ASTM D5720-95

(Practice)Standard Practice for Static Calibration of Electronic Transducer-Based Pressure Measurement Systems for Geotechnical Purposes

Standard Practice for Static Calibration of Electronic Transducer-Based Pressure Measurement Systems for Geotechnical Purposes

SCOPE

1.1 This practice covers the procedure for static calibration of electronic transducer-based systems used to measure fluid pressures in laboratory or in field applications associated with geotechnical testing.

1.2 This practice is used to determine the accuracy of electronic transducer-based pressure measurement systems over the full pressure range of the system or over a specified operating pressure range within the full pressure range.

1.3 This practice may also be used to determine a relationship between pressure transducer system output and applied pressure for use in converting from one value to the other (calibration curve). This relationship for electronic pressure transducer systems is usually linear and may be reduced to the form of a calibration factor or a linear calibration equation.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5720 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Static Calibration of Electronic Transducer-Based Pressure

Measurement Systems for Geotechnical Purposes

This standard is issued under the fixed designation D 5720; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope directly from ANSI/ISA-S37.1 (R1982) and are included for

the convenience of the user.

1.1 This practice covers the procedure for static calibration

3.2 Definitions of Terms Specific to This Standard:

of electronic transducer-based systems used to measure fluid

3.2.1 absolute pressure—pressure measured relative to zero

pressures in laboratory or in field applications associated with

pressure (vacuum) (ANSI, ISA-S37.1).

geotechnical testing.

3.2.2 accuracy—ratio of the error to the full-scale output or

1.2 This practice is used to determine the accuracy of

the ratio of the error to the output, as specified, expressed in

electronic transducer-based pressure measurement systems

percent (ANSI, ISA-S37.1).

over the full pressure range of the system or over a specified

3.2.3 ambient conditions—conditions (pressure, tempera-

operating pressure range within the full pressure range.

ture, etc.) of the medium surrounding the case of the transducer

1.3 This practice may also be used to determine a relation-

(ANSI, ISA-S37.1).

ship between pressure transducer system output and applied

3.2.4 best straight line—line midway between the two

pressure for use in converting from one value to the other

parallel straight lines closest together and enclosing all output

(calibration curve). This relationship for electronic pressure

versus measurand values on a calibration curve (ANSI, ISA-

transducer systems is usually linear and may be reduced to the

S37.1).

form of a calibration factor or a linear calibration equation.

3.2.5 bonded—permanently attached over the length and

1.4 The values stated in SI units are to be regarded as the

width of the active element (ANSI, ISA-S37.1).

standard. The inch-pound units in parentheses are for informa-

3.2.6 bourdon tube—pressure-sensing element consisting of

tion only.

a twisted or curved tube of non-circular cross section that tends

1.5 This standard does not purport to address all of the

to be straightened by the application of internal pressure

safety concerns, if any, associated with its use. It is the

(ANSI, ISA-S37.1).

responsibility of the user of this standard to establish appro-

3.2.7 calibration—test during which known values of mea-

priate safety and health practices and determine the applica-

surand are applied to the transducer and corresponding output

bility of regulatory limitations prior to use. Specific precau-

readings are recorded under specified conditions (ANSI, ISA-

tionary statements are given in Section 7.

S37.1).

2. Referenced Documents 3.2.8 calibration curve—graphical representation of the

calibration record (ANSI, ISA-S37.1).

2.1 ANSI/ISA Standards:

3.2.9 calibration cycle—application of known values of

S37.1 (R1982) Electrical Transducer Nomenclature and Ter-

measurand, and recording of corresponding output readings,

minology

over the full (or specified portion of the) range of a transducer

S37.3 (R1982) Specifications and Tests For Strain Gage

in an ascending and descending direction (ANSI, ISA-S37.1).

Pressure Transducers

3.2.10 calibration record—record (for example, table or

S37.6 (R1982) Specifications and Tests For Potentiometric

graph) of the measured relationship of the transducer output to

Pressure Transducers

the applied measurand over the transducer range (ANSI,

S37.10 (R1982) Specifications and Tests For Piezoelectric

ISA-S37.1).

Pressure and Sound-pressure Transducers

3.2.11 calibration traceability—relation of a transducer

3. Terminology

calibration, through a specified step-by-step process, to an

instrument or group of instruments calibrated by the National

3.1 Terms marked with “(ANSI, ISA-S37.1)” are taken

Institute of Standards and Technology (ANSI, ISA-S37.1).

