ASTM D5953M-96

(Test Method)Standard Test Method for Determination of Non-Methane Organic Compounds (NMOC) in Ambient Air Using Cryogenic Preconcentration and Direct Flame Ionization Detection Method (Metric)

Standard Test Method for Determination of Non-Methane Organic Compounds (NMOC) in Ambient Air Using Cryogenic Preconcentration and Direct Flame Ionization Detection Method (Metric)

SCOPE

1.1 This test method covers a procedure for sampling and determining concentrations of non-methane organic compounds (NMOC) in ambient, indoor, or workplace atmospheres.

1.2 The test method describes the collection of cumulative samples in passivated stainless steel canisters and subsequent laboratory analysis.

1.2.1 This test method describes a procedure for sampling in canisters at final pressures above atmospheric pressure (referred to as pressurized sampling).

1.3 This test method employs a cryogenic trapping procedure for concentration of the NMOC prior to analysis.

1.4 This test method describes the determination of the NMOC by the simple flame ionization detector (FID), without the gas chromatographic columns and complex procedures necessary for species separation.

1.5 The range of this test method is from 20 to 10 000 ppbC (1,2). See 13.4 for procedures for lowering the range.

1.6 The test method may yield less accurate results for some halogenated or oxygenated hydrocarbons emitted from nearby sources of industrial air pollutants. This is especially true if there are high concentrations of chlorocarbons or chlorofluorocarbons present.

1.7 The values stated in SI units are regarded as the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5953M – 96 An American National Standard

METRIC

Standard Test Method for

Determination of Non-Methane Organic Compounds (NMOC)

in Ambient Air Using Cryogenic Preconcentration and Direct

Flame Ionization Detection Method (Metric)

This standard is issued under the fixed designation D 5953M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers a procedure for sampling and 2.1 ASTM Standards:

determining concentrations of non-methane organic com- D 1193 Specification for Reagent Water

pounds (NMOC) in ambient, indoor, or workplace atmo- D 1356 Terminology Relating to Sampling and Analysis of

spheres. Atmospheres

1.2 The test method describes the collection of cumulative D 1357 Practice for Planning the Sampling of the Ambient

samples in passivated stainless steel canisters and subsequent Atmosphere

laboratory analysis. D 5466 Test Method for the Determination of Volatile

1.2.1 This test method describes a procedure for sampling in Organic Chemicals in Atmospheres (Canister Sampling

canisters at final pressures above atmospheric pressure (re- Methodology)

ferred to as pressurized sampling).

3. Terminology

1.3 This test method employs a cryogenic trapping proce-

3.1 Definitions— For definitions of terms used in this test

dure for concentration of the NMOC prior to analysis.

1.4 This test method describes the determination of the method, refer to Terminology D 1356.

3.2 Definitions of Terms Specific to This Standard:

NMOC by the simple flame ionization detector (FID), without

the gas chromatographic columns and complex procedures 3.2.1 cryogen—a refrigerant used to obtain very low tem-

peratures in the cryogenic traps of the analytical system.

necessary for species separation.

1.5 The range of this test method is from 20 to 10 000 ppbC 3.2.1.1 Discussion—Liquid argon (bp − 185.7°C at stan-

dard pressure) is recommended for this test method. Cryogens

(1, 2). See 13.4 for procedures for lowering the range.

1.6 The test method may yield less accurate results for some with lower boiling points, such as liquid nitrogen, should not

be used because of possible trapping of oxygen from the

halogenated or oxygenated hydrocarbons emitted from nearby

sources of industrial air pollutants. This is especially true if sample air, which might lead to the possibility of an explosion

or fire. In addition, methane would be trapped.

there are high concentrations of chlorocarbons or chlorofluo-

rocarbons present. 3.2.2 dynamic calibration—calibration of an analytical sys-

tem with pollutant concentrations that are generated in a

1.7 The values stated in SI units are regarded as the

dynamic, flowing system, such as by quantitative, flow-rate

standard.

1.8 This standard does not purport to address all of the dilution of a high-concentration gas standard with zero gas.

3.2.3 NMOC—non-methane organic compounds.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.2.3.1 Discussion—Total non-methane organic compounds

are those compounds measured by a flame ionization detector,

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. excluding methane and compounds with vapor pressure above

−2

10 kPa, recovered from the canister.

