ASTM D7731-11

(Test Method)Standard Test Method for Determination of Dipropylene Glycol Monobutyl Ether and Ethylene Glycol Monobutyl Ether in Sea Water by Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/MS)

Standard Test Method for Determination of Dipropylene Glycol Monobutyl Ether and Ethylene Glycol Monobutyl Ether in Sea Water by Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/MS)

SIGNIFICANCE AND USE

DPGBE and EGBE have a variety of residential and industrial applications such as, cleaning formulations, surface coatings, inks and cosmetics. These analytes may be released into the environment at levels that may be harmful to aquatic life.

This method has been investigated for use with reagent and sea water.

SCOPE

1.1 This procedure covers the determination of Dipropylene Glycol Monobutyl Ether (DPGBE) and Ethylene Glycol Monobutyl Ether (EGBE) in sea water by direct injection using liquid chromatography (LC) and detection with tandem mass spectrometry (MS/MS). This analyte is qualitatively and quantitatively determined by this method. This method adheres to selected reaction monitoring (SRM) mass spectrometry.

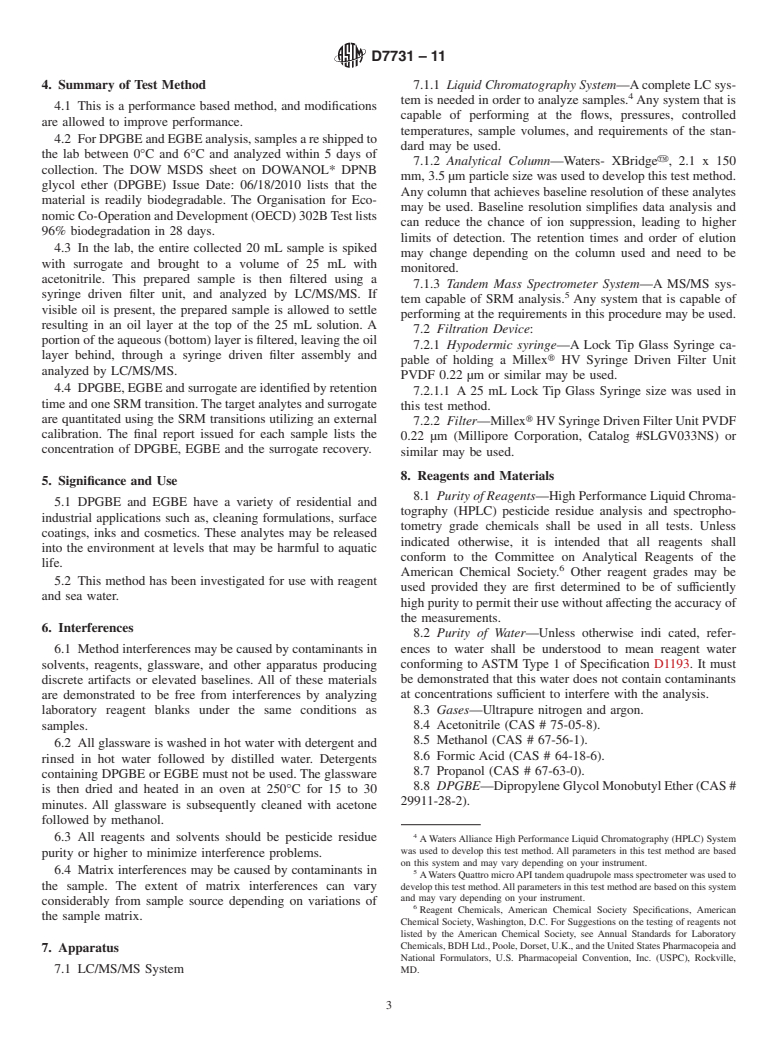

1.2 The Detection Verification Level (DVL) and Reporting Range for DPGBE and EGBE are listed in Table 1.

1.2.1 The DVL is required to be at a concentration at least 3 times below the Reporting Limit (RL) and have a signal/noise ratio greater than 3:1. Fig. 1 and Fig. 2 display the signal/noise ratio of the single reaction monitoring (SRM) transition.

1.2.2 The reporting limit is the concentration of the Level 1 calibration standard as shown in Table 4 for DPGBE and EGBE, taking into account the 20% sample preparation dilution factor.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7731 – 11

Standard Test Method for

Determination of Dipropylene Glycol Monobutyl Ether and

Ethylene Glycol Monobutyl Ether in Sea Water by Liquid

Chromatography/Tandem Mass Spectrometry (LC/MS/MS)

This standard is issued under the fixed designation D7731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

TABLE 1 Detection Verification Level and Reporting Range

1. Scope

Analyte DVL (µg/L) Reporting Range (µg/L)

1.1 This procedure covers the determination of Dipropylene

DPGBE 0.2 1–10

Glycol Monobutyl Ether (DPGBE) and Ethylene Glycol

EGBE 25 125–1250

MonobutylEther(EGBE)inseawaterbydirectinjectionusing

liquid chromatography (LC) and detection with tandem mass

spectrometry (MS/MS). This analyte is qualitatively and quan-

titatively determined by this method. This method adheres to

D2777 Practice for Determination of Precision and Bias of

selected reaction monitoring (SRM) mass spectrometry.

