ASTM D6267/D6267M-13(2022)

(Test Method)Standard Test Method for Apparent Viscosity of Hydrocarbon Resins at Elevated Temperatures

Standard Test Method for Apparent Viscosity of Hydrocarbon Resins at Elevated Temperatures

SIGNIFICANCE AND USE

5.1 This test method is used to measure the apparent viscosity of hydrocarbon resins at elevated temperatures. Elevated temperature viscosity values of a hydrocarbon resin may be related to the properties of coatings, adhesives and the like, containing such a resin.

5.2 For hydrocarbon resins, values of apparent viscosity will usually be a function of shear rate under the conditions of test. Although the type of viscometer described in this test method operates under conditions of relatively low shear rate, shear rate depends on the spindle and rotational speed selected for a determination; therefore, comparisons between apparent viscosity values should be made only for measurements made with similar viscometers under conditions of equivalent shear rate.

SCOPE

1.1 This test method covers the determination of the apparent viscosity of hydrocarbon resins having apparent viscosities up to 2,000,000 millipascal seconds (mPa·s) (Note 1) at temperatures up to 300 °C [572 °F].

Note 1: The SI unit of (dynamic) viscosity is the pascal second. The centipoise (cP) is one millipascal second (mPa·s) and is frequently used as a viscosity unit.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6267/D6267M − 13 (Reapproved 2022)

Standard Test Method for

Apparent Viscosity of Hydrocarbon Resins at Elevated

Temperatures

This standard is issued under the fixed designation D6267/D6267M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the appar-

3.1 The definitions in Terminology D6440 are applicable to

ent viscosity of hydrocarbon resins having apparent viscosities

this test method.

up to 2,000,000 millipascal seconds (mPa·s) (Note 1)at

3.2 Definition Specific to This Standard:

temperatures up to 300 °C [572 °F].

3.3 apparent viscosity, n—of a hydrocarbon resin, the vis-

NOTE 1—The SI unit of (dynamic) viscosity is the pascal second. The

cosity determined by this test method, expressed in millipascal

centipoise (cP) is one millipascal second (mPa·s) and is frequently used as

seconds.

a viscosity unit.

3.3.1 Discussion—Its value may vary with the spindle and

1.2 The values stated in either SI units or inch-pound units

rotational speed selected.

are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to

4. Summary of Test Method

ensure conformance with the standard, each system shall be

4.1 The viscometer described in this test method can be

used independently of the other, and values from the two

used to determine the apparent viscosity of hydrocarbon resins

systems shall not be combined.

at elevated temperatures. Apparent viscosity is determined

1.3 This standard does not purport to address all of the

under temperature equilibrium conditions using a rotating

safety concerns, if any, associated with its use. It is the

spindle type viscometer. The torque on a spindle rotating in a

responsibility of the user of this standard to establish appro-

thermostatted sample holder containing a small amount of

priate safety, health, and environmental practices and deter-

sample is used to measure the relative resistance to rotation.A

mine the applicability of regulatory limitations prior to use.

factor is applied to the torque reading to yield the viscosity in

1.4 This international standard was developed in accor-

mPa·s.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.1 This test method is used to measure the apparent

Barriers to Trade (TBT) Committee.

viscosity of hydrocarbon resins at elevated temperatures.

Elevated temperature viscosity values of a hydrocarbon resin

2. Referenced Documents

may be related to the properties of coatings, adhesives and the

like, containing such a resin.

2.1 ASTM Standards:

D6440 Terminology Relating to Hydrocarbon Resins

5.2 For hydrocarbon resins, values of apparent viscosity

E691 Practice for Conducting an Interlaboratory Study to

will usually be a function of shear rate under the conditions of

Determine the Precision of a Test Method

test. Although the type of viscometer described in this test

E1 Specification for ASTM Liquid-in-Glass Thermometers

method operates under conditions of relatively low shear rate,

shear rate depends on the spindle and rotational speed selected

for a determination; therefore, comparisons between apparent

This test method is under the jurisdiction of ASTM Committee D01 on Paint

viscosity values should be made only for measurements made

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins.

with similar viscometers under conditions of equivalent shear

Current edition approved Dec. 1, 2022. Published December 2022. Originally

rate.

approved in 1998. Last previous edition approved in 2017 as D6267 – 13 (2017).

DOI: 10.1520/D6267_D6267M-13R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Rotational Viscometer—rotating-spindle type with lev-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. eling stand.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

