ASTM E637-98

(Test Method)Standard Test Method for Calculation of Stagnation Enthalpy from Heat Transfer Theory and Experimental Measurements of Stagnation-Point Heat Transfer and Pressure

Standard Test Method for Calculation of Stagnation Enthalpy from Heat Transfer Theory and Experimental Measurements of Stagnation-Point Heat Transfer and Pressure

SCOPE

1.1 This test method covers the calculation from heat transfer theory of the stagnation enthalpy from experimental measurements of the stagnation-point heat transfer and stagnation pressure.

1.2 Advantages:

1.2.1 A value of stagnation enthalpy can be obtained at the location in the stream where the model is tested. This value gives a consistent set of data, along with heat transfer and stagnation pressure, for ablation computations.

1.2.2 This computation of stagnation enthalpy does not require the measurement of any arc heater parameters.

1.3 Limitations and Considerations -There are many factors that may contribute to an error using this type of approach to calculate stagnation enthalpy, including:

1.3.1 Turbulence -The turbulence generated by adding energy to the stream may cause deviation from the laminar equilibrium heat transfer theory.

1.3.2 Equilibrium, Nonequilibrium, or Frozen State of Gas -The reaction rates and expansions may be such that the gas is far from thermodynamic equilibrium.

1.3.3 Noncatalytic Effects -The surface recombination rates and the characteristics of the metallic calorimeter may give a heat transfer deviation from the equilibrium theory.

1.3.4 Free Electric Currents -The arc-heated gas stream may have free electric currents that will contribute to measured experimental heat transfer rates.

1.3.5 Nonuniform Pressure Profile -A nonuniform pressure profile in the region of the stream at the point of the heat transfer measurement could distort the stagnation point velocity gradient.

1.3.6 Mach Number Effects -The nondimensional stagnation-point velocity gradient is a function of the Mach number. In addition, the Mach number is a function of enthalpy and pressure such that an iterative process is necessary.

1.3.7 Model Shape -The nondimensional stagnation-point velocity gradient is a function of model shape.

1.3.8 Radiation Effects -The hot gas stream may contribute a radiative component to the heat transfer rate.

1.3.9 Heat Transfer Rate Measurement -An error may be made in the heat transfer measurement (see Methods E469 and Test Methods E422, E457, E459, and E511).

1.3.10 Contamination -The electrode material may be of a large enough percentage of the mass flow rate to contribute to the heat transfer rate measurement.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 637 – 98

Standard Test Method for

Calculation of Stagnation Enthalpy from Heat Transfer

Theory and Experimental Measurements of Stagnation-Point

Heat Transfer and Pressure

This standard is issued under the fixed designation E637; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The enthalpy (energy per unit mass) determination in a hot gas aerodynamic simulation device is

a difficult measurement. Even at temperatures that can be measured with thermocouples, there are

many corrections to be made at 600 K and above. Methods that are used for temperatures above the

range of thermocouples that give bulk or average enthalpy values are energy balance (see Practice

E341), sonic flow (1, 2), and the pressure rise method (3). Local enthalpy values (thus distribution)

may be obtained by using either an energy balance probe (see Method E470), or the spectrometric

technique described in Ref (4).

1. Scope 1.3.3 Noncatalytic Effects—The surface recombination

rates and the characteristics of the metallic calorimeter may

1.1 This test method covers the calculation from heat

give a heat transfer deviation from the equilibrium theory.

transfer theory of the stagnation enthalpy from experimental

1.3.4 Free Electric Currents—The arc-heated gas stream

measurements of the stagnation-point heat transfer and stagna-

mayhavefreeelectriccurrentsthatwillcontributetomeasured

tion pressure.

experimental heat transfer rates.

1.2 Advantages:

1.3.5 Nonuniform Pressure Profile—Anonuniformpressure

1.2.1 Avalue of stagnation enthalpy can be obtained at the

profile in the region of the stream at the point of the heat

location in the stream where the model is tested. This value

transfer measurement could distort the stagnation point veloc-

gives a consistent set of data, along with heat transfer and

ity gradient.

stagnation pressure, for ablation computations.

1.3.6 Mach Number Effects—The nondimensional

1.2.2 This computation of stagnation enthalpy does not

stagnation-point velocity gradient is a function of the Mach

require the measurement of any arc heater parameters.

number.Inaddition,theMachnumberisafunctionofenthalpy

1.3 Limitations and Considerations—There are many fac-

and pressure such that an iterative process is necessary.

tors that may contribute to an error using this type of approach

1.3.7 Model Shape—The nondimensional stagnation-point

to calculate stagnation enthalpy, including:

velocity gradient is a function of model shape.

