ASTM F899-10

(Specification)Standard Specification for Wrought Stainless Steels for Surgical Instruments

Standard Specification for Wrought Stainless Steels for Surgical Instruments

ABSTRACT

This specification covers the chemical requirements for wrought stainless steels used for the manufacture of surgical instruments. Classes of stainless steels covered here are Class 3 (austenitic stainless steel), Class 4 (martensitic stainless steel), Class 5 (precipitation hardening stainless steel), and Class 6 (ferritic stainless steel). The data contained in this specification, such as typical hardness values, common heat treating cycles, and examples of selected stainless steels that have been used for surgical instruments, are provided for reference only. Mechanical property, heat treatment, hardness, and all other requirements except for chemical composition, are governed by the appropriate material standards as specified or as agreed upon between purchaser and supplier.

SCOPE

1.1 This specification covers the chemistry requirements for wrought stainless steels used for the manufacture of surgical instruments. The data contained in Tables 1-4 of this specification, including typical hardness values, common heat treating cycles, and examples of selected stainless steels that have been used for surgical instruments, is provided for reference only. Mechanical property requirements, heat treating requirements, hardness requirements and all other requirements except chemistry are governed by the appropriate material standards as referenced below or as agreed upon between purchaser and supplier.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F899 – 10

Standard Specification for

1

Wrought Stainless Steels for Surgical Instruments

ThisstandardisissuedunderthefixeddesignationF899;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