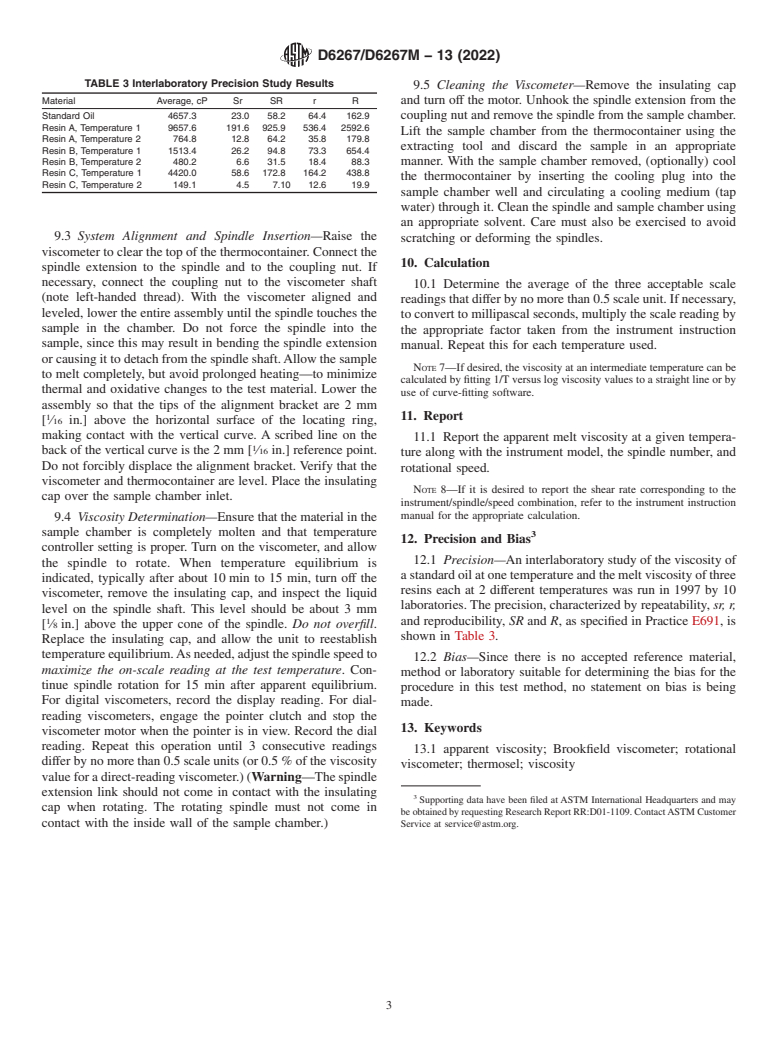

D6267/D6267M − 13 (2022)

TABLE 1 Suitable ASTM Thermometers

6.2 Viscometer Spindles, stainless steel. (Warning—Care

must be taken in the storage and handling of spindles and Scale

Temperature Immersion

Error,

assemblies. Protect them from scratches, dust, corrosion or

Range mm

max

deposits, and mechanical abuse. Replace the spindle extension

90 °C - 170 °C 51 0.2 °C

if it is bent.Avoid touching the calibrated section of the spindle

94 °F - 338 °F 51 0.5 °F

145 °C - 206 °C 76 0.4 °C

with hands. Clean the spindle and sample chamber thoroughly

after each use.Arecommended cleaning procedure is included

in the procedure.)

6.3 Temperature Controller, Thermocontainer (a heater for 8.3.2 Insert the thermometer through the insulating cover of

the sample chamber), and Sample Chamber, designed for use the sample container, into the liquid, and hold it in place at the

with the viscometer in 6.1, complete with locating ring, level required for proper immersion depth. Do not permit the

levelingscrews,safetyguard,spindleextension,insulatingcap, thermometer bulb to rest on the bottom of the sample con-

alignment bracket, cooling plug (optional) and extracting tool. tainer. Adjust the thermal controller set point to provide the

The precision temperature controller shall provide control desired temperature. Repeat this procedure for each test

accuracy of 61.0 °C or better through the range from 100 °C temperature desired.

to150 °C[212 °Fto302 °F]and 62.0 °Corbetterthroughthe

NOTE 3—Particular care must be taken not to overflow the sample

range from 150 °C to 300 °C [302 °F to 572 °F].

chamber when using the 100 °C, 76 mm immersion thermometer, since

the volume of the immersed stem is relatively large.

7. Assembly of Apparatus

7.1 Assemble the apparatus according to the manufacturer’s 9. Procedure

instructions.

9.1 Selection of Spindle—From the estimated viscosity of

the sample and the manufacturer’s instructions, select a vis-

8. Calibration

cometer and spindle combination that will produce readings in

8.1 A digital viscometer should be zeroed according to the

the desired range.

manufacturer’s instructions. For a dial-reading viscometer, no

NOTE 4—Use only spindles appropriate for the viscometer to be used.

zero adjustment is required, since experience has shown that

the zero point will not vary due to changes in the spring.

9.1.1 Wheremorethanonespindleisavailablefortherange

selected, choose the spindle that produces a display or dial

NOTE 2—The viscometer and spindles are precision equipment and

shouldbekeptfromundueshockandmishandling.Physicaldamagetothe

reading between 10 % and 100 % of full scale. The goal is to

instrument will often reveal itself as erratic or no oscillation of the reading

select a combination whose range brackets the estimated

when the instrument, with or without the spindle in place, is operated in

viscosity of the sample.

air. When operating normally, the reading in air will be stable and have

free oscillation about the zero point.

NOTE 5—Accuracy improves as the reading approaches 100 % of full

scale. If the reading is over 100 % of full scale, select a lower speed or a

8.2 The calibration of the instrument may be verified using

smaller spindle, or both. If the reading is under 10 % of full scale, select

standard reference fluids. Suitable fluids are available in

a higher speed or a larger spindle, or both. Whenever possible, when

nominal viscosities up to 15 000 mPa·s at 149 °C [300 °F].The

conducting multiple comparative tests, the same spindle/speed combina-

procedure for instrument calibration using standard reference tion should be used for all tests. When a test must be performed at several

speeds, select a spindle that produces on-scale readings at all required

fluids shall be that described by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.