboard ends

shipment of clamp assemblies of that size shall be rejected and

of the pipe with test plugs.

returned to the manufacturer of the clamp assemblies. The

8.1.1.2 Fill the assembly with water, expel all air, and

manufacturer of the coupling shall retain the test results and

hydrostatically pressurize to 4.3 psi (29.6 kPa) for the duration

related documentation for not less than 7 years.

of the test. One pipe shall be rigidly supported and while the

assembly is under pressure, raise the opposite end of the other

8. Coupling Requirements and Test Methods

pipe ⁄2 in. (12.7 mm) per lineal foot of pipe. Maintain the

8.1 Assemble each coupling tested according to the manu-

pressure for 5 min. Any leakage shall mean failure.

facturer of the coupling’s instructions between two sections of

8.1.2 Shear Test:

randomly selected hubless cast iron soil pipe meeting the

8.1.2.1 Support two joined lengths of randomly selected

requirements of CISPI-301 or Specification A888 or one

hubless cast iron soil pipe on blocks, a minimum of 1 ⁄2 in.

section of randomly selected hubless cast iron soil pipe

(38.1 mm) high, at three locations. One length shall be a

meeting the requirements of CISPI-301 or Specification A888

minimum of 24 in. (609.6 mm) in length, supported on blocks,

and a fitting and conduct the following tests: deflection and

shear. In addition, an unrestrained hydrostatic test will be one near the uncoupled end, and the other immediately

adjacent to the coupling. Firmly restrain this length in position

performed between two sections of machined steel pipe.

8.1.1 Deflection Test: as shown in Fig. 6. The other coupled length shall be a

A1056−08

Dimensions, in. (mm)

Pipe Size,

Overall

in. (mm)

M N O (Dia) P Q

Tolerance

1 ⁄2 (38.100) ± 0.035 (.889) 0.375 (9.525) 0.750 (19.050) 2.100 (53.340) 0.625 (1.587) 0.250 (6.350)

2 (50.800) ± 0.035 (.889) 0.375 (9.525) 0.875 (22.225) 2.560 (65.024) 0.625 (1.587) 0.281 (7.137)

3 (76.200) ± 0.035 (.889) 0.375 (9.525) 1.125 (28.575) 3.560 (90.424) 0.625 (1.587) 0.281 (7.137)

4 (101.600) ± 0.035 (.889) 0.375 (9.525) 1.250 (31.750) 4.590 (116.586) 0.625 (1.587) 0.281 (7.137)

5 (127.000) ± 0.03

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.