ASTM B172-10(2015)

(Specification)Standard Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

Standard Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

ABSTRACT

This specification covers bare rope-lay-stranded conductors having bunch-stranded members from round copper wires, either uncoated or coated with tin, lead, or lead-alloy for use in electrical conductors. Rope-lay-stranded conductors having bunch-stranded members are classified as Class I, Class K, and Class M. Necessary joints in wires or in groups of wires shall be made in accordance with accepted commercial practice, taking into account the size of the wire or group of wires as related to the size of the entire conductor. Conductors of the same size and description furnished on one order shall have the same lay. In very flexible conductors, such as welding conductor, the direction of lay of the stranded members forming rope-lay-stranded conductor may be in the same, rather than in teversed. For the purpose of calculating the mass, cross sections, etc., the density of copper shall be taken. The mass and electrical resistance of a unit length of stranded conductor as a function of the length of lay shall be measured.

SCOPE

1.1 This specification covers bare rope-lay-stranded conductors having bunch-stranded members made from round copper wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors (Explanatory Notes 1 and 2).

1.2 Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective diameters and densities of uncoated wires.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B172 −10 (Reapproved 2015)

Standard Specification for

Rope-Lay-Stranded Copper Conductors Having Bunch-

Stranded Members, for Electrical Conductors

This standard is issued under the fixed designation B172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope tors Having Concentric-Stranded Members, for Electrical

Conductors

1.1 This specification covers bare rope-lay-stranded con-

B189 Specification for Lead-Coated and Lead-Alloy-Coated

ductors having bunch-stranded members made from round

Soft Copper Wire for Electrical Purposes

copper wires, either uncoated or coated with tin, lead, or

B193 Test Method for Resistivity of Electrical Conductor

lead-alloy for use as electrical conductors (Explanatory Notes

Materials

1 and 2).

B263 Test Method for Determination of Cross-Sectional

1.2 Coated wires shall include only those wires with fin-

Area of Stranded Conductors

ished diameters and densities substantially equal to the respec-

B354 Terminology Relating to Uninsulated Metallic Electri-

tive diameters and densities of uncoated wires.

cal Conductors

1.3 The values stated in inch-pound or SI units are to be 2.3 American National Standard:

regarded separately as standard. Each system shall be used ANSI C42.35 Definitions of Electrical Terms

independently of the other. Combining values from the two

3. Classification

systems may result in nonconformance with the specification.

For conductor sizes designated byAWG or kcmil, the require-

3.1 For the purpose of this specification rope-lay-stranded

ments in SI units have been numerically converted from

conductors having bunch-stranded members are classifed as

corresponding values, stated or derived, in inch-pound units.

follows:

For conductor sizes designated by SI units only, the require-

3.1.1 Class I—Conductors consisting of wires 0.0201-in.

ments are stated or derived in SI units.

(0.511-mm) diameter (No. 24 AWG) to produce rope-lay-

1.3.1 For density, resistivity, and temperature, the values

stranded conductors up to 2 000 000 cmil (1013 mm ) in total

stated in SI units are to be regarded as standard.

cross-sectional area. (Typical use is for special apparatus

conductor.)

2. Referenced Documents

3.1.2 Class K—Conductors consisting of wires 0.0100-in.

(0.254-mm) diameter (No. 30 AWG) to produce rope-lay-

2.1 The following documents of the issue in effect at the

stranded conductors up to 1 000 000 cmil (507 mm ) in total

time of reference form a part of this specification to the extent

cross-sectional area. (Typical use is for special portable cord

referenced herein:

and conductors.)

2.2 ASTM Standards:

3.1.3 Class M—Conductors consisting of wires 0.0063-in.

B3 Specification for Soft or Annealed Copper Wire

(0.160-mm) diameter (No. 34 AWG) to produce rope-lay-

B33 Specification for Tin-Coated Soft or Annealed Copper

stranded conductors up to 1 000 000 cmil (507 mm ) in total

Wire for Electrical Purposes

cross-sectional area. (Typical use is for welding conductors.)

B173 Specification for Rope-Lay-Stranded Copper Conduc-

4. Ordering Information

4.1 Orders for material under this specification shall include

This specification is under the jurisdiction of ASTM Committee B01 on

the following information:

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

4.1.1 Quantity of each size and class,

Current edition approved April 1, 2015. Published April 2015. Originally

4.1.2 Conductor size: circular-mil area or AWG (see 7.1),

approved in 1942 to replace portions of B158– 41T. Last previous edition approved

4.1.3 Class (Section 4 and Tables 1-3),

in 2010 as B172 – 10. DOI: 10.1520/B0172-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B172−10 (2015)

A

TABLE 1 Construction Requirements of Class I Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

Uncoated Copper Coated Copper

Wire

Diameter

0.0201

in. Nominal Maximum Nominal Maximum

(0.511 Approximate dc resistance dc resistance dc resistance dc resistance

B

Area of Cross Section mm) Mass @ 20°C @ 20°C @ 20°C @ 20°C

cmil mm Nominal Strand lb/ kg/ Ohm / kft Ohm / km Ohm / Ohm / Ohm / kft Ohm / km Ohm / Ohm /

