ASTM F1670-98

(Test Method)Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Synthetic Blood

Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Synthetic Blood

SCOPE

1.1 This test method is used to evaluate the resistance of materials used in protective clothing to penetration by synthetic blood under conditions of continuous liquid contact. Protective clothing pass/fail determinations are based on visual detection of synthetic blood penetration.

1.1.1 This test method is not always effective in testing protective clothing materials having thick, inner liners which readily absorb the synthetic blood.

1.2 This test method is a means for selecting protective clothing materials for subsequent testing with a more sophisticated barrier test as described in Test Method F1671.

1.3 This test method does not apply to all forms or conditions of blood-borne pathogen exposure. Users of the test method must review modes for work/clothing exposure and assess the appropriateness of this test method for their specific application.

1.4 This test method addresses only the performance of materials or certain material constructions (for example, seams) used in protective clothing. This test method does not address the design, overall construction and components, or interfaces of garments, or other factors which may affect the overall protection offered by the protective clothing.

1.5 The values in SI units or other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1670 – 98

Standard Test Method for

Resistance of Materials Used in Protective Clothing to

Penetration by Synthetic Blood

This standard is issued under the fixed designation F 1670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Workers, primarily those in the health care profession, involved in treating and caring for

individuals injured or sick, can be exposed to biological liquids capable of transmitting disease. These

diseases, which may be caused by a variety of microorganisms, can pose significant risks to life and

health. This is especially true of blood-borne, Hepatitis [Hepatitis B Virus (HBV) and Hepatitis C

Virus (HCV)] and Acquired Immune Deficiency Syndrome (AIDS) [Human Immunodeficiency

Viruses (HIV)]. Since engineering controls can not eliminate all possible exposures, attention is placed

on reducing the potential of direct skin contact through the use of protective clothing that resists

penetration (29 CFR Part 1910.1030). This test method was developed to help assess the effectiveness

of materials used in protective clothing for protecting the wearer against contact with body fluids that

potentially contain blood-borne pathogens. Using synthetic blood, this test method is intended to

identify protective clothing material candidates for further testing according to a more rigorous

procedure involving a surrogate for blood-borne pathogens.

1. Scope address the design, overall construction and components, or

interfaces of garments, or other factors which may affect the

1.1 This test method is used to evaluate the resistance of

overall protection offered by the protective clothing.

materials used in protective clothing to penetration by synthetic

1.5 The values in SI units or other units shall be regarded

blood under conditions of continuous liquid contact. Protective

separately as standard. The values stated in each system must

clothing pass/fail determinations are based on visual detection

be used independently of the other, without combining values

of synthetic blood penetration.

in any way.

1.1.1 This test method is not always effective in testing

1.6 This standard does not purport to address all of the

protective clothing materials having thick, inner liners which

safety concerns, if any, associated with its use. It is the

readily absorb the synthetic blood.

responsibility of the user of this standard to establish appro-

1.2 This test method is a means for selecting protective

priate safety and health practices and determine the applica-

clothing materials for subsequent testing with a more sophis-

bility of regulatory limitations prior to use.

ticated barrier test as described in Test Method F 1671.

1.3 This test method does not apply to all forms or condi-

2. Referenced Documents

tions of blood-borne pathogen exposure. Users of the test

2.1 ASTM Standards:

method must review modes for work/clothing exposure and

D 1331 Test Methods for Surface and Interfacial Tension of

assess the appropriateness of this test method for their specific

Solutions of Surface Active Agents

application.

D 1777 Test Method for Measuring Thickness of Textile

1.4 This test method addresses only the performance of

Materials

materials or certain material constructions (for example,

D 3776 Test Method for Mass Per Unit Area (Weight) of

seams) used in protective clothing. This test method does not

Woven Fabrics

This test method is under the jurisdiction of ASTM Committee F-23 on

Protective Clothing and is the direct responsibility of Subcommittee F23.40 on Annual Book of ASTM Standards, Vol 15.04.

Biological Hazards. Annual Book of ASTM Standards, Vol 07.01.

