ASTM D6586-03(2008)

(Practice)Standard Practice for the Prediction of Contaminant Adsorption On GAC In Aqueous Systems Using Rapid Small-Scale Column Tests

Standard Practice for the Prediction of Contaminant Adsorption On GAC In Aqueous Systems Using Rapid Small-Scale Column Tests

SIGNIFICANCE AND USE

Granular activated carbon (GAC) is commonly used to remove contaminants from water. However if not used properly, GAC can not only be expensive but can at times be ineffective. The development of engineering data for the design of full-scale adsorbers often requires time-consuming and expensive pilot plant studies. This rapid standard practice has been developed to predict adsorption in large-scale adsorbers based upon results from small column testing. In contrast to pilot plant studies, the small-scale column test presented in this practice does not allow for a running evaluation of factors that may affect GAC performance over time. Such factors may include, for example, an increased removal of target compounds by bacterial colonizing GAC or long term fouling of GAC caused by inorganic compounds or background organic matter . Nevertheless, this practice offers more relevant operational data than isotherm testing without the principal drawbacks of pilot plant studies, namely time and expense; and unlike pilot plant studies, small scale studies can be performed in a laboratory using water sampled from a remote location.

This practice known as the rapid small-scale column test (RSSCT) uses empty bed contact time (EBCT) and hydraulic loading to describe the adsorption process. Mean carbon particle diameter is used to scale RSSCT results to predict the performance of a full-scale adsorber.

This practice can be used to compare the effectiveness of different activated carbons for the removal of contaminants from a common water stream.

SCOPE

1.1 This practice covers a test method for the evaluation of granular activated carbon (GAC) for the adsorption of soluble pollutants from water. This practice can be used to estimate the operating capacities of virgin and reactivated granular activated carbons. The results obtained from the small-scale column testing can be used to predict the adsorption of target compounds on GAC in a large column or full scale adsorber application.

1.2 This practice can be applied to all types of water including synthetically contaminated water (prepared by spiking high purity water with selected contaminants), potable waters, industrial waste waters, sanitary wastes and effluent waters.

1.3 This practice is useful for the determination of breakthrough curves for specific contaminants in water, the determination of the lengths of the adsorbates mass transfer zones (MTZ) and the prediction of GAC usage rates for larger scale adsorbers.

1.4 The following safety caveat applies to the procedure section, Section 10, of this practice: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6586 − 03(Reapproved 2008)

Standard Practice for

the Prediction of Contaminant Adsorption On GAC In

Aqueous Systems Using Rapid Small-Scale Column Tests

This standard is issued under the fixed designation D6586; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2854Test Method for Apparent Density of Activated

Carbon

1.1 This practice covers a test method for the evaluation of

D2867Test Methods for Moisture in Activated Carbon

granular activated carbon (GAC) for the adsorption of soluble

D2862Test Method for Particle Size Distribution of Granu-

pollutantsfromwater.Thispracticecanbeusedtoestimatethe

lar Activated Carbon

operating capacities of virgin and reactivated granular acti-

vated carbons. The results obtained from the small-scale

3. Terminology

column testing can be used to predict the adsorption of target

compounds on GAC in a large column or full scale adsorber

3.1 Definitions:

application.

3.1.1 For definitions of terms in this practice relating to

1.2 This practice can be applied to all types of water

activated carbon, refer to Terminology D2652.

including synthetically contaminated water (prepared by spik-

3.1.2 For definitions of terms in this practice relating to

ing high purity water with selected contaminants), potable

water, refer to Terminology D1129.

waters, industrial waste waters, sanitary wastes and effluent

waters.

4. Summary of Practice

1.3 This practice is useful for the determination of break-

4.1 This practice consists of a method for the rapid deter-

through curves for specific contaminants in water, the deter-

mination of breakthrough curves and the prediction of GAC

mination of the lengths of the adsorbates mass transfer zones

(MTZ) and the prediction of GAC usage rates for larger scale usage rates for the removal of soluble contaminants from

adsorbers. water.Thisisaccomplishedbypassingthecontaminatedwater

at a constant controlled rate down flow through a bed of a

1.4 The following safety caveat applies to the procedure

specially sized granular activated carbon until predetermined

section, Section 10, of this practice:This standard does not

levels of breakthrough have occurred.