1.3.1 Turbulence—The turbulence generated by adding en-

1.3.8 Radiation Effects—Thehotgasstreammaycontribute

ergy to the stream may cause deviation from the laminar

a radiative component to the heat transfer rate.

equilibrium heat transfer theory.

1.3.9 Heat Transfer Rate Measurement—An error may be

1.3.2 Equilibrium, Nonequilibrium, or Frozen State of

madeintheheattransfermeasurement(seeMethodsE469and

Gas—The reaction rates and expansions may be such that the

Test Methods E422, E457, E459, and E511).

gas is far from thermodynamic equilibrium.

1.3.10 Contamination—The electrode material may be of a

large enough percentage of the mass flow rate to contribute to

1 the heat transfer rate measurement.

This test method is under the jurisdiction of ASTM Committee E21 on Space

1.4 This standard does not purport to address all of the

SimulationandApplicationsofSpaceTechnology,andisthedirectresponsibilityof

Subcommittee E21.08 on Thermal Protection.

safety concerns, if any, associated with its use. It is the

Current edition approved May 10, 1998. Published July 1998. Originally

responsibility of the user of this standard to establish appro-

published as E637–78. Last previous edition E637–97.

priate safety and health practices and determine the applica-

The boldface numbers in parentheses refer to the list of references appended to

this method. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E637–98

TABLE 1 Heat Transfer and Enthalpy Computation Constants

2. Referenced Documents

for Various Gases

2.1 ASTM Standards:

1/2 1/2 1/2 1/2

K , kg/(N ·m ·s) K ,(N ·m ·s)/kg

i M

E341 Practice for Measuring PlasmaArc Gas Enthalpy by Gas

3/2 1/2 3/2 1/2

(lb/(ft ·s·atm )) ((ft ·s·atm )/lb)

Energy Balance

−4

Air 3.905 3 10 (0.0461) 2561 (21.69)

E422 Test Method for Measuring Heat Flux Using a −4

Argon 5.513 3 10 (0.0651) 1814 (15.36)

3 −4

Carbon dioxide 4.337 3 10 (0.0512) 2306 (19.53)

Water-Cooled Calorimeter

−4

Hydrogen 1.287 3 10 (0.0152) 7768 (65.78)

E457 TestMethodforMeasuringHeat-TransferRateUsing

−4

Nitrogen 3.650 3 10 (0.0431) 2740 (23.20)

a Thermal Capacitance (Slug) Calorimeter

E459 TestMethodforMeasuringHeat-TransferRateUsing

a Thin-Skin Calorimeter

0.5

E469 Method for Measuring Heat Flux Using a Multiple-

K q˙ b D/U !

~

M oo Eq3

4 H – H 5 (2)

F G

e w 0.5

Wafer Calorimeter

~b D/U !

~P / R! oo x 50

t

E470 Method for Measuring Gas Enthalpy Using Calori-

Where the “modified” Newtonian stagnation-point velocity

metric Probes

gradient is given by:

E511 Test Method for Measuring Heat Flux Using a

Copper-Constantan Circular Foil, Heat-Flux Gage

2 0.5

~4 @~g21! M 12#

oo

~b D/U ! 5 (3)

oo x 50 F 2 G

3. Significance and Use

g M

oo

3.1 The purpose of this test method is to provide a standard

calculation of the stagnation enthalpy of an aerodynamic

A potential problem exists when using Eq 3 to remove the

simulation device using the heat transfer theory and measured

“modified” Newtonian velocity gradient because of the singu-

values of stagnation point heat transfer and pressure. A

larity at M =0. The procedure recommended here should be

oo

stagnation enthalpy obtained by this test method gives a

limited to M > 0.1

oo

consistent set of data, along with heat transfer and stagnation

where:

pressure for ablation computations.

−1

b = stagnation-point velocity gradient, s ,

D = hemispherical diameter, m (or ft),

4. Enthalpy Computations

U = freestream velocity, m/s (or ft/s),

`

4.1 This method of calculating the stagnation enthalpy is

(bD/U ) = dimensionless stagnation velocity gradi-

` x=0

based on experimentally measured values of the stagnation-

ent,

pointheattransferrateandpressuredistributionandtheoretical

K = enthalpy computation constant,

M

1/2 1/2 3/2 1/2

calculation of laminar equilibrium catalytic stagnation-point

(N ·m · s)/kg or (ft ·atm ·s)/lb, and

heat transfer on a hemispherical body. The equilibrium cata-

M` = the freestream Mach number.

lytic theoretical laminar stagnation-point heat transfer rate for

For subsonic Mach numbers, an expression for (bD/U )

