ASTM F2878-19

(Test Method)Standard Test Method for Protective Clothing Material Resistance to Hypodermic Needle Puncture

Standard Test Method for Protective Clothing Material Resistance to Hypodermic Needle Puncture

ABSTRACT

This test method is used for determining the force required to cause a hypodermic needle to penetrate through protective clothing material. It defines three common hypodermic needles - 21-, 25-, 28- gauge needles - to evaluate puncture resistance of protective clothing. This test method does not attempt to simulate all use conditions. A number of variables which impact puncture resistance, such as stiffness of backing materials, presence of lubricants, and tension on the specimen, are not addressed by this test method.

SIGNIFICANCE AND USE

5.1 This test method evaluates puncture resistance of protective clothing materials which may include: plastics or elastomeric films, coated fabrics, flexible materials, laminates, leathers, or textile materials.

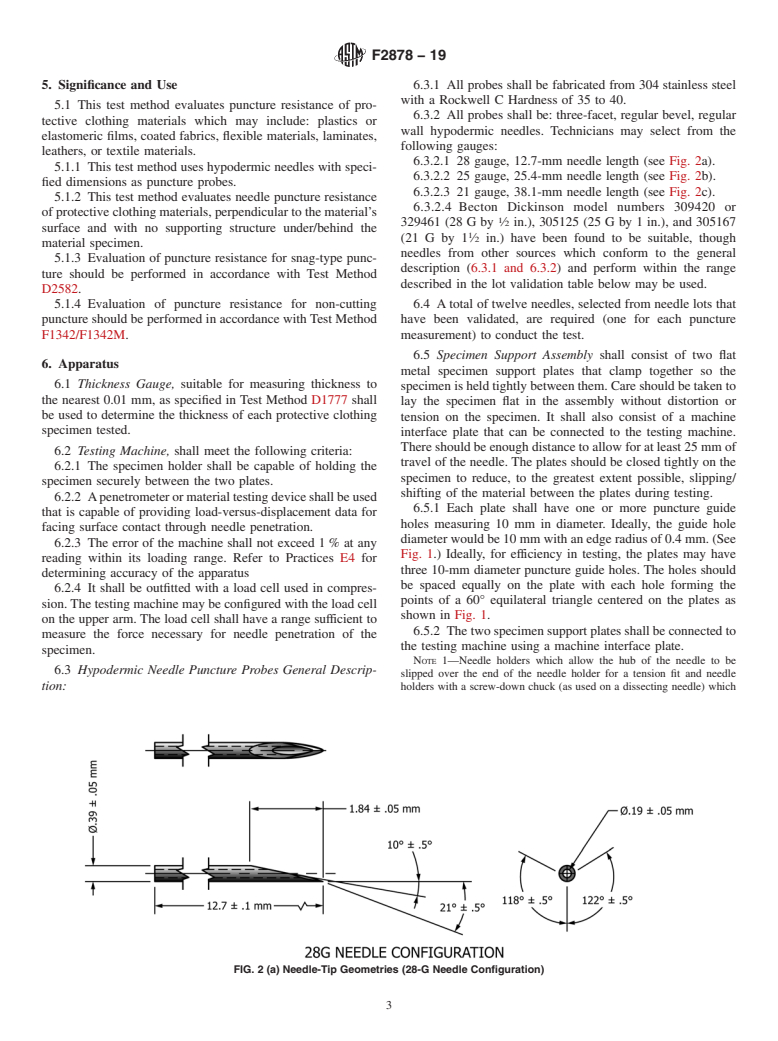

5.1.1 This test method uses hypodermic needles with specified dimensions as puncture probes.

5.1.2 This test method evaluates needle puncture resistance of protective clothing materials, perpendicular to the material’s surface and with no supporting structure under/behind the material specimen.

5.1.3 Evaluation of puncture resistance for snag-type puncture should be performed in accordance with Test Method D2582.

5.1.4 Evaluation of puncture resistance for non-cutting puncture should be performed in accordance with Test Method F1342/F1342M.

SCOPE

1.1 This test method is used to determine the force required to cause a sharp-edged hypodermic needle to penetrate through protective clothing material. The standard describes three needles that may be used: 21-, 25-, or 28-gauge needles.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2878 − 19

Standard Test Method for

Protective Clothing Material Resistance to Hypodermic

1

Needle Puncture

This standard is issued under the fixed designation F2878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Occupational exposures to bloodborne pathogens (BBP) caused by needlestick injuries are a

concern for healthcare professionals, law enforcement officers, first responders, and others.

