ASTM D6493-11(2022)

(Test Method)Standard Test Methods for Softening Point of Hydrocarbon Resins and Rosin Based Resins by Automated Ring-and-Ball Apparatus

Standard Test Methods for Softening Point of Hydrocarbon Resins and Rosin Based Resins by Automated Ring-and-Ball Apparatus

SIGNIFICANCE AND USE

4.1 For hydrocarbon resins and rosin based resins, softening does not take place at a definite temperature. As the temperature rises, these materials gradually change from brittle solids or very viscous liquids to less viscous liquids. For this reason, determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results obtained are to be comparable.

SCOPE

1.1 These test methods are intended for determining the softening point of hydrocarbon resins, rosin based resins and similar materials by means of an automated ring-and-ball apparatus. Portions are similar in technical content to the automated-apparatus versions of Test Methods D36, E28, and ISO 4625.

1.1.1 The ring-and-ball softening point of a hydrocarbon resin and rosin based resins may also be determined with lower precision using the manual ring-and-ball softening point procedure in Test Methods E28.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6493 − 11 (Reapproved 2022)

Standard Test Methods for

Softening Point of Hydrocarbon Resins and Rosin Based

Resins by Automated Ring-and-Ball Apparatus

This standard is issued under the fixed designation D6493; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E28 Test Methods for Softening Point of Resins Derived

from Pine Chemicals and Hydrocarbons, by Ring-and-

1.1 These test methods are intended for determining the

Ball Apparatus

softening point of hydrocarbon resins, rosin based resins and

E177 Practice for Use of the Terms Precision and Bias in

similar materials by means of an automated ring-and-ball

ASTM Test Methods

apparatus. Portions are similar in technical content to the

E691 Practice for Conducting an Interlaboratory Study to

automated-apparatus versions of Test Methods D36, E28, and

Determine the Precision of a Test Method

ISO 4625.

2.2 ISO Standard:

1.1.1 The ring-and-ball softening point of a hydrocarbon

ISO 4625 Binders for paints and varnishes—Determination

resinandrosinbasedresinsmayalsobedeterminedwithlower

of softening point–Ring-and-ball method

precision using the manual ring-and-ball softening point pro-

cedure in Test Methods E28.

3. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

3.1 These test methods are for the determination of the

standard. The values given in parentheses are for information

softening point—the temperature at which a disk of the resin

only.

held within a horizontal ring is forced downward a distance of

1.3 This standard does not purport to address all of the

25.4 mm (1.00 in.) under the weight of a standard steel ball, as

safety concerns, if any, associated with its use. It is the

the specimen is heated at 5 °C⁄min. in a specified liquid bath.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Significance and Use

mine the applicability of regulatory limitations prior to use.

4.1 For hydrocarbon resins and rosin based resins, softening

1.4 This international standard was developed in accor-

does not take place at a definite temperature. As the tempera-

dance with internationally recognized principles on standard-

ture rises, these materials gradually change from brittle solids

ization established in the Decision on Principles for the

or very viscous liquids to less viscous liquids. For this reason,

Development of International Standards, Guides and Recom-

determination of the softening point must be made by a fixed,

mendations issued by the World Trade Organization Technical

arbitrary, and closely defined method if the results obtained are

Barriers to Trade (TBT) Committee.

to be comparable.

2. Referenced Documents

5. Sample Preparation

2.1 ASTM Standards:

5.1 Preparation of Sample by the Pour Method: This

D36 Test Method for Softening Point of Bitumen (Ring-and-

procedure is suitable for resins that can be heated and poured

Ball Apparatus)

without adverse effect on the softening point.

E1 Specification for ASTM Liquid-in-Glass Thermometers

5.1.1 Select a sample representative of the material to be

tested.The sample should consist of flakes, pastilles, or broken

lumps. Avoid inclusion of finely divided material or dust.

These test methods are under the jurisdiction of ASTM Committee D01 on

5.1.2 Select a quantity of resin having a volume at least

Paint and Related Coatings, Materials, and Applications and are the direct

twice that necessary to fill the desired number of rings, and

responsibility of Subcommittee D01.34 on Pine Chemicals and Hydrocarbon

Resins.

melt it in a clean container, using an oven, hot plate, sand bath

Current edition approved Dec. 1, 2022. Published December 2022. Originally

or oil bath to prevent local overheating. If necessary, stir

approved in 1999. Last previous edition approved in 2015 as D6493 – 11 (2015).

slowly, taking care to avoid incorporating air bubbles in the

DOI: 10.1520/D6493-11R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6493 − 11 (2022)

sample. Melt the sample completely, but do not heat it above a 5.3 Preparation of Samples Having a Low Softening Point

temperature necessary to pour the material readily. The time (up to 35°C (95°F)):

from the beginning of heating to pouring should not exceed

5.3.1 Place a ring on a piece of aluminum foil. Pour the

15 min.

material to be tested into the ring, then place the foil and the

5.1.3 Formaterialsthattendtocrackorshrinkintheringon

filled ring on dry ice or in a freezer to cool. The material in the

cooling, immediately before filling the ring, preheat the ring to

ring must be free of bubbles.

