ASTM G103-97(2005)

(Practice)Standard Practice for Evaluating Stress-Corrosion Cracking Resistance of Low Copper 7XXX Series Al-Zn-Mg-Cu Alloys in Boiling 6% Sodium Chloride Solution

Standard Practice for Evaluating Stress-Corrosion Cracking Resistance of Low Copper 7XXX Series Al-Zn-Mg-Cu Alloys in Boiling 6% Sodium Chloride Solution

SIGNIFICANCE AND USE

This practice is normally used for stress-corrosion screening for the development of Al-Zn-Mg-Cu alloys containing less than 0.26 % copper. Effects on stress-corrosion resistance due to variables such as composition, thermo-mechanical processing, other fabrication variables, and magnitude of applied stress may be compared.

For a given mechanical method of stressing, the relative stress-corrosion resistance of the low copper Al-Zn-Mg-Cu alloys in atmospheric exposure correlates better with performance in boiling 6 % sodium chloride solution than with other accelerated testing media (7-9). In addition, this practice is relatively rapid.

This practice is not applicable to 2XXX (Al-Cu), 5XXX (Al-Mg), 6XXX (Al-Mg-Si), and the 7XXX (Al-Zn-Mg-Cu) series alloys containing more than 1.2 % copper.

4.3.1 For 7XXX series alloys containing between 0.26 % and 1.2 % copper, there is no general agreement as to whether this practice or Practice G 44 correlates better with stress-corrosion resistance in service (5-8, 10).

SCOPE

1.1 This practice primarily covers the test medium which may be used with a variety of test specimens and methods of applying stress. Exposure times, criteria of failure, and so on, are variable and not specified.

1.2 This stress-corrosion testing practice is intended for statically loaded smooth non-welded or welded specimens of 7XXX series Al-Zn-Mg-Cu alloys containing less than 0.26 % copper.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section for additional precautions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G103–97 (Reapproved 2005)

Standard Practice for

Evaluating Stress-Corrosion Cracking Resistance of Low

Copper 7XXX Series Al-Zn-Mg-Cu Alloys in Boiling 6%

Sodium Chloride Solution

This standard is issued under the fixed designation G103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Continuous immersion in boiling 6 % sodium chloride solution historically was considered to be an

effectiveacceleratedSCCtestingmediumforallAl-Zn-Mg-Cualloys(1, 2), butinmorerecentyears,

alternate immersion in 3.5 % sodium chloride solution (Practice G44) has become the favored test

medium for the high copper (1.2 to 2.6 % Cu) 7XXX series alloys (3, 4). Evidence to date shows,

however, that the boiling 6 % sodium chloride medium correlates better with outdoor atmospheric

exposure than Practice G44 for the 7XXX series alloys containing little or no copper (5, 6, 7, 8).

1. Scope mine the applicability of regulatory limitations prior to use.

See Section 8 for additional precautions.

1.1 This practice primarily covers the test medium which

may be used with a variety of test specimens and methods of

2. Referenced Documents

applying stress. Exposure times, criteria of failure, and so on,

2.1 ASTM Standards:

are variable and not specified.

B580 Specification for Anodic Oxide Coatings on Alumi-

1.2 This stress-corrosion testing practice is intended for

num

statically loaded smooth non-welded or welded specimens of

D1193 Specification for Reagent Water

7XXX seriesAl-Zn-Mg-Cu alloys containing less than 0.26 %

G30 Practice for Making and Using U-Bend Stress-

copper.

Corrosion Test Specimens

1.3 This standard may involve hazardous materials, opera-

G38 Practice for Making and Using C-Ring Stress-

tions, and equipment. This standard does not purport to

Corrosion Test Specimens

address all of the safety concerns, if any, associated with its

G39 Practice for Preparation and Use of Bent-Beam Stress-

use. It is the responsibility of the user of this standard to

Corrosion Test Specimens

establish appropriate safety and health practices and deter-

G44 Practice for Exposure of Metals and Alloys by Alter-

nate Immersion in Neutral 3.5 % Sodium Chloride Solu-

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion tion

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

tally Assisted Cracking.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

approved in 1989. Last previous edition approved in 1997 as G103 – 97. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/G0103-97R05. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G103–97 (2005)

G49 Practice for Preparation and Use of Direct Tension 4.3 This practice is not applicable to 2XXX (Al-Cu), 5XXX

Stress-Corrosion Test Specimens (Al-Mg), 6XXX (Al-Mg-Si), and the 7XXX (Al-Zn-Mg-Cu)

G58 Practice for Preparation of Stress-Corrosion Test series alloys containing more than 1.2 % copper.

Specimens for Weldments 4.3.1 For 7XXX series alloys containing between 0.26 %

and 1.2 % copper, there is no general agreement as to whether

3. Summary of Practice

this practice or Practice G44 correlates better with stress-

corrosion resistance in service (5-8, 10).

