ASTM A815/A815M-00

(Specification)Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings

Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings

SCOPE

1.1 This specification covers two general classes, WP and CR, of wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings of seamless and welded construction covered by the latest revision of Specification A 960. Fittings differing from these standards may be furnished in accordance with Supplementary Requirement S8.

1.1.1 Class WP fittings are subdivided into four subclasses: Classes WP-S, WP-W, WP-WX, and WP-WU. They are manufactured to the requirements of Specification A960, and they shall have pressure ratings compatible with 12.2 . Class WP-S fittings are those manufactured from seamless product by a seamless method of manufacture (marked with class symbol WP-S); Class WP-W fittings are those which contain welds where the fitting fabrication or construction welds have been radiographed (marked with class symbol WP-W); and Class WP-WX fittings are those which contain welds where all welds have been radiographed (marked with class symbol WP-WX); and Class WP-WU fittings are those which contain welds where all welds have been ultrasonically tested (marked with class symbol WP-WU).

1.1.2 Class CR fittings are those manufactured to the requirements of MSS SP-43, and they shall have pressure ratings compatible with 12.3.

1.2 This specification does not apply to cast fittings.

1.3 Optional supplementary requirements are provided. When desired, one or more of these may be specified in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation [SI units], the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 815/A 815M – 00 An American National Standard

Standard Specification for

Wrought Ferritic, Ferritic/Austenitic, and Martensitic

Stainless Steel Piping Fittings

This standard is issued under the fixed designation A 815/A 815M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

1.1 This specification covers two general classes, WP and

two systems may result in nonconformance with the specifi-

CR, of wrought ferritic, ferritic/austenitic, and martensitic

cation.

stainless steel fittings of seamless and welded construction

covered by the latest revision of ANSI B16.9, ANSI B16.11,

2. Referenced Documents

ANSI B16.28, MSS Standard Practice SP-79, and MSS Stan-

2.1 ASTM Standards:

dard Practice SP-43. Fittings differing from these standards

A 262 Practices for Detecting Susceptibility to Intergranu-

may be furnished in accordance with Supplementary Require-

lar Attack in Austenitic Stainless Steels

ment S8.

A 370 Test Methods and Definitions for Mechanical Testing

1.1.1 Class WP fittings are subdivided into four subclasses:

of Steel Products

Classes WP-S, WP-W, WP-WX, and WP-WU. They are

A 388/A388M Practice for Ultrasonic Examination of

manufactured to the requirements of ANSI B16.9, B16.11,

Heavy Steel Forgings

B16.28, or MSS Standard Practice SP-79, and they shall have

A 751 Test Methods, Practices, and Terminology for

pressure ratings compatible with 12.2. Class WP-S fittings are

Chemical Analysis of Steel Products

those manufactured from seamless product by a seamless

A 763 Practices for Detecting Susceptibility to Intergranu-

method of manufacture (marked with class symbol WP-S);

lar Attack in Ferritic Stainless Steels

Class WP-W fittings are those which contain welds where the

E 165 Test Method for Liquid Penetrant Examination

fitting fabrication or construction welds have been radio-

2.2 ASME Standards:

graphed (marked with class symbol WP-W); and Class

B16.9 Wrought Steel Butt-Welding Fittings

WP-WX fittings are those which contain welds where all welds

B16.11 Forged Steel Fittings, Socket-Welding and Threaded

have been radiographed (marked with class symbol WP-WX);

B16.28 Wrought Steel Butt-Welding Short Radius Elbows

and Class WP-WU fittings are those which contain welds

and Returns

where all welds have been ultrasonically tested (marked with

2.3 MSS Standards:

class symbol WP-WU).

SP-25 Standard Marking System for Valves, Fittings,

1.1.2 Class CR fittings are those manufactured to the

Flanges, and Unions

requirements of MSS SP-43, and they shall have pressure

SP-43 Standard Practice for Light Weight Stainless Steel

ratings compatible with 12.3.

Butt-Welding Fittings

1.2 This specification does not apply to cast fittings.

SP-79 Socket-Welding Reducer Inserts

1.3 Optional supplementary requirements are provided.

2.4 ASME Boiler and Pressure Vessel Codes:

When desired, one or more of these may be specified in the

Section VIII Division I, Pressure Vessels

order.

Section IX Welding Qualifications

1.4 This specification is expressed in both inch-pound units

2.5 ASNT Standard:

and in SI units. However, unless the order specifies the

SNT-TC-1A(1984) Recommended Practice for Nondestruc-

applicable “M” specification designation [SI units], the mate-

tive Testing Personnel Qualification and Certification

rial shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 03.03.

1 5

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Available from American Society of Mechanical Engineers, Three Park

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Avenue, New York, NY 10016-5990.

