ASTM E2140-01

(Test Method)Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head

Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head

SIGNIFICANCE AND USE

This test method is a standard procedure for determining water leakage through metal roof panel system sideseams, endlaps, and roof plane penetrations when the roof system is subjected to a specified static water pressure head.

Note 2—In applying the results of tests by this method, note that the performance of a roof or its components or both, is in part a function of proper installation and adjustment. In service, the performance will also depend on the integrity of the supporting construction, roof slope, and on the resistance of components to deterioration by various causes: corrosive atmosphere, aging, ice, vibration, thermal cycling, etc. It is difficult to simulate the identical complex wetting, aging and other variable conditions that can be encountered in service, including wind-blown ponded water, the effects of temperature and age on sealant performance, differential pressure across the joints due to wind, snow and ice accumulation, densification and migration, and abrasions within the joint components which may occur during thermal cycling and other weather events. Some joint conditions are more sensitive than others to these factors.

This test method will evaluate the resistance of roof panels, sideseams, endlaps, and roof plane penetrations to water submersion. It will not evaluate panel resistance to wind driven rain.

Note 3—See E 1646 for a test which evaluates resistance to wind driven rain.

This test method is not a structural adequacy test.

This test method is applicable to single skin metal panels, the exterior skin of factory assembled composite panels, and the exterior skin of field assembled composite systems as long as means can be provided to distinguish leakage through the exterior panel sideseams/endlaps and perimeter leakage.

SCOPE

1.1 This Laboratory test method covers the determination of the resistance to water penetration of exterior metal roof panel system sideseams, endlaps, and roof plane penetrations when a specified static water pressure head is applied to the outside face of the roof panel.Note 1

This test method is intended to evaluate water-barrier (not water-shedding) roof system joints and details. These systems are also referred to as hydrostatic roof systems.

1.2 This test method is limited to specimens in which the sideseams and attachments are clearly visible and in which the source of leakage is readily observable.

1.3 This test method excludes performance at roof perimeter conditions.

1.4 This test method is suitable for evaluating leakage at roof plane penetrations such as fasteners, curbs, pipes and expansion joints under a static water pressure head.

1.5 The proper use of this test method requires a knowledge of the principles of water pressure.

1.6 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of inch-pound units are approximate.

1.7 The text of this standard includes notes and footnotes excluding tables and figures, which provide explanatory material. These notes and footnotes shall not be considered as requirements of the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E2140–01

Standard Test Method for

Water Penetration of Metal Roof Panel Systems by Static

Water Pressure Head

This standard is issued under the fixed designation E2140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This Laboratory test method covers the determination of 2.1 ASTM Standards:

the resistance to water penetration of exterior metal roof panel E631 Terminology of Building Constructions

system sideseams, endlaps, and roof plane penetrations when a E1646 Test Method for Water Penetration of Exterior Metal

specified static water pressure head is applied to the outside Roof Panel Systems by Uniform Static Air Pressure

face of the roof panel. Difference

NOTE 1—This test method is intended to evaluate water-barrier (not

3. Terminology

water-shedding) roof system joints and details. These systems are also

3.1 Definitions—For definitions of general terms relating to

referred to as hydrostatic roof systems.

building construction used in this method, see Terminology

1.2 This test method is limited to specimens in which the

E631.

sideseams and attachments are clearly visible and in which the

3.2 Definitions of Terms Specific to This Standard:

source of leakage is readily observable.

3.2.1 composite roof systems—roofsystemsconsistingofan

1.3 Thistestmethodexcludesperformanceatroofperimeter

exterior metal skin and other components. Factory assembled

conditions.

composite panels consist of an exterior metal skin, insulation

1.4 This test method is suitable for evaluating leakage at

and interior metal skin. Field assembled composite systems

roof plane penetrations such as fasteners, curbs, pipes and

consist of exterior metal skins, underlayment and a structural

expansion joints under a static water pressure head.

roof deck.

1.5 The proper use of this test method requires a knowledge

3.2.2 panel endlap—the connection between two in-line

of the principles of water pressure.

metal panels across the width of the panels.

1.6 The values stated in inch-pound units are to be regarded

3.2.3 panel sideseam—the connection between two adja-

as the standard. The SI equivalents of inch-pound units are

cent metal panels along the length of the panels.

approximate.

3.2.4 specimen—the entire assembled unit submitted for

1.7 The text of this standard includes notes and footnotes

test as described in Section 8.

excluding tables and figures, which provide explanatory mate-

3.2.5 water leakage—penetration of water through the

rial. These notes and footnotes shall not be considered as

plane of the innermost face of the test specimen during the test

requirements of the standard.

period.

