ASTM A21-94(1999)

(Specification)Standard Specification for Carbon Steel Axles, Non-Heat-Treated and Heat-Treated, for Railway Use (Withdrawn 2003)

Standard Specification for Carbon Steel Axles, Non-Heat-Treated and Heat-Treated, for Railway Use (Withdrawn 2003)

SCOPE

1.1 This specification covers nonheat-treated axles up to and including those 6 1/2 in. (165.1 mm) nominal diameter at the center and heat-treated axles of all sizes for freight cars, passenger cars, and locomotives.

1.2 This specification is for axles with machined bodies. For axles with as-forged bodies, see Specification A383.

1.3 The grades of carbon steel axles are as follows:

1.3.1 Grade U -Nonheat-treated.

1.3.2 Grade F -Double normalized and tempered. (All freight axles over 6 1/2 in. (165.1 mm) nominal diameter at the center shall be Grade F.)

1.3.3 Grade G -Quenched and tempered.

1.3.4 Grade H -Normalized, quenched, and tempered.

1.3.5 Grades F, G, and H axles are used in heavy-duty service on locomotives, cars, and other equipment.

1.4 Typical designs for plain and roller bearing axles are shown in the Manual of Standards and Recommended Practice of the Association of American Railroads.

1.5 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.6 The values stated in inch-pound units are to be regarded as the standard.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 21 – 94 (Reapproved 1999)

Standard Specification for

Carbon Steel Axles, Non-Heat-Treated and Heat-Treated, for

Railway Use

This standard is issued under the fixed designation A 21; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Alloy Ultrasonic Standard Reference Blocks

E 381 Method of Macroetch Testing Steel Bars, Billets,

1.1 This specification covers nonheat-treated axles up to and

1 Blooms, and Forgings

including those 6 ⁄2 in. (165.1 mm) nominal diameter at the

2.2 Military Standards:

center and heat-treated axles of all sizes for freight cars,

MIL-STD-129 Marking for Shipment and Storage

passenger cars, and locomotives.

MIL-STD-163 Steel Mill Products, Preparation for Ship-

1.2 This specification is for axles with machined bodies. For

ment and Storage

axles with as-forged bodies, see Specification A 383.

2.3 Federal Standard:

1.3 The grades of carbon steel axles are as follows:

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

1.3.1 Grade U—Nonheat-treated.

1.3.2 Grade F—Double normalized and tempered. (All

3. Ordering Information

freight axles over 6 ⁄2 in. (165.1 mm) nominal diameter at the

3.1 The inquiry, order, or contract for material under this

center shall be Grade F.)

specification shall include the following information:

1.3.3 Grade G—Quenched and tempered.

3.1.1 Quantity (number of pieces),

1.3.4 Grade H—Normalized, quenched, and tempered.

3.1.2 ASTM designation and year of issue,

1.3.5 Grades F, G, and H axles are used in heavy-duty

3.1.3 Grade,

service on locomotives, cars, and other equipment.

3.1.4 Design and size,

1.4 Typical designs for plain and roller bearing axles are

3.1.5 Intended service, and

shown in the Manual of Standards and Recommended Practice

2 3.1.6 Supplementary requirements (if any).

of the Association of American Railroads.

1.5 Supplementary requirements are provided for use when

4. Manufacture

additional testing or inspection is desired. These shall apply

4.1 Process—The steel shall be made by any of the follow-

only when specified individually by the purchaser in the order.

ing processes: open-hearth, electric-furnace, or basic-oxygen.

1.6 The values stated in inch-pound units are to be regarded

4.2 Discard—Sufficient discard shall be made to assure

as the standard.

freedom from piping and undue segregation.

2. Referenced Documents 4.3 Forging Practice—The axles may be made direct from

the ingot or from blooms. The total reduction from ingot or

2.1 ASTM Standards:

strand cast bloom to forging shall not be less than 3 to 1, unless

A 370 Test Methods and Definitions for Mechanical Testing

3 otherwise specified.

of Steel Products

4.4 Cooling and Heating:

A 383 Specification for Axles, Railway, Carbon Steel, Un-

4 4.4.1 After axle blooms are produced they shall be slow

treated for Export and General Industrial Use

5 cooled in closed containers, hoods, or furnaces.

E 112 Test Methods for Determining Average Grain Size

4.4.2 Blooms shall be reheated for forging in a manner

E 127 Practice for Fabricating and Checking Aluminum

which will prevent internal bursts and overheating.

