ASTM D6579-11(2020)

(Practice)Standard Practice for Molecular Weight Averages and Molecular Weight Distribution of Hydrocarbon, Rosin and Terpene Resins by Size-Exclusion Chromatography

Standard Practice for Molecular Weight Averages and Molecular Weight Distribution of Hydrocarbon, Rosin and Terpene Resins by Size-Exclusion Chromatography

SIGNIFICANCE AND USE

5.1 The MW averages and the MWD are important characteristics of a resin. They may be used for a variety of correlations for fundamental studies, processing, or product applications. The MW and MWD values may also be used for production quality control of resins.

5.2 Limitations—Comparison of SEC molecular weight values should be made only if the data were obtained under identical chromatographic conditions.

SCOPE

1.1 This practice covers the determination of apparent molecular weight (MW) averages and molecular weight distributions (MWD) for THF-soluble hydrocarbon, rosin and terpene resins by size-exclusion chromatography (SEC). This technique is not absolute; it requires calibration with standards of known molecular weight. This practice is applicable to resins containing molecular-weight components that have elution volumes falling within the elution volume range defined by polystyrene standards.

Note 1: SEC is also known as gel permeation chromatography (GPC).

1.2 SEC systems employ low-volume liquid chromatography components and columns packed with relatively small (generally 3 to 20 μm) microporous particles. High-performance liquid chromatography instrumentation and automated data handling systems for data acquisition and processing are also required.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6579 − 11 (Reapproved 2020)

Standard Practice for

Molecular Weight Averages and Molecular Weight

Distribution of Hydrocarbon, Rosin and Terpene Resins by

Size-Exclusion Chromatography

This standard is issued under the fixed designation D6579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers the determination of apparent

D804Terminology Relating to Pine Chemicals, Including

molecular weight (MW) averages and molecular weight distri-

Tall Oil and Related Products

butions (MWD) for THF-soluble hydrocarbon, rosin and ter-

D3016Practice for Use of Liquid Exclusion Chromatogra-

pene resins by size-exclusion chromatography (SEC). This

phy Terms and Relationships

technique is not absolute; it requires calibration with standards

D6440Terminology Relating to Hydrocarbon Resins

of known molecular weight. This practice is applicable to

resins containing molecular-weight components that have elu-

3. Terminology

tion volumes falling within the elution volume range defined

3.1 For definitions of size-exclusion chromatography terms,

by polystyrene standards.

see Practice D3016.

NOTE1—SECisalsoknownasgelpermeationchromatography(GPC).

3.2 For definition of terpene resin, see Terminology D804.

1.2 SEC systems employ low-volume liquid chromatogra-

3.3 For definitions of resin terms, see Terminology D6440.

phy components and columns packed with relatively small

(generally 3 to 20 µm) microporous particles. High-

4. Summary of Practice

performance liquid chromatography instrumentation and auto-

4.1 Inthispractice,adilutesolutionofahydrocarbon,rosin

mated data handling systems for data acquisition and process-

or terpene resin sample is injected into a liquid mobile phase

ing are also required.

containing the same solvent used to prepare the resin solution.

The mobile phase transports the resin into and through a

1.3 The values stated in SI units are to be regarded as the

chromatography column (or set of columns connected in

standard. The values given in parentheses are for information

series) packed with a rigid or semirigid, porous substrate that

only.

separates the molecules according to their size in solution. A

1.4 This standard does not purport to address all of the

detectormonitorstheeluateasafunctionofelutionvolume(or

safety concerns, if any, associated with its use. It is the

time). Upon emerging from the column(s), the fractions of

responsibility of the user of this standard to establish appro-

size-separated molecules are detected and their elution vol-

priate safety, health, and environmental practices and deter-

umes (or times) and (usually) concentrations recorded.

mine the applicability of regulatory limitations prior to use.

Through calibration, the elution volumes (or times) are con-

1.5 This international standard was developed in accor-

verted to apparent molecular weights, and various molecular

dance with internationally recognized principles on standard-

weight parameters for the sample resin are calculated from the

ization established in the Decision on Principles for the

molecular weight/concentration data.