3.2.4 ppm C and ppb C—concentration units of parts per

This test method is under the jurisdiction of ASTM Committee D-22 on

million and parts per billion of organic carbon as detected by

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom-

mittee D22.03 on Ambient Atmospheres and Source Emissions.

the FID.

Current edition approved May 10, 1996. Published July 1996.

3.2.4.1 Discussion—During calibration with propane, for

This test method is based on EPA Method TO-12: “Determination of Non-

example, they are equivalent to parts per million by volume

Methane Organic Compounds (NMOC) in Ambient Air Using Cryogenic Pre-

(ppm (v)) or parts per billion by volume (ppb (v)), respectively,

Concentration and Direct Flame Ionization Detection (PDFID)”, Compendium of

Methods for the Determination of Toxic Organic Compounds in Ambient Air ,EPA

multiplied by the number of carbon atoms in propane.

600 4-89-017, U.S. Environmental Protection Agency, Research Triangle Park, NC,

March 1990.

3 4

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 11.01.

this standard. Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5953M

4. Summary of Test Method (2-6) 5.3 Conventional test methods that depend on gas chroma-

tography and qualitative and quantitative species evaluation are

4.1 An air sample is extracted directly from the ambient air,

excessively difficult and expensive to operate and maintain

collected in a precleaned sample canister and transported to a

when speciated measurements are not needed. The test method

laboratory.

described here involves a simple, cryogenic preconcentration

4.2 A fixed-volume portion of the sample air is drawn from

procedure with subsequent direct detection with the FID. The

the canister at a low flow rate through a glass-bead filled trap

test method is sensitive and provides accurate measurements of

that is cooled to approximately −186°C with liquid argon. The

ambient total NMOC concentrations where speciated data are

cryogenic trap simultaneously collects and concentrates the

not required.

NMOC using condensation, while allowing the nitrogen,

5.4 An application of the test method is the monitoring of

oxygen, methane, and other compounds with boiling points

the cleanliness of canisters.

below −186°C to pass through the trap without retention. The

5.5 Another use of the test method is the screening of

system is dynamically calibrated so that the volume of sample

canister samples prior to analysis.

passing through the trap does not have to be quantitatively

5.6 Collection of ambient air samples in pressurized canis-

measured, but must be precisely repeatable between the cali-

ters provides the following advantages:

bration and the analytical phases.

5.6.1 Convenient integration of ambient samples over a

4.3 After the fixed-volume air sample has been drawn

specific time period,

through the trap, a helium carrier gas flow is diverted to pass

5.6.2 Capability of remote sampling with subsequent central

through the trap, in the opposite direction to the sample flow,

laboratory analysis,

and into an FID. When the residual air and methane have been

5.6.3 Ability to ship and store samples, if necessary,

flushed from the trap and the FID baseline restabilizes, the

5.6.4 Unattended sample collection,

cryogen is removed and the temperature of the trap is raised to

5.6.5 Analysis of samples from multiple sites with one

80 to 90°C.

analytical system,

4.4 The organic compounds previously collected in the trap

5.6.6 Collection of replicate samples for assessment of

revolatilize due to the increase in temperature and are carried

measurement precision, and

into the FID, resulting in a response peak or peaks from the

5.6.7 Specific hydrocarbon analysis can be performed with

FID. The area of the peak or peaks is integrated, and the

the same sample system.

integrated value is translated to concentration units using a

previously obtained calibration curve relating integrated peak

6. Interferences

areas with known concentrations of propane.

6.1 In laboratory evaluations, moisture in the sample has

4.5 The cryogenic trap simultaneously concentrates the

been found to cause a positive shift in the FID baseline. The

NMOC while separating and removing the methane from air

effect of this shift is minimized by carefully selecting the

samples. The technique is thus direct reading using FID for

integration termination point and adjusting the baseline used

NMOC and, because of the concentration step, it is more

for calculating the area of the NMOC peaks.

sensitive than conventional continuous NMOC analyzers.