purport to address all of the safety concerns, if any, associated

with its use. It is the responsibility of the user of this standard

4.2 When the assumption is made that conditions of con-

to establish appropriate safety and health practices and

stant diffusivity exist within the GAC column, the break-

determine the applicability of regulatory limitations prior to

through data obtained from the column test can be used to

use.

estimate the size and operational conditions for a full-scale

carbon adsorber.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

D1129Terminology Relating to Water

D1193Specification for Reagent Water

5.1 Granular activated carbon (GAC) is commonly used to

D2652Terminology Relating to Activated Carbon

remove contaminants from water. However if not used

properly, GAC can not only be expensive but can at times be

1 ineffective.Thedevelopmentofengineeringdataforthedesign

This practice is under the jurisdiction of ASTM Committee D28 on Activated

Carbon and is the direct responsibility of Subcommittee D28.02 on Liquid Phase

of full-scale adsorbers often requires time-consuming and

Evaluation.

expensive pilot plant studies. This rapid standard practice has

Current edition approved Aug. 1, 2008. Published September 2008. Originally

been developed to predict adsorption in large-scale adsorbers

approved in 2000. Last previous edition approved in 2003 as D6586–03. DOI:

10.1520/D6586-03R08.

based upon results from small column testing. In contrast to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pilotplantstudies,thesmall-scalecolumntestpresentedinthis

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

practice does not allow for a running evaluation of factors that

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. may affect GAC performance over time. Such factors may

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6586 − 03 (2008)

include, for example, an increased removal of target com- and large-column tests, respectively.The condition of constant

pounds by bacterial colonizing GAC or long term fouling of diffusivity also requires the Reynolds numbers for the RSSCT

GAC caused by inorganic compounds or background organic and the large-column be equal. This means the following

matter . Nevertheless, this practice offers more relevant opera- equation must also be satisfied:

tional data than isotherm testing without the principal draw-

V R

sc lc

5 (2)

backs of pilot plant studies, namely time and expense; and

V R

lc rc

unlike pilot plant studies, small scale studies can be performed

where: V and V are the hydraulic loadings in the RSSCT

in a laboratory using water sampled from a remote location. sc lc

and large columns, respectively. Based upon the above

5.2 Thispracticeknownastherapidsmall-scalecolumntest

equations, the operating conditions for the RSSCT can be

(RSSCT) uses empty bed contact time (EBCT) and hydraulic

selected to precisely simulate the desired (specified) operating

loading to describe the adsorption process. Mean carbon

conditions for a full-scale adsorber.

particle diameter is used to scale RSSCT results to predict the

NOTE 1—There is an important issue relating to RSSCT design using

performance of a full-scale adsorber.

Equation 2 . Sometimes using leads to a design with a high head loss,

5.3 This practice can be used to compare the effectiveness

which increases dramatically with operating time, as the GAC is crushed

of different activated carbons for the removal of contaminants by a large pressure drop across the RSSCT. This may be avoided by

loweringthesuperficialvelocityaslongasdispersiondoesnotbecomethe

from a common water stream.

dominant transport mechanism and intraparticle mass transfer is limiting

theadsorptionrate.ThePecletnumberbasedondiametercanbeestimated

6. Summary of Practice

from the following equation :

6.1 The development of the RSSCT is based on the

Pe 50.334 for160#Re·Sc#40,000

d

When the velocity is reduced below what is given in EquationA, axial

dispersed-flow pore surface diffusion model (DFPSDM)

dispersion,whichiscausedbymoleculardiffusion,canbemoreimportant

(Crittenden, et al ) which takes into account many of the

intheRSSCTthaninthefullscaleprocess.Consequently,EquationAcan

mechanisms that are known to occur in fixed-bed adsorption.

be used to check whether dispersion becomes important as the velocity of

The following mechanisms, which cause the breakthrough

the RSSCT is reduced in an effort to reduce the head loss. Typical Sc

curves for an adsorber to spread out and create the mass values for SOCs is ~ 2000; consequently, the Re for the RSSCT must be

kept greater than ~0.1 and the Pe must be kept above 50 for the length of

transfer zone are included in the DFPSDM: external mass-

the mass transfer zone.

transfer resistance or film transfer, axial mixing due to disper-

NOTE2—Empty-bedcontacttime(EBCT)isdefinedasthebedvolume

sion and the internal mass-transfer resistances of pore and

(in liters) divided by the water flow rate in liters/minute. For example if a

surface diffusion.

full scale adsorber holds 20 000 Lof activated carbon and the water flow

rate is 2500 L/min, the EBCT would be equal to 20 000/2500 or 8.0 min.

