ASTM F47-94

(Test Method)Test Method for Crystalographic Perfection of Silicon by Preferential Etch Techniques (Withdrawn 1998)

Test Method for Crystalographic Perfection of Silicon by Preferential Etch Techniques (Withdrawn 1998)

General Information

Standards Content (Sample)

~~

H 075951Ö o548375 737

DIN 50434

Designation: F 47 - 94

AMERICAN SOCIETY FOR TESTING AND MATERIALS

4Tb

1916 RaceSt. Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed In the current combined index, will appear in the next eddion.

Standard Test Method for

Crystallographic Perfection of Silicon by Preferential Etch

Techniques?

This standard is issued under the fixed designation F 47; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (0 indicates an editorial change since. the last revision or reapproval.

INTRODUCïION

This test method is valid, but limited in scope and application. A series of task forces has been

established within F 1.06 Section D, to enhance and expand the applicability of this and other

related documents. When the new test method is approved, this test method will be withdrawn.

1. Scope and hazard statements are given in Section 10.

1.1 This test method2 is used to determine whether an

2. Referenced Documents

ingot or piece of silicon is monocrystalline in structure and if

so, the density of dislocations which may be present. Swirls 2.1 ASTM Standards:

and striations may also be delineated. These crystal defects D 1 193 Specification for Reagent Wate9

are described to avoid confusion when counting dislocation E 7 Terminology Relating to Metallography4

etch pits. F 26 Test Methods for Determining the Orientation of a

Semiconductive Single Crystal?

NOTE 1-Test Method F416, although destructive, is preferred for

F 416 Test Method for Detection of Oxidation Induced

detection of oxidation induced defects.

Defects in Polished Silicon Wafers5

1.2 This procedure is suitable for silicon crystals with

2.2 American National Standard:

dislocation densities between O and 100 O00 cm-*.

B74.10 Specification for Grading of Abrasive Microgrits6

1.3 Silicon crystals doped either p or n type and with

2.3 SEMI Standard:

resistivities as low as 0.005 il cm may be evaluated. This test

C1 Specifications for Reagents?

method is applicable for evaluation of silicon crystals grown

3. Terminology

in either a [ 1 1 i] or a [ 1001 direction.

1.4 This test method utilizes a chemical preferential

3.1 Definitions:

etchant to delineate crystallographic defects. Two etchants

3.1.1 The following are definitions of crystallographic

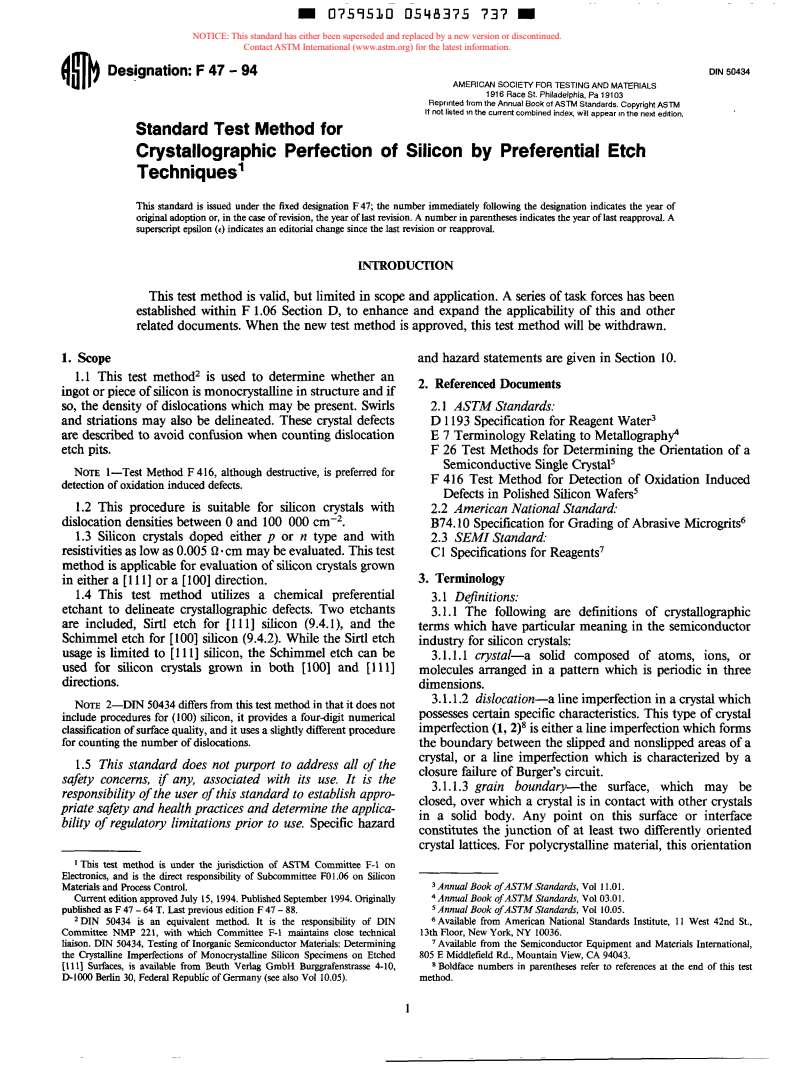

[ 11 i] silicon (9.4.1), and the

are included, Sirtl etch for

terms which have particular meaning in the semiconductor

Schimmel etch for [ 1001 silicon (9.4.2). While the Sirtl etch

industry for silicon crystals:

usage is limited to [ 1 1 i] silicon, the Schimmel etch can be

3.1.1.1 crystal-a solid composed of atoms, ions, or

used for silicon crystals grown in both [lo01 and [ill]

molecules arranged in a pattern which is periodic in three

directions.

dimensions.

3.1.1.2 dislocation-a line imperfection in a crystal which

NOTE 2-DIN 50434 differs from this test method in that it does not

possesses certain specific characteristics. This type of crystal

include procedures for (100) silicon, it provides a fourdigit numerical

imperfection (1, 2)s is either a line imperfection which forms

classification of surface quaiity, and it uses a slightly different procedure

for counting the number of dislocations.

the boundary between the slipped and nonslipped areas of a

crystal, or a line imperfection which is characterized by a

1.5 This standard does not purport to address all of the

closure failure of Burger?s circuit.

safety concerns, if any, associated with its use. It is the

3.1.1.3 grain boundary-the surface, which may be

responsibility of the user of this standard to establish appro-

closed, over which a crystal is in contact with other crystals

priate safety and health practices and determine the applica-

on this surface or interface

in a solid body. Any point

bility of regulatory limitations prior to use. Specific hazard

constitutes the junction of at least two differently oriented

crystal lattices. For polycrystalline material, this orientation

__

This test method is under the jurisdiction of ASTM Committee F-1 on

Electronics, and is the direct responsibility of Subcommittee F01.06 on Silicon

Materials and Process Control. Annual Book ofASTM Standards, Vol i 1.01.

Current edition approved July 15, 1994. Published September 1994. Onginally Annual Book of ASTM Standaràs, Vol 03.01.

published as F 47 - 64 T. Last previous edition F 47 - 88. Annual Book ofASTM Standards, Vol 10.05.

2DIN 50434 is an equivalent method. It is the responsibility of DIN Available from American National Standards Institute, 11 West 42nd St.,

Committee NMP 221, with which Committee F-1 maintains close technical 13th Floor, New York, Ny 10036.

liaison. DIN 50434, Testing of inorganic Semiconductor Materials: Determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.