3.2.12 capsule—pressure-sensing element consisting of two

This practice is under the jurisdiction of ASTM Committee D-18 on Soil and

metallic diaphragms joined around their peripheries (ANSI,

Rock and is the direct responsibility of Subcommittee D18.95 on Information

ISA-S37.1).

Retrieval and Data Automation.

Current edition approved April 15, 1995. Published June 1995.

3.2.13 diaphragm—sensing element consisting of a thin,

Available from Instrument Society of America, P.O. Box 12277, Research

usually circular, plate that is deformed by pressure differential

Triangle Park, NC 27709.

D 5720

applied across the plate (ANSI, ISA-S37.1). the applied measurand.

3.2.14 differential pressure—difference in pressure between 3.2.34 overload—maximum magnitude of measurand that

can be applied to a transducer without causing a change in

two points of measurement (ANSI, ISA-S37.1).

performance beyond specified tolerance (ANSI, ISA-S37.1).

3.2.15 end points—outputs at the specified upper and lower

3.2.35 piezoelectric—converting a change of measurand

limits of the range (ANSI, ISA-S37.1).

into a change in the electrostatic charge or voltage generated by

3.2.16 end-point line—straight line between the end points

certain materials when mechanically stressed (ANSI, ISA-

(ANSI, ISA-S37.1).

S37.1).

3.2.17 end point linearity—linearity referred to the end-

3.2.36 piezoresistance—converting a change of measurand

point line (ANSI, ISA-S37.1).

into a change in resistance when mechanically stressed.

3.2.18 environmental conditions—specified external condi-

3.2.37 potentiometric—converting a change of measurand

tions (shock, vibration, temperature, etc.) to which a transducer

into a voltage-ratio change by a change in the position of a

may be exposed during shipping, storage, handling, and

moveable contact on a resistance element across which exci-

operation (ANSI, ISA-S37.1).

tation is applied (ANSI, ISA-S37.1).

3.2.19 error—algebraic difference between the indicated

3.2.38 range—measurand values, over which a transducer

value and the true value of the measurand (ANSI, ISA-S37.1).

is intended to measure, specified by their upper and lower

3.2.20 excitation—external electrical voltage or current, or

limits (ANSI, ISA-S37.1).

both, applied to a transducer for its proper operation (ANSI,

3.2.39 repeatability—ability of a transducer to reproduce

ISA-S37.1).

output readings when the same measurand value is applied to

3.2.21 fluid—a substance, such as a liquid or gas, that is

it consecutively, under the same conditions, and in the same

capable of flowing and that changes its shape at a steady rate

direction (ANSI, ISA-S37.1).

when acted upon by a force.

3.2.39.1 Discussion—Repeatability is expressed as the

3.2.22 full-scale output—algebraic difference between the

maximum difference between output readings; it is expressed

end points (ANSI, ISA-S37.1).

in percent of full-scale output. Two calibration cycles are used

3.2.23 gage pressure—pressure measured relative to ambi-

to determine repeatability unless otherwise specified.

ent pressure (ANSI, ISA-S37.1).

3.2.40 room conditions—ambient environmental condi-

3.2.24 hermetically sealed—manufacturing process by

tions, under that transducers must commonly operate, that have

which a device is sealed and rendered airtight.

been established as follows: (a) temperature: 25 6 10°C (77 6

3.2.25 hysteresis—maximum difference in output, at any

18°F); (b) relative humidity: 90 % or less; and (c) barometric

measurand value within the specified range, when the value is

pressure: 986 10 kPa (29 6 3 in. Hg). Tolerances closer than

approached first with increasing and then with decreasing

shown above are frequently specified for transducer calibration

measurand (ANSI, ISA-S37.1).

and test environments (ANSI, ISA-S37.1).

3.2.25.1 Discussion—Hysteresis is expressed in percent of

3.2.41 sealed gage pressure—pressure measured relative to

full-scale output, during any one calibration cycle.

normal atmospheric pressure that is sealed within the trans-

3.2.26 least-squares line—straight line for which the sum of

ducer.

the squares of the residuals (deviations) is minimized (ANSI,

3.2.42 sensing element—that part of the transducer that

ISA-S37.1).

responds directly to the measurand (ANSI, ISA-S37.1).

