ASTM C1173-22

(Specification)Standard Specification for Flexible Transition Couplings for Underground Piping Systems

Standard Specification for Flexible Transition Couplings for Underground Piping Systems

ABSTRACT

This specification describes the properties of devices or assemblies suitable for use as flexible transition couplings for underground drainage and sewer piping systems. Couplings that may include bushings or inserts, and meet the requirements of this specification are suitable for joining plain end pipe or fittings. Couplings shall be permitted to have a center stop, the components shall be designed so that the elastomeric material is compressed to form a hydrostatic seal when the joint is assembled. Assemblies shall be tested in different areas and each component shall conform to specified physical and mechanical requirements, namely: hardness, tensile strength, elongation, heat aging, hardness, ozone resistance, water absorption, and chemical resistance for the elastomeric materials; tension band performance, torque resistance, free running torque for the stainless steel materials; and deflection sealing resistance, and shear loading resistance for the joint assemblies.

SCOPE

1.1 This specification describes the properties of devices or assemblies suitable for use as flexible transition couplings, hereinafter referred to as “couplings,” for underground drainage and sewer piping systems.

1.2 Flexible transition couplings that conform to the requirements of this standard are suitable for joining plain-end pipe or fittings. The pipe to be joined shall be of similar or dissimilar materials, size, or both.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The ASTM standards referenced herein shall be considered mandatory.

1.5 The committee with jurisdiction over this standard is not aware of another comparable standard for materials covered in this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1173 −22

Standard Specification for

Flexible Transition Couplings for Underground Piping

1

Systems

This standard is issued under the fixed designation C1173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for Cold Heading and Cold Forging

A644Terminology Relating to Iron Castings

1.1 This specification describes the properties of devices or

D395Test Methods for Rubber Property—Compression Set

assemblies suitable for use as flexible transition couplings,

D412TestMethodsforVulcanizedRubberandThermoplas-

hereinafter referred to as “couplings,” for underground drain-

tic Elastomers—Tension

age and sewer piping systems.

D471Test Method for Rubber Property—Effect of Liquids

1.2 Flexible transition couplings that conform to the re-

D543Practices for Evaluating the Resistance of Plastics to

quirements of this standard are suitable for joining plain-end

Chemical Reagents

pipe or fittings. The pipe to be joined shall be of similar or

D573Test Method for Rubber—Deterioration in an Air

dissimilar materials, size, or both.

Oven

1.3 The values stated in inch-pound units are to be regarded D624Test Method for Tear Strength of Conventional Vul-

canized Rubber and Thermoplastic Elastomers

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only D638Test Method for Tensile Properties of Plastics

D1149Test Methods for Rubber Deterioration—Cracking in

and are not considered standard.

an Ozone Controlled Environment

1.4 TheASTM standards referenced herein shall be consid-

D2240Test Method for Rubber Property—Durometer Hard-

ered mandatory.

ness

1.5 Thecommitteewithjurisdictionoverthisstandardisnot

D3045Practice for Heat Aging of Plastics Without Load

aware of another comparable standard for materials covered in

D6147TestMethodforVulcanizedRubberandThermoplas-

this standard.

tic Elastomer—Determination of Force Decay (Stress

1.6 This international standard was developed in accor- Relaxation) in Compression

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions—For definitions of terms used in this

mendations issued by the World Trade Organization Technical

standard, see Terminology A644.

Barriers to Trade (TBT) Committee.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 center stop, n—an integral part of the gasket centered

2. Referenced Documents

on its axial length, intended to limit the insertion depth of the

2

2.1 ASTM Standards:

pipe to be coupled.

A240/A240MSpecification for Chromium and Chromium-

3.2.2 clamp assembly, n—that portion of the coupling ex-

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

cluding the gasket.

Vessels and for General Applications

A493Specification for Stainless Steel Wire and Wire Rods 3.2.3 coupling, n—the complete assembly.

3.2.4 fitting, n—parts of a pipeline other than straight pipe

couplings or valves.

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.75 on Gaskets and 3.2.5 flexible transition couplings, n—devices used to form

Coupling for Plumbing and Sewer Piping.

a leakproof joint between sections of plain-end pipe or fittings

Current edition approved June 1, 2022. Published June 2022. Originally

of the same or different materials, of the same or different size,

approved in 1991. Last previous edition approved in 2018 as C1173–18. DOI:

or any combination of materials or pipe sizes.