6.2 To simulate full-scale performance, the amount of

6.3 The assumption that conditions of constant diffusivity

spreading in the breakthrough curve relative to column depth

existwithintheGACcolumndoesnotapplytoallwatersorall

must be identical for the RSSCT and the full-scale column. To

targetcompounds.Forexamplethisassumptiondoesnotapply

achieve this, the relative contributions of the mechanisms that

for the decolorization of water and the adsorption of large

cause most of the spreading are matched by maintaining

molecules, such as humic and fulvic acids. It is recommended

similarity as the GAC process is scaled. Studies have shown

thatatleastoneRSSCTpilot-columncomparisonbeconducted

that matching of the spreading of the breakthrough curve can

to aid in selecting the RSSCT design variables for a given

beachievedbyequatingthedimensionlessgroupsinPFPSDM

water matrix (Crittenden, et al ). A detailed comparison be-

(Plug Flow Pore Surface Diffusion Model). Under the condi-

tween the constant diffusivity and proportional diffusivity

tions that intraparticle diffusivities are assumed to be indepen-

approaches and their respective domains of application is

dent of the carbon particle radius, i.e. the condition of constant

beyond the scope of this practice.

diffusivity, the following equation describes the relationship

between the small and large columns:

6.4 GAC bed volume and preparation methods are impor-

tant design parameters for the RSSCT. The GAC bed volume

EBCT R t

sc sc sc

5 5 (1)

S D

usedwilldeterminetherequiredwaterpumpingrateandaffect

EBCT R t

lc lc lc

theamountofwaterneededtocompletethetest.Theminimum

where:EBCT andEBCT aretheempty-bedcontacttimes

sc lc

column diameter needed to avoid channeling should be 50

forthesmall-column(RSSCT)andthelarge-column(full-scale

particlediameters.Forthe10-mmdiametercolumncommonly

adsorber), respectively; R and R are the radii of the carbon

sc lc

used in RSSCT systems, a 60 by 80 mesh carbon should be

particlesusedinthesmallandlargecolumns,respectively;and

used. Proper GAC sampling (Practice E300) and preparation

t and t are the elapsed times required to conduct the small-

sc lc

(grinding, classification and washing) are required for repro-

ducible results.

Owen,D.M.,Chowdhury,Z.K.,Summers,R.S.,Hooper,S.M.,andSolarik,G.,

6.5 Based upon the water feed rate to the column, the time

“Determination of Technology and Costs for GAC Treatment Using the ICR

required to reach the desired breakpoint and the weight of

Methodology,”AWWAGAC&MembraneWorkshop,March1996,Cincinnati,OH.

Knappe,D.,Snoeyink,V.,Roche,P.,Prados,M.andBourbigot,M.,“TheEffect

of Preloading on RSSCT Predictions of Atrazine Removal By GAC Adsorbers”, Crittenden, J. C., Berrigan, J. K., Jr., Hand, D. W., and Lykins, B. W., Jr.

Water Research, Vol. 31, No. 11, 1997, pp. 2899-2909. "Design of rapid fixed-bed adsorption tests for non-constant diffusivities," Journal

Crittenden, J. C., Berrigan, J. K., Jr., and Hand, D. W., "Design of rapid of Environmental Engineering, Vol. 113, No. 2, pp. 243-259, 1987.

small-scale adsorption tests for a constant surface diffusivity," Journal Water Fried, J. J., Groundwater Pollution. Elsevier Scientific, Amsterdam, The

Pollution Control Federation, Vol. 58, No. 4, pp. 312-319, 1986. Netherlands, 1975.

D6586 − 03 (2008)

carbon used, GAC usage rates for treating the water can be 8.1.2 GAC Support—Acolumn of fine glass wool installed

calculated. Breakthrough curves for each contaminant being to give a flat surface across the diameter of the column can be

monitored during the column test can also be generated. used for support of the GAC column.Alternatively the carbon

bed can be supported on a 100-mesh stainless steel screen

placed between two short sleeves made from ⁄2 in. PTFE

7. Interferences

tubing (see Fig. 2).The sleeves should be sized to fit tightly in

7.1 Insoluble materials such as oils and greases, suspended

the column to prevent any fluid from flowing between the

solids, and emulsions will interfere with the adsorption of

sleeves and the column wall.