Development of International Standards, Guides and Recom-

5. Significance and Use

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5.1 The MW averages and the MWD are important charac-

teristics of a resin. They may be used for a variety of

correlations for fundamental studies, processing, or product

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2020.PublishedJuly2020.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2000. Last previous edition approved in 2015 as D6579–11 (2015). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6579-11R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6579 − 11 (2020)

applications. The MW and MWD values may also be used for distort the concentration gradient in the emerging stream. This

production quality control of resins. requirement imposes severe limitations on the volume of

solution available for detection. For example, use of detectors

5.2 Limitations—ComparisonofSECmolecularweightval-

with cell volumes greater than 15 µL generally will not be

ues should be made only if the data were obtained under

acceptable for this practice. A differential refractometer has

identical chromatographic conditions.

moderate sensitivity and general utility.The differential refrac-

tometer provides a signal proportional to the difference in

6. Apparatus

refractive index (RI) between the solvent and the column

6.1 Solvent Reservoir—The solvent reservoir must hold

eluate. The detector should respond to a change of no more

sufficient solvent to ensure consistency of composition for a

–7 –8

than10 to10 RIunitandhaveacellvolume≤10µL.Other

number of analyses. The reservoir should isolate the solvent

types of detectors may be used.

from the atmosphere, permit control of the environment in

contact with the solvent, and be inert to the solvent employed. NOTE 3—The principal disadvantage of the differential refractometer is

that precise control of temperature, pressure, and flow rate is required to

Some means of agitation (for example, magnetic stirring) is

maintain a stable signal for an appropriate level of sensitivity. For

recommended to ensure uniform composition.

–4

example, most organic liquids have a temperature coefficient of 10 RI

units per K. Consequently, the temperature within the RI detector cell

6.2 Solvent Pumping System—The principal requirement of

–4

must be controlled to within 10 °C.

the pumping system is production of a relatively constant and

pulseless flow of solvent through the columns. In general, the 6.6 Tubing and Fittings—All tubing between the sample

rate of flow should be adjustable between 0.1 and 5.0 mL/min, injector and the detector should be no greater than 0.25 mm

and back pressures should not exceed limits specified by the (0.010 in.) in internal diameter and of sufficient thickness for

column manufacturer. If the elution volume is not being use at pressures up to 42 MPa. Connecting tubing should be

measured directly or corrected for systematic changes, the kept as short as possible, and all fittings and connectors must

precision in the flow rate must be at least 60.3% under the

be designed to prevent backmixing and to have low dead

conditions and over the time interval required for running a volumes.

typical analysis.

6.7 Data Handling Systems—Means must be provided for

6.3 Sample Injector—The purpose of an injection system is determining chromatographic peak heights or integrated area

to generate a sharply defined zone of solution containing the

segments at prescribed intervals under the chromatogram and

resin when introducing the resin into the flow stream. A for handling and reporting the data. This can best be accom-

valve-and-loop assembly or any of a number of commercially

plished by means of a computer or a real-time data acquisition

available high-performance liquid chromatography automatic system with either off-line or on-line data processing.

injection systems can be used for this purpose. It is required

NOTE4—DataacquisitionandhandlingsystemsforSEChavenotbeen

that contribution to band spreading be minimal and that the

standardized. However, a number of manufacturers provide chromatogra-

injectorbeabletooperateatthebackpressuregeneratedbythe

phy data systems that include SEC software. Also, some users have

developed their own specialized software.

columns.