Applicable Test Methods of Committee D19 on Water

1.2 The Detection Verification Level (DVL) and Reporting

2.2 Other Standards:

Range for DPGBE and EGBE are listed in Table 1.

EPApublication SW-846 Test Methods for Evaluating Solid

1.2.1 The DVL is required to be at a concentration at least

Waste, Physical/Chemical Methods

3 times below the Reporting Limit (RL) and have a signal/

3. Terminology

noise ratio greater than 3:1. Fig. 1 and Fig. 2 display the

signal/noise ratio of the single reaction monitoring (SRM)

3.1 Definitions:

transition.

3.1.1 detection verification level, DVL, n—a concentration

1.2.2 The reporting limit is the concentration of the Level 1

that has a signal/noise ratio greater than 3:1 and is at least 3

calibration standard as shown in Table 4 for DPGBE and

times below the Reporting Limit (RL).

EGBE, taking into account the 20% sample preparation dilu-

3.1.2 reporting limit, RL, n—the concentration of the

tion factor.

lowest-level calibration standard used for quantification.

1.3 The values stated in SI units are to be regarded as

3.1.2.1 Discussion—In this test method, a 20 mL sample

standard. No other units of measurement are included in this

aliquot is diluted to a 25 mL final volume after thoroughly

standard.

rinsing the collection vial with acetonitrile for quantitative

1.4 This standard does not purport to address all of the

transfer.Inthiscase,thelowestcalibrationlevelof100ppbfor

safety concerns, if any, associated with its use. It is the

EGBE would allow for a reporting limit of 125 ppb to be

responsibility of the user of this standard to establish appro-

achieved.

priate safety and health practices and determine the applica-

3.2 Abbreviations:

bility of regulatory limitations prior to use.

3.2.1 ppb—parts per billion, µg/L

3.2.2 ppt—parts per trillion, ng/L

2. Referenced Documents

-3

3.2.3 mM—millimolar,1x10 moles/L

2.1 ASTM Standards:

3.2.4 NA—no addition

D1193 Specification for Reagent Water

3.2.5 ND—non-detect

This test method is under the jurisdiction of ASTM Committee D19 on Water

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

Organic Substances in Water.

Current edition approved May 1, 2011. Published May, 2011. DOI: 10.1520/

D7731–11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from from National Technical Information Service (NTIS), U.S.

Standards volume information, refer to the standard’s Document Summary page on Department of Commerce, 5285 Port Royal Road, Springfield, VA, 22161 or at

the ASTM website. http://www.epa.gov/epawaste/hazard/testmethods/index.htm

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7731 – 11

FIG. 1 Detection Verification Level Signal/Noise Ratio.

FIG. 2 Reporting Level (Calibra tion standard) Signal/Noise Ratio.

D7731 – 11

4. Summary of Test Method 7.1.1 Liquid Chromatography System—Acomplete LC sys-

tem is needed in order to analyze samples. Any system that is

4.1 This is a performance based method, and modifications

capable of performing at the flows, pressures, controlled

are allowed to improve performance.

temperatures, sample volumes, and requirements of the stan-

4.2 ForDPGBEandEGBEanalysis,samplesareshippedto

dard may be used.

the lab between 0°C and 6°C and analyzed within 5 days of

7.1.2 Analytical Column—Waters- XBridgey, 2.1 x 150

collection. The DOW MSDS sheet on DOWANOL* DPNB

mm, 3.5 µm particle size was used to develop this test method.

glycol ether (DPGBE) Issue Date: 06/18/2010 lists that the

Any column that achieves baseline resolution of these analytes

material is readily biodegradable. The Organisation for Eco-

may be used. Baseline resolution simplifies data analysis and

nomicCo-OperationandDevelopment(OECD)302BTestlists

can reduce the chance of ion suppression, leading to higher

96% biodegradation in 28 days.

limits of detection. The retention times and order of elution

4.3 In the lab, the entire collected 20 mL sample is spiked

may change depending on the column used and need to be

with surrogate and brought to a volume of 25 mL with

monitored.

acetonitrile. This prepared sample is then filtered using a

7.1.3 Tandem Mass Spectrometer System—A MS/MS sys-

syringe driven filter unit, and analyzed by LC/MS/MS. If

tem capable of SRM analysis. Any system that is capable of

visible oil is present, the prepared sample is allowed to settle

performing at the requirements in this procedure may be used.

resulting in an oil layer at the top of the 25 mL solution. A

7.2 Filtration Device:

portion of the aqueous (bottom) layer is filtered, leaving the oil

7.2.1 Hypodermic syringe—A Lock Tip Glass Syringe ca-

layer behind, through a syringe driven filter assembly and

pable of holding a Millext HV Syringe Driven Filter Unit

analyzed by LC/MS/MS.

