ASTM D7014-04

(Practice)Standard Practice for Assembly and Placement of Double-Twisted Wire Mesh Gabions and Revet Mattresses

Standard Practice for Assembly and Placement of Double-Twisted Wire Mesh Gabions and Revet Mattresses

SIGNIFICANCE AND USE

Gabions and Revet Mattresses, as described in Specification A 975, are used to achieve soil stability and prevent soil erosion and are also used as retaining wall structures to resist movements due to gravity. Their ability to function properly depends on correct design and installation. This standard practice describes the proper installation of gabions and revet mattresses to ensure the products function as intended by the manufacturers.

This practice offers a set of instructions for performing one or more specific operations and does not replace professional judgment. Not all aspects of this practice may be applicable in all situations. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’many unique aspects.

SCOPE

1.1 This specification covers standard practice for assembly, placement and filling of double-twisted wire mesh gabions and revet mattresses used for various erosion control, soil retention or freestanding structures. The product size, type and alignment must be determined by the user. Gabions and Revet Mattresses shall be installed in accordance with project plans and specifications when available.

1.2 This standard is expressed in SI (metric) units. American (inch-pound) units are provided in parenthesis for information purposes.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D7014–04

Standard Practice for

Assembly and Placement of Double-Twisted Wire Mesh

Gabions and Revet Mattresses

This standard is issued under the fixed designation D7014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 Thisspecificationcoversstandardpracticeforassembly, 3.1 Definitions of Terms Specific to This Standard:

placementandfillingofdouble-twistedwiremeshgabionsand 3.1.1 gabion, n—a wire mesh container of variable sizes,

revet mattresses used for various erosion control, soil retention uniformly partitioned into internal cells, interconnected with

or freestanding structures. The product size, type and align- other similar units, and filled with stone at the project site to

ment must be determined by the user. Gabions and Revet form flexible, permeable, monolithic structures such as retain-

Mattresses shall be installed in accordance with project plans ing walls, sea walls, channel linings, revetments and weirs for

and specifications when available. erosion control projects.

1.2 ThisstandardisexpressedinSI(metric)units.American 3.1.2 revet mattress, n—a double-twisted wire mesh con-

(inch-pound) units are provided in parenthesis for information tainer uniformly partitioned into internal cells with relatively

purposes. small height in relation to other dimensions, having smaller

1.3 This standard may involve hazardous materials, opera- mesh openings than the mesh used for gabions: revet mat-

tions, and equipment. This standard does not purport to tressesaregenerallyusedforriverbankprotectionandchannel

address all of the safety concerns, if any, associated with its linings.

use. It is the responsibility of the user of this standard to 3.1.3 double-twisted wire mesh, n—a non raveling mesh

establish appropriate safety and health practices and deter- made by twisting continuous pairs of wires through three one

mine the applicability of regulatory limitations prior to use. half ( ⁄2) turns (commonly called double-twisted) which are

then interconnected to adjacent wires to form hexagonal-

2. Referenced Documents

shaped openings.

2.1 ASTM Standards:

3.1.4 selvedge wire, n—a terminal wire used to edge the

A975 Specification for Double−Twisted Hexagonal Mesh wire mesh perpendicular to the double twist by mechanically

Gabions and Revet Mattresses (Metallic−Coated Steel

wrapping the mesh wires around it at least 2.5 times or by

Wire or Metallic-Coated Steel Wire With Poly(Vinyl inserting it through the twists and folding one mesh length.

Chloride) (PVC) Coating)

3.1.5 edge wire, n—a terminal wire used to edge the wire

D6711 Practice for Specifying Rock to Fill Gabions, Revet mesh parallel to the double twist by continuously weaving it

Mattresses, and Gabion Mattresses

into the wire mesh.

2.2 AASHTO Standard: 3.1.6 lacing wire, n—for gabions and revet mattresses,a

AASHTO M288 Geotextile Specification for Highway Ap-

metallic coated steel wire or metallic coated steel wire with

plication PVCcoatingusedtoassembleandinterconnectemptyunits,to

close and secure stone filled units and for internal stiffeners.

3.1.7 fastener, n—an alternate connector to lacing wire,

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

used for binding operations for gabions and revet mattresses.

Rock and is the direct responsibility of Subcommittee D18.25 on Erosion and

3.1.8 stiffener, n—for gabions, a length of metallic coated

Sediment Control Technology.

Current edition approved Jan. 1, 2004. Published February 2004. DOI: 10.1520/

steel wire or metallic coated steel wire with PVC coating used

D7014-04.

for support of facing by connecting the front panel to the back

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

panelofagabion(stiffenerformedattheprojectsiteusingwire

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on having the same diameter as for the lacing wire) or across the

the ASTM website.

corners of a gabion cell (pre-formed stiffener as specified in

Available from American Association of State Highway and Transportation

Specification A975).

Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7014–04

4. Significance and Use 6. Assembly

4.1 Gabions and Revet Mattresses, as described in Specifi- 6.1 Gabions—The folded units shall be taken out from the

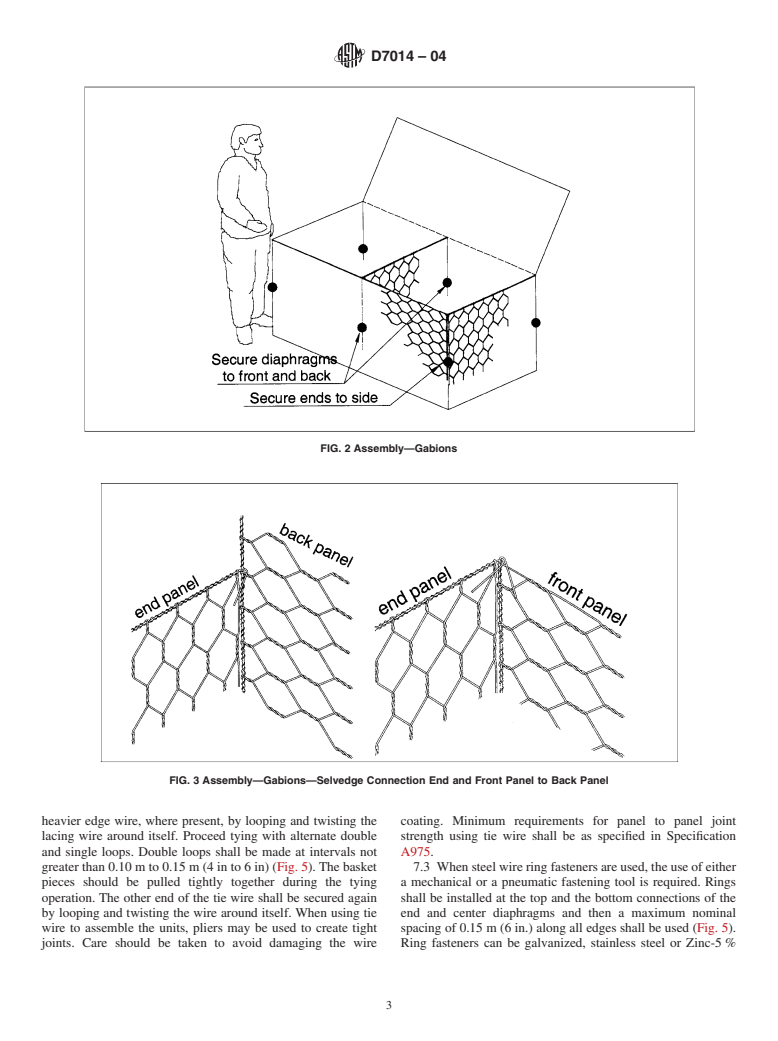

cationA975, are used to achieve soil stability and prevent soil bundle and placed on a hard, flat surface. Gabions shall be

erosion and are also used as retaining wall structures to resist opened, unfolded and pressed out to their original shape (Fig.

movements due to gravity. Their ability to function properly 1). Front, back and end panels shall be lifted to a vertical

depends on correct design and installation. This standard position to form an open box shape (Fig. 2). Panels shall be

practice describes the proper installation of gabions and revet fastened together with the projecting heavier gauge selvedge

mattresses to ensure the products function as intended by the wirebyfirmlywrappingtheselvedgewirearoundtheselvedge

manufacturers. oredgewireoftheintersectingpanelorthebackpanel(Fig.3).

4.2 This practice offers a set of instructions for performing Inner diaphragm panels shall be lifted into a vertical position

one or more specific operations and does not replace profes- and secured in the same manner. All edges of the diaphragms

sional judgment. Not all aspects of this practice may be and end panels shall be tied or fastened to the front and back

applicable in all situations. This ASTM standard is not in- of the gabion as specified in Section 7.

tendedtorepresentorreplacethestandardofcarebywhichthe 6.2 Revet Mattresses—The folded units shall be taken out

adequacy of a given professional service must be judged, nor from the bundle and placed on a hard, flat surface. Revet

should this document be applied without consideration of a mattresses shall be opened, unfolded and pressed out to their

project’s many unique aspects. original shape. Front, back and end panels shall be lifted to a

vertical position to form an open box shape (Fig. 4). End flaps

5. Material Delivery

shall be folded and/or overlapped, as appropriate.All edges of

5.1 Gabions and revet mattresses are manufactured with all

the diaphragms and end panels shall be tied or fastened to the

components mechanically connected at the production facility

front and back of the mattress, as specified in Section 7.

with the exception of the mattress lid, which is produced

7. Fastening Procedure

separately from the base, as per Specification A975. All

gabions and revet mattresses are supplied in the collapsed 7.1 All gabions and revet mattresses must be fastened as

form, either folded and bundled or rolled, for shipping. The specified in 7.2 and 7.3 at each step of construction. Initial

bundles are banded together at the factory for shipping and assembly, tying of adjacent units along the contacting edges,

handling. Revet mattress bases and lids may be packed in tying of the lid to sides, tying of lid to top of diaphragms, and

separate bundles. Lacing wire is shipped in coils having a re-tying of cut gabions or revet mattresses.

diameter approximately 0.60 m (2 ft). Fasteners are shipped in 7.2 When using tie wire, cut a piece of wire approximately

boxes. Preformed stiffeners are shipped in bundles. 1.5 times the length of the edge to be tied. The maximum

5.2 All gabions and revet mattresses shall be labeled to length of the edge to be tied at one time shall not exceed 1 m

show their dimensions, the number of pieces, and the manu- (or 3 ft). Longer edges shall be joined by several lengths of

facturer’s color code if applicable. wire. Tie wires shall be secured around the selvedge wire or

FIG. 1 Assembly—Gabions

D7014–04

FIG. 2 Assembly—Gabions

FIG. 3 Assembly—Gabions—Selvedge Connection End and Front Panel to Back Panel

heavier edge wire, where present, by looping and twisting the coating. Minimum requirements for panel to panel joint

lacing wire around itself. Proceed tying with alternate double strength using tie wire shall be as specified in Specification

and single loops. Double loops shall be made at intervals not A975.

greaterthan0.10mto0.15m(4into6in)(Fig.5).Thebasket 7.3 Whensteelwireringfastenersareused,theuseofeither

pieces should be pulled tightly together during the tying a mechanical or a pneumatic fastening tool is required. Rings

operation. The other end of the tie wire shall be secured again

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.