6.2 With helium as a carrier gas, FID response is quite

4.6 The sample is injected into the hydrogen-rich flame of

uniform for most hydrocarbon compounds, but the response

the FID, where the organic vapors burn, producing ionized

can vary considerably for other types of organic compounds.

molecular fragments. The resulting ion fragments are then

collected and detected. Because this test method employs a

7. Apparatus

helium carrier gas, the detector response is nearly identical for

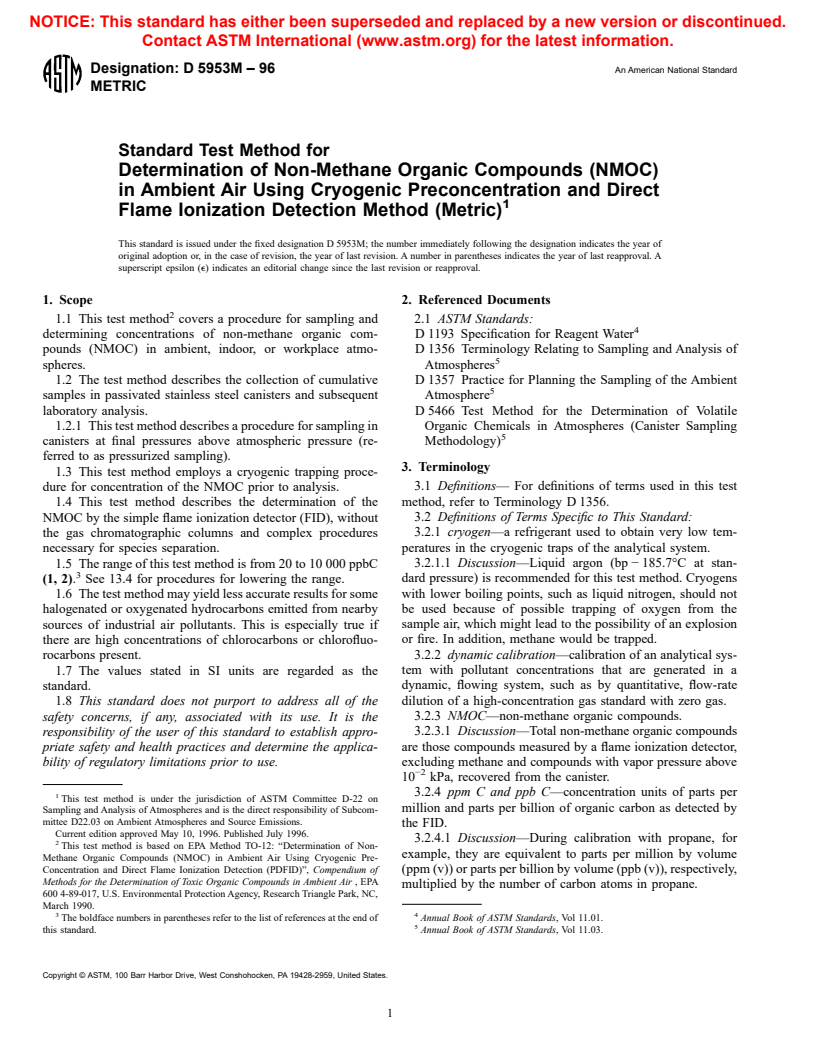

7.1 Sample Collection System, (Fig. 1).

many hydrocarbon compounds of interest. Thus, the historical

7.1.1 Sample Canister(s), stainless steel, Summa -polished

short-coming of varying FID response to aromatic, olefinic,

vessel(s) of 4 to 6 L capacity, used for automatic collection of

and paraffinic hydrocarbons is minimized. The FID is much

integrated field air samples.

less sensitive to most organic compounds containing functional

7.1.1.1 Mark each canister with a unique identification

groups such as carbonyls, alcohols, halocarbons, etc.

number stamped on its frame.

7.1.2 Sample Pump, stainless steel, metal bellows type.

5. Significance and Use

7.1.2.1 Ensure that the pump is free of leaks, and uncon-

5.1 Many industrial processes require determination of

taminated by oil or organic compounds.

NMOC in the atmosphere.

7.1.2.2 Shock mount the pump to minimize vibration.

5.2 Accurate measurements of ambient concentrations of

7.1.3 Pressure Gage, 0 to 210 kPa (0 to 30 psig).

NMOC are important for the control of photochemical smog

7.1.4 Solenoid Valve, controls the sample flow to the canis-

because these organic compounds are primary precursors of

ter with negligible temperature rise.

atmospheric ozone and other oxidants (7, 8).

7.1.5 Flow Control Device, mass flowmeter, critical orifice,

5.2.1 The NMOC concentrations typically found at urban

or short capillary to maintain the sample flow over the

sites may range up to 1 to 3 ppm C or higher. In order to

sampling period.

determine transport of precursors into an area, measurement of

NMOC upwind of the area may be necessary. Rural NMOC

concentrations originating from areas free from NMOC

The Summa process is a trademark of Molectrics, Inc., 4000 E. 89th St.,

sources are likely to be less than a few tenths of 1 ppm C. Cleveland, OH 44105.