soluble materials by the GAC. Suspended solids in the column

8.1.3 Feed Pumps—A liquid metering pump capable of

feed can lead to increased pressure drop and interfere with the

maintaining a steady flow rate of 6 0.05 mL/min at a column

operation of the column. These materials must be removed by

back pressure of up to 100 psig should be used. To prevent

suitable means before the water being treated is introduced to

over-pressurization of the column system in the event of

the column.

column plugging during operation, the pump should be set up

7.2 Air bubbles can interfere with water flow through the

with a bypass loop that allows the discharge from the pump to

column and lead to misleading results. A means for removing

beventedbacktothepumpinletthroughanadjustablepressure

air bubbles that are introduced into the system with the feed

relief device. The column inlet pressure and water flow rate

water should be incorporated to prevent these problems from

should be monitored and recorded throughout the run.

occurring.

8.1.4 Water Filtration—Afilter to remove suspended solids

that may be present in the water should be installed after the

8. RSSCT Test Apparatus

metering pump. A 47-mm inline filter housing with a 1.5 µm

8.1 The RSSCT test apparatus should be constructed of glassmicro-fiberfilterhasbeenfoundtobeadequatetoremove

glass, PTFE and/or stainless steel, to minimize the adsorption suspended solids that may prematurely plug the carbon bed.

Care must be exercised to ensure organic contaminants in the

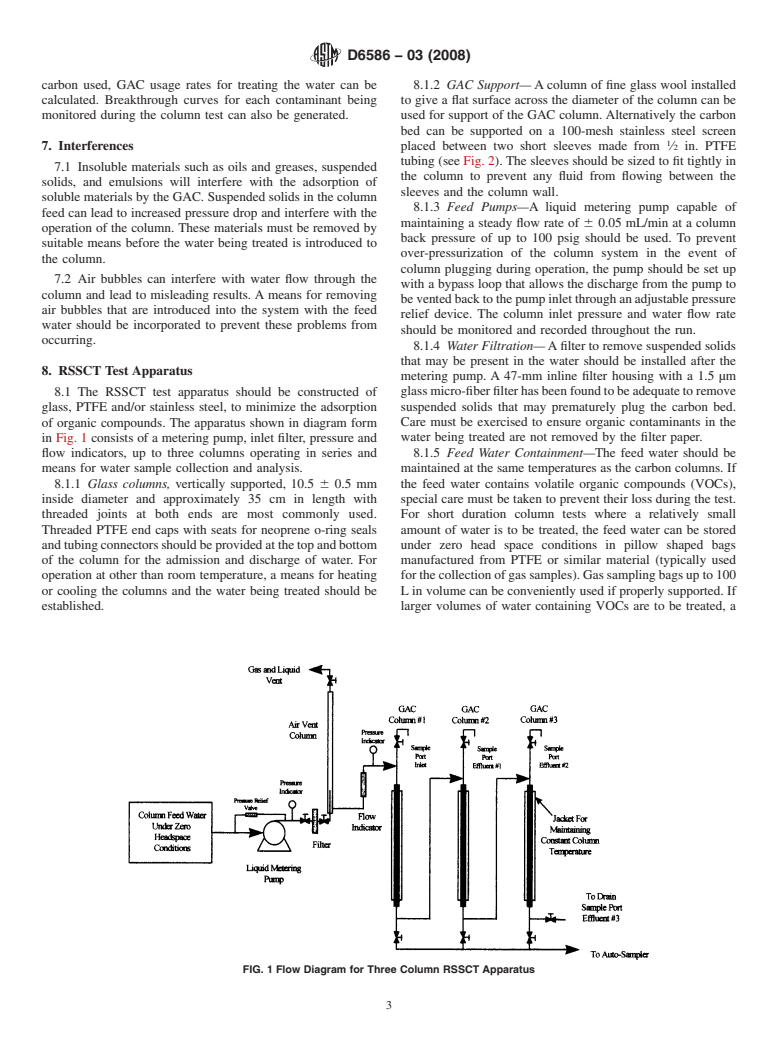

of organic compounds. The apparatus shown in diagram form

in Fig. 1 consists of a metering pump, inlet filter, pressure and water being treated are not removed by the filter paper.

flow indicators, up to three columns operating in series and 8.1.5 Feed Water Containment—The feed water should be

means for water sample collection and analysis. maintained at the same temperatures as the carbon columns. If