Size Number Construction 1000 ft. km kft km kft km

C

AWG of Wires AbyBbyC

2 000 000 1013 . . . 4921 19 by 7 by 37 6439 9583 0.00555 0.0182 0.00566 0.0186 0.00577 0.0189 0.00589 0.0193

1 900 000 963 . . . 4788 19 by 7 by 36 6265 9324 0.00584 0.0192 0.00596 0.0196 0.00607 0.0199 0.00619 0.0203

1 800 000 912 . . . 4522 19 by 7 by 34 5917 8806 0.00616 0.0202 0.00628 0.0206 0.00641 0.0210 0.00654 0.0214

1 750 000 887 . . . 4389 19 by 7 by 33 5743 8547 0.00634 0.0208 0.00647 0.0212 0.00659 0.0216 0.00672 0.0220

1 700 000 861 . . . 4256 19 by 7 by 32 5569 8288 0.00653 0.0214 0.00666 0.0218 0.00679 0.0223 0.00693 0.0227

1 600 000 811 . . . 3990 19 by 7 by 30 5221 7770 0.00694 0.0228 0.00708 0.0233 0.00721 0.0237 0.00735 0.0242

1 500 000 760 . . . 3724 19 by 7 by 28 4873 7252 0.00740 0.0243 0.00755 0.0248 0.00769 0.0252 0.00784 0.0257

1 400 000 709 . . . 3458 19 by 7 by 26 4525 6734 0.00793 0.0260 0.00809 0.0265 0.00824 0.0270 0.00840 0.0275

1 300 000 659 . . . 3192 19 by 7 by 24 4177 6216 0.00854 0.0280 0.00871 0.0286 0.00888 0.0291 0.00906 0.0297

1 250 000 633 . . . 3059 19 by 7 by 23 4003 5957 0.00888 0.0291 0.00906 0.0297 0.00923 0.0303 0.00941 0.0309

1 200 000 608 . . . 2926 19 by 7 by 22 3829 5698 0.00925 0.0303 0.00944 0.0309 0.00962 0.0316 0.00981 0.0322

1 100 000 557 . . . 2793 19 by 7 by 21 3655 5439 0.0101 0.0331 0.0103 0.0338 0.0105 0.0344 0.0107 0.0351

1 000 000 507 . . . 2527 19 by 7 by 19 3307 4921 0.0111 0.0364 0.0113 0.0371 0.0115 0.0379 0.0117 0.0387

900 000 456 . . . 2261 19 by 7 by 17 2959 4403 0.0123 0.0405 0.0125 0.0413 0.0128 0.0421 0.0131 0.0429

800 000 405 . . . 1995 19 by 7 by 15 2611 3885 0.0139 0.0455 0.0142 0.0464 0.0144 0.0473 0.0147 0.0482

750 000 380 . . . 1862 19 by 7 by 14 2436 3626 0.0148 0.0485 0.0151 0.0495 0.0154 0.0505 0.0157 0.0515

700 000 355 . . . 1729 19 by 7 by 13 2262 3367 0.0159 0.0520 0.0162 0.0530 0.0165 0.0541 0.0168 0.0552

650 000 329 . . . 1596 19 by 7 by 12 2088 3108 0.0171 0.0560 0.0174 0.0571 0.0178 0.0583 0.0182 0.0594

600 000 304 . . . 1470 7 by 7 by 30 1906 2836 0.0183 0.0601 0.0187 0.0613 0.0191 0.0625 0.0195 0.0638

550 000 279 . . . 1372 7 by 7 by 28 1779 2647 0.0200 0.0656 0.0204 0.0669 0.0208 0.0682 0.0212 0.0696

500 000 253 . . . 1225 7 by 7 by 25 1588 2363 0.0220 0.0721 0.0224 0.0735 0.0229 0.0750 0.0234 0.0765

450 000 228 . . . 1127 7 by 7 by 23 1461 2174 0.0244 0.0802 0.0249 0.0817 0.0254 0.0834 0.0259 0.0850

400 000 203 . . . 980 7 by 7 by 20 1270 1891 0.0275 0.0902 0.0281 0.0920 0.0286 0.0938 0.0292 0.0957

350 000 177 . . . 882 7 by 7 by 18 1143 1701 0.0314 0.103 0.0320 0.105 0.0327 0.107 0.0334 0.109

300 000 152 . . . 735 7 by 7 by 15 953 1418 0.0366 0.120 0.0373 0.122 0.0381 0.125 0.0389 0.128

250 000 127 . . . 637 7 by 7 by 13 826 1229 0.0440 0.144 0.0449 0.147 0.0457 0.150 0.0466 0.153

211 600 107 0000 532 19 by 28 683 1017 0.0515 0.169 0.0525 0.172 0.0536 0.176 0.0546 0.180

