ASTM D1776/D1776M-20

(Practice)Standard Practice for Conditioning and Testing Textiles

Standard Practice for Conditioning and Testing Textiles

ABSTRACT

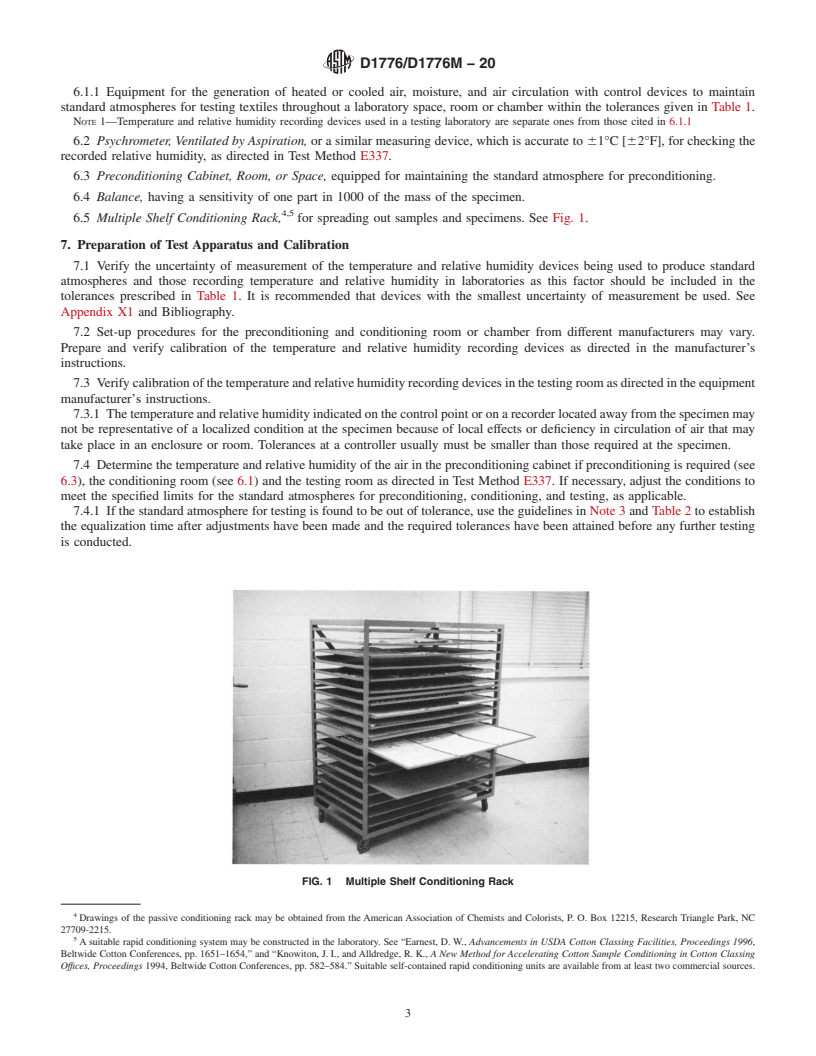

This practice covers the conditioning and testing of textiles in those instances where such conditioning is specified in a test method. Because prior exposure of textiles to high or low humidity may affect the equilibrium moisture pick-up, a procedure also is given for preconditioning the material when specified. The equipments to be used in the conditioning and testing of textiles shall include conditioning room or chamber, psychrometer ventilated by aspiration, preconditioning cabinet, room, or suitable container, balance, and multiple shelf conditioning rack. The conditioning room or chamber shall consist of equipment for maintaining the standard atmosphere for testing textiles throughout the room or chamber within the tolerances given and including facilities for circulating air over all surfaces of the exposed sample or specimen and equipment for recording the temperature and relative humidity of the air in the conditioning room or chamber. Samples or specimens requiring preconditioning shall be brought to a relatively low moisture content in a specified atmosphere. Samples or specimens requiring conditioning shall be brought to moisture equilibrium for testing in the standard atmosphere for testing textiles, or when required.

SCOPE

1.1 This practice covers the conditioning and testing of textiles when conditioning is specified in a test method. Because prior exposure of textiles to high or low humidity may affect moisture pick-up equilibrium, a procedure also is given for preconditioning the material when required.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1776/D1776M −20

Standard Practice for

1

Conditioning and Testing Textiles

This standard is issued under the fixed designation D1776/D1776M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope and Thermal Properties

D5867 Test Methods for Measurement of Physical Proper-

1.1 This practice covers the conditioning and testing of

ties of Raw Cotton by Cotton Classification Instruments

textiles when conditioning is specified in a test method.

D7269 Test Methods for Tensile Testing of Aramid Yarns

Becausepriorexposureoftextilestohighorlowhumiditymay

D7744 Test Methods for Tensile Testing of High Perfor-

affect moisture pick-up equilibrium, a procedure also is given

mance Polyethylene Tapes

for preconditioning the material when required.