8.1.1 Glass columns, vertically supported, 10.5 6 0.5 mm the feed water contains volatile organic compounds (VOCs),

inside diameter and approximately 35 cm in length with special care must be taken to prevent their loss during the test.

threaded joints at both ends are most commonly used. For short duration column tests where a relatively small

Threaded PTFE end caps with seats for neoprene o-ring seals amount of water is to be treated, the feed water can be stored

andtubingconnectorsshouldbeprovidedatthetopandbottom under zero head space conditions in pillow shaped bags

of the column for the admission and discharge of water. For manufactured from PTFE or similar material (typically used

operation at other than room temperature, a means for heating forthecollectionofgassamples).Gassamplingbagsupto100

or cooling the columns and the water being treated should be Lin volume can be conveniently used if properly supported. If

established. larger

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6586–00 Designation:D6586–03 (Reapproved 2008)

Standard Practice for

the Prediction of Contaminant Adsorption On GAC In

Aqueous Systems Using Rapid Small-Scale Column Tests

This standard is issued under the fixed designation D 6586; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers a test method for the evaluation of granular activated carbon (GAC) for the adsorption of soluble

pollutants from water. This practice can be used to estimate the operating capacities of virgin and reactivated granular activated

carbons. The results obtained from the small-scale column testing can be used to predict the adsorption of target compounds on

GAC in a large column or full scale adsorber application.

1.2 This practice can be applied to all types of water including synthetically contaminated water (prepared by spiking high

purity water with selected contaminants), potable waters, industrial waste waters, sanitary wastes and effluent waters.

1.3 This practice is useful for the determination of breakthrough curves for specific contaminants in water, the determination

of the lengths of the adsorbates mass transfer zones (MTZ) and the prediction of GAC usage rates for larger scale adsorbers.

1.4 The following safety caveat applies to the procedure section, Section 10, of this practice: This standard does not purport

to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 1129 Terminology Relating to Water

D 1193 Specifications for Reagent Water

D 2652 Terminology Relating to Activated Carbon

D 2854 Test Method for Apparent Density of Activated Carbon

D 2867Test Method Moisture Content of Activated Carbon Test Methods for Moisture in Activated Carbon

D 2862 Test Method for Particle Size Distribution of Granular Activated Carbon

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms in this practice relating to activated carbon, refer to Terminology D 2652.

3.1.2 For definitions of terms in this practice relating to water, refer to Terminology D 1129.

4. Summary of Practice

4.1 This practice consists of a method for the rapid determination of breakthrough curves and the prediction of GAC usage rates

for the removal of soluble contaminants from water. This is accomplished by passing the contaminated water at a constant

controlled rate down flow through a bed of a specially sized granular activated carbon until predetermined levels of breakthrough

have occurred.

4.2 When the assumption is made that conditions of constant diffusivity exist within the GAC column, the breakthrough data

obtained from the column test can be used to estimate the size and operational conditions for a full-scale carbon adsorber.

5. Significance and Use

5.1 Granular activated carbon (GAC) is commonly used to remove contaminants from water. However if not used properly,

GAC can not only be expensive but can at times be ineffective. The development of engineering data for the design of full-scale

This practice is under the jurisdiction of ASTM Committee D-28 on Activated Carbon and is the direct responsibility of Subcommittee D28. 02 on Liquid PHase

Evaluation.

Current edition approved Sept. 10, 2000. Published November 2000.

ThispracticeisunderthejurisdictionofASTMCommitteeD28onActivatedCarbonandisthedirectresponsibilityofSubcommitteeD28.02onLiquidPhaseEvaluation.

Current edition approved Aug. 1, 2008. Published September 2008. Originally approved in 2000. Last previous edition approved in 2003 as D 6586–03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6586–03 (2008)

adsorbers often requires time-consuming and expensive pilot plant studies. This rapid standard practice has been developed to

predict adsorption in large-scale adsorbers based upon results from small column testing. In contrast to pilot plant studies, the

small-scale column test presented in this practice does not allow for a running evaluation of factors that may affect GAC

performance over time. Such factors may include, for example, an increased removal of target compounds by bacterial colonizing

3 4

GAC or long term fouling of GAC caused by inorganic compounds or background organic matter . Nevertheless, this practice

offers more relevant operational data than isotherm testing without the principal drawbacks of pilot plant studies, namely time and

expense; and unlike pilot plant studies, small scale studies can be performed in a laboratory using water sampled from a remote

location.