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Available from Manufacturers’ Standardization Society of the Valve and

Materials for Piping and Special Purpose Applications. Fittings Industry, 127 Park St., N.E., Vienna, VA 22180.

Current edition approved Mar. 10, 2000. Published May 2000. Originally Available from American Society for Nondestructive Testing, 4153 Arlingate

published as A 815 – 83. Last previous edition A 815/A 815M – 99. Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 815/A 815M

3. Ordering Information 4. Materials

3.1 It is the purchaser’s responsibility to specify in the

4.1 The material for fittings shall consist of forgings, bars,

purchase order all ordering information necessary needed to

plates, or seamless or welded tubular products that conform to

purchase the needed material. Examples of such information

the chemical requirements in Table 1.

include but are not limited to the following:

4.2 The steel shall be melted by one of the following

3.1.1 Quantity, number of fittings of each kind,

processes:

3.1.2 Description of fitting and nominal dimension (stan-

4.2.1 Electric furnace (with separate degassing and refining

dard or special),

optional),

3.1.3 Steel composition by grade and Class designation,

4.2.2 Vacuum furnace, or

3.1.4 Class WP or CR shall be specified. Class WP fittings

4.2.3 Electric furnace followed by vacuum or electroslag-

may be further defined by specifying Class WP-S, WP-W, or

consumable remelting.

WP-WX,

4.3 If secondary melting is employed, the heat shall be

3.1.4.1 Unless Class WP-S, WP-W, or WP-WX is specified

defined as all ingots remelted from a primary heat.

by the purchaser, any may be furnished at the option of the

supplier,

5. Manufacture

3.1.4.2 Class CR fittings shall not be substituted for fittings

5.1 Forming—Forging or shaping operations may be per-

ordered to Class WP, but Class WP may be substituted for

Class CR, and formed by hammering, pressing, piercing, extruding, upsetting,

rolling, bending, fusion welding, machining or by combination

3.1.5 Supplementary requirements, if any.

3.1.6 Additional requirements (see 4.1, 13.2, and 16.1). of two or more of these operations. The forming procedure

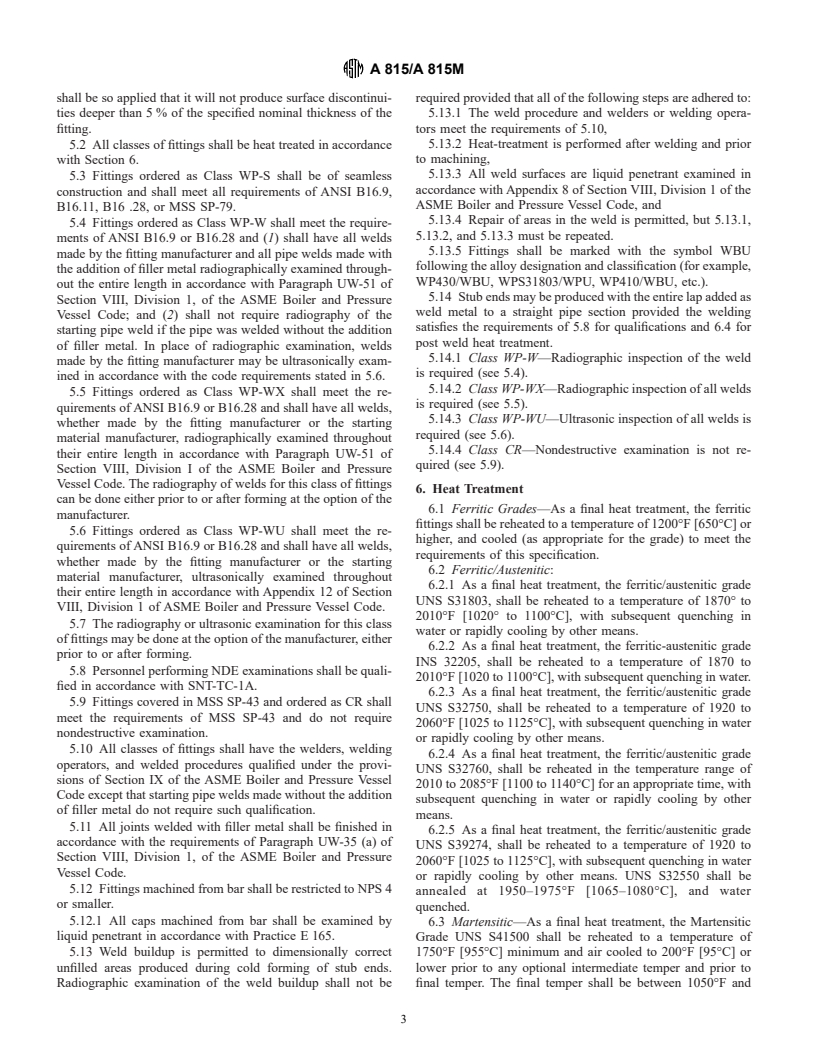

TABLE 1 Chemical Requirements

NOTE 1—Where an ellipsis (. . .) appears in this table, there is no requirement.