4.4.3 After forging, axles shall be slow cooled in closed

containers, covered conveyors, or in hoods. If axles (Grades F,

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

G, and H) are heat-treated directly from the forging, they shall

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

be slow cooled following the final heat treatment.

A01.06 on Steel Forgings and Billets.

Current edition approved Feb. 15, 1994. Published April 1994. Originally

NOTE 1—After slow cooling, Grade U axles may be single normalized

published as A 21 – 1900 T. Last previous edition A 21 – 85.

Obtainable from the Mechanical Division, Association of American Railroads,

1920 L St. N.W., Washington, DC 20036.

3 6

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 03.03.

4 7

Annual Book of ASTM Standards, Vol 01.04. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

A 21 – 94 (1999)

in accordance with 4.4.4 and 4.5.2. TABLE 1 Chemical Requirements

Composition, %

4.4.4 Axles (Grades F, G, and H) that are heat-treated

Nonheat-

directly from forging (1) shall be cooled below the transfor- Heat-Treated

Element Treated

mation temperature or to approximately 1000°F (538°C) be-

Grade U Grade F Grades G and H

min max min max min max

fore any reheating operation and (2) must not be permitted to

Carbon 0.40 0.55 0.45 0.59 . . . . . .

cool below 500°F (260°C) without slow cooling as defined in

Manganese 0.60 0.90 0.60 0.90 0.60 0.90

4.4.3.

Phosphorus . . . 0.045 . . . 0.045 . . . 0.045

Sulfur . . . 0.050 . . . 0.050 . . . 0.050

NOTE 2—As the temperature of the axles approaches the minimum of

Silicon 0.15 . . . 0.15 . . . 0.15 . . .

500°F (260°C) a supplemental heat source may be necessary to assure an

effective slow cooling cycle.

4.4.5 When properly vacuum-degassed steel is used, the ages of the elements specified in Table 1. The analysis shall be

made from a test sample taken preferably during the pouring of

slow cooling requirements of 4.4.1, 4.4.3, and 4.4.4 may be

omitted but axle blooms must then be pile cooled. the cast or heat. The chemical composition thus determined

shall conform to the requirements in Table 1.

4.5 Heat Treatment:

4.5.1 Axles for heat treatment shall be reheated gradually 5.3 Product Analysis—An analysis may be made by the

purchaser from one axle representing each heat. The chemical

and uniformly to a suitable temperature to refine the grain

structure. composition thus determined shall conform to the requirements

of 5.1 subject to tolerances included in Table 2. The sample for

4.5.2 Normalizing—After heating to a suitable temperature

the axles shall be withdrawn from the furnace and allowed to these analyses shall be taken from one end of the test axle or

full-sized prolongation at a point midway between the center

cool in air. A furnace charge thus treated is called a normalizing

charge. Cooling may be accelerated by increased air circulation and surface. If drillings are taken, they shall be obtained using

a ⁄8-in. (16-mm) diameter drill or turnings may be taken from

which must be controlled to provide reasonably uniform

cooling. a tension test specimen.

4.5.3 Double Normalizing—The procedure shall consist of

6. Mechanical Requirements and Tests for Nonheat-

two separate normalizing treatments. The second shall be

Treated Axles

performed at a lower temperature than the first treatment. A

6.1 At the option of the manufacturer, either drop tests or

furnace charge thus treated is termed a double-normalizing

tension tests (but normally not both) shall be performed to

charge. Cooling may be accelerated by increased air circulation

qualify each heat of steel.

which must be controlled to provide reasonably uniform

6.2 Drop Test:

cooling.

6.2.1 The test axle shall be so placed on supports 3 ft (914

NOTE 3—A single normalizing treatment shall be permitted when all

mm) apart that the tup will strike it midway between the ends.

other requirements for Grade F are met.

It shall stand without fracture five blows from a tup of 2240 lb

4.5.4 Quenching—After heating to a suitable temperature

(1016 kg) falling from a height H such that H in feet equals the

the axles shall be quenched in a suitable medium under

square of the diameter of the axle at the center in inches, H =

reasonably uniform conditions. A furnace charge thus treated is 2

d . The axles shall be rotated through 180° after the first and

termed a quenching charge.

third blows.