6.8 Recorder/Plotter (Optional)—Either a recording poten-

6.4 Columns—Stainless steel columns with uniform and

tiometer or a printing device connected to a data handling

highly polished inside walls should be used. Columns with

system may be used to plot the chromatographic data. Pen

lengths ranging from 15 to 50 cm, plus special end fittings,

response and signal-to-noise ratio should be chosen so that the

frits, and connectors designed to minimize dead volume and

concentration signal is not appreciably perturbed.

back-mixing are recommended. Micro-particulate, semirigid

organic gels, and rigid, solid, porous packing materials are

6.9 Other Components (Optional)—Special solvent line

used for SEC. Generally, the packing materials have narrow

filters, pressure monitors, pulse dampers, flowmeters, thermo-

particle size distributions, with particle sizes in the range from

stated ovens, syphon counters, plotters, raw data storage

3 to 20 µm. Packing materials are available in a variety of

systems,software,andsoforth,areoftenincorporatedwiththe

shapes and pore sizes. Columns may be packed with particles

essential components previously listed.

of relatively uniform pore size or with a “mixed bed” of

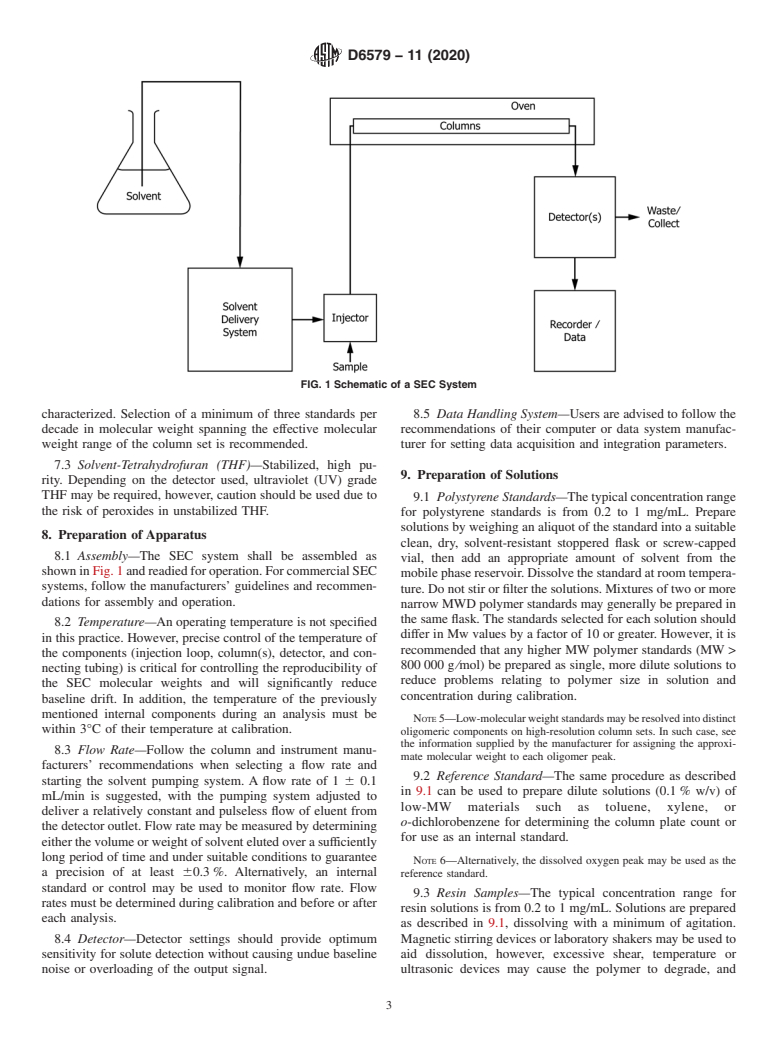

6.10 The interrelationships of the components are shown

particles to produce a broad range of pore sizes for polymer

schematicallyinFig.1.Useofadegasserlocatedinthesolvent

separation. If a set of columns is used, it is recommended that

reservoir or between the reservoir and pumping system is

the columns be connected, starting from the injector outlet,

recommended to remove air from the solvent.

from columns having the smallest to those having the largest

6.11 Analytical Balance, sensitive to 60.0001 g.

packing pore size.