167 800 85 000 418 19 by 22 537 799 0.0649 0.213 0.0662 0.217 0.0675 0.221 0.0689 0.225

133 100 67.4 00 342 19 by 18 439 654 0.0818 0.268 0.0834 0.273 0.0851 0.279 0.0868 0.285

105 600 53.5 0 266 19 by 14 342 508 0.103 0.338 0.105 0.345 0.107 0.352 0.109 0.359

83 690 42.4 1 210 7 by 30 267 397 0.129 0.423 0.132 0.431 0.134 0.440 0.137 0.449

66 360 33.6 2 161 7 by 23 205 305 0.163 0.533 0.166 0.544 0.169 0.555 0.172 0.566

52 620 26.7 3 133 7 by 19 169 252 0.205 0.673 0.209 0.686 0.213 0.699 0.217 0.713

41 740 21.1 4 105 7 by 15 134 199 0.258 0.848 0.263 0.865 0.269 0.882 0.274 0.900

33 090 16.8 5 84 7 by 12 107 159 0.326 1.07 0.333 1.09 0.339 1.11 0.346 1.13

26 240 13.3 6 63 7 by 9 80 119 0.411 1.35 0.419 1.38 0.427 1.40 0.436 1.43

A

The constructions shown in this table are typical of those used in the industry. It is not intended that this table preclude other constructions which may be desireable for

specific applications. The constructions shown provide for finished, covered or non-covered, stranded conductor approximately of the area indicated. When specified by

the purchaser, the number of strands may be increased to provide additional area to compensate for draw-down during subsequent processing.

B

Values for the mass of the completed conductor are approximate. The mass values are based upon the standard stranding increments listed in Explanatory Note 6.

C

Strand Construction—#A by #B by #C: where #C is the number of wires in each bunch-stranded member; #B is the number of bunch stranded members which make-up

each rope-stranded member; and #A (where used) is the number of rope-stranded members in the conductor. Where #A is not given, the conductor consists of one

rope-stranded member. For example, 19 by 7 by 32 indicates a construction consisting of 19 rope-stranded members, each of which consists of 7 bunch-stranded

members with 32 wires each.

4.1.4 Whether coated or uncoated; if coated, designate type 5. Joints

of coating (see 11.1),

5.1 Necessary joints in wires or in groups of wires shall be

4.1.5 Details of special-purpose lays, if required (see 6.2,

made in accordance with accepted commercial practice, taking

6.3, and Explanatory Note 3),

into account the size of the wire or group of wires as related to

4.1.6 Package size (see 15.1),

the size of the entire conductor.

4.1.7 Special package marking, if required (Section 14),

5.2 Bunch-stranded members or rope-stranded members

4.1.8 Lagging, if required (see 15.2), and

forming the completed conductor may be joined as a unit by

4.1.9 Place of inspection (Section 13). soldering, brazing, or welding.

B172−10 (2015)

A

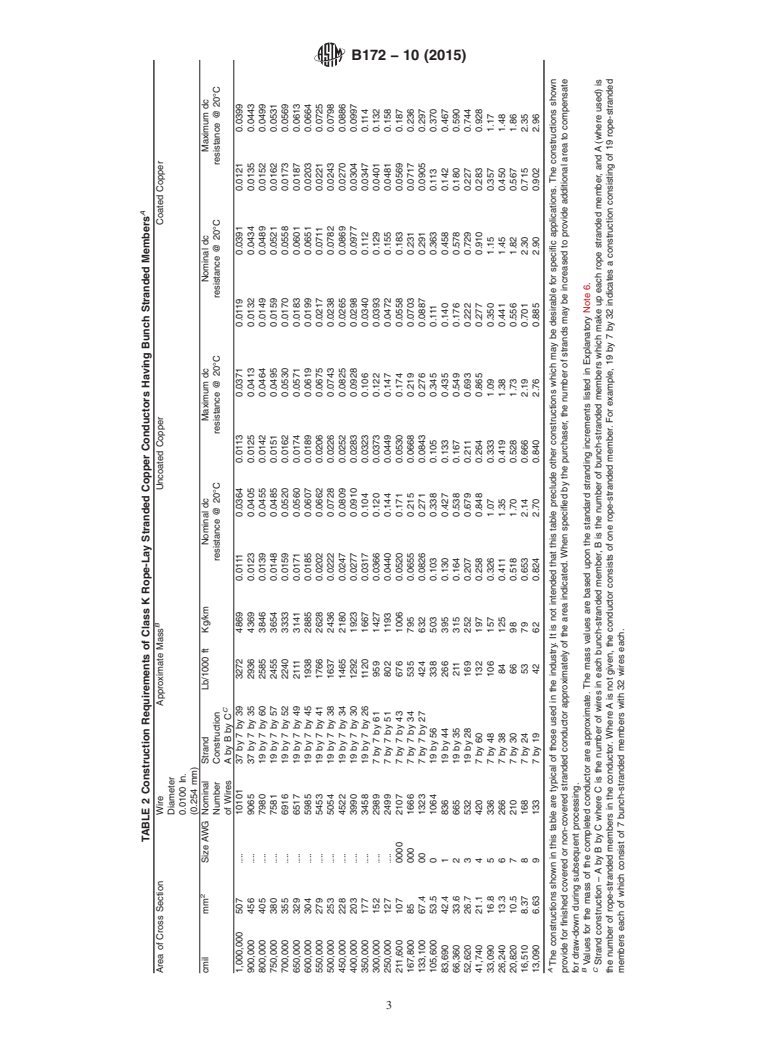

TABLE 2 Construction Requirements of Class K Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