Current edition approved Feb. 10, 1998. Published April 1998. Originally Annual Book of ASTM Standards, Vol 07.02.

published as ES – 21. Last previous edition F 1670 – 97.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1670–98

E 105 Practice for Probability Sampling of Materials 3.5.1 Discussion—The potential hazard is contact with

E 171 Specification for Standard Atmospheres for Condi- blood.

tioning and Testing Flexible Barrier Materials 3.6 synthetic blood, n—a mixture of a red dye/surfactant,

F 903 Test Method for Resistance of Materials Used in thickening agent, and distilled water having a surface tension

Protective Clothing to Penetration by Liquids and viscosity representative of blood and some other body

F 1671 Test Method for Resistance of Protective Clothing fluids, and the color of blood.

Materials to Penetration by Blood-Borne Pathogens Using 3.6.1 Discussion—The synthetic blood in this test method

Viral Penetration as a Test System does not simulate all of the characteristics of real blood or body

2.2 Military Standard: fluids, for example, polarity (a wetting characteristic), coagu-

MIL-STD-105 Sampling Procedures and Tables for Inspec- lation, content of cell matter.

tion by Attributes

4. Summary of Test Method

2.3 ANSI/ASQC Standards:

ANSI/ASQC Z1.4 Sampling Procedures and Tables for

4.1 A specimen is subjected to a body fluid simulant

Inspection by Attributes

(synthetic blood) for a specified time and pressure.

2.4 ISO Standard:

4.2 Visual observation is made to determine when, or if,

ISO 2859-1 Sampling Plans for Inspection by Attributes

penetration occurs.

2.5 OSHA Standard:

4.3 Any evidence of synthetic blood penetration constitutes

29 CFR Part 1910.1030 Occupational Exposure to Blood-

failure. Results are reported as pass/fail.

borne Pathogens: Final Rule, Federal Register, Vol 56, No

235, Dec. 6, 1991, pp. 6175–64182.

TABLE 1 Specimen Exposure Procedures

Procedure Pressure/Time Sequence and Retaining Screen Options

3. Terminology

A 0 kPa (0 psig) for 5 min, followed by 13.8 kPa (2 psig) for 1

3.1 blood-borne pathogen, n—an infectious secreted or

min, followed by 0 kPa (0 psig) for 54 min.

excreted bacterium, virus, or other disease inducing microbe A retaining screen is not used to support the sample.

B 0 kPa (0 psig) for 5 min, followed by 13.8 kPa (2 psig) for 1

carried in blood or other body fluids.

min, followed by 0 kPa (0 psig) for 54 min.

3.2 body fluid, n—any liquid produced (secreted or ex-

A retaining screen is used to support the sample. The type

must be specified in the report.

creted) by the human body.

3.2.1 Discussion—In this test method, body fluids include

those liquids potentially infected with blood-borne pathogens,

including, but not limited to, blood, semen, vaginal secretions,

5. Significance and Use

cerebrospinal fluid, synovial fluid and peritoneal fluid, amni-

5.1 This test method is based on Test Method F 903 for

otic fluid, saliva in dental procedures, and any body fluid that

measuring resistance of chemical protective clothing materials

is visibly contaminated with blood, and all body fluids in

to penetration by liquids. This test method is normally used to

situations where it is difficult or impossible to differentiate

11 evaluate specimens from individual finished items of protective

between body fluids.

clothing and individual samples of materials that are candidates

3.3 body fluid simulant, n—a liquid which is used to act as

for items of protective clothing.

a model for human body fluids.

5.1.1 Finished items of protective clothing include gloves,

3.3.1 Discussion—In this test method, synthetic blood is

arm shields, aprons, gowns, coveralls, hoods, and boots.

used as a body fluid simulant.

5.1.2 The phrase “specimens from finished items” encom-

3.4 penetration, n—the flow of a liquid through closures,

passes seamed and other discontinuous regions as well as the

porous material, seams and pinholes or other imperfections in

usual continuous regions of protective clothing items.

a protective clothing material on a non-molecular level.