Composition, %

C, Mn, P, S, Si, Cu,

A

Grade UNS Ni Cr Mo N Ti Other

max max max max max max

Ferritic Steels

WP27 S44627 0.010 0.75 0.020 0.020 0.40 0.50 25.0– 0.75– 0.20 0.015 . Cb

27.5 1.50 max 0.05–0.20

WP33 S44626 0.06 0.75 0.040 0.020 0.75 0.50 25.0– 0.75– 0.20 0.040 0.20–1.00 .

27.0 1.50 max (73(C+N)) min

WP429 S42900 0.12 1.0 0.040 0.030 0.75 0.50 14.0– . . . . .

16.0

WP430 S43000 0.12 1.00 0.040 0.030 1.00 0.50 16.0– . . . . .

18.0

WP430TI S43036 0.10 1.00 0.040 0.030 1.00 0.75 16.0– . . . (53C) min 0.75 .

19.5 max

WP446 S44600 0.20 1.50 0.040 0.030 0.75 0.50 23.0– . . . . . . 0.25 . . . . . .

27.0

Ferritic/Austenitic Steels

S31803 S31803 0.030 2.00 0.030 0.020 1.0 4.5– 21.0– 2.5– . . . 0.08– . .

6.5 23.0 3.5 0.20

S32750 S32750 0.030 1.20 0.035 0.020 0.8 6.0– 24.0– 3.0– 0.5 0.24– . .

8.0 26.0 5.0 0.32

S32950 S32950 0.030 2.00 0.035 0.010 0.60 3.5– 26.0– 1.00– . . . 0.15– . .

5.2 29.0 2.50 0.35

S32760 S32760 0.030 1.00 0.030 0.010 1.00 6.0– 24.0– 3.0– 0.50– 0.20– . W

B B B

8.0 26.0 4.0 1.00 0.30 0.50–1.00

S39274 S32974 0.030 1.00 0.030 0.020 0.80 6.0– 24.0– 2.50– 0.20– 0.24– . W

B

8.0 26.0 3.50 0.80 0.32 1.50–2.50

S32550 S32550 0.04 1.50 0.040 0.030 1.00 4.5– 24.0– 2.9– 1.50– 0.10– . .

6.5 27.0 3.9 2.50 0.25

S32205 S32205 0.030 2.00 0.030 0.020 1.00 4.5– 22.0– 3.0– . . . 0.14– . .

6.5 23.0 3.5 0.20

Martensitic Steels

WP410 S41000 0.15 1.00 0.040 0.030 1.00 0.50 11.5– . . . . .

max 13.5

UNS S41500 0.05 0.50– 0.030 0.030 0.60 3.5– 11.5– 0.50– . . . W

S41500 1.00 5.5 14.0 1.00 0.50–1.00

A

Maximun unless otherwise indicated.

B

%Cr+3.3 3 %Mo+16 3 %N=40 min.

A 815/A 815M

shall be so applied that it will not produce surface discontinui- required provided that all of the following steps are adhered to:

ties deeper than 5 % of the specified nominal thickness of the 5.13.1 The weld procedure and welders or welding opera-

fitting. tors meet the requirements of 5.10,

5.13.2 Heat-treatment is performed after welding and prior

5.2 All classes of fittings shall be heat treated in accordance

to machining,

with Section 6.

5.13.3 All weld surfaces are liquid penetrant examined in

5.3 Fittings ordered as Class WP-S shall be of seamless

accordance with Appendix 8 of Section VIII, Division 1 of the

construction and shall meet all requirements of ANSI B16.9,

ASME Boiler and Pressure Vessel Code, and

B16.11, B16 .28, or MSS SP-79.

5.13.4 Repair of areas in the weld is permitted, but 5.13.1,

5.4 Fittings ordered as Class WP-W shall meet the require-

5.13.2, and 5.13.3 must be repeated.

ments of ANSI B16.9 or B16.28 and (1) shall have all welds

5.13.5 Fittings shall be marked with the symbol WBU

made by the fitting manufacturer and all pipe welds made with

following the alloy designation and classification (for example,

the addition of filler metal radiographically examined through-

WP430/WBU, WPS31803/WPU, WP410/WBU, etc.).

out the entire length in accordance with Paragraph UW-51 of

5.14 Stub ends may be produced with the entire lap added as

Section VIII, Division 1, of the ASME Boiler and Pressure

weld metal to a straight pipe section provided the welding

Vessel Code; and (2) shall not require radiography of the

satisfies the requirements of 5.8 for qualifications and 6.4 for

starting pipe weld if the pipe was welded without the addition

post weld heat treatment.

of filler metal. In place of radiographic examination, welds

5.14.1 Class WP-W—Radiographic inspection of the weld

made by the fitting manufacturer may be ultrasonically exam-

is required (see 5.4).

ined in accordance with the code requirements stated in 5.6.