10.1520/C1173-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.6 free torque, n—the torque value expressed in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

lbf·in./Nm when the clamp is tightened four revolutions of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. screw nut; while in the free state, this value does not include

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1173−22

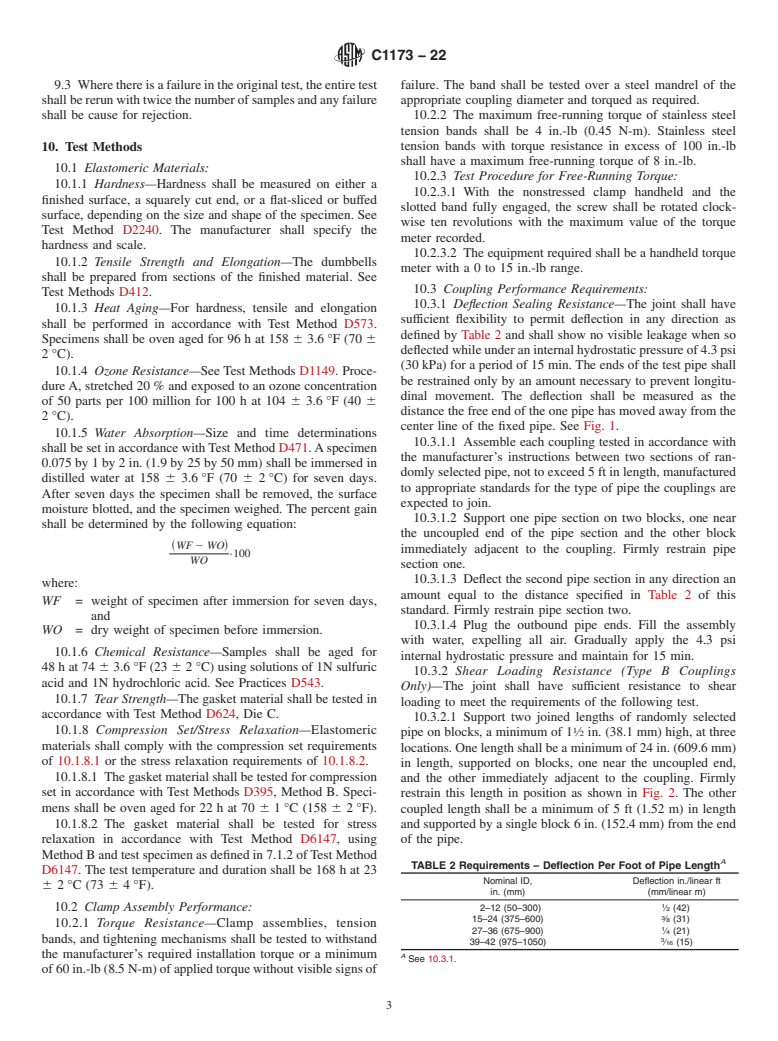

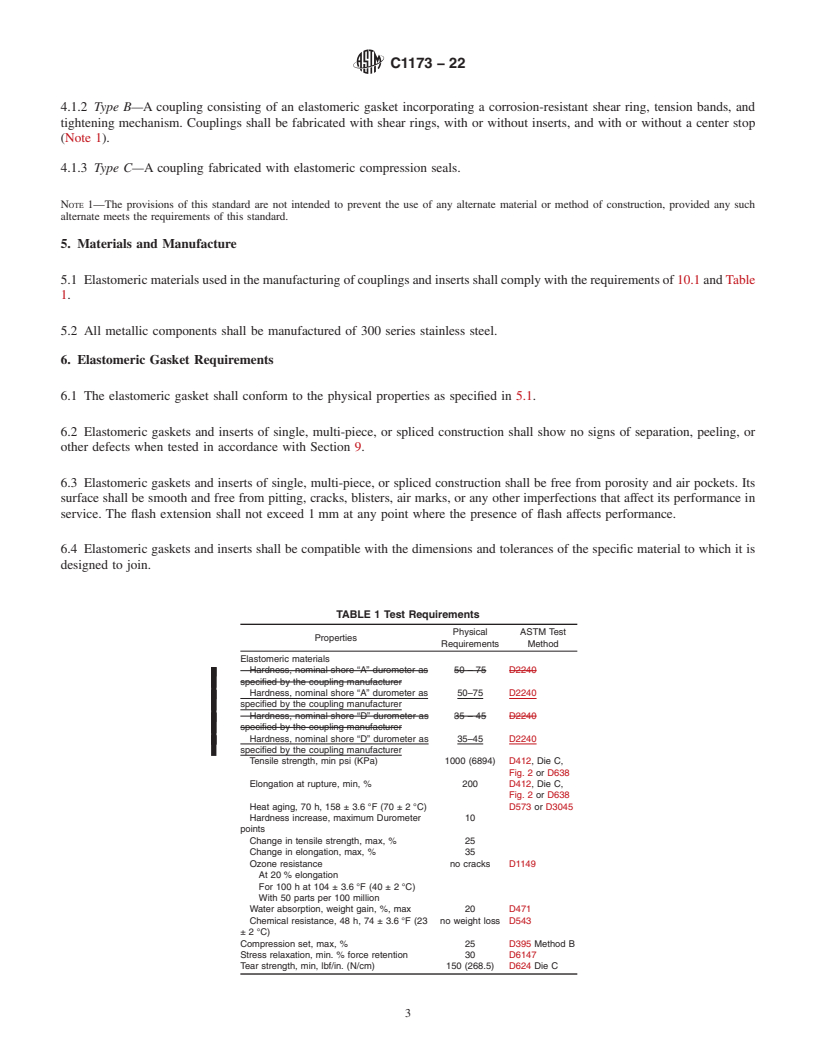

TABLE 1 Test Requirements

any breakaway effects due to staking or passage of the band

ends beyond the screw heads. Physical ASTM Test

Properties

Requirements Method

3.2.7 inserts, n—a bushing or ring

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1173 − 18 C1173 − 22

Standard Specification for

Flexible Transition Couplings for Underground Piping

1

Systems

This standard is issued under the fixed designation C1173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification describes the properties of devices or assemblies suitable for use as flexible transition couplings, hereinafter

referred to as “couplings,” for underground drainage and sewer piping systems.

1.2 Couplings that may include bushings, inserts, or shear rings and Flexible transition couplings that conform to the requirements

of this standard are suitable for joining plain-end pipe or fittings. The pipe to be joined shall be of similar or dissimilar materials,

size, or both.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The ASTM standards referenced herein shall be considered mandatory.

1.5 The committee with jurisdiction over this standard is not aware of another comparable standard for materials covered in this

standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

A493 Specification for Stainless Steel Wire and Wire Rods for Cold Heading and Cold Forging

