ASTM D3387-83(2003)

(Test Method)Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM)

Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM)

SCOPE

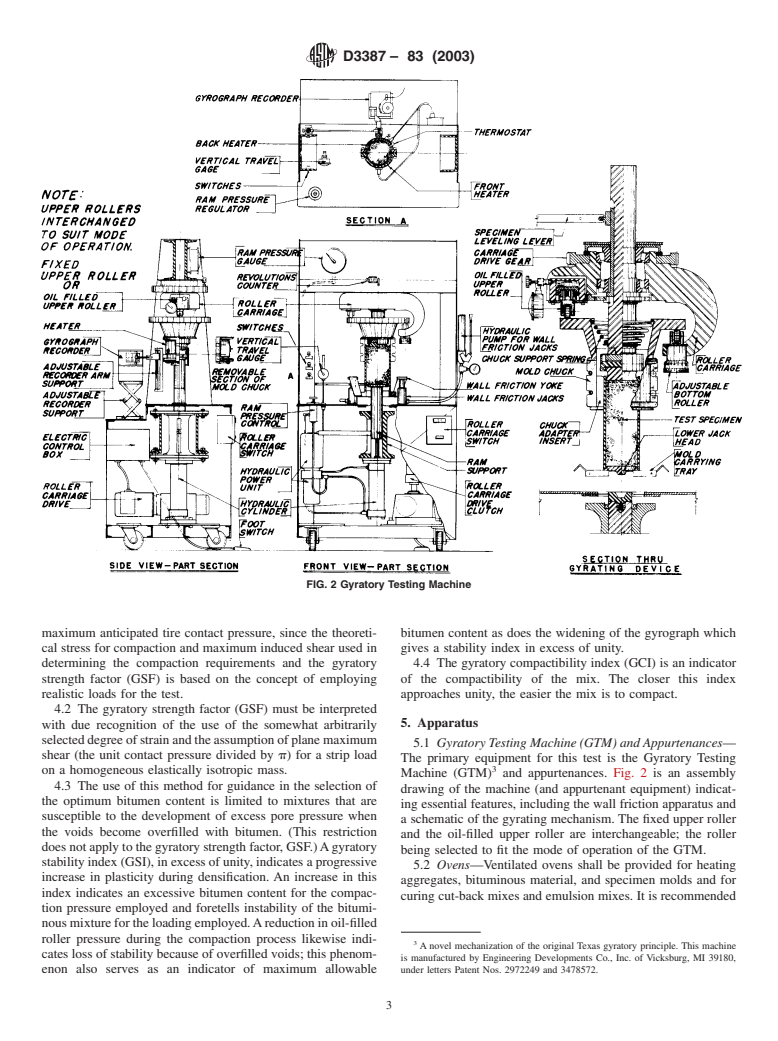

1.1 This test method covers two separate modes of operation of the Gyratory Testing Machine (GTM), namely: (1) GTM fixed roller mode; and (2) GTM oil-filled roller mode. The fixed roller mode of operation is employed in testing for compaction and strain indices only, while the oil-filled roller mode of operation is employed in testing for strength properties as well as compaction and strain indices. This test method is for use with mixtures containing asphalt cement, asphalt cut-back, asphalt emulsion, or tar and aggregate up to 1 in. (25.4 mm) maximum size in the 4-in. (101.6-mm) diameter specimen and 1.5 in. (38.1 mm) maximum size in the 6-in. (152.4-mm) diameter specimen.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3387– 83(Reapproved 2003)

Standard Test Method for

Compaction and Shear Properties of Bituminous Mixtures

by Means of the U.S. Corps of Engineers Gyratory Testing

1

Machine (GTM)

This standard is issued under the fixed designation D3387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