1.8 This standard does not purport to address all of the

3.2.6 water pressure head—the distance from the surface of

safety concerns, if any, associated with its use. It is the

the water to the lowest point or cell of the metal panel

responsibility of the user of this standard to establish appro-

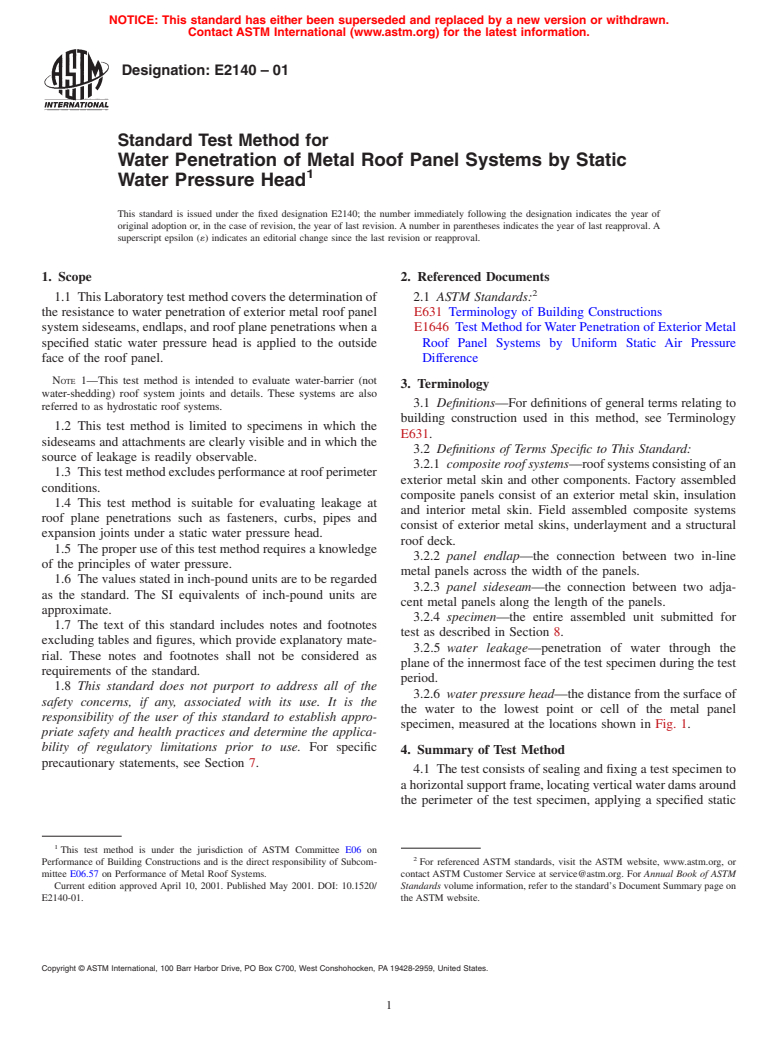

specimen, measured at the locations shown in Fig. 1.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

4. Summary of Test Method

precautionary statements, see Section 7.

4.1 The test consists of sealing and fixing a test specimen to

ahorizontalsupportframe,locatingverticalwaterdamsaround

the perimeter of the test specimen, applying a specified static

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Building Constructions and is the direct responsibility of Subcom- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mittee E06.57 on Performance of Metal Roof Systems. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 10, 2001. Published May 2001. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2140-01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2140–01

FIG. 1 Plan of Typical Three-Span Test Specimen Mounted in Chamber

water head to the outside face of the test specimen and systems as long as means can be provided to distinguish

observing for water leakage on the underside of the test leakage through the exterior panel sideseams/endlaps and

specimen. perimeter leakage.

5. Significance and Use 6. Apparatus

5.1 Thistestmethodisastandardprocedurefordetermining

6.1 This description of apparatus is general in nature and

water leakage through metal roof panel system sideseams, any arrangement of equipment capable of performing the test

endlaps, and roof plane penetrations when the roof system is

procedure within the allowable tolerances is permitted.

subjected to a specified static water pressure head.

NOTE 4—One such alternate test apparatus arrangement consists of

perimeter seals erected on top of the test specimen.

