ASTM F1838-98

(Performance Requirements)Standard Performance Requirements for Child's Plastic Chairs for Outdoor Use

Standard Performance Requirements for Child's Plastic Chairs for Outdoor Use

SCOPE

1.1 These standard performance requirements establish nationally recognized performance requirements for Class A (residential) and Class B (nonresidential) child's plastic chairs intended for outdoor use.

1.2 These standard performance requirements are not applicable to chaises, multipositional chairs, upholstered chairs, or other types of furniture.

1.3 These standard performance requirements cover the performance of product regarding aspects of outdoor weathering, impact, static load, and rear leg testing.

1.4 Products Manufactured from Recycle Plastics:

1.4.1 Products may be manufactured from recycled plastics a long as the performance requirements are met.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in an parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1838 – 98

Standard Performance Requirements for

1

Child’s Plastic Chairs for Outdoor Use

This standard is issued under the fixed designation F 1838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (Carbon-Arc Type) With and Without Water for Exposure

5

of Nonmetallic Materials

1.1 These standard performance requirements establish na-

tionally recognized performance requirements for Class A

3. Terminology

(residential) and Class B (nonresidential) child’s plastic chairs

3.1 Definitions:

intended for outdoor use.

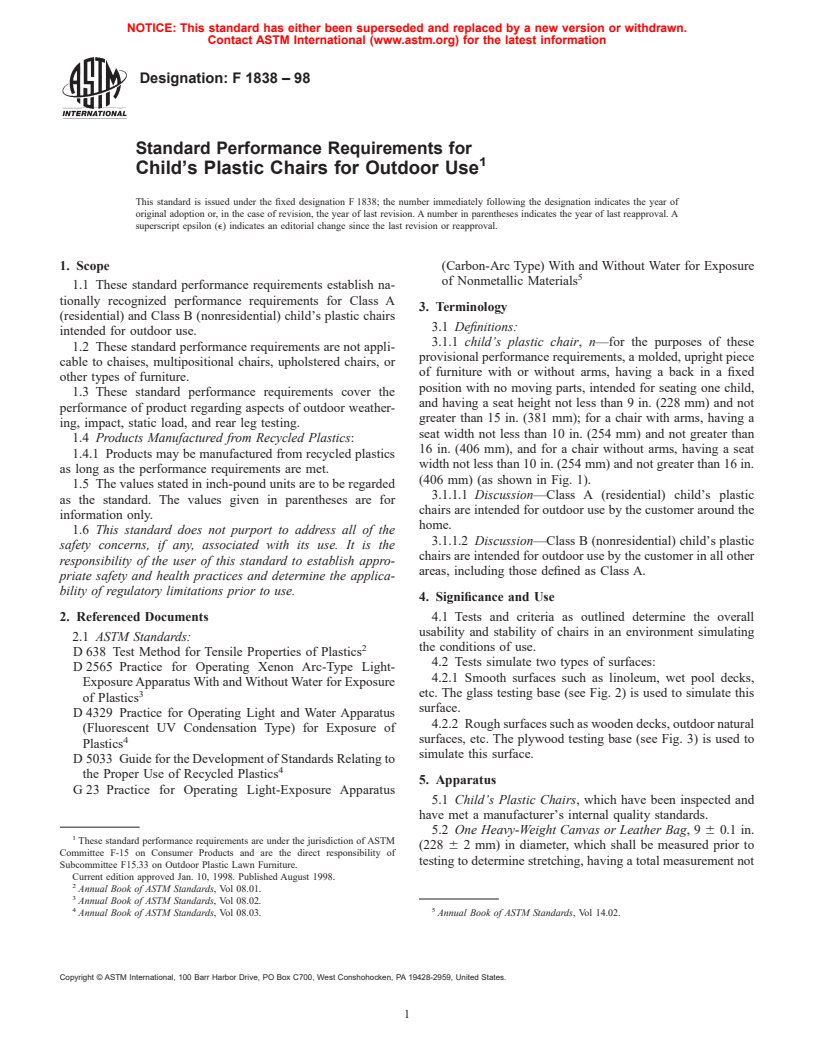

3.1.1 child’s plastic chair, n—for the purposes of these

1.2 These standard performance requirements are not appli-

provisional performance requirements, a molded, upright piece

cable to chaises, multipositional chairs, upholstered chairs, or

of furniture with or without arms, having a back in a fixed

other types of furniture.

position with no moving parts, intended for seating one child,

1.3 These standard performance requirements cover the

and having a seat height not less than 9 in. (228 mm) and not

performance of product regarding aspects of outdoor weather-

greater than 15 in. (381 mm); for a chair with arms, having a

ing, impact, static load, and rear leg testing.

seat width not less than 10 in. (254 mm) and not greater than

1.4 Products Manufactured from Recycled Plastics:

16 in. (406 mm), and for a chair without arms, having a seat

1.4.1 Products may be manufactured from recycled plastics

width not less than 10 in. (254 mm) and not greater than 16 in.

as long as the performance requirements are met.

(406 mm) (as shown in Fig. 1).

1.5 The values stated in inch-pound units are to be regarded

3.1.1.1 Discussion—Class A (residential) child’s plastic

as the standard. The values given in parentheses are for

chairs are intended for outdoor use by the customer around the

information only.

home.