` x=0

a hemispherical body is as follows (5):

for a hemisphere is given in Ref (6) as follows:

R bD

q 5 K ~H – H ! (1)

53–0.755 M ~M ,1! (4)

Πi e w S D

x 50 ` `

P

U

t

`

where:

For a Mach number of 1 or greater, (bD/U ) for a

` x=0

q = stagnation-point heat transfer rate, W/m (or Btu/

hemisphere based on “classical” Newtonian flow theory is

ft ·s),

presented in Ref (7) as follows:

P = model stagnation pressure, Pa (or atm),

t

R = hemispherical nose radius, m (or ft),

8@~g21!M 2 12#

bD g21

`

H = stagnation enthalpy, J/kg (or Btu/lb),

S D 5H F1 1

e

x 50

U 2 2

~g11!M

`

`

H = wall enthalpy, J/kg (or Btu/lb), and

w

1 0.5

K = heat transfer computation constant.

i g21

g21!M 2 12

@~ #

`

4.2 Low Mach Number Correction—Eq 1 is simple and

G J (5)

2gM 2 ~g21!

`

convenient to use since K can be considered approximately

i

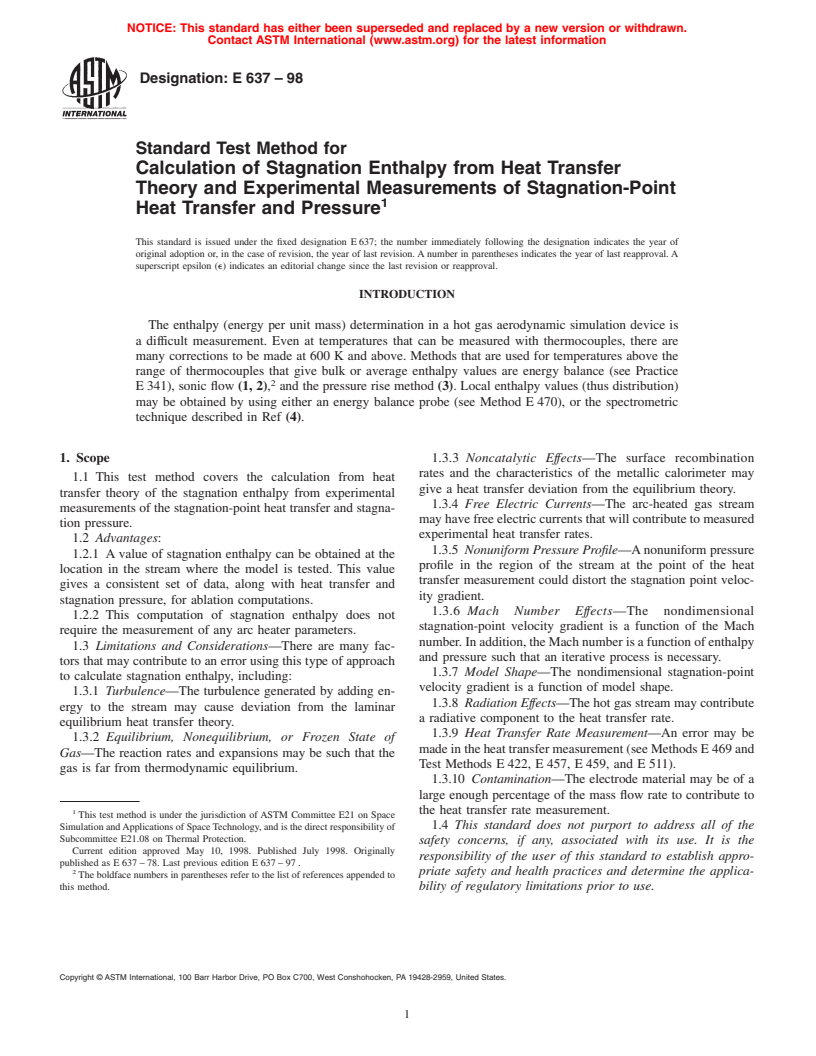

Avariation of (bD/U ) with M and g is shown in Fig.

constant(seeTable1).However,Eq1isbasedonastagnation-

` x=0 `

1.The value of the Newtonian dimensionless velocity gradient

point velocity gradient derived using “modified” Newtonian

approaches a constant value as the Mach number approaches

flow theory which becomes inaccurate for M <2.An

oo

infinity:

improved Mach number dependence at lower Mach numbers

can be obtained by removing the “modified” Newtonian

bD g21

5 4 (6)

exprssion and replacing it with a more appropriate expression S D x 50,M→` Œ S D

U g

`

as follows:

and thus, since g, the ratio of specific heats, is a function of

enthalpy, (bD/U ) is also a function of enthalpy.Again, an

` x=0

iteration is necessary. From Fig. 1, it can be seen that

Annual Book of ASTM Standards, Vol 15.03.