B

Area of Cross Section Wire Approximate Mass Uncoated Copper Coated Copper

Diameter

0.0100 In.

(0.254 mm)

cmil mm Size AWG Nominal Strand Lb/1000 ft Kg/km Nominal dc Maximum dc Nominal dc Maximum dc

Number Construction resistance @ 20°C resistance @ 20°C resistance @ 20°C resistance @ 20°C

C

of Wires AbyBbyC

1,000,000 507 {. 10101 37 by 7 by 39 3272 4869 0.0111 0.0364 0.0113 0.0371 0.0119 0.0391 0.0121 0.0399

900,000 456 {. 9065 37 by 7 by 35 2936 4369 0.0123 0.0405 0.0125 0.0413 0.0132 0.0434 0.0135 0.0443

800,000 405 {. 7980 19 by 7 by 60 2585 3846 0.0139 0.0455 0.0142 0.0464 0.0149 0.0489 0.0152 0.0499

750,000 380 {. 7581 19 by 7 by 57 2455 3654 0.0148 0.0485 0.0151 0.0495 0.0159 0.0521 0.0162 0.0531

700,000 355 {. 6916 19 by 7 by 52 2240 3333 0.0159 0.0520 0.0162 0.0530 0.0170 0.0558 0.0173 0.0569

650,000 329 {. 6517 19 by 7 by 49 2111 3141 0.0171 0.0560 0.0174 0.0571 0.0183 0.0601 0.0187 0.0613

600,000 304 {. 5985 19 by 7 by 45 1938 2885 0.0185 0.0607 0.0189 0.0619 0.0199 0.0651 0.0203 0.0664

550,000 279 {. 5453 19 by 7 by 41 1766 2628 0.0202 0.0662 0.0206 0.0675 0.0217 0.0711 0.0221 0.0725

500,000 253 {. 5054 19 by 7 by 38 1637 2436 0.0222 0.0728 0.0226 0.0743 0.0238 0.0782 0.0243 0.0798

450,000 228 {. 4522 19 by 7 by 34 1465 2180 0.0247 0.0809 0.0252 0.0825 0.0265 0.0869 0.0270 0.0886

400,000 203 {. 3990 19 by 7 by 30 1292 1923 0.0277 0.0910 0.0283 0.0928 0.0298 0.0977 0.0304 0.0997

350,000 177 {. 3458 19 by 7 by 26 1120 1667 0.0317 0.104 0.0323 0.106 0.0340 0.112 0.0347 0.114

300,000 152 {. 2989 7 by 7 by 61 959 1427 0.0366 0.120 0.0373 0.122 0.0393 0.129 0.0401 0.132

250,000 127 {. 2499 7 by 7 by 51 802 1193 0.0440 0.144 0.0449 0.147 0.0472 0.155 0.0481 0.158

211,600 107 0000 2107 7 by 7 by 43 676 1006 0.0520 0.171 0.0530 0.174 0.0558 0.183 0.0569 0.187

167,800 85 000 1666 7 by 7 by 34 535 795 0.0655 0.215 0.0668 0.219 0.0703 0.231 0.0717 0.236

133,100 67.4 00 1323 7 by 7 by 27 424 632 0.0826 0.271 0.0843 0.276 0.0887 0.291 0.0905 0.297

105,600 53.5 0 1064 19 by 56 338 503 0.103 0.338 0.105 0.345 0.111 0.363 0.113 0.370

83,690 42.4 1 836 19 by 44 266 395 0.130 0.427 0.133 0.435 0.140 0.458 0.142 0.467

66,360 33.6 2 665 19 by 35 211 315 0.164 0.538 0.167 0.549 0.176 0.578 0.180 0.590

52,620 26.7 3 532 19 by 28 169 252 0.207 0.679 0.211 0.693 0.222 0.729 0.227 0.744

41,740 21.1 4 420 7 by 60 132 197 0.258 0.848 0.264 0.865 0.277 0.910 0.283 0.928

33,090 16.8 5 336 7 by 48 106 157 0.326 1.07 0.333 1.09 0.350 1.15 0.357 1.17

26,240 13.3 6 266 7 by 38 84 125 0.411 1.35 0.419 1.38 0.441 1.45 0.450 1.48

20,820 10.5 7 210 7 by 30 66 98 0.518 1.70 0.528 1.73 0.556 1.82 0.567 1.86

16,510 8.37 8 168 7 by 24 53 79 0.653 2.14 0.666 2.19 0.701 2.30 0.715 2.35

13,090 6.63 9 133 7 by 19 42 62 0.824 2.70 0.840 2.76 0.885 2.90 0.902 2.96

A

The constructions shown in this table are typical of those used in the industry. It is not intended that this table preclude other constructions which may be desirable for specific applications. The constructions shown

provide for finished covered or non-covered stranded conductor approximately of the area indicated. When specified by the purchaser, the number of strands may be increased to provide additional area to compensate

for draw-down during subsequent processing.