1.6 This standard does not purport to address all of the

3.1.1.2 Discussion—Class B (nonresidential) child’s plastic

safety concerns, if any, associated with its use. It is the

chairs are intended for outdoor use by the customer in all other

responsibility of the user of this standard to establish appro-

areas, including those defined as Class A.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents 4.1 Tests and criteria as outlined determine the overall

usability and stability of chairs in an environment simulating

2.1 ASTM Standards:

2 the conditions of use.

D 638 Test Method for Tensile Properties of Plastics

4.2 Tests simulate two types of surfaces:

D 2565 Practice for Operating Xenon Arc-Type Light-

4.2.1 Smooth surfaces such as linoleum, wet pool decks,

Exposure Apparatus With and Without Water for Exposure

3 etc. The glass testing base (see Fig. 2) is used to simulate this

of Plastics

surface.

D 4329 Practice for Operating Light and Water Apparatus

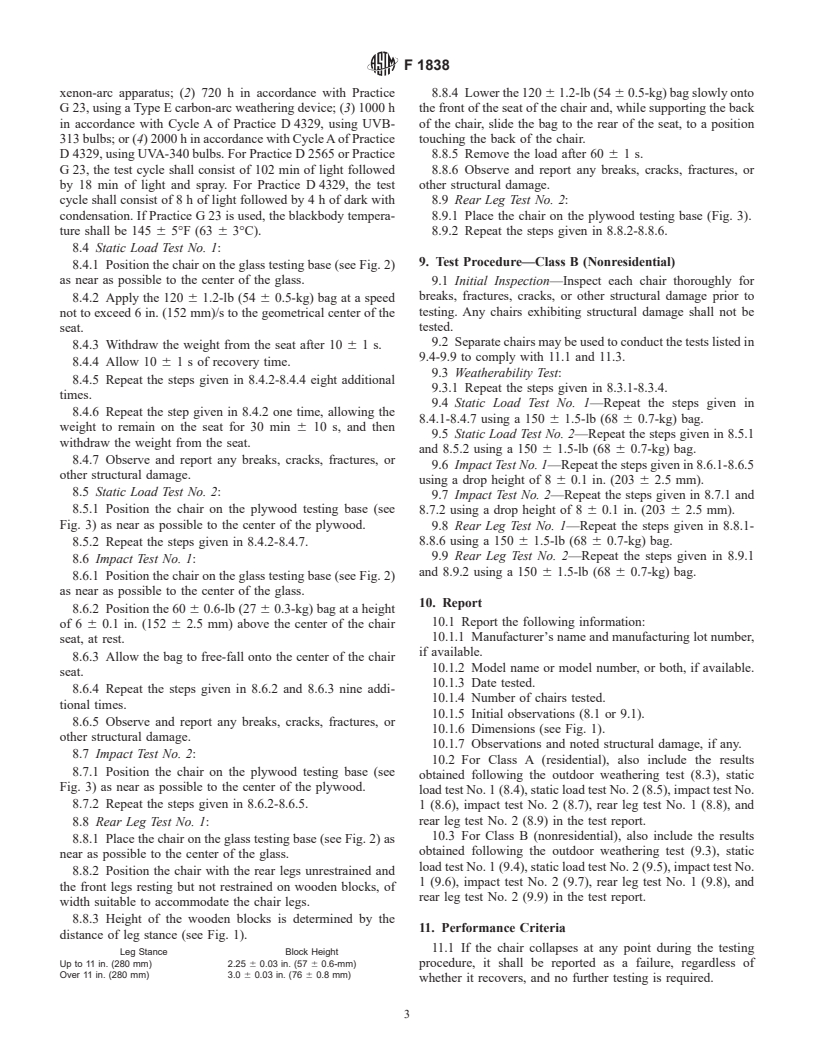

4.2.2 Rough surfaces such as wooden decks, outdoor natural

(Fluorescent UV Condensation Type) for Exposure of

4 surfaces, etc. The plywood testing base (see Fig. 3) is used to

Plastics

simulate this surface.

D 5033 Guide for the Development of Standards Relating to

4

the Proper Use of Recycled Plastics

5. Apparatus

G 23 Practice for Operating Light-Exposure Apparatus

5.1 Child’s Plastic Chairs, which have been inspected and

have met a manufacturer’s internal quality standards.

5.2 One Heavy-Weight Canvas or Leather Bag,9 6 0.1 in.

1

These standard performance requirements are under the jurisdiction of ASTM

(228 6 2 mm) in diameter, which shall be measured prior to

Committee F-15 on Consumer Products and are the direct responsibility of

testing to determine stretching, having a total measurement not

Subcommittee F15.33 on Outdoor Plastic Lawn Furniture.

Current edition approved Jan. 10, 1998. Published August 1998.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 08.02.

4 5

Annual Book of ASTM Standards, Vol 08.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1838

NOTE 1—(A) Poly(methyl methacrylate) sheet, 0.25 6 0.03-in. (6 6

0.1-mm) thickness; and (B) AC exterior glue fir plywood sheet, 0.75 6

0.08 in. (19 6 0.2 mm) or greater in thickness.

NOTE 2—(A) and (B) shall be roughly the same dimensions, 48 in.

(1219 mm) or greater.

FIG. 3 Plywood Testing Base

5.4 One Heavy-Weight Canvas or Leather Bag, identical to

the bag describ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.