ASTM B658/B658M-11

(Specification)Standard Specification for Seamless and Welded Zirconium and Zirconium Alloy Pipe

Standard Specification for Seamless and Welded Zirconium and Zirconium Alloy Pipe

ABSTRACT

This specification covers seamless and welded zirconium and zirconium alloy pipe. The pipe is furnished in three grades as follows; grade R60702- unalloyed zirconium, grade R60704- zirconium-tin alloy, and grade R60705- zirconium-niobium alloy. Seamless pipe shall be made from any seamless method that will yield a product meeting the requirements prescribed. Pipe containing welded seams or other joints made by welding shall comply with the given provisions. The pipe shall be furnished in the annealed or stress-relieved condition. The material shall conform to the requirements as to chemical composition prescribed. The material, as represented by the test specimens, shall conform to the tensile properties prescribed.

SCOPE

1.1 This specification covers three grades of seamless and welded zirconium pipe.

1.2 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.3 The following precautionary caveat pertains only to the test methods portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B658/B658M – 11

Standard Specification for

1

Seamless and Welded Zirconium and Zirconium Alloy Pipe

This standard is issued under the fixed designation B658/B658M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ASME Standard:

5

2 ASME Boiler and Pressure Vessel Code, Section VIII

1.1 This specification covers three grades of seamless and

5

ASME Boiler and Pressure Vessel Code, Section IX

welded zirconium pipe.

1.2 Unless a single unit is used, for example corrosion mass

3. Terminology

2

gain in mg/dm , the values stated in either inch-pound or SI

3.1 Definitions of Terms Specific to This Standard:

units are to be regarded separately as standard. The values

3.1.1 annealed, n—for purposes of this specification “an-

stated in each system are not exact equivalents; therefore each

nealed” denotes material that exhibits a recrystallized grain

system must be used independently of the other. SI values

structure.

cannot be mixed with inch-pound values.

3.2 Lot Definitions:

1.3 The following precautionary caveat pertains only to the

3.2.1 pipe, n—a lot shall consist of a material of the same

test methods portions of this specification: This standard does

size, shape, condition, and finish produced from the same ingot

not purport to address all of the safety concerns, if any,

or powder blend by the same reduction schedule and the same

associated with its use. It is the responsibility of the user of this

heat treatment parameters. Unless otherwise agreed between

standard to establish appropriate safety and health practices

manufacturer and purchaser, a lot shall be limited to the

and determine the applicability of regulatory limitations prior

product of an 8 h period for final continuous anneal, or to a

to use.

single furnace load for final batch anneal.

2. Referenced Documents

4. Classification

3

2.1 ASTM Standards:

4.1 The pipe is furnished in three grades as follows:

B614 Practice for Descaling and Cleaning Zirconium and

4.1.1 Grade R60702—Unalloyed zirconium.

Zirconium Alloy Surfaces

4.1.2 Grade R60704—Zirconium-tin alloy.

E8/E8M Test Methods for Tension Testing of Metallic

4.1.3 Grade R60705—Zirconium-niobium alloy.

Materials

E29 Practice for Using Significant Digits in Test Data to

5. Ordering Information

Determine Conformance with Specifications

5.1 Orders for materials under this specification should

E2626 Guide for Spectrometric Analysis of Reactive and

include the following information:

Refractory Metals

5.1.1 Quantity (weight or total length),

2.2 ANSI Standard:

4 5.1.2 Name of material (zirconium pipe),

B36.19 Stainless Steel Pipe

5.1.3 Grade number (see 4.1),

5.1.4 Nominal pipe size and schedule (Table X1.1),

1

This specification is under the jurisdiction of ASTM Committee B10 on

5.1.5 Lengths (random or specified cut lengths),

Reactive and Refractory Metals and Alloys and is the direct responsibility of

5.1.6 Method of manufacture (Section 6),

Subcommittee B10.02 on Zirconium and Hafnium.

5.1.7 Workmanship and quality level requirements (Section

Current edition approved April 1, 2011. Published April 2011. Originally

approved in 1979. Last previous edition approved in 2006 as B658/B658M – 06. 10),

DOI: 10.1520/B0658_B0658M-11.

5.1.8 ASTM designation and year of issue, and

2

For ASME Boiler and Pressure Vessel Code Applications, see related Specifi-

cation SB-658 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5

the ASTM website. Available from American Society of Mechanical Engineers (ASME), ASME

4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

4th Floor, New York, NY 10036, http://www.ansi.org. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B658/B658M – 11