A644 Terminology Relating to Iron Castings

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.75 on Gaskets and Coupling

for Plumbing and Sewer Piping.

Current edition approved Feb. 1, 2018June 1, 2022. Published February 2018June 2022. Originally approved in 1991. Last previous edition approved in 20142018 as

C1173 – 10 (2014).C1173 – 18. DOI: 10.1520/C1173-18.10.1520/C1173-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1173 − 22

D573 Test Method for Rubber—Deterioration in an Air Oven

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D638 Test Method for Tensile Properties of Plastics

D1149 Test Methods for Rubber Deterioration—Cracking in an Ozone Controlled Environment

D2240 Test Method for Rubber Property—Durometer Hardness

D3045 Practice for Heat Aging of Plastics Without Load

D6147 Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation)

in Compression

3. Terminology

3.1 Definitions—For definitions of terms used in this standard, see Terminology A644.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 center stop, n—an integral part of the gasket centered on its axial length, intended to limit the insertion depth of the pipe

to be coupled.

3.2.2 clamp assembly, n—that portion of the coupling excluding the gasket.

3.2.3 coupling, n—the complete assembly.

3.2.4 fitting, n—parts of a pipeline other than straight pipe couplings or valves.

3.2.5 flexible transition couplings, n—devices used to form a leakproof joint between sections of plain-end pipe or fittings of the

same or different materials, of the same or different size, or any combination of materials or pipe sizes.

3.2.6 free torque, n—the torque value expressed in lbf·in./Nm when the clamp is tightened four

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.