ASTM A3-01(2006)

(Specification)Standard Specification for Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)

Standard Specification for Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)

ABSTRACT

This specification covers steel joint bars of low-carbon, medium-carbon, and high-carbon grades (Grades 1, 2, and 3) for railway applications. Steel shall be made through basic-oxygen or electric-furnace processes and cast through continuous process or in ingots. An analysis of each heat or cast shall be made to determine the percentage compositions of carbon, manganese, phosphorus, and sulfur. Tension test shall also be made to conform to specified tensile strength and elongation values. Guidelines on the dimensions and physical variations of joint bars are given. Inspection, rejection, rehearing, certification, and product marking procedures are cited.

SCOPE

1.1 This specification covers steel joint bars for connecting steel rails in mine, industrial, and standard railroad track.

1.2 Three grades of joint bars are defined for applications where non-heat treated bars are suitable:

1.2.1 Grade 1, low-carbon, primarily for industrial and mine use.

1.2.2 Grade 2, medium-carbon, primarily for industrial and mine use.

1.2.3 Grade 3, high-carbon, for general use in standard railroad track. They may be used in the production of insulated track joints.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A3 – 01 (Reapproved 2006)

Standard Specification for

Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-

Treated)

This standard is issued under the fixed designationA3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

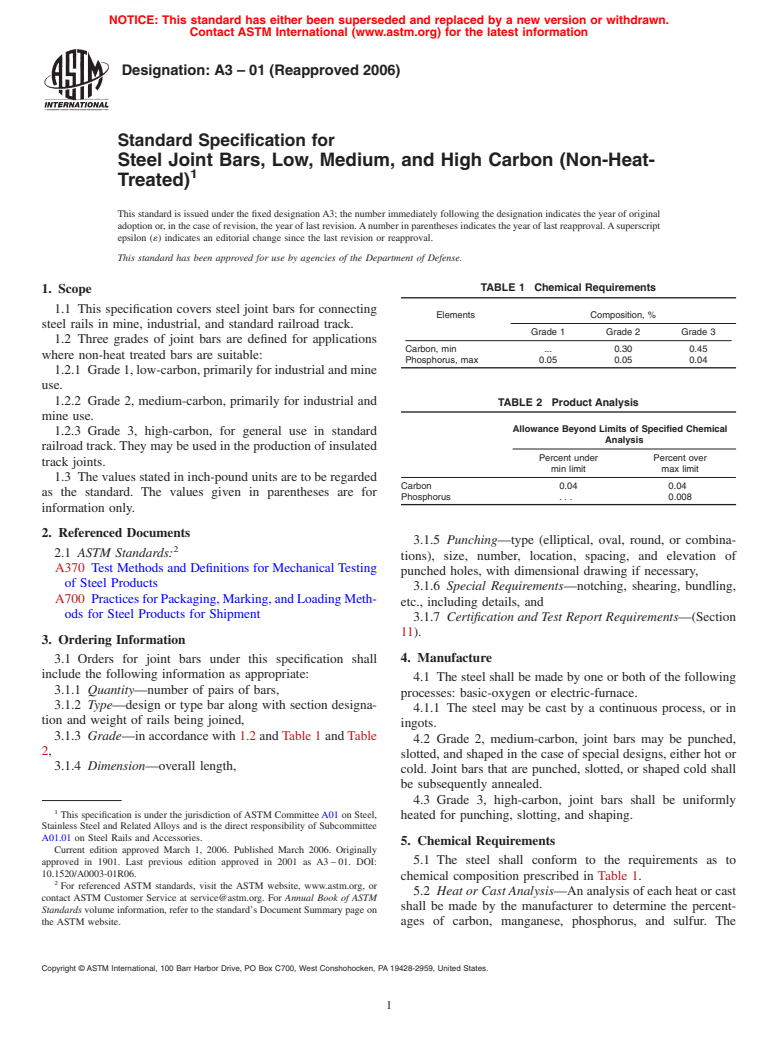

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers steel joint bars for connecting

Elements Composition, %

steel rails in mine, industrial, and standard railroad track.

Grade 1 Grade 2 Grade 3

1.2 Three grades of joint bars are defined for applications

Carbon, min . 0.30 0.45

where non-heat treated bars are suitable:

Phosphorus, max 0.05 0.05 0.04

1.2.1 Grade 1, low-carbon, primarily for industrial and mine

use.