Transmission of diseases such as human immunodeficiency virus (HIV) and Hepatitis C (Hep C) as

a result of percutaneous needlestick injuries have been documented worldwide. These diseases can

lead to life-long chronic health problems and possibly death.

Work practice safety procedures, including the use of personal protective equipment (PPE) such as

gloves, aprons, and sleeves, are used to diminish the risk of occupational exposure to BBPs through

needlestick injury.

The purpose of this standard is to measure relative hypodermic needle puncture resistance offered

by various materials based on the conditions specified within the standard. This standard does not

attempt to simulate all use conditions.Anumber of variables which impact puncture resistance are not

addressed by this standard. For example, stiffness of backing materials, presence of lubricants, and

tension on the specimen may all impact puncture resistance but are not considered by this standard.

This standard defines three common hypodermic needles to evaluate puncture resistance. Through

development of this standard, it has been observed that needle diameter has an effect on puncture

resistance. Therefore, needles of various diameters have been specified. Users of this method may

specify testing with one or more of the needles defined within the standard.

The hypodermic needles referenced have been selected with consideration to three main points:

(1) As needle gauge increases, the load required to puncture materials taken from commonly

available hypodermic needle-resistant PPE increases. The performance is not linear and therefore

relatively large-gauge (21 G) and small-gauge (28 G) needles are provided to better understand a

material’s performance against one end of the spectrum or the other.

(2) Certain end-use applications are concerned with protection from either large-gauge needles or

small-gaugeneedles.Forexample,policeofficerssearchingsuspectedintravenousdrugusersaremost

commonly at risk of injury from fine-gauge needles (28 G), but not large-gauge needles. Whereas,

workers inoculating poultry on commercial farms may be concerned with large-gauge needles (21 G),

but not small-gauge needles.

(3) Certain materials are optimized to resist either large-gauge or small-gauge needles and testing

against the other would not be useful. Other materials may be engineered for resistance to the full

breadth of the gauge spectrum. For example, in applications such as healthcare, where a broad range

of needle gauges is expected, testing against both ends of the spectrum allows for a better

understanding of robustness.

1. Scope 1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method is used to determine the force required

standard.

to cause a sharp-edged hypodermic needle to penetrate through

protective clothing material. The standard describes three 1.3 This standard does not purport to address all of the

needles that may be used: 21-, 25-, or 28-gauge needles. safety concerns, if any, associated with its use. It is the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2878 − 19

responsibility of the user of this standard to establish appro- 3.1.2 penetration, n—when the beveled tip of the needle has

priate safety, health, and environmental practices and deter- passed through the specimen as defined in 4.3.

mine the applicability of regulatory limitations prior to use.

3.1.3 penetrometer, n—a material tester or similar device

1.4 This international standard was developed in accor-

consisting of a movable crosshead with accurate speed control,

dance with internationally recognized principles on standard-

a load cell used in compression, a needle holder, and a

ization established in the Decision on Principles for the

specimen holder. The needle holder should be attached to the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2878 − 10 F2878 − 19

Standard Test Method for

Protective Clothing Material Resistance to Hypodermic

1

Needle Puncture

This standard is issued under the fixed designation F2878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Occupational exposures to bloodborne pathogens (BBP) caused by needlestick injuries are a

concern for healthcare professionals, law enforcement officers, first responders, and others.

Transmission of diseases such as Human Immunodeficiency Virushuman immunodeficiency virus

(HIV) and Hepatitis C (Hep C) as a result of percutaneous needlestick injuries have been documented

worldwide. These diseases can lead to life-long chronic health problems and possibly death.

Work practice safety procedures, including the use of personal protective equipment (PPE) such as

gloves, aprons, and sleeves, are used to diminish the risk of occupational exposure to BBP’sBBPs

through needlestick injury.

The purpose of this standard is to measure relative hypodermic needle puncture resistance offered

by various materials based on the conditions specified within the standard. This standard does not

attempt to simulate all use conditions. A number of variables which impact puncture resistance are not

addressed by this standard. For example, stiffness of backing materials, presence of lubricants, and

tension on the specimen may all impact puncture resistance,resistance but are not considered by this

standard.

This standard defines three common hypodermic needles to evaluate puncture resistance. Through

development of this standard, it has been observed that needle diameter has an effect on puncture

resistance. Therefore, needles of various diameters have been specified. Users of this method may

specify testing with one or more of the needles defined within the standard.