5.14.2 Class WP-WX—Radiographic inspection of all welds

5.5 Fittings ordered as Class WP-WX shall meet the re-

is required (see 5.5).

quirements of ANSI B16.9 or B16.28 and shall have all welds,

5.14.3 Class WP-WU—Ultrasonic inspection of all welds is

whether made by the fitting manufacturer or the starting

required (see 5.6).

material manufacturer, radiographically examined throughout

5.14.4 Class CR—Nondestructive examination is not re-

their entire length in accordance with Paragraph UW-51 of

quired (see 5.9).

Section VIII, Division I of the ASME Boiler and Pressure

Vessel Code. The radiography of welds for this class of fittings

6. Heat Treatment

can be done either prior to or after forming at the option of the

6.1 Ferritic Grades—As a final heat treatment, the ferritic

manufacturer.

fittings shall be reheated to a temperature of 1200°F [650°C] or

5.6 Fittings ordered as Class WP-WU shall meet the re-

higher, and cooled (as appropriate for the grade) to meet the

quirements of ANSI B16.9 or B16.28 and shall have all welds,

requirements of this specification.

whether made by the fitting manufacturer or the starting

6.2 Ferritic/Austenitic:

material manufacturer, ultrasonically examined throughout

6.2.1 As a final heat treatment, the ferritic/austenitic grade

their entire length in accordance with Appendix 12 of Section

UNS S31803, shall be reheated to a temperature of 1870° to

VIII, Division 1 of ASME Boiler and Pressure Vessel Code.

2010°F [1020° to 1100°C], with subsequent quenching in

5.7 The radiography or ultrasonic examination for this class

water or rapidly cooling by other means.

of fittings may be done at the option of the manufacturer, either

6.2.2 As a final heat treatment, the ferritic-austenitic grade

prior to or after forming.

INS 32205, shall be reheated to a temperature of 1870 to

5.8 Personnel performing NDE examinations shall be quali-

2010°F [1020 to 1100°C], with subsequent quenching in water.

fied in accordance with SNT-TC-1A.

6.2.3 As a final heat treatment, the ferritic/austenitic grade

5.9 Fittings covered in MSS SP-43 and ordered as CR shall

UNS S32750, shall be reheated to a temperature of 1920 to

meet the requirements of MSS SP-43 and do not require

2060°F [1025 to 1125°C], with subsequent quenching in water

nondestructive examination.

or rapidly cooling by other means.

5.10 All classes of fittings shall have the welders, welding

6.2.4 As a final heat treatment, the ferritic/austenitic grade

operators, and welded procedures qualified under the provi-

UNS S32760, shall be reheated in the temperature range of

sions of Section IX of the ASME Boiler and Pressure Vessel

2010 to 2085°F [1100 to 1140°C] for an appropriate time, with

Code except that starting pipe welds made without the addition

subsequent quenching in water or rapidly cooling by other

of filler metal do not require such qualification.

means.

5.11 All joints welded with filler metal shall be finished in

6.2.5 As a final heat treatment, the ferritic/austenitic grade

accordance with the requirements of Paragraph UW-35 (a) of

UNS S39274, shall be reheated to a temperature of 1920 to

Section VIII, Division 1, of the ASME Boiler and Pressure

2060°F [1025 to 1125°C], with subsequent quenching in water

Vessel Code.

or rapidly cooling by other means. UNS S32550 shall be

5.12 Fittings machined from bar shall be restricted to NPS 4

annealed at 1950–1975°F [1065–1080°C], and water

or smaller.

quenched.

5.12.1 All caps machined from bar shall be examined by

6.3 Martensitic—As a final heat treatment, the Martensitic

liquid penetrant in accordance with Practice E 165. Grade UNS S41500 shall be reheated to a temperature of

5.13 Weld buildup is permitted to dimensionally correct 1750°F [955°C] minimum and air cooled to 200°F [95°C] or

unfilled areas produced during cold forming of stub ends. lower prior to any optional intermediate temper and prior to

Radiographic examination of the weld buildup shall not be final temper. The final temper shall be between 1050°F and

A 815/A 815M

1150°F [565°C and 620°C]. WP410 shall be heat treated in the same requirements as the base metal.

accordance with 6.1. 7.2.1 Welds on S23950 base metal shall be made with

6.4 All welding shall be done prior to final heat treatment. nominal 26 % Cr, 8 % Ni, 2 % Mo weld metal.

6.5 Fittings machined directly from a f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.