A

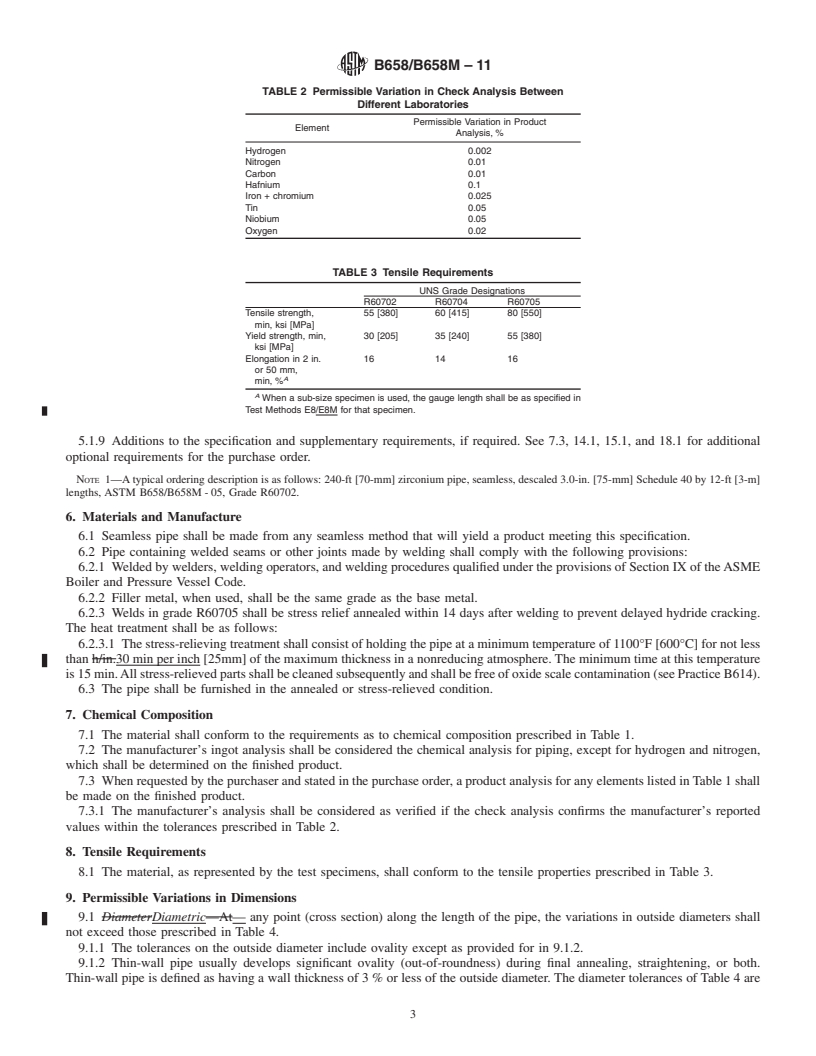

TABLE 1 Chemical Requirements

Composition, %

Element UNS Grade Designation

R60702 R60704 R60705

Zirconium + hafnium, min 99.2 97.5 95.5

Hafnium, max 4.5 4.5 4.5

Iron + chromium 0.2 max 0.2 to 0.4 0.2 max

Tin . 1.0to2.0 .

Hydrogen, max 0.005 0.005 0.005

Nitrogen, max 0.025 0.025 0.025

Carbon, max 0.05 0.05 0.05

Niobium . . . . . . 2.0 to 3.0

Oxygen, max 0.16 0.18 0.18

A

By agreement between the purchaser and the manufacturer, analysis may be required and limits established for e

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B658/B658M–06 Designation: B658/B658M – 11

Standard Specification for

1

Seamless and Welded Zirconium and Zirconium Alloy Pipe

This standard is issued under the fixed designation B658/B658M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This specification covers three grades of seamless and welded zirconium pipe.

2

1.2 Unless a single unit is used, for example corrosion mass gain in mg/dm , the values stated in either inch-pound or SI units

are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must

be used independently of the other. SI values cannot be mixed with inch-pound values.

1.3 The following precautionary caveat pertains only to the test methods portions of this specification. specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

3

2.1 ASTM Standards:

B614 Practice for Descaling and Cleaning Zirconium and Zirconium Alloy Surfaces

E88/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications Practice for Using

Significant Digits in Test Data to Determine Conformance with Specifications

E2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals

2.2 ANSI Standard:

4

B36.19 Stainless Steel Pipe

2.3 ASME Standard:

5

ASME Boiler and Pressure Vessel Code, Section VIII

5

ASME Boiler and Pressure Vessel Code, Section IX

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 annealed, n—for purposes of this specification “annealed” denotes material that exhibits a recrystallized grain structure.

3.2 Lot Definitions:

3.2.1 pipe, n—a lot shall consist of a material of the same size, shape, condition, and finish produced from the same ingot or

powder blend by the same reduction schedule and the same heat treatment parameters. Unless otherwise agreed between

manufacturer and purchaser, a lot shall be limited to the product of an 8 h period for final continuous anneal, or to a single furnace

load for final batch anneal.

4. Classification

4.1 The pipe is furnished in three grades as follows:

4.1.1 Grade R60702—Unalloyed zirconium.

4.1.2 Grade R60704—Zirconium-tin alloy.

4.1.3 Grade R60705—Zirconium-niobium alloy.

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.02 on Zirconium and Hafnium.

Current edition approved Sept.April 1, 2006.2011. Published September 2006.April 2011. Originally approved in 1979. Last previous edition approved in 20052006 as

B658/B658M – 056. DOI: 10.1520/B0658_B0658M-0611.

2

For ASME Boiler and Pressure Vessel Code Applications, see related Specification SB-658 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B658/B658M – 11

5. Ordering Information

5.1 Orders for materials under this specification should include the following information:

5.1.1 Quantity (weight or total length),

5.1.2 Name of material (zirconium pipe),

5.1.3 Grade number (see 4.1),

5.1.4 Nominal pipe size and schedule (Table X1.1),

5.1.5 Lengths (random or specified cut lengths),

5.1.6 Method of manufacture (Section 6),

5.1.7 Workmanship and quality level requirements (Section 10),

5.1.8 ASTM designation and year of issue, and

A

TABLE 1 Chemical Requirements

Composition, %

Ele

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.