The hypodermic needles referenced have been selected with consideration to three main points:

(1) As ) As needle gauge increases, the load required to puncture materials taken from commonly

available hypodermic needle resistant needle-resistant PPE increases. The performance is not linear

and therefore relatively large gauge (21 g) and small gauge (28 g) large-gauge (21 G) and small-gauge

(28 G) needles are provided to better understand a material’s performance against one end of the

spectrum or the other.

(2) Certain ) Certain end-use applications are concerned with protection from either large gauge

large-gauge needles or small gauge small-gauge needles. For example, police officers searching

suspected intravenous drug users are most commonly at risk of injury from fine gauge fine-gauge

needles (28 g),(28 G), but not large gauge large-gauge needles. Whereas, workers inoculating poultry

on commercial farms may be concerned with large gauge large-gauge needles (21 g),(21 G), but not

small gauge small-gauge needles.

(3) Certain ) Certain materials are optimized to resist either large gauge or small gauge large-gauge

or small-gauge needles and testing against the other would not be useful. Other materials may be

engineered for resistance to the full breadth of the gauge spectrum. For example, in applications,

applications such as healthcare, where a broad range of needle gauges areis expected, testing against

both ends of the spectrum allows for a better understanding of robustness.

1

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.20 on Physical.

Current edition approved Nov. 1, 2010Feb. 1, 2019. Published January 2011March 2019. DOI:10.1520/F2878-10.Originally approved in 2010. Last previous edition

approved in 2010 as F2878 – 10. DOI:10.1520/F2878-19.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2878 − 19

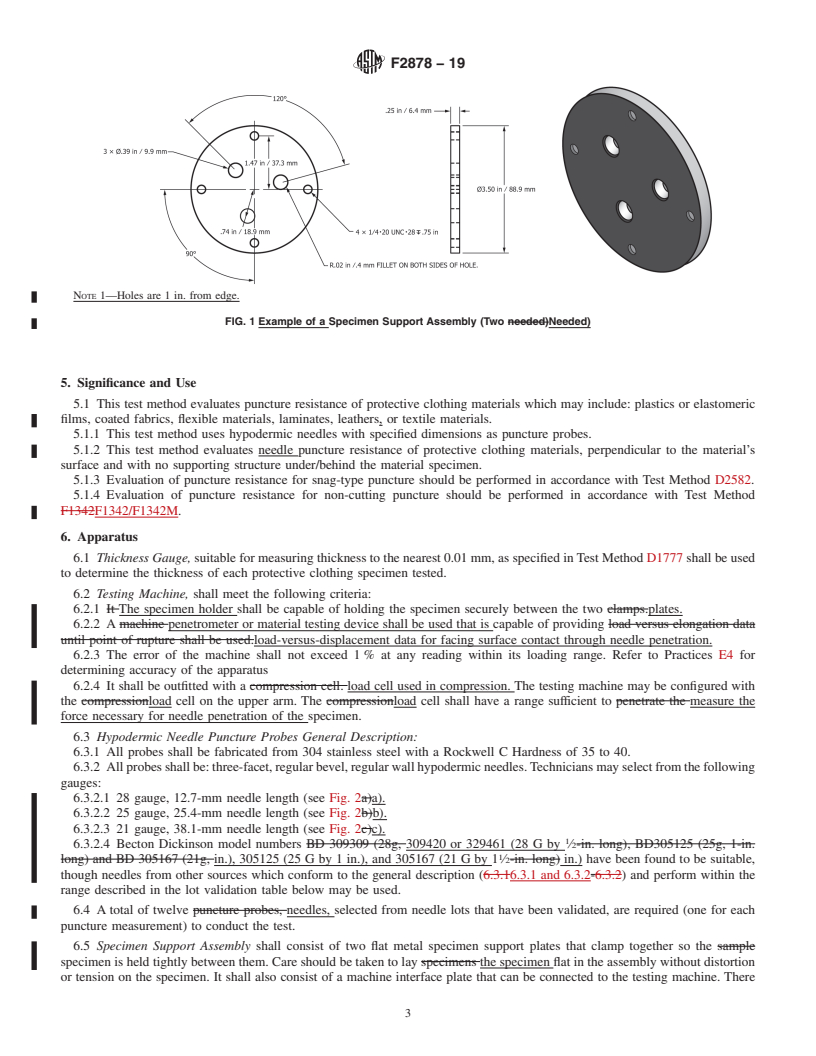

1. Scope

1.1 This test method is used to determine the force required to cause a sharp-edged puncture probe (hypodermic needle)

hypodermic needle to penetrate through protective clothing material. The standard describes three test probes needles that may be

used: 21-, 25-, or 28-gauge needles.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.