1.2.2 Grade 2, medium-carbon, primarily for industrial and

TABLE 2 Product Analysis

mine use.

Allowance Beyond Limits of Specified Chemical

1.2.3 Grade 3, high-carbon, for general use in standard

Analysis

railroad track. They may be used in the production of insulated

Percent under Percent over

track joints.

min limit max limit

1.3 The values stated in inch-pound units are to be regarded

Carbon 0.04 0.04

as the standard. The values given in parentheses are for

Phosphorus . . . 0.008

information only.

2. Referenced Documents

3.1.5 Punching—type (elliptical, oval, round, or combina-

2.1 ASTM Standards:

tions), size, number, location, spacing, and elevation of

A370 Test Methods and Definitions for Mechanical Testing

punched holes, with dimensional drawing if necessary,

of Steel Products

3.1.6 Special Requirements—notching, shearing, bundling,

A700 PracticesforPackaging,Marking,andLoadingMeth-

etc., including details, and

ods for Steel Products for Shipment

3.1.7 Certification and Test Report Requirements—(Section

11).

3. Ordering Information

3.1 Orders for joint bars under this specification shall 4. Manufacture

include the following information as appropriate:

4.1 The steel shall be made by one or both of the following

3.1.1 Quantity—number of pairs of bars,

processes: basic-oxygen or electric-furnace.

3.1.2 Type—design or type bar along with section designa-

4.1.1 The steel may be cast by a continuous process, or in

tion and weight of rails being joined,

ingots.

3.1.3 Grade—in accordance with 1.2 and Table 1 and Table

4.2 Grade 2, medium-carbon, joint bars may be punched,

2,

slotted, and shaped in the case of special designs, either hot or

3.1.4 Dimension—overall length,

cold. Joint bars that are punched, slotted, or shaped cold shall

be subsequently annealed.

4.3 Grade 3, high-carbon, joint bars shall be uniformly

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

heated for punching, slotting, and shaping.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.01 on Steel Rails and Accessories.

5. Chemical Requirements

Current edition approved March 1, 2006. Published March 2006. Originally

5.1 The steel shall conform to the requirements as to

approved in 1901. Last previous edition approved in 2001 as A3 – 01. DOI:

10.1520/A0003-01R06.

chemical composition prescribed in Table 1.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Heat or Cast Analysis—An analysis of each heat or cast

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shall be made by the manufacturer to determine the percent-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ages of carbon, manganese, phosphorus, and sulfur. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A3 – 01 (2006)

TABLE 3 Tensile Requirements

8. Workmanship, Finish, and Appearance

8.1 The joint bars shall be straight, subject to the variations

Grade 1 Grade 2 Grade 3

prescribed in 7.3, 7.4, and Table 4.

ksi MPa ksi MPa ksi MPa

8.2 The general appearance with respect to soundness and

Tensile strength, 55 380 68 470 85 585

surface finish shall be consistent with good commercial prac-

min

Elongation in 2 in. 22 20 15 tice as determined by visual inspection.

or 50 mm, min

9. Inspection

9.1 The manufacturer shall afford the purchaser’s inspector

all reasonable facilities necessary to satisfy that the material is

analysis shall be made from a test sample taken preferably

being produced and furnished in accordance with this specifi-

during the pouring of the heat or cast. The chemical composi-

cation. Mill inspection by the purchaser shall not interfere

tion thus determined shall conform to the requirement in Table

unnecessarily with the manufacturer’s operations.All tests and

1. Manganese and sulfur determinations are for information

inspections shall be made at the place of manufacture, unless

only.

otherwise agreed upon.

5.3 Product Analysis—When ladle tests are not available,

10. Rejection and Rehearing

finished material representing the heat may be product tested.

The product analysis allowance beyond the limits of the

10.1 Material that fails to conform to the requirements of

specified ladle analysis shall be within the limits for product

this specification may be rejected. Rejections shall be reported

analyses specified in Table 2.

tothemanufacturerorsupplierpromptlyandinwriting.Incase

5.3.1 An analysis may be made by the purchaser from a

of dissatisfaction with the test results, the manufacturer or

sampletakenfromafinishedjointbarrepresentingeachheator supplier may make claim for a rehearing.

cast. The chemical composi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.