D 5953M

taining a stable flame throughout all phases of the analytical

cycle.

7.3.2 Data Reduction Device, such as a computer, equipped

with data acquisition hardware and software and a laser printer,

or an electronic integrator, with chart recorder, capable of

integrating the area of one or more FID response peaks and

calculating peak area corrected for baseline drift.

7.3.2.1 If a separate integrator and chart recorder are used,

exercise care to ensure that these components do not interfere

with each other electrically or electronically.

7.3.2.2 Range selector controls on both the integrator and

the FID analyzer may not provide accurate range ratios, so

prepare individual calibration curves for each range.

7.3.2.3 The integrator must be capable of marking the

beginning and ending of peaks, constructing the appropriate

baseline between the start and end of the integration period,

and calculating the peak area.

FIG. 1 Sample System for Automatic Collection of Integrated Air

7.3.3 Cryogenic Trap, constructed from a single piece of

Samples

chromatographic-grade stainless steel tubing (3 mm outside

diameter, 2 mm inside diameter), as shown in Fig. 4.

7.3.3.1 Pack the central portion of the trap (70 to 100 mm)

7.1.6 Particulate Matter Filter, inert in-line filter, 2μ m or

with silanized 180 to 250 μm (60/80 mesh) glass beads, with

less, or other suitable filter, used to filter the air sample.

small silanized glass wool plugs, to retain the beads.

7.1.7 Auxiliary Vacuum Pump or Blower, draws sample air

7.3.3.2 The arms of the trap must be of such length to permit

through the sample inlet line to reduce inlet residence time to

the beaded portion of the trap to be submerged below the level

no greater than 10 s.

of cryogen in the Dewar flask.

7.1.7.1 Shock mount the pump to minimize vibration.

7.3.3.3 Connect the trap directly to the six-port valve (7.3.4)

7.1.8 Timer, programmable, and electrically connected to

to minimize the line length between the trap (7.3.3) and the

the solenoid valve (7.1.4) and pumps (7.1.2 and 7.1.7), capable

FID (7.3.1).

of controlling the pumps and the solenoid valve.

7.3.3.4 Mount the trap to allow clearance so the Dewar flask

7.1.9 Sample Inlet Line, transports the sample air into the

may be applied and withdrawn to facilitate cooling and heating

sample system, consisting of stainless steel tubing components.

the trap (see 7.3.12).

7.2 Sample Canister Cleaning System, (Fig. 2).

7.3.4 Six-Port Valve— Locate the six-port valve and as

7.2.1 Vacuum Pump, capable of evacuating sample canis-

much of the interconnecting tubing as practical inside an oven

ter(s) to an absolute pressure of # 2 Pa (15 μm Hg).

or otherwise heat it to 80 to 90°C to minimize wall losses or

7.2.2 Manifold, stainless steel manifold with connections

adsorption/desorption in the connecting tubing. All lines must

for simultaneously cleaning several canisters.

be as short as practical.

7.2.3 Shut-off Valve(s), nine required.

7.3.5 Multistage Pressure Regulators (3 required), standard

7.2.4 Pressure Gage, 0 to 350 kPa (0 to 50 psig)–monitors

two-stage, stainless steel diaphragm regulators with pressure

zero-air pressure.

gages, for helium, air, and hydrogen cylinders.

7.2.5 Cryogenic Trap (2 required), U-shaped open tubular

7.3.6 Auxilliary Flow or Pressure Regulators (2 required),

trap cooled with liquid argon used to prevent contamination

to maintain constant flow rates, within 1 mL/min for the helium

from back diffusion of oil from vacuum pump, and providing

carrier and the hydrogen.

clean, zero-air to the sample canister(s).

7.3.7 Fine Needle Valve (2 required)—One adjusts the

7.2.6 Vacuum Gage, capable of measuring vacuum in the

sample flow rate through the trap, and the other adjusts the

manifold to an absolute pressure of 15 Pa (0.1 mm Hg) or less,

sample flow rate from the canister.

with scale divisions of 0.1 Pa (0.5 μm Hg).

7.3.8 Dewar Flask, holds cryogen used to cool the trap,

7.2.7 Flow Control Valve, regulates flow of zero-air into the

sized to contain the submerged portion of the trap.

canister(s).

7.3.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.