5.2 Medical protective clothing materials are intended to be

3.4.1 Discussion—In this test method, the penetration liquid

a barrier to blood, body fluids, and other potentially infectious

is synthetic blood.

materials. Many factors can affect the wetting and penetration

3.5 protective clothing, n—any material or combination of

characteristics of body fluids, such as surface tension, viscos-

materials used in an item of clothing for the purpose of

ity, and polarity of the fluid, as well as the structure and relative

isolating parts of the body from a potential hazard.

hydrophilicity or hydrophobicity of the materials. The surface

tension range for blood and body fluids (excluding saliva) is

approximately 0.042 to 0.060 N/m (1). To help simulate the

wetting characteristics of blood and body fluids, the surface

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 15.09.

tension of the synthetic blood is adjusted to approximate the

Annual Book of ASTM Standards, Vol 11.03.

lower end of this surface tension range. The resulting surface

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

tension of the synthetic blood is approximately 0.042 6 0.002

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from American Society for Quality Control, 611 E. Wisconsin Ave., N/m.

Milwaukee, WI 53202.

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

11 12

Available from Supt. of Documents, U.S. Government Printing Office, The boldface numbers in parentheses refer to the list of references at the end

Washington, DC 20402. of this standard.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1670–98

5.3 The synthetic blood mixture is prepared with a red dye

to aid in visual detection and a thickening agent to simulate the

flow characteristics of blood.

5.4 Part of the protocol in Procedure A and B in Table 1 for

exposing the protective clothing material specimens with

synthetic blood involves pressurization of the test cell to 13.8

kPa (2 psig). This hydrostatic pressure has been documented to

discriminate between protective clothing material performance

and correlate with visual penetration results that are obtained

with a human factors validation (2). Some studies, however,

suggest that mechanical pressures exceeding 345 kPa (50 psig)

can occur during clinical use (3,4). Therefore, it is important to

understand that this test method does not simulate all the

physical stresses and pressures that are exerted on protective

clothing garments during actual use. This test method is offered

to identify those protective clothing materials that warrant

further evaluation with a microbiological challenge.

5.5 Since this test method uses visual observation rather

than analytical measurements for determination of penetration,

use this test method as a preliminary evaluation for possible

penetration of blood and other body fluids. Perform subsequent

testing with a microbiological challenge and analytical tech-

nique using Test Method F 1671.

NOTE 1—No viral resistance claims can be made based on this test

method as materials can pass the test method and fail Test Method F 1671.