5.2 This practice known as the rapid small-scale column test (RSSCT) uses empty bed contact time (EBCT) and hydraulic

loading to describe the adsorption process. Mean carbon particle diameter is used to scale RSSCT results to predict the

performance of a full-scale adsorber.

5.3 This practice can be used to compare the effectiveness of different activated carbons for the removal of contaminants from

a common water stream.

6. Summary of Practice

6.1 The development of the RSSCTis based on the dispersed-flow pore surface diffusion model (DFPSDM) (Crittenden, et al )

which takes into account many of the mechanisms that are known to occur in fixed-bed adsorption. The following mechanisms,

which cause the breakthrough curves for an adsorber to spread out and create the mass transfer zone are included in the DFPSDM:

external mass-transfer resistance or film transfer, axial mixing due to dispersion and the internal mass-transfer resistances of pore

and surface diffusion.

6.2 To simulate full-scale performance, the amount of spreading in the breakthrough curve relative to column depth must be

identical for the RSSCT and the full-scale column. To achieve this, the relative contributions of the mechanisms that cause most

6 5

of the spreading are matched by maintaining similarity as the GAC process is scaled. Crittenden et. al. Studies have shown that

matching of the spreading of the breakthrough curve can be achieved by assuming equating the dimensionless groups in PFPSDM

(Plug Flow Pore Surface Diffusion Model). Under the conditions that intraparticle diffusivities are assumed to be independent of

the carbon particle radius, i.e. the condition of constant diffusivity. Under these conditions of constant diffusivity, the following

equation describes the relationship between the small and large columns:

EBCT |R | t

sc sc sc

5 5 (1)

EBCT |R | t

lc lc lc

EBCT R t

sc sc sc

5 5 (1)

S D

EBCT R t

lc lc lc

where: EBCT and EBCT are the empty-bed contact times for the small-column (RSSCT) and the large-column (full-scale

sc lc

adsorber), respectively; R and R are the radii of the carbon particles used in the small and large columns, respectively; and t

sc lc sc

and t are the elapsed times required to conduct the small- and large-column tests, respectively. The condition of constant

lc

diffusivity also requires the Reynolds numbers for the RSSCT and the large-column be equal. This means the following equation

must also be satisfied:

V R

sc lc

5 (2)

V R

lc rc

where: V and V are the hydraulic loadings in the RSSCT and large columns, respectively. Based upon the above equations,

sc lc

the operating conditions for the RSSCT can be selected to precisely simulate the desired (specified) operating conditions for a

full-scale adsorber.

NOTE1—Empty-bed contact time (EBCT) is defined as the volume (in liters) of carbon in the adsorber bed divided by the water flow rate in

litres/minute. For example if a full scale adsorber holds 20 000 L of activated carbon and the water flow rate is 2500 L/min, the EBCT would be equal

to 20 000/2500 or 8.0 min.

6.3The assumption that conditions of constant diffusivity exist within the GAC column does not apply to all waters or all target

compounds.Forexamplethisassumptiondoesnotapplyforthedecolorizationofwaterandtheadsorptionoflargemolecules,such

Annual Book of ASTM Standards, Vol 15.01.

Owen, D.M., Chowdhury, Z.K., Summers, R.S., Hooper, S.M., and Solarik, G., “Determination of Technology and Costs for GAC Treatment Using the ICR

Methodology,” AWWA GAC & Membrane Workshop, March 1996, Cincinnati, OH.

Owen, D.M., Chowdhury, Z.K., Summers, R.S., Hooper, S.M., and Solarik, G., “Determination of Technology and Costs for GAC Treatment Using the ICR

Methodology” AWWA GAC & Membrane Workshop, March 1996, Cincinnati, OH.

Knappe, D., Snoeyink, V., Roche, P., Prados, M. and Bourbigot, M., “The Effect of Preloading on RSSCT Predictions ofAtrazine Removal By GACAdsorbers”, Water

Research, Vol. 31, No. 11, 1997, pp. 2899-2909.

Knappe, D., Snoeyink, V., Roche, P., Prados, M. and Bourbigot, M., “The Effect of Preloading on RSSCT Predictions ofAtrazine Removal By GACAdsorbers”, Water

Research, Vol 31, No. 11, 1997, pp. 2899-2909.