B

Values for the mass of the completed conductor are approximate. The mass values are based upon the standard stranding increments listed in Explanatory Note 6.

C

Strand construction – A by B by C where C is the number of wires in each bunch-stranded member, B is the number of bunch-stranded members which make up each rope stranded member, and A (where used) is

the number of rope-stranded members in the conductor. Where A is not given, the conductor consists of one rope-stranded member. For example, 19 by 7 by 32 indicates a construction consisting of 19 rope-stranded

members each of which consist of 7 bunch-stranded members with 32 wires each.

B172−10 (2015)

A

TABLE 3 Construction requirements of Class M Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

B

Area of Cross Section Wire Ap

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B172 − 10 B172 − 10 (Reapproved 2015)

Standard Specification for

Rope-Lay-Stranded Copper Conductors Having Bunch-

Stranded Members, for Electrical Conductors

This standard is issued under the fixed designation B172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers bare rope-lay-stranded conductors having bunch-stranded members made from round copper

wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors (Explanatory Notes 1 and 2).

1.2 Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective

diameters and densities of uncoated wires.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification. For

conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding

values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or

derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B3 Specification for Soft or Annealed Copper Wire

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B173 Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conduc-

tors

B189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

2.3 American National StandardStandard::

ANSI C42.35 Definitions of Electrical Terms

3. Classification

3.1 For the purpose of this specification rope-lay-stranded conductors having bunch-stranded members are classifed as follows:

3.1.1 Class I—Conductors consisting of wires 0.0201-in. (0.511-mm) diameter (No. 24 AWG) to produce rope-lay-stranded

conductors up to 2 000 000 cmil (1013 mm ) in total cross-sectional area. (Typical use is for special apparatus conductor.)

3.1.2 Class K—Conductors consisting of wires 0.0100-in. (0.254-mm) diameter (No. 30 AWG) to produce rope-lay-stranded

conductors up to 1 000 000 cmil (507 mm ) in total cross-sectional area. (Typical use is for special portable cord and conductors.)

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved April 1, 2010April 1, 2015. Published May 2010April 2015. Originally approved in 1942 to replace portions of B158–41 – 41 T. Last previous

ε1

edition approved in 20072010 as B172 – 01aB172 – 10. (2007) . DOI: 10.1520/B0172-10.10.1520/B0172-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B172 − 10 (2015)

3.1.3 Class M—Conductors consisting of wires 0.0063-in. (0.160-mm) diameter (No. 34 AWG) to produce rope-lay-stranded

conductors up to 1 000 000 cmil (507 mm ) in total cross-sectional area. (Typical use is for welding conductors.)

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size and class,

4.1.2 Conductor size: circular-mil area or AWG (see 7.1),

4.1.3 Class (Section 4 and Tables 1-3),

4.1.4 Whether coated or uncoated; if coated, designate type of coating (see 11.1),

4.1.5 Details of special-purpose lays, if required (see 6.2, 6.3, and Explanatory Note 3),

4.1.6 Package size (see 15.1),

4.1.7 Special package marking, if required (Section 14),

4.1.8 Lagging, if required (see 15.2), and

4.1.9 Place of inspection (Section 13).

A

TABLE 1 Construction Requirements of Class I Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

Uncoated Copper Coated Copper

Wire

Diameter

0.0201

in. Nominal Maximum Nominal Maximum

(0.511 Approximate dc resistance dc resistance dc resistance dc resistance

B

Area of Cross Section mm) Mass @ 20°C @ 20°C @ 20°C @ 20°C

cmil mm Nominal Strand lb/ kg/ Ohm / kft Ohm / km Ohm / Ohm / Ohm / kft Ohm / km Ohm / Ohm /

Size Number Construction 1000 ft. km kft km kft km

C

AWG of Wires A by B by C

2 000 000 1013 . . . 4921 19 by 7 by 37 6439 9583 0.00555 0.0182 0.00566 0.0186 0.00577 0.0189 0.00589 0.0193

1 900 000 963 . . . 4788 19 by 7 by 36 6265 9324 0.00584 0.0192 0.00596 0.0196 0.00607 0.0199 0.00619 0.0203

1 800 000 912 . . . 4522 19 by 7 by 34 5917 8806 0.00616 0.0202 0.00628 0.0206 0.00641 0.0210 0.00654 0.0214