5.6 Testing without considering degradation by physical,

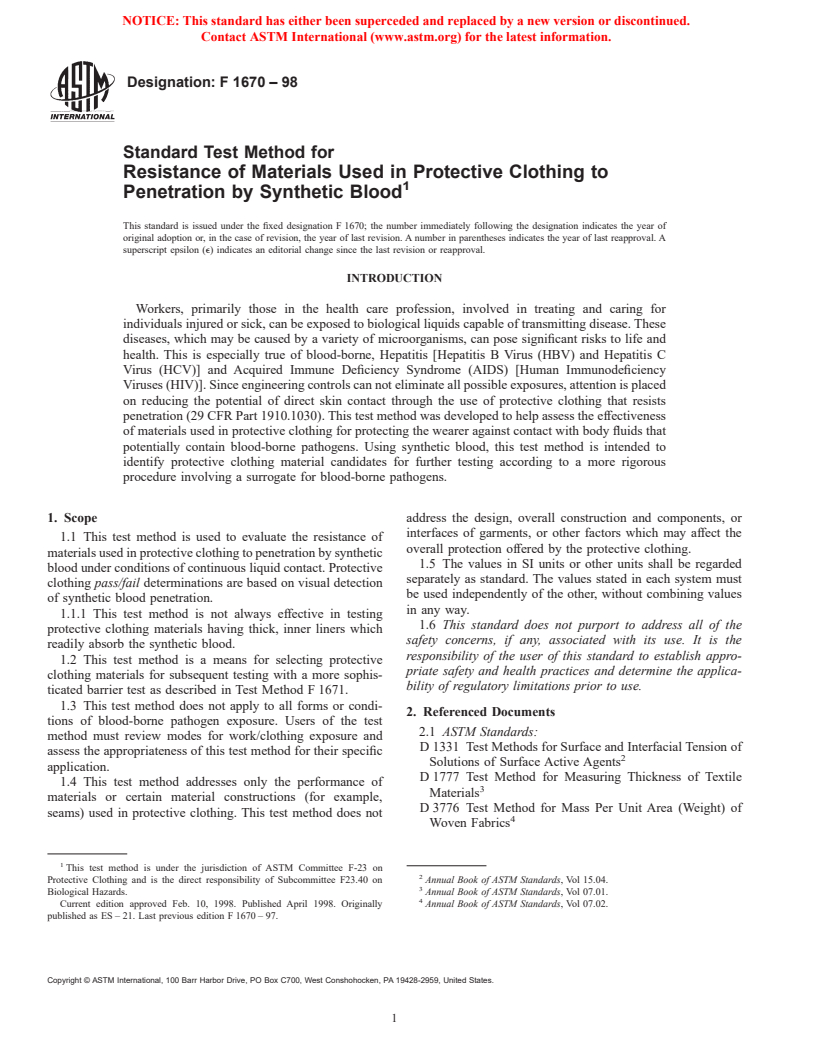

FIG. 1 Exploded View of the Penetration Test Cell with

chemical, and thermal stresses which could negatively impact

Retaining Screen

the performance of the protective barrier, could lead to a false

sense of security. Consider tests which assess the impact of

storage conditions and shelf life for disposable products, and

Method D 1777, used to determine the thickness of each

the effects of laundering and sterilization for reusable products.

protective clothing material specimen tested.

The integrity of the protective barrier can also be compromised

6.2 Penetration Test Cell, to restrain the specimen during

during use by such effects as flexing and abrasion (5). It is also

contact with the pressurized test synthetic blood. In the test

possible that prewetting by contaminating materials such as

cell, the specimen acts as a partition separating synthetic blood

alcohol and perspiration can also compromise the integrity of

from the view side of the test cell. It consists of a cell body that

the protective barrier. If these conditions are of concern,

is fastened to a cell support. The cell body has a capacity of

evaluate the performance of protective clothing materials for

approximately 60 mL (2.0 oz) for synthetic blood. A flange

synthetic blood penetration following an appropriate precon-

cover, with an open area to allow visual observation and a

ditioning technique representative of the expected conditions

transparent cover are included. The cell body has a top port for

of use.

filling and a drain valve for draining the penetration test cell.

5.7 While this test method involves a qualitative determi-

Other items, such as a fitting to allow attachment of the air line

nation of the protective clothing material resistance to penetra-

to the top port in the cell body, gaskets, and the retaining screen

tion by synthetic blood under specific test conditions, it is

are also required. Specifications for the penetration test cell are

possible to use this test method as a material quality control or

provided in Test Method F 903. A diagram of the test cell and

assurance procedure.

apparatus are provided in Figs. 1 and 2, respectively.

5.7.1 If this procedure is used for quality control, perform

6.3 Retaining Screen, a smooth finish plastic or metal

proper statistical design and analysis of the data, when more

square mesh screen meeting the following specifications used

than three specimens are tested. This type of analysis includes,

for Procedure B from Table 1:

but is not limited to, the number of individual specimens tested,

% open area >50

the average percent passing and/or failing with a standard

Should limit deflection of sample to <= 5.0 mm (0.2 in.)

deviation. Data reported in this way helps to establish confi-

dence limits concerning product performance. Examples of

acceptable sampling plans are found in references such as

MIL-STD-105, ANSI/ASQC Z1.4, and ISO 2859-1.

The penetration test apparatus is available from Wilson Road Machine Shop,

1170 Wilson Road, Rising Sun, MD 21911.

Acceptable retaining screen materials are 11 by 11 nylon screen (No.

6. App

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.