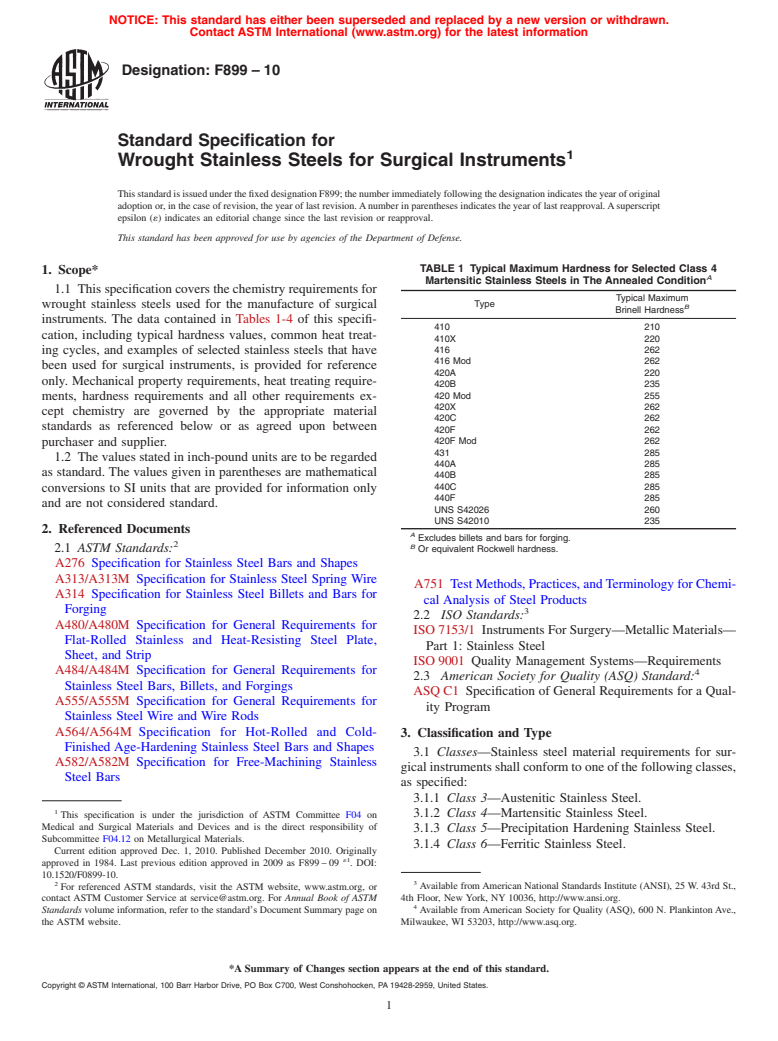

TABLE 1 Typical Maximum Hardness for Selected Class 4

1. Scope*

A

Martensitic Stainless Steels in The Annealed Condition

1.1 This specification covers the chemistry requirements for

Typical Maximum

Type

wrought stainless steels used for the manufacture of surgical

B

Brinell Hardness

instruments. The data contained in Tables 1-4 of this specifi-

410 210

cation, including typical hardness values, common heat treat-

410X 220

ing cycles, and examples of selected stainless steels that have 416 262

416 Mod 262

been used for surgical instruments, is provided for reference

420A 220

only. Mechanical property requirements, heat treating require-

420B 235

420 Mod 255

ments, hardness requirements and all other requirements ex-

420X 262

cept chemistry are governed by the appropriate material

420C 262

standards as referenced below or as agreed upon between

420F 262

420F Mod 262

purchaser and supplier.

431 285

1.2 The values stated in inch-pound units are to be regarded

440A 285

as standard. The values given in parentheses are mathematical

440B 285

440C 285

conversions to SI units that are provided for information only

440F 285

and are not considered standard.

UNS S42026 260

UNS S42010 235

2. Referenced Documents

A

Excludes billets and bars for forging.

2

B

2.1 ASTM Standards: Or equivalent Rockwell hardness.

A276 Specification for Stainless Steel Bars and Shapes

A313/A313M Specification for Stainless Steel Spring Wire

A751 Test Methods, Practices, andTerminology for Chemi-

A314 Specification for Stainless Steel Billets and Bars for

cal Analysis of Steel Products

Forging

3

2.2 ISO Standards:

A480/A480M Specification for General Requirements for

ISO 7153/1 Instruments For Surgery—Metallic Materials—

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

Part 1: Stainless Steel

Sheet, and Strip

ISO 9001 Quality Management Systems—Requirements

A484/A484M Specification for General Requirements for 4

2.3 American Society for Quality (ASQ) Standard:

Stainless Steel Bars, Billets, and Forgings

ASQ C1 Specification of General Requirements for a Qual-

A555/A555M Specification for General Requirements for

ity Program

Stainless Steel Wire and Wire Rods

A564/A564M Specification for Hot-Rolled and Cold-

3. Classification and Type

Finished Age-Hardening Stainless Steel Bars and Shapes

3.1 Classes—Stainless steel material requirements for sur-

A582/A582M Specification for Free-Machining Stainless

gicalinstrumentsshallconformtooneofthefollowingclasses,

Steel Bars

as specified:

3.1.1 Class 3—Austenitic Stainless Steel.

1

This specification is under the jurisdiction of ASTM Committee F04 on 3.1.2 Class 4—Martensitic Stainless Steel.

Medical and Surgical Materials and Devices and is the direct responsibility of

3.1.3 Class 5—Precipitation Hardening Stainless Steel.

Subcommittee F04.12 on Metallurgical Materials.

3.1.4 Class 6—Ferritic Stainless Steel.

Current edition approved Dec. 1, 2010. Published December 2010. Originally

´1

approved in 1984. Last previous edition approved in 2009 as F899 – 09 . DOI:

10.1520/F0899-10.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

the ASTM website. Milwaukee, WI 53203, http://www.asq.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