Discontinued, see 1983 Annual Book of ASTM Standards, Vol 15.03. (bD/U ) for a hemisphere is approximately 1 for large

` x=0

E637–98

FIG. 1 Dimensionless Velocity Gradient as a Function of Mach Number and Ratio of Specific Heats

Mach numbers and g=1.2. K is tabulated in Table 1 using 4.4 Velocity Gradient Calculation from Pressure

M

(bD/U ) =1 and K from Ref (5). Distribution—The dimensionless stagnation-point velocity

` x=0 i

4.3 Mach Number Determination: gradient may be obtained from an experimentally measured

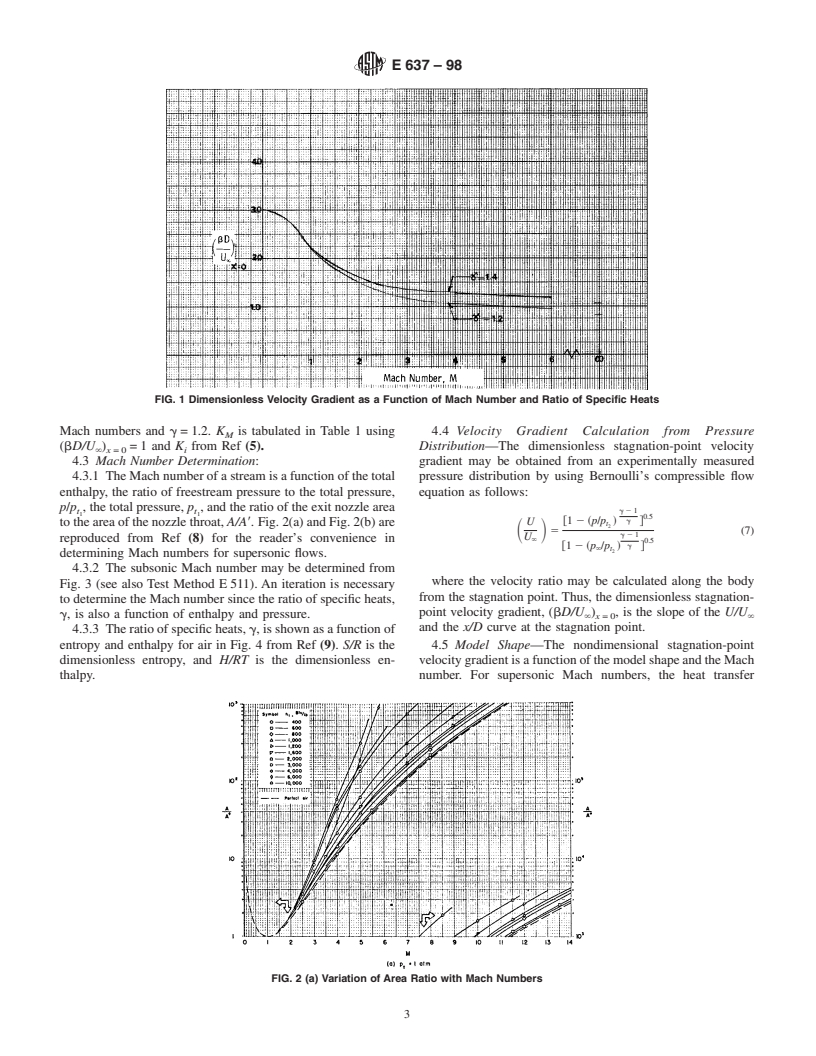

4.3.1 TheMachnumberofastreamisafunctionofthetotal pressure distribution by using Bernoulli’s compressible flow

enthalpy, the ratio of freestream pressure to the total pressure, equation as follows:

p/p ,thetotalpressure, p ,andtheratiooftheexitnozzlearea

g21

t t

1 1

0.5

1 2 p/p ! g

U @ ~ #

totheareaofthenozzlethroat, A/A8.Fig.2(a)andFig.2(b)are t

5 (7)

S D

g21

U

reproduced from Ref (8) for the reader’s convenience in `

0.5

g

@1 2 ~p /p ! #

` t

determining Mach numbers for supersonic flows.

4.3.2 The subsonic Mach number may be determined from

where the velocity ratio may be calculated along the body

Fig. 3 (see also Test Method E511). An iteration is necessary

from the stagnation point. Thus, the dimensionless stagnation-

todeterminetheMachnumbersincetheratioofspecificheats,

point velocity gradient, (bD/U ) , is the slope of the U/U

g, is also a function of enthalpy and pressure.