1 750 000 887 . . . 4389 19 by 7 by 33 5743 8547 0.00634 0.0208 0.00647 0.0212 0.00659 0.0216 0.00672 0.0220

1 700 000 861 . . . 4256 19 by 7 by 32 5569 8288 0.00653 0.0214 0.00666 0.0218 0.00679 0.0223 0.00693 0.0227

1 600 000 811 . . . 3990 19 by 7 by 30 5221 7770 0.00694 0.0228 0.00708 0.0233 0.00721 0.0237 0.00735 0.0242

1 500 000 760 . . . 3724 19 by 7 by 28 4873 7252 0.00740 0.0243 0.00755 0.0248 0.00769 0.0252 0.00784 0.0257

1 400 000 709 . . . 3458 19 by 7 by 26 4525 6734 0.00793 0.0260 0.00809 0.0265 0.00824 0.0270 0.00840 0.0275

1 300 000 659 . . . 3192 19 by 7 by 24 4177 6216 0.00854 0.0280 0.00871 0.0286 0.00888 0.0291 0.00906 0.0297

1 250 000 633 . . . 3059 19 by 7 by 23 4003 5957 0.00888 0.0291 0.00906 0.0297 0.00923 0.0303 0.00941 0.0309

1 200 000 608 . . . 2926 19 by 7 by 22 3829 5698 0.00925 0.0303 0.00944 0.0309 0.00962 0.0316 0.00981 0.0322

1 100 000 557 . . . 2793 19 by 7 by 21 3655 5439 0.0101 0.0331 0.0103 0.0338 0.0105 0.0344 0.0107 0.0351

1 000 000 507 . . . 2527 19 by 7 by 19 3307 4921 0.0111 0.0364 0.0113 0.0371 0.0115 0.0379 0.0117 0.0387

900 000 456 . . . 2261 19 by 7 by 17 2959 4403 0.0123 0.0405 0.0125 0.0413 0.0128 0.0421 0.0131 0.0429

800 000 405 . . . 1995 19 by 7 by 15 2611 3885 0.0139 0.0455 0.0142 0.0464 0.0144 0.0473 0.0147 0.0482

750 000 380 . . . 1862 19 by 7 by 14 2436 3626 0.0148 0.0485 0.0151 0.0495 0.0154 0.0505 0.0157 0.0515

700 000 355 . . . 1729 19 by 7 by 13 2262 3367 0.0159 0.0520 0.0162 0.0530 0.0165 0.0541 0.0168 0.0552

650 000 329 . . . 1596 19 by 7 by 12 2088 3108 0.0171 0.0560 0.0174 0.0571 0.0178 0.0583 0.0182 0.0594

600 000 304 . . . 1470 7 by 7 by 30 1906 2836 0.0183 0.0601 0.0187 0.0613 0.0191 0.0625 0.0195 0.0638

550 000 279 . . . 1372 7 by 7 by 28 1779 2647 0.0200 0.0656 0.0204 0.0669 0.0208 0.0682 0.0212 0.0696

500 000 253 . . . 1225 7 by 7 by 25 1588 2363 0.0220 0.0721 0.0224 0.0735 0.0229 0.0750 0.0234 0.0765

450 000 228 . . . 1127 7 by 7 by 23 1461 2174 0.0244 0.0802 0.0249 0.0817 0.0254 0.0834 0.0259 0.0850

400 000 203 . . . 980 7 by 7 by 20 1270 1891 0.0275 0.0902 0.0281 0.0920 0.0286 0.0938 0.0292 0.0957

350 000 177 . . . 882 7 by 7 by 18 1143 1701 0.0314 0.103 0.0320 0.105 0.0327 0.107 0.0334 0.109

300 000 152 . . . 735 7 by 7 by 15 953 1418 0.0366 0.120 0.0373 0.122 0.0381 0.125 0.0389 0.128

250 000 127 . . . 637 7 by 7 by 13 826 1229 0.0440 0.144 0.0449 0.147 0.0457 0.150 0.0466 0.153

211 600 107 0000 532 19 by 28 683 1017 0.0515 0.169 0.0525 0.172 0.0536 0.176 0.0546 0.180

167 800 85 000 418 19 by 22 537 799 0.0649 0.213 0.0662 0.217 0.0675 0.221 0.0689 0.225

133 100 67.4 00 342 19 by 18 439 654 0.0818 0.268 0.0834 0.273 0.0851 0.279 0.0868 0.285

105 600 53.5 0 266 19 by 14 342 508 0.103 0.338 0.105 0.345 0.107 0.352 0.109 0.359

83 690 42.4 1 210 7 by 30 267 397 0.129 0.423 0.132 0.431 0.134 0.440 0.137 0.449

66 360 33.6 2 161 7 by 23 205 305 0.163 0.533 0.166 0.544 0.169 0.555 0.172 0.566

52 620 26.7 3 133 7 by 19 169 252 0.205 0.673 0.209 0.686 0.213 0.699 0.217 0.713

41 740 21.1 4 105 7 by 15 134 199 0.258 0.848 0.263 0.865 0.269 0.882 0.274 0.900

33 090 16.8 5 84 7 by 12 107 159 0.326 1.07 0.333 1.09 0.339 1.11 0.346 1.13

26 240 13.3 6 63 7 by 9 80 119 0.411 1.35 0.419 1.38 0.427 1.40 0.436 1.43

A

The constructions shown in this table are typical of those used in the industry. It is not intended that this table preclude other constructions which may be desireable for

specific applications. The constructions shown provide for finished, covered or non-covered, stranded conductor approximately of the area indicated. When specified by

the purchaser, the number of strands may be increased to provide additional area to compensate for draw-down during subsequent processing.