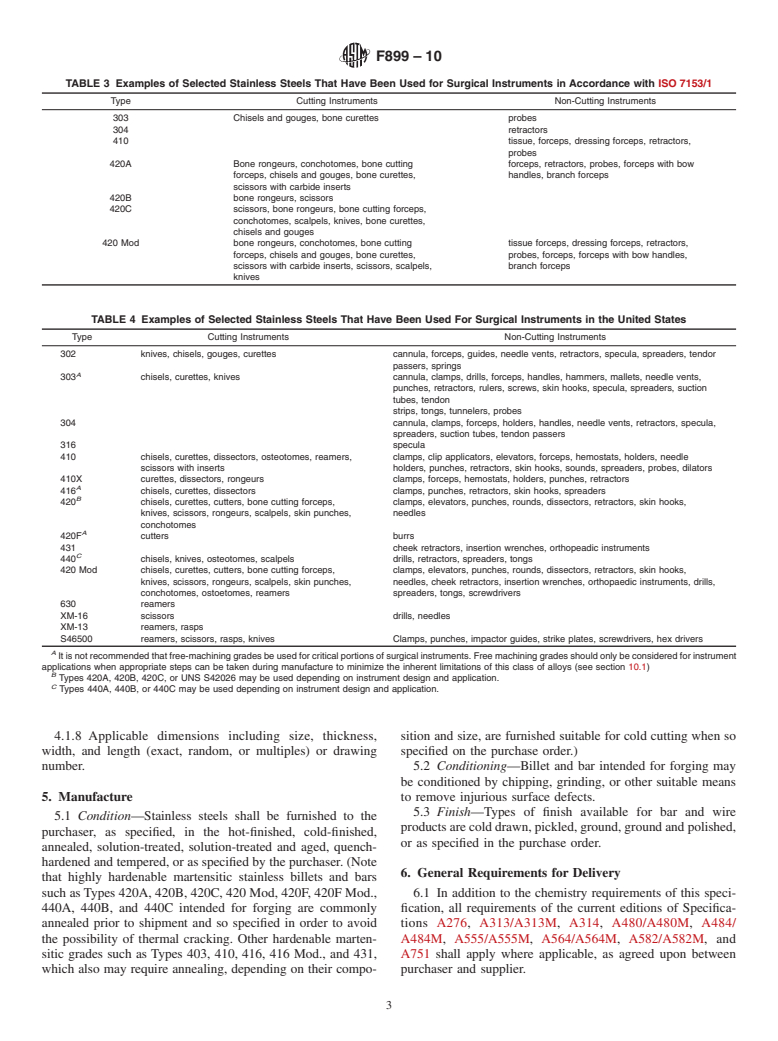

F899 – 10

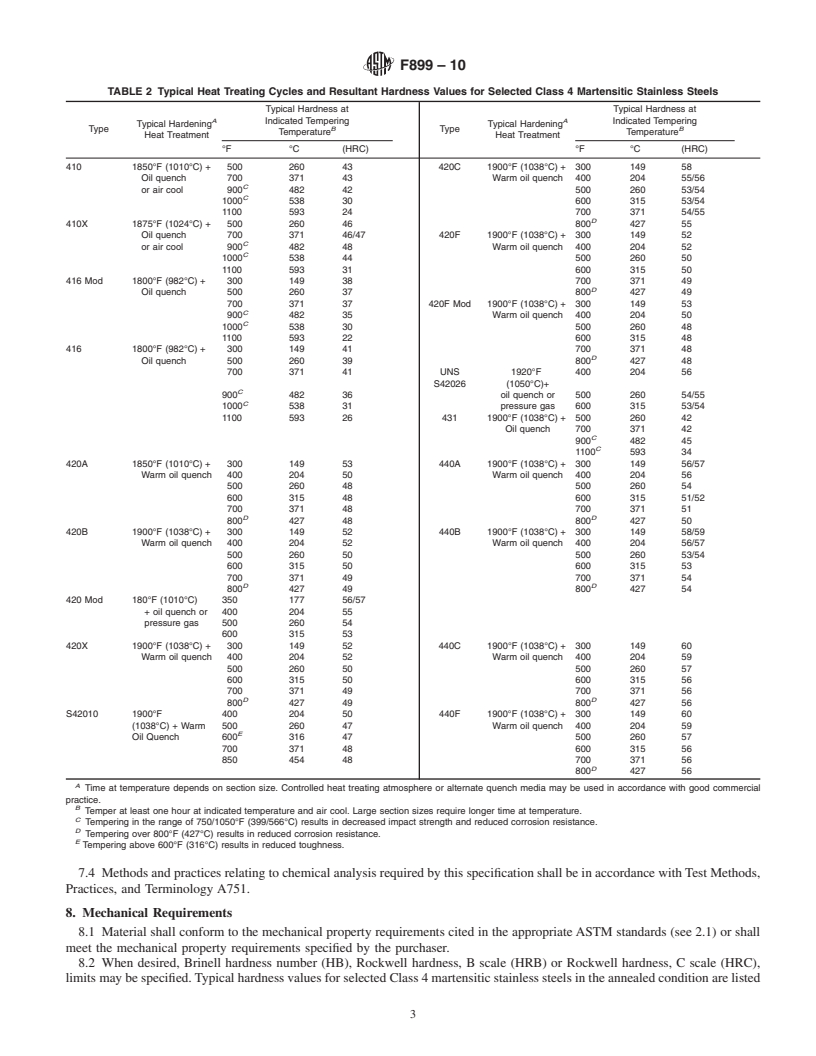

TABLE 2 Typical Heat Treating Cycles and Resultant Hardness Values for Selected Class 4 Martensitic Stainless Steels

Typical Hardness at Typical Hardness at

A Indicated Tempering A Indicated Tempering

Typical Hardening Typical Hardening

B B

Type Type

Temperature Temperature

Heat Treatment Heat Treatment

°F °C (HRC) °F °C (HRC)

410 1850°F (1010°C) + 500 260 43 420C 1900°F (1038°C) + 300 149 58

Oil quench 700 371 43 Warm oil quench 400 204 55/56

C

or air cool 900 482 42 500 260 53/54

C

1000 538 30 600 315 53/54

1100 593 24 700 371 54/55

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F899–09 Designation: F899 – 10

Standard Specification for

1

Wrought Stainless Steels for Surgical Instruments

ThisstandardisissuedunderthefixeddesignationF899;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—“Other Elements” in Table8 were corrected editorially in April 2010.

1. Scope*

1.1 This specification covers the chemistry requirements for wrought stainless steels used for the manufacture of surgical

instruments.The data contained inTables 1-4 of this specification, including typical hardness values, common heat treating cycles,

and examples of selected stainless steels that have been used for surgical instruments, is provided for reference only. Mechanical

propertyrequirements,heattreatingrequirements,hardnessrequirementsandallotherrequirementsexceptchemistryaregoverned

by the appropriate material standards as referenced below or as agreed upon between purchaser and supplier.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A276 Specification for Stainless Steel Bars and Shapes

A313/A313M Specification for Stainless Steel Spring Wire

A314 Specification for Stainless Steel Billets and Bars for Forging