` x=0 `

and the x/D curve at the stagnation point.

4.3.3 Theratioofspecificheats, g,isshownasafunctionof

entropy and enthalpy for air in Fig. 4 from Ref (9). S/R is the 4.5 Model Shape—The nondimensional stagnation-point

velocitygradientisafunctionofthemodelshapeandtheMach

dimensionless entropy, and H/RT is the dimensionless en-

thalpy. number. For supersonic Mach numbers, the heat transfer

FIG. 2 (a) Variation of Area Ratio with Mach Numbers

E637–98

FIG. 2 (b) Variation of Area Ratio with Mach Numbers (continued)

FIG. 3 Subsonic Pressure Ratio as a Function of Mach Number and g

relationship between a hemisphere and other axisymmetric radiant energy are the hot gas stream itself or the gas heating

blunt bodies is shown in Fig. 5 (10). In Fig. 5, r is the corner device, or both. For instance, arc heaters operated at high

c

radius, r isthebodyradius, r isthenoseradius,and q˙ isthe pressure (10 atm or higher) can produce significant radiant

b n s,h

stagnation-point heat transfer rate on a hemisphere. For sub- fluxes at the nozzle exit plane.

sonic Mach numbers, the same type of variation is shown in 4.6.2 The proper application requires some knowledge of

Fig. 6 (6). the radiant environment in the stream at the desired operating

4.6 Radiation Effects: conditions. Usually, it is necessary to measure the radiant heat

4.6.1 As this test method depends on the accurate determi- transfer rate either directly or indirectly.The following is a list

nation of the convective stagnation-point heat transfer, any of suggested methods by which the necessary measurements

radiant energy absorbed by the calorimeter surface and incor- can be made.

rectly attributed to the convective mode will directly affect the 4.6.2.1 Direct Measurement with Radiometer—

overall accuracy of the test method. Generally, the sources of Radiometers are available for the measurement of the incident

E637–98

FIG. 4 Isentropic Exponent for Air in Equilibrium

FIG. 6 Stagnation-Point Heat Transfer Ratio to a Blunt Body and

FIG. 5 Stagnation-Point Heating-Rate Parameters on

a Hemisphere as a Function of the Body-to-Nose Radius in a

Hemispherical Segments of Different Curvatures for Varying

Subsonic Stream

Corner-Radius Ratios

radiant flux while excluding the convective heat transfer. In its The basic radiometer view angle should be 120° or greater.

simplest form, the radiometer is a slug, thin-skin, or circular This technique allows for immersion of the radiometer in the

foil calorimeter with a sensing area with a coating of known test stream and direct measurement of the radiant heat transfer

absorptance and covered with some form of window. The rate. There is a major limitation to this technique, however, in

purpose of the window is to prevent convective heat transfer that even with high-pressure water cooling of the radiometer

from affecting the calorimeter while transmitting the radiant enclosure, the window is poorly cooled and thus the use of

energy.Thewindowisusuallymadeofquartzorsapphire.The windows is limited to relatively low convective heat transfer

sensing surface is at the stagnation point of a test probe and is conditions or very short exposure times, or both.Also, stream

located in such a manner that the view angle is not restricted. contaminants coat the window and reduce its transmittance.

E637–98

4.6.2.2 Direct Measurement with Radiometer Mounted in

Cavity—Thetwolimitationsnotedin4.6.2.1maybeovercome

by mounting the radiometer at the bottom of a cavity open to

the stagnation point of the test probe (see Fig. 7). Good results

can be obtained by using a simple calorimeter in place of the

radiometer with a material of known absorptance. When using

this configuration, the measured radiant heat transfer rate is

used in the following equation to determine the stagnation-

point radiant heat transfer, assuming diffuse radiation:

q˙ 5 q˙ (8)

r r

1 2

a F

2 12

FIG. 8 Circular Cavity Configuration (see Eq 8)

where:

q˙ = radiant transfer at stagnation point,

r

levels is difficult. There are many schemes that could be used

q˙ = radiant transfer at bottom of cavity (measured),

r

to measure incident radiant flux indirectly. One such would be

a = absorptance of sensor surface, and

the measurement of the radiant flux reflected from a surface in

F = configuration factor.

the test stream. This technique depends primarily on the

For a circular cavity geometry (recommended), F is

accurate determination of surface reflectance under actual test

ConfigurationA-3 of Ref (11) and can be determined from the

conditions. The surface absorptance and a measurement of the

following equation:

surfac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.