PVDF 0.22 µm or similar may be used.

4.4 DPGBE,EGBEandsurrogateareidentifiedbyretention

7.2.1.1 A 25 mL Lock Tip Glass Syringe size was used in

timeandoneSRMtransition.Thetargetanalytesandsurrogate

this test method.

are quantitated using the SRM transitions utilizing an external

7.2.2 Filter—MillextHVSyringeDrivenFilterUnitPVDF

calibration. The final report issued for each sample lists the

0.22 µm (Millipore Corporation, Catalog #SLGV033NS) or

concentration of DPGBE, EGBE and the surrogate recovery.

similar may be used.

8. Reagents and Materials

5. Significance and Use

8.1 Purity of Reagents—High Performance Liquid Chroma-

5.1 DPGBE and EGBE have a variety of residential and

tography (HPLC) pesticide residue analysis and spectropho-

industrial applications such as, cleaning formulations, surface

tometry grade chemicals shall be used in all tests. Unless

coatings, inks and cosmetics. These analytes may be released

indicated otherwise, it is intended that all reagents shall

into the environment at levels that may be harmful to aquatic

conform to the Committee on Analytical Reagents of the

life.

American Chemical Society. Other reagent grades may be

5.2 This method has been investigated for use with reagent

used provided they are first determined to be of sufficiently

and sea water.

highpuritytopermittheirusewithoutaffectingtheaccuracyof

the measurements.

6. Interferences

8.2 Purity of Water—Unless otherwise indi cated, refer-

6.1 Method interferences may be caused by contaminants in ences to water shall be understood to mean reagent water

solvents, reagents, glassware, and other apparatus producing conforming to ASTM Type 1 of Specification D1193. It must

be demonstrated that this water does not contain contaminants

discrete artifacts or elevated baselines. All of these materials

are demonstrated to be free from interferences by analyzing at concentrations sufficient to interfere with the analysis.

8.3 Gases—Ultrapure nitrogen and argon.

laboratory reagent blanks under the same conditions as

samples. 8.4 Acetonitrile (CAS # 75-05-8).

8.5 Methanol (CAS # 67-56-1).

6.2 All glassware is washed in hot water with detergent and

8.6 Formic Acid (CAS # 64-18-6).

rinsed in hot water followed by distilled water. Detergents

8.7 Propanol (CAS # 67-63-0).

containing DPGBE or EGBE must not be used. The glassware

8.8 DPGBE—DipropyleneGlycolMonobutylEther(CAS#

is then dried and heated in an oven at 250°C for 15 to 30

29911-28-2).

minutes. All glassware is subsequently cleaned with acetone

followed by methanol.

6.3 All reagents and solvents should be pesticide residue AWatersAlliance High Performance Liquid Chromatography (HPLC) System

was used to develop this test method. All parameters in this test method are based

purity or higher to minimize interference problems.

on this system and may vary depending on your instrument.

6.4 Matrix interferences may be caused by contaminants in

AWatersQuattromicroAPItandemquadrupolemassspectrometerwasusedto

the sample. The extent of matrix interferences can vary develop this test method.All parameters in this test method are based on this system

and may vary depending on your instrument.

considerably from sample source depending on variations of

Reagent Chemicals, American Chemical Society Specifications, American

the sample matrix.

Chemical Society, Washington, D.C. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals,BDHLtd.,Poole,Dorset,U.K.,andtheUnitedStatesPharmacopeiaand

7. Apparatus

National Formulators, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

7.1 LC/MS/MS System MD.

D7731 – 11

8.9 EGBE—Ethylene Glycol Monobutyl Ether (CAS# 111- 11.2.3 Seal Wash—60% Acetonitrile/40% 2-propanol.

76-2). 11.3 Mass Spectrometer Parameters :

8.10 n-NP2EO—normal- Nonylphenol Diethoxylate (CAS# 11.3.1 To acquire the maximum number of data points per