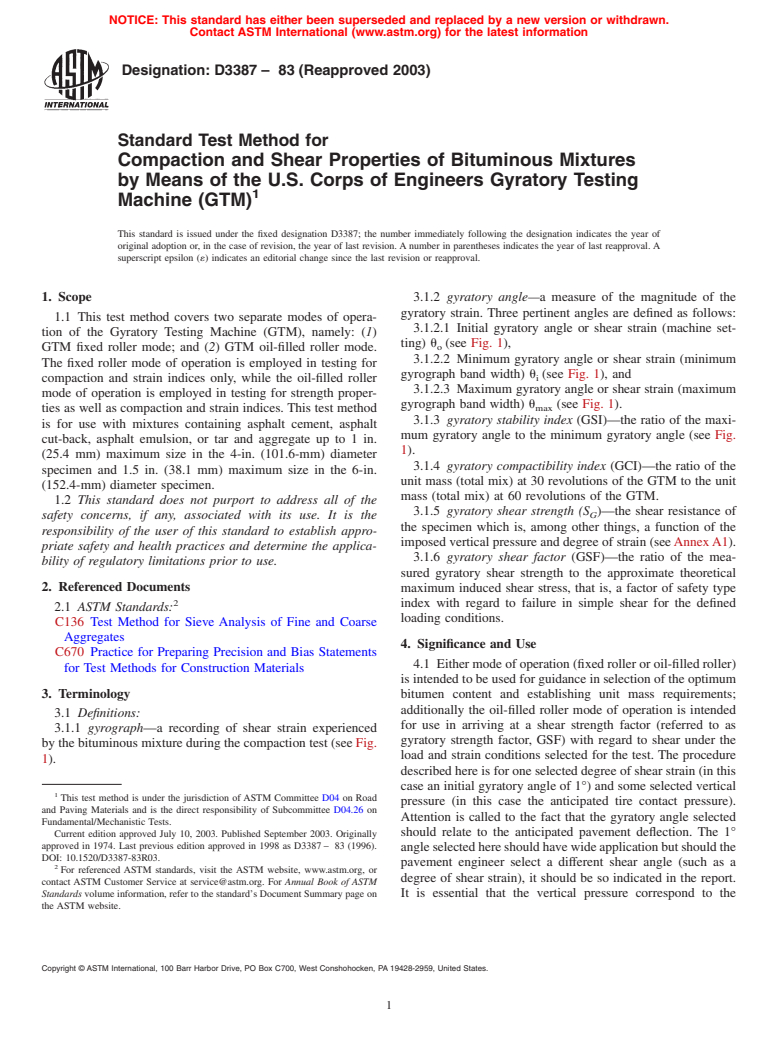

1. Scope 3.1.2 gyratory angle—a measure of the magnitude of the

gyratory strain. Three pertinent angles are defined as follows:

1.1 This test method covers two separate modes of opera-

3.1.2.1 Initial gyratory angle or shear strain (machine set-

tion of the Gyratory Testing Machine (GTM), namely: (1)

ting) u (see Fig. 1),

GTM fixed roller mode; and (2) GTM oil-filled roller mode. o

3.1.2.2 Minimum gyratory angle or shear strain (minimum

The fixed roller mode of operation is employed in testing for

gyrograph band width) u (see Fig. 1), and

compaction and strain indices only, while the oil-filled roller i

3.1.2.3 Maximum gyratory angle or shear strain (maximum

mode of operation is employed in testing for strength proper-

gyrograph band width) u (see Fig. 1).

ties as well as compaction and strain indices. This test method max

3.1.3 gyratory stability index (GSI)—the ratio of the maxi-

is for use with mixtures containing asphalt cement, asphalt

mum gyratory angle to the minimum gyratory angle (see Fig.

cut-back, asphalt emulsion, or tar and aggregate up to 1 in.

1).

(25.4 mm) maximum size in the 4-in. (101.6-mm) diameter

3.1.4 gyratory compactibility index (GCI)—the ratio of the

specimen and 1.5 in. (38.1 mm) maximum size in the 6-in.

unit mass (total mix) at 30 revolutions of the GTM to the unit

(152.4-mm) diameter specimen.

mass (total mix) at 60 revolutions of the GTM.

1.2 This standard does not purport to address all of the

3.1.5 gyratory shear strength (S )—the shear resistance of

G

safety concerns, if any, associated with its use. It is the

the specimen which is, among other things, a function of the

responsibility of the user of this standard to establish appro-

imposed vertical pressure and degree of strain (seeAnnexA1).

priate safety and health practices and determine the applica-

3.1.6 gyratory shear factor (GSF)—the ratio of the mea-

bility of regulatory limitations prior to use.

sured gyratory shear strength to the approximate theoretical

2. Referenced Documents

maximum induced shear stress, that is, a factor of safety type

2

index with regard to failure in simple shear for the defined

2.1 ASTM Standards:

loading conditions.

C136 Test Method for Sieve Analysis of Fine and Coarse

Aggregates

4. Significance and Use

C670 Practice for Preparing Precision and Bias Statements

4.1 Either mode of operation (fixed roller or oil-filled roller)

for Test Methods for Construction Materials

is intended to be used for guidance in selection of the optimum

3. Terminology

bitumen content and establishing unit mass requirements;

additionally the oil-filled roller mode of operation is intended

3.1 Definitions:

for use in arriving at a shear strength factor (referred to as

3.1.1 gyrograph—a recording of shear strain experienced

gyratory strength factor, GSF) with regard to shear under the

by the bituminous mixture during the compaction test (see Fig.

load and strain conditions selected for the test. The procedure

1).

described here is for one selected degree of shear strain (in this

case an initial gyratory angle of 1°) and some selected vertical

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

pressure (in this case the anticipated tire contact pressure).

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

Attention is called to the fact that the gyratory angle selected

Fundamental/Mechanistic Tests.

should relate to the anticipated pavement deflection. The 1°

Current edition approved July 10, 2003. Published September 2003. Originally

approved in 1974. Last previous edition approved in 1998 as D3387 – 83 (1996).

angleselectedhereshouldhavewideapplicationbutshouldthe

DOI: 10.1520/D3387-83R03.

pavement engineer select a different shear angle (such as a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

degree of shear strain), it should be so indicated in the report.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on It is essential that the vertical pressure correspond to the

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.