ASTM B102-00(2005)

(Specification)Standard Specification for Lead- and Tin-Alloy Die Castings (Withdrawn 2011)

Standard Specification for Lead- and Tin-Alloy Die Castings (Withdrawn 2011)

ABSTRACT

This specification covers lead- and tin-alloy die castings. The chemical composition shall conform to the required values of tin, antimony, lead, copper, arsenic, zinc, and aluminum. Chemical analysis shall be taken from the material by drilling, sawing, milling, turning, or clipping a representative piece or pieces. Tension or impact tests shall be specified.

SCOPE

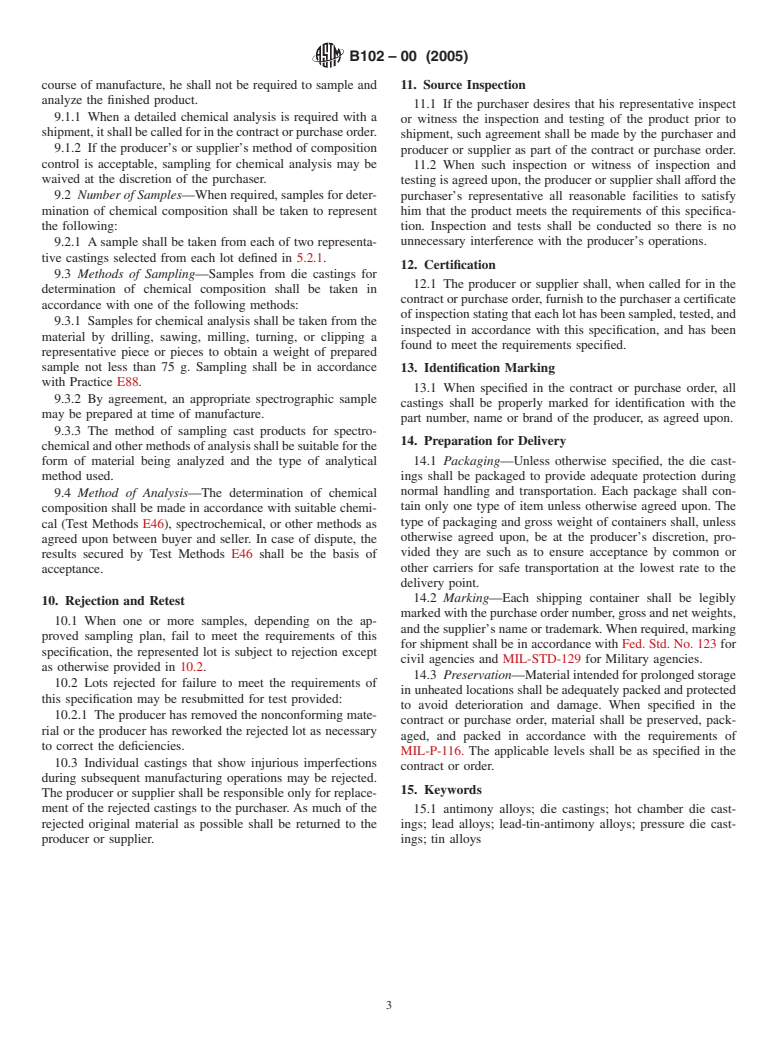

1.1 This specification covers die castings produced from five alloys whose primary metal is either lead or tin. lists the designations for these alloys as well as their chemical compositions.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers die castings produced from five alloys whose primary metal is either lead or tin. Table 1 lists the designations for these alloys as well as their chemical compositions.

Formerly under the jurisdiction of Committee B02 on Nonferrous Metals and Alloys, this specification was withdrawn in May 2011 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B102 – 00 (Reapproved 2005)

Standard Specification for

Lead- and Tin-Alloy Die Castings

This standard is issued under the fixed designation B102; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E46 Test Methods for Chemical Analysis of Lead- and

Tin-Base Solder

1.1 This specification covers die castings produced from

E88 Practice for Sampling Nonferrous Metals andAlloys in

five alloys whose primary metal is either lead or tin. Table 1

Cast Form for Determination of Chemical Composition

lists the designations for these alloys as well as their chemical

2.3 Federal Standards:

compositions.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.2 The values stated in either SI units or inch-pound units

2.4 Military Standards:

are to be regarded separately as standard. The values stated in

MIL-STD-129 Marking for Shipment and Storage (Mili-

each system may not be exact equivalents; therefore, each

tary Agencies)

system shall be used independently of the other. Combining

MIL-P-116 Methods of Preservation

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 die casting, n—a metal object produced by the intro-

responsibility of the user of this standard to become familiar

duction of molten metal under substantial pressure into a metal

with all hazards including those identified in the appropriate

die and characterized by a high degree of fidelity to the die

Material Safety Data Sheet (MSDS) for this product/material

cavity.

as provided by the manufacturer, to establish appropriate

safety and health practices, and determine the applicability of

4. Ordering Information

regulatory limitations prior to use.

4.1 Orders for die castings shall include the following basic

2. Referenced Documents information:

4.1.1 This specification number and date,

2.1 The following documents of the issue in effect on date

4.1.2 Quantity and delivery schedule, as required,

of order acceptance form a part of this specification to the

4.1.3 Part name and number,

extent referenced herein.