A480/A480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A555/A555M Specification for General Requirements for Stainless Steel Wire and Wire Rods

A564/A564M Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

A582/A582M Specification for Free-Machining Stainless Steel Bars

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

3

2.2 ISO Standards:

ISO 7153/1 Instruments For Surgery—Metallic Materials—Part 1: Stainless Steel

ISO 9001 Quality Management Systems—Requirements

4

2.3 American Society for Quality (ASQ) Standard:

ASQ C1 Specification of General Requirements for a Quality Program

3. Classification and Type

3.1 Classes—Stainless steel material requirements for surgical instruments shall conform to one of the following classes, as

specified:

3.1.1 Class 3—Austenitic Stainless Steel.

3.1.2 Class 4—Martensitic Stainless Steel.

3.1.3 Class 5—Precipitation Hardening Stainless Steel.

3.1.4 Class 6—Ferritic Stainless Steel.

3.2 Type—Where applicable, the commercially recognized type of stainless steel is included in Tables 5 and 6.

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved Feb. 1, 2009. Published February 2009. Originally approved in 1984. Last previous edition approved in 2007 as F899–07. DOI:

10.1520/F0899-09E01.

´1

Current edition approved Dec. 1, 2010. Published December 2010. Originally approved in 1984. Last previous edition approved in 2009 as F899 – 09 . DOI:

10.1520/F0899-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave., Milwaukee, WI 53203, http://www.asq.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F899 – 10

TABLE 1 Typical Maximum Hardness for Selected Class 4

A

Martensitic Stainless Steels in The Annealed Condition

Typical Maximum

Type

B

Brinell Hardness

410 210

410X 220

416 262

416 Mod 262

420A 220

420B 235

420 Mod 255

420X 262

420C 262

420F 262

420F Mod 262

431 285

440A 285

440B 285

440C 285

440F 285

UNS S42026 260

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.