Crittenden, J. C., Berrigan, J. K., Jr., and Hand, D. W., 9Design of rapid small-scale adsorption tests for a constant surface diffusivity,9 Journal Water Pollution Control

Federation, Vol. 58, No. 4, pp. 312-319, 1986.

D6586–03 (2008)

as humic acids. It is recommended that at least one RSSCT pilot-column comparison be conducted to aid in selecting the RSSCT

design variables for a given water matrix (Crittenden, et al 1—There is an important issue relating to RSSCT design using

Equation 2 . Sometimes using 2 leads to a design with a high head loss, which increases dramatically with operating time, as the

GAC is crushed by a large pressure drop across the RSSCT. This may be avoided by lowering the superficial velocity as long as

dispersion does not become the dominant transport mechanism and intraparticle mass transfer is limiting the adsorption rate. The

Peclet number based on diameter can be estimated from the following equation :

Pe 5 0.334 for 160 # Re · Sc # 40,000

d

When the velocity is reduced below what is given in Equation A, axial dispersion, which is caused by molecular diffusion, can be more important in

the RSSCT than in the full scale process. Consequently, Equation A can be used to check whether dispersion becomes important as the velocity of the

RSSCT is reduced in an effort to reduce the head loss. Typical Sc values for SOCs is ~ 2000; consequently, the Re for the RSSCT must be kept greater

than ~0.1 and the Pe must be kept above 50 for the length of the mass transfer zone.

NOTE 2—Empty-bed contact time (EBCT) is defined as the bed volume (in liters) divided by the water flow rate in liters/minute. For example if a full

scale adsorber holds 20 000 L of activated carbon and the water flow rate is 2500 L/min, the EBCT would be equal to 20 000/2500 or 8.0 min.

6.3 The assumption that conditions of constant diffusivity exist within the GAC column does not apply to all waters or all target

compounds.Forexamplethisassumptiondoesnotapplyforthedecolorizationofwaterandtheadsorptionoflargemolecules,such

as humic and fulvic acids. It is recommended that at least one RSSCT pilot-column comparison be conducted to aid in selecting

the RSSCT design variables for a given water matrix (Crittenden, et al ). A detailed comparison between the constant diffusivity

and proportional diffusivity approaches and their respective domains of application is beyond the scope of this practice.

6.4 GAC bed volume and preparation methods are important design parameters for the RSSCT.The GAC bed volume used will

determine the required water pumping rate and affect the amount of water needed to complete the test. The minimum column

diameter needed to avoid channeling and to minimize column head loss should be 50 particle diameters. For the 10-mm diameter

column commonly used in RSSCT systems, a 60 by 80 mesh carbon should be used. Proper GAC sampling (Practice E 300) and

preparation (grinding, classification and washing) are required for reproducible results.

6.5 Based upon the water feed rate to the column, the time required to reach the desired breakpoint and the weight of carbon

used, GAC usage rates for treating the water can be calculated. Breakthrough curves for each contaminant being monitored during

the column test can also be generated.

7. Interferences

7.1 Insoluble materials such as oils and greases, suspended solids, and emulsions will interfere with the adsorption of soluble

materials by the GAC. Suspended solids in the column feed can lead to increased pressure drop and interfere with the operation

of the column. These materials must be removed by suitable means before the water being treated is introduced to the column.

7.2 Air bubbles can interfere with water flow through the column and lead to misleading results. A means for removing air

bubbles that are introduced into the system with the feed water should be incorporated to prevent these problems from occurring.

8. RSSCT Test Apparatus

8.1 TheRSSCTtestapparatusshouldbeconstructedofglass,PTFEand/orstainlesssteel,tominimizetheadsorptionoforganic

compounds. The apparatus shown in diagram form in Fig. 1 consists of a metering pump, inlet filter, pressure and flow indicators,

up to three columns operating in series and means for water sample collection and analysis.

8.1.1 Glass columns, vertically supported, 10.5 6 0.5 mm inside diameter and approximately 35 cm in length with threaded

joints at both ends are most commonly used. Threaded PTFE end caps with seats for neoprene o-ring seals and tubing connectors

should be provided at the top and bottom of the column for the admission and discharge of water. For operation at other than room

temperature, a means for heating or cooling the columns and the water being treated should be established.

8.1.2 GAC Support—Acolumn of fine glass wool installed to give a flat surface across the diameter of the column can be used

forsupportoftheGACcolumn.Alternativelythecarbonbedcanbesupportedona100-mesh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.