4.5.5 Tempering—Axles shall be reheated gradually to, and

6.2.2 Before the axle is drop tested, the center shall be

held at, a suitable temperature below the critical range and

calipered to the nearest ⁄8 in. (3.2 mm) and the height of drop

shall then be allowed to cool under suitable conditions. A

in feet, to the nearest ⁄2 ft, shall not be less than the square of

furnace charge thus treated is termed a tempering charge.

the actual diameter at the center in inches.

4.5.6 Heat treatment may be performed in either batch-type

6.2.3 The permanent set produced by the first blow shall not

furnaces or continuous furnaces.

exceed that given by the following equation in which L =

4.6 Straightening:

length of axle in inches and d = diameter of axle at center in

4.6.1 Any straightening of axle forgings shall be done

inches:

before machining and in such a manner as to leave the axle

Permanent set, max, in. 5 L/1.9d 2 d/2 1 ½

body free of injurious marks.

4.6.2 Straightening shall preferably be performed at a tem-

6.2.4 The drop test requirements for AAR untreated stan-

perature no lower than 950°F (510°C). Straightening per-

dard plain bearing axles Classes A to E are shown in Table 3.

formed at a temperature lower than 950°F shall be followed by

Drop test requirements for AAR standard roller bearing axles,

a furnace stress-relieving procedure or applicable heat treat-

Classes B to E, are shown in Table 4. Class F and all other plain

ment.

or roller bearing axles over 6 ⁄2 in. nominal diameter at center

5. Chemical Requirements

are not subject to drop test (Section 1).

5.1 Chemical Composition—The steel shall conform 6.2.5 The permanent set is the difference between the

to the requirements for chemical composition shown in distance from a straightedge to the middle point of the axle,

Table 1. measured before the first blow and distance measured in the

5.2 Cast or Heat Analysis—An analysis of each cast or heat same manner after the blow. The straightedge shall rest on the

shall be made by the manufacturer to determine the percent- end collars or ends of the axle.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

A 21 – 94 (1999)

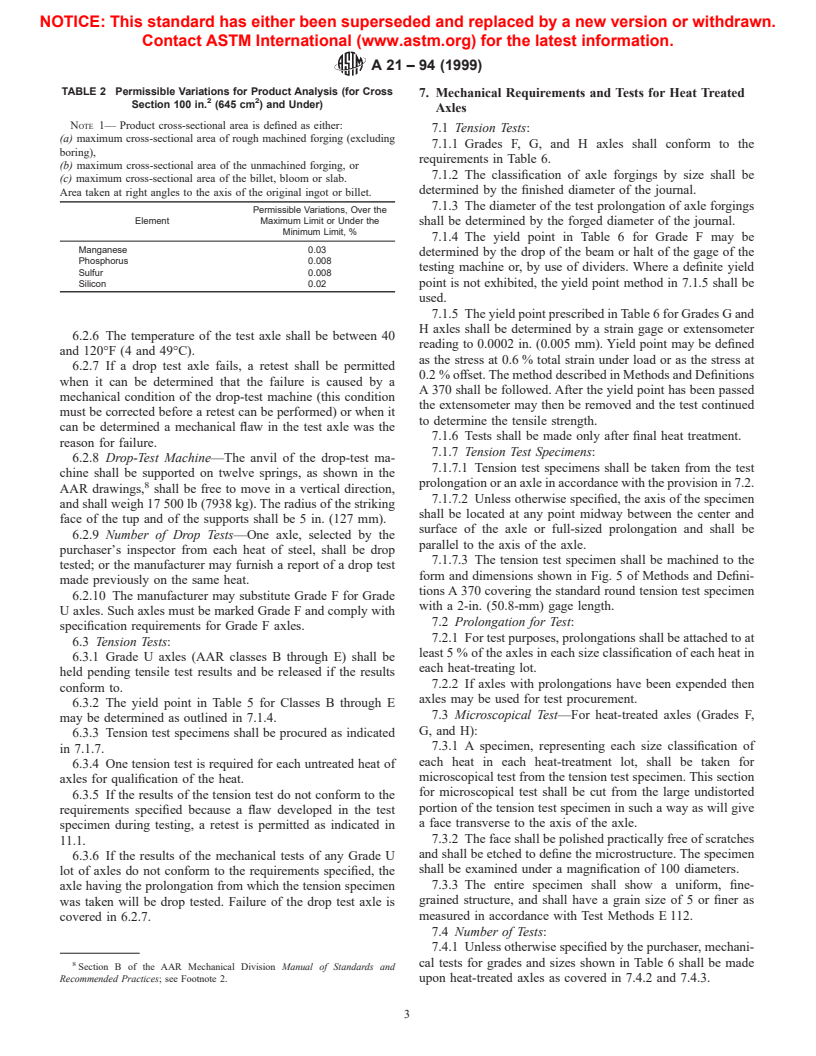

TABLE 2 Permissible Variations for Product Analysis (for Cross

7. Mechanical Requirements and Tests for Heat Treated

2 2

Section 100 in. (645 cm ) and Under)