NOTE 2—Select the number of columns and pore sizes based on the

7. Reagents and Materials

molecular weight range of the resins being analyzed, and on the degree of

7.1 Low-MW Standards—Low-MW compounds, such as

resolution required.

toluene, xylene, or o-dichlorobenzene, that are used for deter-

6.5 Detectors—The purpose of the detector is to continu-

mining plate count, or as internal standards, must be of high

ously monitor the concentration of solute eluting from the

purity.

chromatographic column(s). Consequently, the detector must

be sufficiently sensitive and respond linearly to the solute 7.2 Polystyrene Standards—Unimodal, narrow, MW stan-

concentration. Additionally, the detector must not appreciably dards that bracket the desired range of the resins being

D6579 − 11 (2020)

FIG. 1 Schematic of a SEC System

characterized. Selection of a minimum of three standards per 8.5 Data Handling System—Users are advised to follow the

decade in molecular weight spanning the effective molecular recommendations of their computer or data system manufac-

weight range of the column set is recommended. turer for setting data acquisition and integration parameters.

7.3 Solvent-Tetrahydrofuran (THF)—Stabilized, high pu-

9. Preparation of Solutions

rity. Depending on the detector used, ultraviolet (UV) grade

THF may be required, however, caution should be used due to

9.1 PolystyreneStandards—Thetypicalconcentrationrange

the risk of peroxides in unstabilized THF.

for polystyrene standards is from 0.2 to 1 mg/mL. Prepare

solutions by weighing an aliquot of the standard into a suitable

8. Preparation of Apparatus

clean, dry, solvent-resistant stoppered flask or screw-capped

8.1 Assembly—The SEC system shall be assembled as

vial, then add an appropriate amount of solvent from the

showninFig.1andreadiedforoperation.ForcommercialSEC

mobilephasereservoir.Dissolvethestandardatroomtempera-

systems, follow the manufacturers’ guidelines and recommen-

ture.Donotstirorfilterthesolutions.Mixturesoftwoormore

dations for assembly and operation.

narrowMWDpolymerstandardsmaygenerallybepreparedin

the same flask.The standards selected for each solution should

8.2 Temperature—An operating temperature is not specified

differ in Mw values by a factor of 10 or greater. However, it is

in this practice. However, precise control of the temperature of

recommended that any higher MW polymer standards (MW >

the components (injection loop, column(s), detector, and con-

800000 g⁄mol) be prepared as single, more dilute solutions to

necting tubing) is critical for controlling the reproducibility of

reduce problems relating to polymer size in solution and

the SEC molecular weights and will significantly reduce

concentration during calibration.

baseline drift. In addition, the temperature of the previously

mentioned internal components during an analysis must be

NOTE5—Low-molecularweightstandardsmayberesolvedintodistinct

within 3°C of their temperature at calibration.

oligomeric components on high-resolution column sets. In such case, see

the information supplied by the manufacturer for assigning the approxi-

8.3 Flow Rate—Follow the column and instrument manu-

mate molecular weight to each oligomer peak.

facturers’ recommendations when selecting a flow rate and

9.2 Reference Standard—The same procedure as described

starting the solvent pumping system. A flow rate of 1 6 0.1

in 9.1 can be used to prepare dilute solutions (0.1% w/v) of

mL/min is suggested, with the pumping system adjusted to

low-MW materials such as toluene, xylene, or

deliver a relatively constant and pulseless flow of eluent from

o-dichlorobenzene for determining the column plate count or

the detector outlet. Flow rate may be measured by determining

for use as an internal standard.

eitherthevolumeorweightofsolventelutedoverasufficiently

long period of time and under suitable conditions to guarantee

NOTE 6—Alternatively, the dissolved oxygen peak may be used as the

a precision of at least 60.3%. Alternatively, an internal

reference standard.

standard or control may be used to monitor flow rate. Flow

9.3 Resin Samples—The typical concentration range for

rates must be determined during calibration and before or after

resin solutions is from 0.2 to 1 mg/mL. Solutions are prepared

each analysis.

as described in 9.1, dissolving with a minimum of agitation.

8.4 Detector—Detector settings should provide optimum Magnetic stirring devices or laboratory shakers may be used to

sensitivity for solute detection without causing undue baseline aid dissolution, however, excessive shear, temperature or

noise or overloading of the output signal. ultrasoni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.