3.2.27 least squares linearity—linearity referred to the

3.2.43 static calibration—calibration performed under

least-squares line (ANSI, ISA-S37.1).

room conditions and in the absence of any vibration, shock, or

3.2.28 linearity—closeness of a calibration curve to a speci-

acceleration (unless one of these is the measurand) (ANSI,

fied straight line (ANSI, ISA-S37.1).

ISA-S37.1).

3.2.28.1 Discussion—Linearity is expressed as the maxi-

3.2.44 strain gage—converting a change of measurand into

mum deviation of any calibration point from a specified

a change in resistance due to strain (ANSI, ISA-S37.1).

straight line, during any one calibration cycle. Linearity is

3.2.45 theoretical output—product of the applied pressure

expressed in percent of full-scale output.

or vacuum and the ratio of full-scale output to calibrated

3.2.29 measurand—physical quantity, property, or condi-

pressure range.

tion that is measured (ANSI, ISA-S37.1).

3.2.46 transducer—device that provides a usable output in

3.2.30 measured fluid—fluid that comes in contact with the

response to a specified measurand (ANSI, ISA-S37.1).

sensing element (ANSI, ISA-S37.1).

3.2.47 transduction element—electrical portion of a trans-

3.2.31 normal atmospheric pressure—101.325 kPa (14.696

ducer in which the output originates (ANSI, ISA-S37.1).

lbf/in. ); equivalent to the pressure exerted by the weight of a

3.2.48 warm-up period—period of time, starting with the

column of mercury 760 mm (29.92 in.) high at 0°C (32°F) at

application of excitation to the transducer, required to ensure

a point on the earth where the acceleration of gravity is 9.8066

that the transducer will perform within all specified tolerances

2 2

m/s (32.1739 ft/s ).

(ANSI, ISA-S37.1).

3.2.32 operating environmental conditions—environmental

4. Summary of Practice

conditions during exposure to which a transducer must perform

in some specified manner (ANSI, ISA-S37.1). 4.1 A pressure transducer based measurement system (pres-

3.2.33 output—electrical or numerical quantity, produced sure transducer, readout system, power supply, and signal

by a transducer or measurement system, that is a function of conditioner), pressure standard, and appropriate controllers,

D 5720

regulators, and valves are connected to pressure or vacuum

sources, or both.

4.2 Pressure or vacuum is applied in predetermined inter-

vals over the full range (or a specified portion of the full range)

of the pressure measurement system.

4.3 The pressure measurement system output is compared at

each pressure or vacuum interval to the applied pressure or

vacuum as indicated by the pressure standard.