2 4.1.4 Alloy (Table 1), and

2.2 ASTM Standards:

4.1.5 Drawings of die casting, when required, giving all

B23 Specification for White Metal Bearing Alloys (Known

necessary dimensions and showing latest revisions and allow-

Commercially as “Babbitt Metal”)

ances for machining, if any. Location of ejector pin marks or

B275 Practice for Codification of Certain Nonferrous Met-

parting lines shall be at the option of the producer, unless

als and Alloys, Cast and Wrought

specifically designated on the drawing.

E8 Test Methods for Tension Testing of Metallic Materials

4.2 Additional tests, options and special inspection require-

E23 Test Methods for Notched Bar Impact Testing of

ments as provided below shall be specified in the contract or

Metallic Materials

purchase order, as additional procedures. Extended delivery

E29 Practice for Using Significant Digits in Test Data to

time may be involved.

Determine Conformance with Specifications

4.2.1 Chemical analysis (9.1.1),

4.2.2 Quality assurance (Section 9),

This specification is under the jurisdiction of ASTM Committee B02 on

4.2.3 Special proof tests or mechanical properties (Section

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

7),

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1936. Last previous edition approved in 2000 as B102 - 00 DOI:

10.1520/B0102-00R05. Withdrawn. The last approved version of this historical standard is referenced

For referenced ASTM standards, visit the ASTM website, www.astm.org, or on www.astm.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B102 – 00 (2005)

A

TABLE 1 Chemical Requirements

Composition, %

B,C

Alloy Tin Antimony Lead Copper Other Elements, max

Min Desired Max Min Desired Max Min Desired Max Min Desired Max Iron Arsenic Zinc Aluminum

D

CY44A 90 91 92 4 4.5 5 . . 0.35 4 4.5 5 0.08 0.08 0.01 0.01

YC135A 80 82 84 12 13 14 . . 0.35 4 5 6 0.08 0.08 0.01 0.01

D

PY1815A 64 65 66 14 15 16 17 18 19 1.5 2 2.5 0.08 0.15 0.01 0.01

D

YT155A 4 5 6 14 15 16 79 80 81 . . 0.50 . 0.15 0.01 0.01

D

Y10A . . . 9.25 10 10.75 89 90 91 . . 0.50 . 0.15 0.01

A

Forpurposesofacceptanceandrejection,theobservedvalueorcalculatedvalueobtainedfromanalysisshouldberoundedofftothenearestunitinthelastright-hand

place of figures, used in expressing the specified limit, in accordance with the rounding procedure prescribed in Section 3 of Recommended Practice E29.

B

These alloy designations were established in accordance with Recommended Practice B275.

C

Prior to 1952 these alloys were designated as No. 1, No. 2, No.3, No. 4, and No. 5, respectively.

D

These alloys are similar to grades Nos.1, 5, 8 and 12, respectively, of Specification B23.

4.2.4 General quality options for internal soundness or for test specimen shown in Fig. 18 of Test Methods E8, and the

finish (Section 11), impact test specimen shown in Fig. 6 ofTest Method E23 shall

4.2.5 Source inspection (Section 11), be used.

4.2.6 Certification (Section 12), 6.2 When specified in the contract or purchase order, die

4.2.7 Marking for identification (Section 13), and castings shall withstand proof tests without failure as defined

4.2.8 Special packaging (Section 14). by agreement between the purchaser and the producer or

supplier.

5. Quality Assurance

7. Permissible Variations in Dimensions

5.1 Responsibility for Inspection—When specified in the

contract or purchase order, the producer or supplier is respon- 7.1 Permissible variations in dimensions shall be within the

limits specified on the drawings or in the contract or purchase

sible for the performance of all inspection and test require-

order.

ments specified herein. Except as otherwise specified in the

7.2 Dimensional tolerance deviations waived by the pur-

contract or order, the producer or supplier may use his own or

chasershallbeconfirmedinwritingtotheproducerorsupplier.

any other suitable facilities for the performance of the inspec-

tion and test requirements specified herein, unless disapproved

8. General Quality

by the purchaser. The purchaser shall have the right to perform

any of the inspections and tests set forth in this specification.

8.1 Internal Soundness—When specified, the soundness of

Quality assurance standards shall be agreed upon between the

die castings shall conform to standards or requirements agreed

producer or supplier and purchaser at the time a contract or upon between the producer or supplier and the purchaser. The

order is placed.

number and extent of imperfections shall not exceed those

5.2 Lot Definition— An inspection lot shall be defined as specified by the purchaser. The standards or requirements may

follows:

consist of radiographs, photographs, or sectioned die castings.

5.2.1 An inspection lot shall consist of the production from 8.2 Imperfections inherent in die castings shall not be cause

each die or compound die on each machine for each 24 h

for rejection provided it is demonstrated that the die castings

during the first week of normal operation and the production are in accordance with the requirements and standards agreed

for each 48 h thereafter of normal operation. Any significant

upon.

change in the machine, composition, die or continuity of

8.3 Workmanship— Die castings shall be of uniform quality

operation shall be considered as the start of a new lot. Die

free of injurious discontinuities that will adversely affect their

castings inspected by this method shall be so marked or

serviceability.

handled during the finishing operations as not to lose their

8.4 Finish—When specified in the contract or purchase

identity.

order the as-cast surface

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.