Axles

NOTE 1— Product cross-sectional area is defined as either:

7.1 Tension Tests:

(a) maximum cross-sectional area of rough machined forging (excluding

7.1.1 Grades F, G, and H axles shall conform to the

boring),

requirements in Table 6.

(b) maximum cross-sectional area of the unmachined forging, or

7.1.2 The classification of axle forgings by size shall be

(c) maximum cross-sectional area of the billet, bloom or slab.

determined by the finished diameter of the journal.

Area taken at right angles to the axis of the original ingot or billet.

7.1.3 The diameter of the test prolongation of axle forgings

Permissible Variations, Over the

Element Maximum Limit or Under the shall be determined by the forged diameter of the journal.

Minimum Limit, %

7.1.4 The yield point in Table 6 for Grade F may be

Manganese 0.03

determined by the drop of the beam or halt of the gage of the

Phosphorus 0.008

testing machine or, by use of dividers. Where a definite yield

Sulfur 0.008

Silicon 0.02 point is not exhibited, the yield point method in 7.1.5 shall be

used.

7.1.5 The yield point prescribed in Table 6 for Grades G and

H axles shall be determined by a strain gage or extensometer

6.2.6 The temperature of the test axle shall be between 40

reading to 0.0002 in. (0.005 mm). Yield point may be defined

and 120°F (4 and 49°C).

as the stress at 0.6 % total strain under load or as the stress at

6.2.7 If a drop test axle fails, a retest shall be permitted

0.2 % offset. The method described in Methods and Definitions

when it can be determined that the failure is caused by a

A 370 shall be followed. After the yield point has been passed

mechanical condition of the drop-test machine (this condition

the extensometer may then be removed and the test continued

must be corrected before a retest can be performed) or when it

to determine the tensile strength.

can be determined a mechanical flaw in the test axle was the

7.1.6 Tests shall be made only after final heat treatment.

reason for failure.

7.1.7 Tension Test Specimens:

6.2.8 Drop-Test Machine—The anvil of the drop-test ma-

7.1.7.1 Tension test specimens shall be taken from the test

chine shall be supported on twelve springs, as shown in the

8 prolongation or an axle in accordance with the provision in 7.2.

AAR drawings, shall be free to move in a vertical direction,

7.1.7.2 Unless otherwise specified, the axis of the specimen

and shall weigh 17 500 lb (7938 kg). The radius of the striking

shall be located at any point midway between the center and

face of the tup and of the supports shall be 5 in. (127 mm).

surface of the axle or full-sized prolongation and shall be

6.2.9 Number of Drop Tests—One axle, selected by the

parallel to the axis of the axle.

purchaser’s inspector from each heat of steel, shall be drop

7.1.7.3 The tension test specimen shall be machined to the

tested; or the manufacturer may furnish a report of a drop test

form and dimensions shown in Fig. 5 of Methods and Defini-

made previously on the same heat.

tions A 370 covering the standard round tension test specimen

6.2.10 The manufacturer may substitute Grade F for Grade

with a 2-in. (50.8-mm) gage length.

U axles. Such axles must be marked Grade F and comply with

7.2 Prolongation for Test:

specification requirements for Grade F axles.

7.2.1 For test purposes, prolongations shall be attached to at

6.3 Tension Tests:

least 5 % of the axles in each size classification of each heat in

6.3.1 Grade U axles (AAR classes B through E) shall be

each heat-treating lot.

held pending tensile test results and be released if the results

7.2.2 If axles with prolongations have been expended then

conform to.

axles may be used for test procurement.

6.3.2 The yield point in Table 5 for Classes B through E

7.3 Microscopical Test—For heat-treated axles (Grades F,

may be determined as outlined in 7.1.4.

G, and H):

6.3.3 Tension test specimens shall be procured as indicated

7.3.1 A specimen, representing each size classification of

in 7.1.7.

each heat in each heat-treatment lot, shall be taken for

6.3.4 One tensio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.