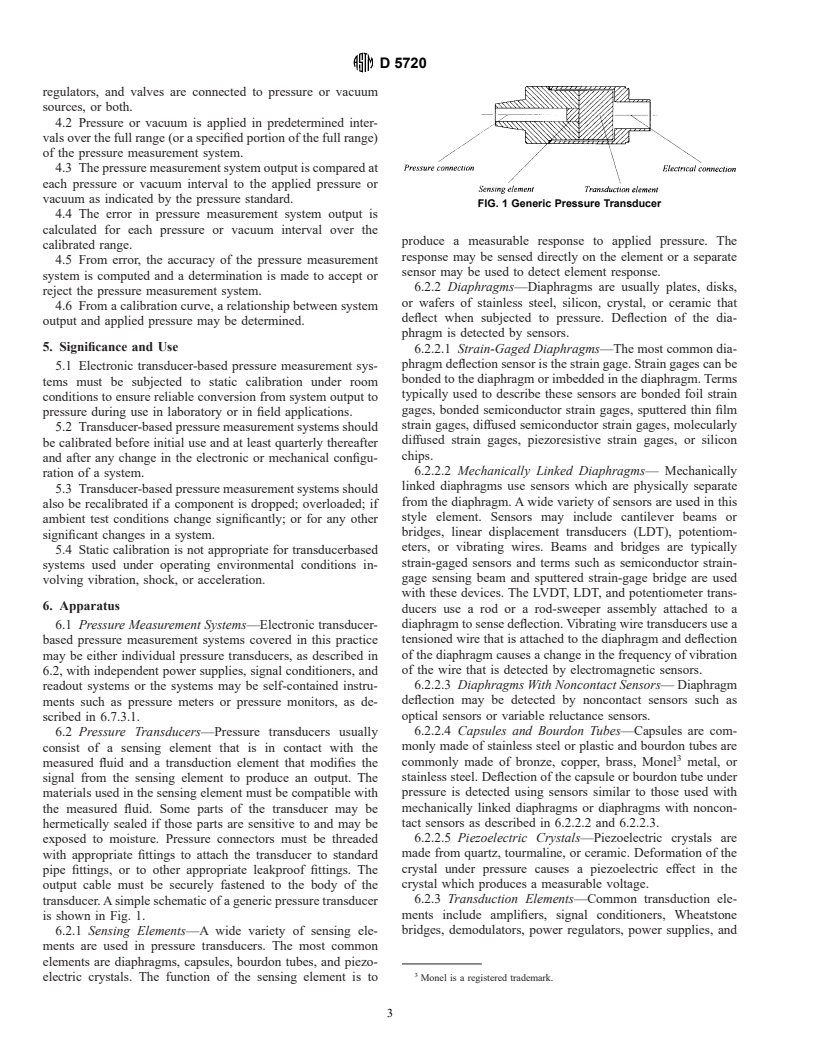

FIG. 1 Generic Pressure Transducer

4.4 The error in pressure measurement system output is

calculated for each pressure or vacuum interval over the

produce a measurable response to applied pressure. The

calibrated range.

response may be sensed directly on the element or a separate

4.5 From error, the accuracy of the pressure measurement

sensor may be used to detect element response.

system is computed and a determination is made to accept or

6.2.2 Diaphragms—Diaphragms are usually plates, disks,

reject the pressure measurement system.

or wafers of stainless steel, silicon, crystal, or ceramic that

4.6 From a calibration curve, a relationship between system

deflect when subjected to pressure. Deflection of the dia-

output and applied pressure may be determined.

phragm is detected by sensors.

5. Significance and Use

6.2.2.1 Strain-Gaged Diaphragms—The most common dia-

phragm deflection sensor is the strain gage. Strain gages can be

5.1 Electronic transducer-based pressure measurement sys-

bonded to the diaphragm or imbedded in the diaphragm. Terms

tems must be subjected to static calibration under room

typically used to describe these sensors are bonded foil strain

conditions to ensure reliable conversion from system output to

gages, bonded semiconductor strain gages, sputtered thin film

pressure during use in laboratory or in field applications.

strain gages, diffused semiconductor strain gages, molecularly

5.2 Transducer-based pressure measurement systems should

diffused strain gages, piezoresistive strain gages, or silicon

be calibrated before initial use and at least quarterly thereafter

chips.

and after any change in the electronic or mechanical configu-

6.2.2.2 Mechanically Linked Diaphragms— Mechanically

ration of a system.

linked diaphragms use sensors which are physically separate

5.3 Transducer-based pressure measurement systems should

from the diaphragm. A wide variety of sensors are used in this

also be recalibrated if a component is dropped; overloaded; if

style element. Sensors may include cantilever beams or

ambient test conditions change significantly; or for any other

bridges, linear displacement transducers (LDT), potentiom-

significant changes in a system.

eters, or vibrating wires. Beams and bridges are typically

5.4 Static calibration is not appropriate for transducerbased

strain-gaged sensors and terms such as semiconductor strain-

systems used under operating environmental conditions in-

gage sensing beam and sputtered strain-gage bridge are used

volving vibration, shock, or acceleration.

with these devices. The LVDT, LDT, and potentiometer trans-

6. Apparatus

ducers use a rod or a rod-sweeper assembly attached to a

diaphragm to sense deflection. Vibrating wire transducers use a

6.1 Pressure Measurement Systems—Electronic transducer-

tensioned wire that is attached to the diaphragm and deflection

based pressure measurement systems covered in this practice

of the diaphragm causes a change in the frequency of vibration

may be either individual pressure transducers, as described in

of the wire that is detected by electromagnetic sensors.

6.2, with independent power supplies, signal conditioners, and

6.2.2.3 Diaphragms With Noncontact Sensors— Diaphragm

readout systems or the systems may be self-contained instru-

deflection may be detected by noncontact sensors such as

ments such as pressure meters or pressure monitors, as de-

optical sensors or variable reluctance sensors.

scribed in 6.7.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.