NOTE 2—In applying the results of tests by this method, note that the

performance of a roof or its components or both, is in part a function of

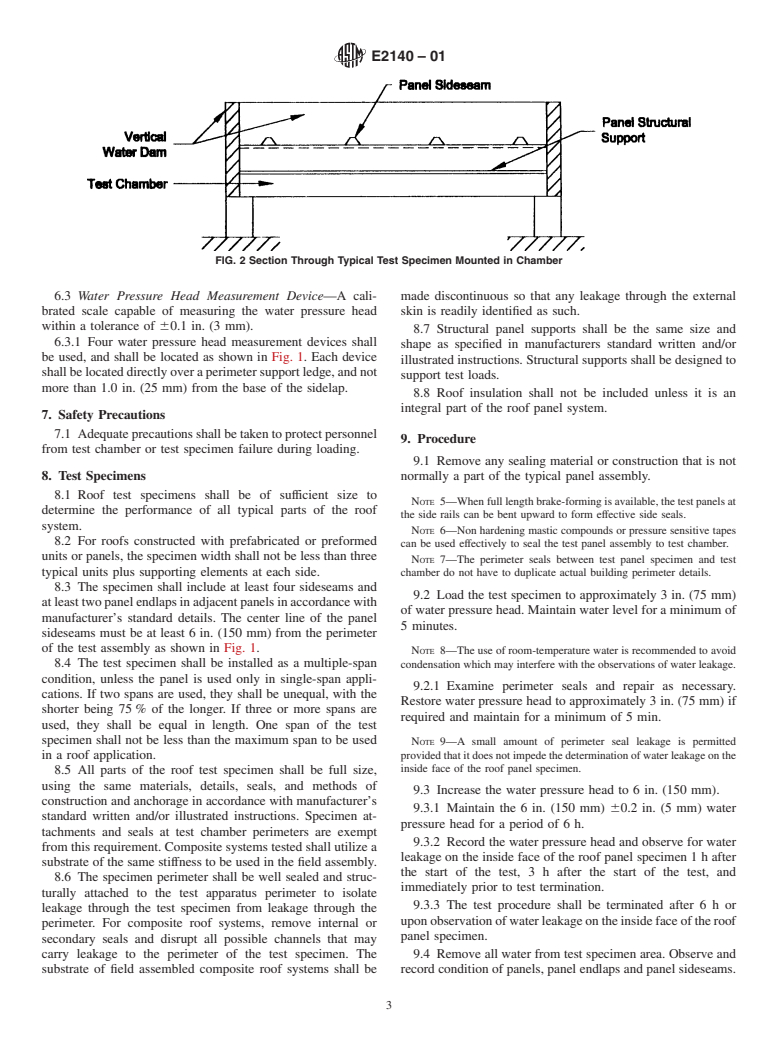

6.2 Test Chamber—(See Figs. 1 and 2). A well-sealed

proper installation and adjustment. In service, the performance will also

chamber or box with either an opening, a removable mounting

depend on the integrity of the supporting construction, roof slope, and on

panel or one open face in which or against which the specimen

the resistance of components to deterioration by various causes: corrosive

atmosphere, aging, ice, vibration, thermal cycling, etc. It is difficult to is installed and sealed. The test chamber shall be maintained in

simulate the identical complex wetting, aging and other variable condi-

a horizontal position.

tions that can be encountered in service, including wind-blown ponded

6.2.1 The test chamber shall be provided with a horizontal

water, the effects of temperature and age on sealant performance,

perimeter support ledge to which test specimens may be

differential pressure across the joints due to wind, snow and ice accumu-

attached and sealed.

lation, densification and migration, and abrasions within the joint compo-

6.2.2 The test specimen shall be anchored to the test

nents which may occur during thermal cycling and other weather events.

chamber perimeter to adequately resist imposed test loads

Some joint conditions are more sensitive than others to these factors.

without leakage or failure.

5.2 This test method will evaluate the resistance of roof

6.2.3 The test chamber shall be provided with a vertical

panels, sideseams, endlaps, and roof plane penetrations to

water dam around the perimeter of the chamber. Water dam

water submersion. It will not evaluate panel resistance to wind

shall be well sealed and of sufficient height to maintain the

driven rain.

required water pressure head.

NOTE 3—See E1646 for a test which evaluates resistance to wind

6.2.4 A means of viewing all areas under the roof panel

driven rain.

specimen shall be provided to facilitate observations for water

5.3 This test method is not a structural adequacy test. leakage. It is important to isolate perimeter leakage from

5.4 This test method is applicable to single skin metal leakage in areas under evaluation. For factory assembled

panels, the exterior skin of fa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.