approximately the temperature at which the material is to be

5.3.2 After cooling, cut and scrape off any excess material

poured. The ring, while being filled, should rest bottom down

using a slightly heated spatula, then slide the ring gently from

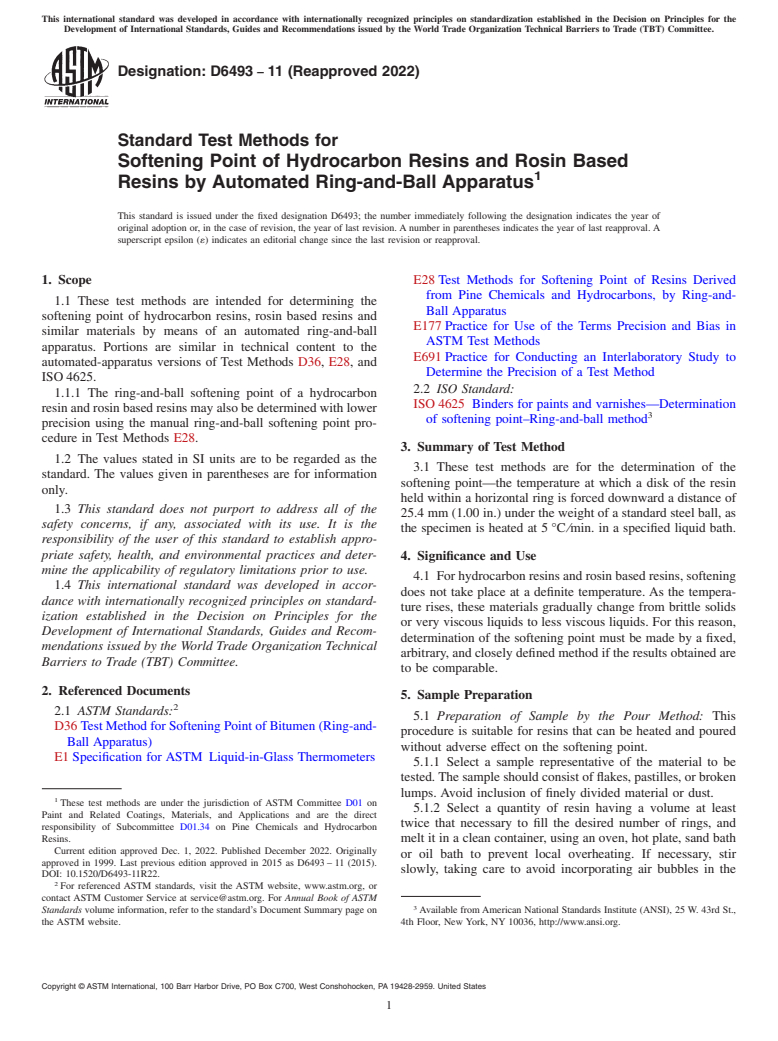

(see Fig. 1(a)) on a suitable metal surface. Pour the sample into

thefoil.Placetheringinthesupportingapparatus,andperform

the ring so as to leave an excess on cooling. After cooling a

the softening point determination in accordance with Section

minimum of 30 min, trim off the excess resin from the top and

12.

outsideofthering.Toremoveexcessresinfromthetop,cutthe

excess off cleanly with a heated knife or spatula, or grasp the

6. Apparatus

ring in a pair of tongs and draw the top surface quickly and

firmly over the surface of a heated plate.

6.1 Automated Ring-and-Ball Softening Point Instrument,

NOTE 1—If the determination is repeated, us a clean container and a having a test assembly consisting of: a ring holder, a metal

fresh sample.

plate, and a cover mounted on two support rods (see Fig. 1(b)

and (d)), a built in digital temperature that should be standard-

5.2 Preparation of Sample by the Powder Method: This

ized periodically to ensure that it meets the specifications for

procedure is suitable for high softening-point materials that

cannot be heated and poured without adverse effects on the and gives the same readings as thermometers given in Speci-

fication E1, a digital temperature display, a heating unit and a

softening point. See Appendix X1.1, Alternate Sample Prepa-

ration Procedures. heating-rate controller.

FIG. 1 Shouldered Ring, Ring Holder, Ball-Centering Guide, and Assembly of Apparatus

D6493 − 11 (2022)

6.2 Ring—A brass, shouldered ring conforming to the di- 8. Calibration

mensions shown in Fig. 1(a).

8.1 The calibration of any automated ring and ball softening

point apparatus must be performed on a regular basis, since

6.3 Ball—A steel ball, 9.53 mm 6 0.1 mm ( ⁄8 in.) in

accurate temperature control is required. Follow the manufac-

diameter, weighing between 3.45 g and 3.55 g.

turer’s instructions for calibration of the instrument.

6.4 Ball-Centering Guide (optional), having the dimensions

given in Fig. 1(c). 9. Procedure for Materials Having a Softening Point

Between 35 °C (95 °F) and <80 °C (176 °F)

6.5 Beaker, 600 mL, borosilicate glass, to hold the bath

9.1 Add a stir bar or stirrer to the 600 mL beaker. Add

liquid. ensure that the dimensions will properly fit the heating

approximately 500 mL of water, conforming to the require-

unit.

ments in 7.1.1. Ensure that the beaker is properly positioned on

6.6 Stirrer—Eitheramagneticstirringmotorandamagnetic

the heater in the test unit. Place the prepared sample rings in

stir bar, or a direct-driven agitator with a stirring motor. The

the test assembly. Place a ball-centering guide and ball on top

dimensions of a stir bar must be such that the bar spins freely

of each sample ring. Place the test assembly in the beaker.

under the test assembly. The bath must be stirred at a speed

Place the temperature-measuring device in the opening in the

sufficient to ensure uniform temperature distribution without

cover of the test assembly. Verify that the control unit is set for

causing significant sideways displacement of the resin as it

the correct bath liquid.

sags below the ring.

9.2 Heat the bath so that the temperature of the water is

raised uniformly at a rate of 5 °C (10 °F)⁄min. Protect the bath

7. Reagents and Materials

from drafts, using shields if necessary. Reject any test in which

7.1 Bath Liquids:

the rate of temperature rise does not fall within these limits.

7.1.1 Distilled or Deionized Water, Freshly Boiled—For The test is complete when the light beam has been interrupted

softening points between 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.