Not available). SRM channel while maintaining adequate sensitivity, the tune

8.11 EGBE-D4 (2-butoxyethanol (1,1,2,2-D4)) (Optional parameters may be optimized according to your instrument.

Surrogate, Unlabeled CAS# 111-76- 2). Each peak requires at least 10 scans per peak for adequate

quantitation. This procedure contains DPGBE, EGBE and one

9. Hazards

surrogate which are in three SRM acquisition functions to

optimize sensitivity. Variable parameters regarding retention

9.1 Normal laboratory safety applies to this method. Ana-

lysts should wear safety glasses, gloves, and lab coats when times, SRM transitions, and cone and collision energies are

shown in Table 3. Mass spectrometer parameters used in the

working in the lab.Analysts should review the Material Safety

Data Sheets (MSDS) for all reagents used in this method. development of this method are listed here:

Capillary Voltage: 3.5 kV

10. Sampling

Cone: Variable depending on analyte (Table 3)

Extractor: 2 Volts

10.1 Sampling and Preservation–—Grab samples should be

RF Lens: 0.2 Volts

collected in 20 mL pre-cleaned glass vials with Teflont lined

Source Temperature: 120°C

septa caps demonstrated to be free of interferences. The vial

Desolvation Temperature: 350°C

should be filled to approximately 20 mL. This may be just

Desolvation Gas Flow: 800 L/hr

below the neck of the vial, depending on the vial manufacturer.

Cone Gas Flow: 25 L/hr

This test method is based on a 20 mLsample size per analysis.

Low Mass Resolution 1: 14.5

Each sample should be collected in duplicate and a quadrupli-

High Mass Resolution 1: 14.5

cate sample must be included with each sample batch of 10 for

Ion Energy 1: 0.5

MS/MSD quality control analyses. Store samples between 0°C

Entrance Energy: -1

and6°Cfromsamplecollectiontosamplepreparation.Analyze

Collision Energy: Variable depending on analyte (Table 3)

the sample within 5 days of collection.

Exit Energy: 1

11. Preparation of Apparatus

Low Mass Resolution 2: 14.5

High Mass resolution 2: 14.5

11.1 Liquid Chromatograph Operating Conditions

Ion Energy 2: 0.8

11.1.1 Injection volumes of all calibration standards and

Multiplier: 650

samples are made at 100 µLvolume.The first sample analyzed

-3

Gas Cell Pirani Gauge: 7.0 x 10 Torr

after the calibration curve is a blank to ensure there is no

Inter-Channel Delay : 0.1 seconds

carry-over. The gradient conditions for the liquid chromato-

Inter-Scan Delay: 0.1 seconds

graph are shown inTable 2. Divert the column flow away from

Dwell: 0.1 seconds

the electrospray source for 0 to 5 minutes after injection. Flow

Solvent Delay: 5 minutes

diversion to waste may be done using the mass spectrometer

divert valve, divert tubing configurations vary from manual

12. Calibration and Standardization

injection. Sea water samples contain nonvolatile salts, the first

5 minute elution is diverted in order to keep the mass 12.1 The mass spectrometer must be calibrated p er manu-

spectrometer source clean. facturer specifications before analysis. In order to obtain

11.2 LC Conditions: accurateanalyticalvaluesthroughusingthistestmethodwithin

11.2.1 Needle Wash Solvent—60% Acetonitrile/40% the confidence limits, the following procedures must be fol-

lowed when performing the test method. Prepare all solutions

2-propanol

11.2.2 Temperatures—Column, 30°C; Sample compart- in the lab using Class A volumetric glassware.

12.2 Calibration and Standardization—To calibrate the in-

ment, 15°C.

strument, analyze six calibration standards and the DVL

containing(nominalconcentrationsinTable4)DPGBE,EGBE

and n-NP2EO.Acalibration solution is prepared from standard

Asourceof n-NP2EOisAccustandard,Inc.125MarketStreet,NewHaven,CT

06513 or Cambridge Isotope Laboratories, 50 Frontage Road, Andover, MA materials or they are purchased as certified solutions. Level 6

01810-5413.

calibration solution containing the targets and surrogate is

A source of EGBE-D4 is Cambridge Isotope Laboratories, 50 Frontage Road,

prepared and aliquots of that solution are diluted to prepare

Andover, MA 01810-5413.

TABLE 2 Gradient C onditions for Liquid Chromatography

Time (min) Flow (mL/min) Percent 95% Water/ 5% CH CN Percent CH CN Percent 2% Formic Acid 95% Water/ 5% CH CN

3 3 3

0.0 0.30 95 0 5

2.0 0.30 95 0 5

5.0 0.30 0 95 5

14.0 0.30 0 95 5

15.0 0.30 95 0 5

18.0 0.30 95 0 5

D7731 – 11

TABLE 3 Retention Times, SRM transitions, and Specific Mass Spectrometer Parameters

Analyte Retention time (min) Cone Voltage (Volts) Collision Energy (eV) SRM Mass Transition (Precursor > Product)

DPGBE 8.5 19 7 191.3 > 115.1

EGBE 7.6 13 13 119.1 > 62.9

n-NP2EO (Surrogate)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.