B

Values for the mass of the completed conductor are approximate. The mass values are based upon the standard stranding increments listed in Explanatory Note 6.

C

Strand Construction—#A by #B by #C: where #C is the number of wires in each bunch-stranded member; #B is the number of bunch stranded members which make-up

each rope-stranded member; and #A (where used) is the number of rope-stranded members in the conductor. Where #A is not given, the conductor consists of one

rope-stranded member. For example, 19 by 7 by 32 indicates a construction consisting of 19 rope-stranded members, each of which consists of 7 bunch-stranded

members with 32 wires each.

B172 − 10 (2015)

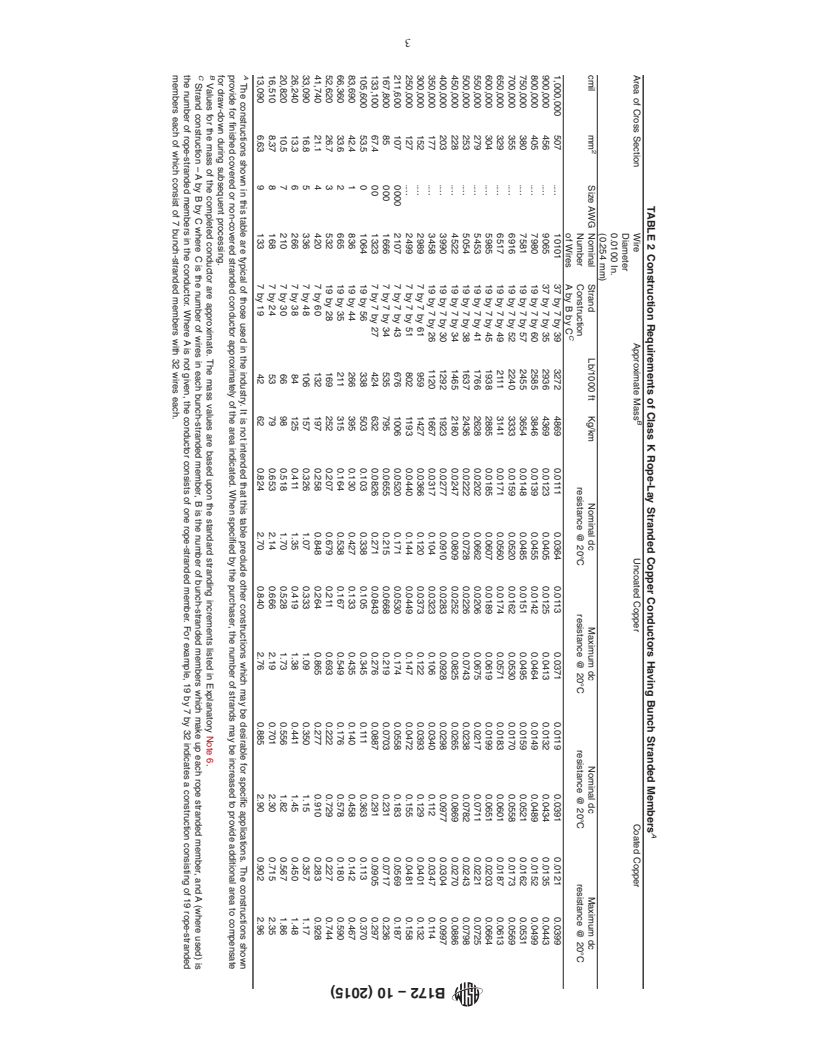

A

TABLE 2 Construction Requirements of Class K Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

B

Area of Cross Section Wire Approximate Mass Uncoated Copper Coated Copper

Diameter

0.0100 In.

(0.254 mm)

cmil mm Size AWG Nominal Strand Lb/1000 ft Kg/km Nominal dc Maximum dc Nominal dc Maximum dc

Number Construction resistance @ 20°C resistance @ 20°C resistance @ 20°C resistance @ 20°C

C

of Wires A by B by C

1,000,000 507 {. 10101 37 by 7 by 39 3272 4869 0.0111 0.0364 0.0113 0.0371 0.0119 0.0391 0.0121 0.0399

900,000 456 {. 9065 37 by 7 by 35 2936 4369 0.0123 0.0405 0.0125 0.0413 0.0132 0.0434 0.0135 0.0443