E337 Test Method for Measuring Humidity with a Psy-

1.2 The values stated in either SI units or inch-pound units

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

are to be regarded separately as standard. The values stated in

peratures)

each system are not necessarily exact equivalents; therefore, to

2.2 ISO Standard:

ensure conformance with the standard, each system shall be

ISO 139 Textiles StandardAtmosphere for Conditioning and

used independently of the other, and values from the two 3

Testing

systems shall not be combined.

3. Terminology

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 For terminology related to conditioning see Terminol-

responsibility of the user of this standard to establish appro-

ogy D4920.

priate safety, health, and environmental practices and deter-

3.2 The following terms are relevant to this standard:

mine the applicability of regulatory limitations prior to use.

accelerated conditioning, moisture content, moisture

1.4 This international standard was developed in accor-

equilibrium, moisture equilibrium for preconditioning, mois-

dance with internationally recognized principles on standard-

ture equilibrium for testing, precondition, standard atmosphere

ization established in the Decision on Principles for the

for preconditioning textiles, standard atmosphere for testing

Development of International Standards, Guides and Recom-

textiles, uncertainty of (in) measurement.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.3 For definitions of other textile terms used in this

standard see Terminology D123.

2. Referenced Documents

2 4. Summary of Practice

2.1 ASTM Standards:

D123 Terminology Relating to Textiles 4.1 Samples or specimens requiring preconditioning are

D618 Practice for Conditioning Plastics for Testing brought to relatively low moisture content in a specified

D885 Test Methods for Tire Cords, Tire Cord Fabrics, and atmosphere. Samples or specimens not requiring pre-

Industrial Filament Yarns Made from Manufactured conditioning are brought to moisture equilibrium (specific to

Organic-Base Fibers fiber-content)accordingtothestandardatmospheresfortesting

D4920 Terminology Relating to Conditioning, Chemical, textiles as shown in Table 1.

4.2 Understanding of tolerance and uncertainty of measure-

ment has evolved since the creation of the original version of

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

this standard. Due to this new understanding, uncertainty of

is the direct responsibility of Subcommittee D13.51 on Conditioning, Chemical and

Thermal Properties. measurement has been taken into account in determining

Current edition approved Feb. 1, 2020. Published March 2020. Originally

acceptable tolerances for the standard atmospheres for testing

approved in 1960. Last previous edition approved in 2016 as D1776/D1776M–16.

textiles as shown in Table 1.

DOI: 10.1520/D1776_D1776M-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer tot he standard’s Document summary page on Available fromAmerican National Standards Institute, 11 W. 42nd Street, 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1776/D1776M − 20

TABLE 1 Standard Atmosph

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1776/D1776M − 16 D1776/D1776M − 20

Standard Practice for

1

Conditioning and Testing Textiles

This standard is issued under the fixed designation D1776/D1776M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice covers the conditioning and testing of textiles when conditioning is specified in a test method. Because prior

exposure of textiles to high or low humidity may affect moisture pick-up equilibrium, a procedure also is given for preconditioning

the material when required.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D618 Practice for Conditioning Plastics for Testing

D885 Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns Made from Manufactured Organic-Base

Fibers

D4920 Terminology Relating to Conditioning, Chemical, and Thermal Properties

D5867 Test Methods for Measurement of Physical Properties of Raw Cotton by Cotton Classification Instruments

D7269 Test Methods for Tensile Testing of Aramid Yarns

D7744 Test Methods for Tensile Testing of High Performance Polyethylene Tapes

E337 Test Method for Measuring Humidity with a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

2.2 ISO Standard:

3

ISO 139 Textiles Standard Atmosphere for Conditioning and Testing

3. Terminology

3.1 For terminology related to conditioning see Terminology D4920.

3.2 The following terms are relevant to this standard: accelerated conditioning, moisture content, moisture equilibrium, moisture

equilibrium for preconditioning, moisture equilibrium for testing, precondition, standard atmosphere for preconditioning textiles,

standard atmosphere for testing textiles, uncertainty of (in) measurement.

3.3 For definitions of other textile terms used in this standard see Terminology D123.

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.51 on Conditioning, Chemical and

Thermal Properties.

Current edition approved Jan. 1, 2016Feb. 1, 2020. Published January 2016March 2020. Originally approved in 1960. Last previous edition approved in 20152016 as

D1776/D1776MD1776–15.–16. DOI: 10.1520/D1776_D1776M-16.10.1520/D1776_D1776M-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer tot he standard’s Document summary page on the ASTM website.

3

Available from American National Standards Institute, 11 W. 42nd Street, 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1776/D1776M − 20

4. Summary of Practice

4.1 Samples or specimens requiring preconditioning are brought to relatively low moisture content in a specified atmosphere.

Samples or specimens not requiring pre-conditioning are brought to moisture equilibrium (specific to fiber-content) according to

the standard atmospheres for testing textiles as shown in Table 1.

4.2 Understanding of tolerance and uncertainty of measurement has evolved since the creation of the original version of this

standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.