800,000 405 {. 7980 19 by 7 by 60 2585 3846 0.0139 0.0455 0.0142 0.0464 0.0149 0.0489 0.0152 0.0499

750,000 380 {. 7581 19 by 7 by 57 2455 3654 0.0148 0.0485 0.0151 0.0495 0.0159 0.0521 0.0162 0.0531

700,000 355 {. 6916 19 by 7 by 52 2240 3333 0.0159 0.0520 0.0162 0.0530 0.0170 0.0558 0.0173 0.0569

650,000 329 {. 6517 19 by 7 by 49 2111 3141 0.0171 0.0560 0.0174 0.0571 0.0183 0.0601 0.0187 0.0613

600,000 304 {. 5985 19 by 7 by 45 1938 2885 0.0185 0.0607 0.0189 0.0619 0.0199 0.0651 0.0203 0.0664

550,000 279 {. 5453 19 by 7 by 41 1766 2628 0.0202 0.0662 0.0206 0.0675 0.0217 0.0711 0.0221 0.0725

500,000 253 {. 5054 19 by 7 by 38 1637 2436 0.0222 0.0728 0.0226 0.0743 0.0238 0.0782 0.0243 0.0798

450,000 228 {. 4522 19 by 7 by 34 1465 2180 0.0247 0.0809 0.0252 0.0825 0.0265 0.0869 0.0270 0.0886

400,000 203 {. 3990 19 by 7 by 30 1292 1923 0.0277 0.0910 0.0283 0.0928 0.0298 0.0977 0.0304 0.0997

350,000 177 {. 3458 19 by 7 by 26 1120 1667 0.0317 0.104 0.0323 0.106 0.0340 0.112 0.0347 0.114

300,000 152 {. 2989 7 by 7 by 61 959 1427 0.0366 0.120 0.0373 0.122 0.0393 0.129 0.0401 0.132

250,000 127 {. 2499 7 by 7 by 51 802 1193 0.0440 0.144 0.0449 0.147 0.0472 0.155 0.0481 0.158

211,600 107 0000 2107 7 by 7 by 43 676 1006 0.0520 0.171 0.0530 0.174 0.0558 0.183 0.0569 0.187

167,800 85 000 1666 7 by 7 by 34 535 795 0.0655 0.215 0.0668 0.219 0.0703 0.231 0.0717 0.236

133,100 67.4 00 1323 7 by 7 by 27 424 632 0.0826 0.271 0.0843 0.276 0.0887 0.291 0.0905 0.297

105,600 53.5 0 1064 19 by 56 338 503 0.103 0.338 0.105 0.345 0.111 0.363 0.113 0.370

83,690 42.4 1 836 19 by 44 266 395 0.130 0.427 0.133 0.435 0.140 0.458 0.142 0.467

66,360 33.6 2 665 19 by 35 211 315 0.164 0.538 0.167 0.549 0.176 0.578 0.180 0.590

52,620 26.7 3 532 19 by 28 169 252 0.207 0.679 0.211 0.693 0.222 0.729 0.227 0.744

41,740 21.1 4 420 7 by 60 132 197 0.258 0.848 0.264 0.865 0.277 0.910 0.283 0.928

33,090 16.8 5 336 7 by 48 106 157 0.326 1.07 0.333 1.09 0.350 1.15 0.357 1.17

26,240 13.3 6 266 7 by 38 84 125 0.411 1.35 0.419 1.38 0.441 1.45 0.450 1.48

20,820 10.5 7 210 7 by 30 66 98 0.518 1.70 0.528 1.73 0.556 1.82 0.567 1.86

16,510 8.37 8 168 7 by 24 53 79 0.653 2.14 0.666 2.19 0.701 2.30 0.715 2.35

13,090 6.63 9 133 7 by 19 42 62 0.824 2.70 0.840 2.76 0.885 2.90 0.902 2.96

A

The constructions shown in this table are typical of those used in the industry. It is not intended that this table preclude other constructions which may be desirable for specific applications. The constructions shown

provide for finished covered or non-covered stranded conductor approximately of the area indicated. When specified by the purchaser, the number of strands may be increased to provide additional area to compensate

for draw-down during subsequent processing.

B

Values for the mass of the completed conductor are approximate. The mass values are based upon the standard stranding increments listed in Explanatory Note 6.

C

Strand construction – A by B by C where C is the number of wires in each bunch-stranded member, B is the number of bunch-stranded members which make up each rope stranded member, and A (where used) is

the number of rope-stranded members in the conductor. Where A is not given, the conductor consists of one rope-stranded member. For example, 19 by 7 by 32 indicates a construction consisting of 19 rope-stranded

members each of which consist of 7 bunch-stranded members with 32 wires each.

B172 − 10 (2015)

A

TABLE 3 Construction requirements of Class M Rope-Lay Stranded Copper Conductors Having Bunch Stranded Members

B

Area of Cross Section Wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.