3.1 Stressed specimens are totally and continuously im-

mersed in boiling 6 % sodium chloride solution for up to 168

5. Apparatus

h. Various types of smooth test specimens and methods of

stressing may be used. Performance is based on time to visual

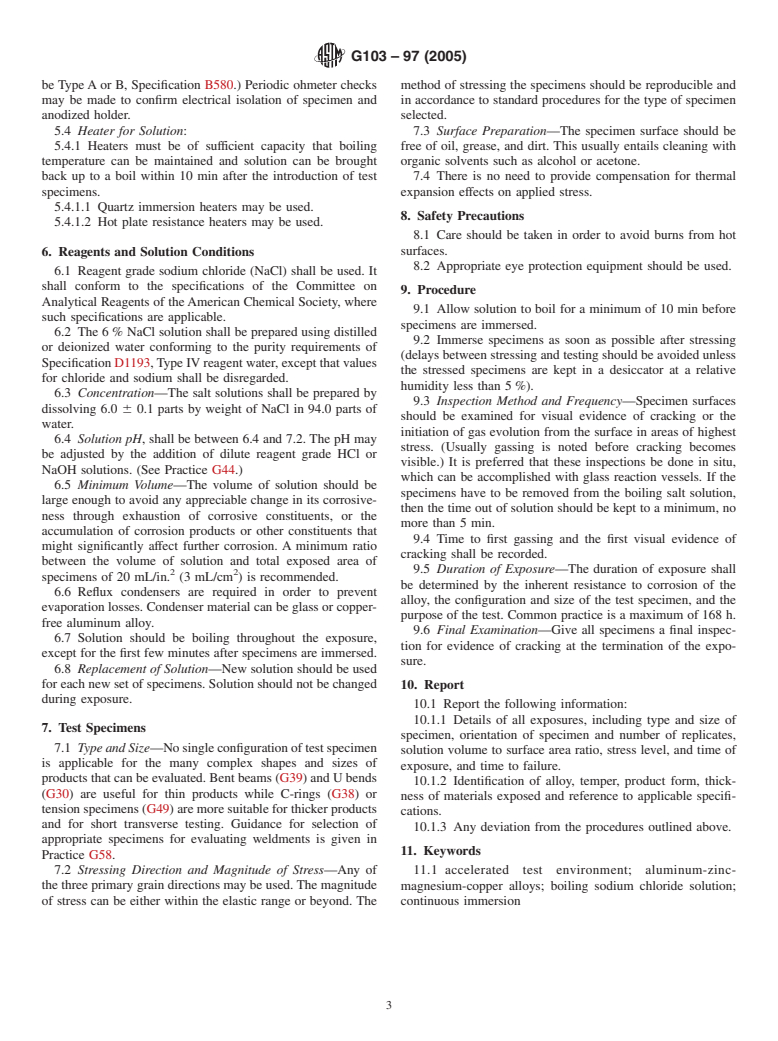

5.1 Fig. 1 illustrates one type of apparatus that has been

cracking.

used.

5.2 Materials of Construction:

4. Significance and Use

5.2.1 Materialsofconstructionthatcomeincontactwiththe

4.1 This practice is normally used for stress-corrosion boiling salt solution shall be such that they are not affected by

screening for the development ofAl-Zn-Mg-Cu alloys contain- the corrodent to an extent that they can cause contamination of

ing less than 0.26 % copper. Effects on stress-corrosion resis- the solution and change its corrosiveness.

tanceduetovariablessuchascomposition,thermo-mechanical 5.2.2 Useofglassoraluminumcontainersandcondensersis

processing, other fabrication variables, and magnitude of recommended.

applied stress may be compared. 5.2.3 Metallic materials of construction should be limited to

4.2 For a given mechanical method of stressing, the relative copper free aluminum alloys, which may be anodized to

stress-corrosion resistance of the low copper Al-Zn-Mg-Cu provide electrical contact resistance.

alloys in atmospheric exposure correlates better with perfor- 5.3 Specimen Holders—The specimen holders should be

mance in boiling 6 % sodium chloride solution than with other designed to electrically insulate the specimens from each other

accelerated testing media (7-9). In addition, this practice is and from other bare metal. An anodized aluminum holder has

relatively rapid. been found to be appropriate. (Satisfactory anodic coating may

U bend specimens (Practice G39) stressed in an anodized aluminum fixture (right photo) are placed in a pyrex battery jar (left photo), which is placed over a mag-

netic stirrer. The 6 % salt solution is heated to boiling by means of two quartz immersion heaters. A powerstat controls the heat output of the quartz heaters. A cold

water circulating aluminum condenser tube is placed just below the aluminum cover to prevent evaporation losses. Stressed specimens are placed in the jar after

the solution comes to a boil. Specimens are examined in place for visual evidence of cracking.

FIG. 1 Boiling 6% NaCl—Stress-Corrosion Testing Practice

G103–97 (2005)

be TypeAor B, Specification B580.) Periodic ohmeter checks method of stressing the specimens should be reproducible and

may be made to confirm electrical isolation of specimen and in accordance to standard procedures for the type of specimen

anodized holder. selected.

5.4 Heater for Solution: 7.3 Surface Preparation—The specimen surface should be

5.4.1 Heaters must be of sufficient capacity that boiling free of oil, grease, and dirt. This usually entails cleaning with

temperature can be maintained and solution can be brought organic solvents such as alcohol or acetone.

back up to a boil within 10 min after the introduction of test 7.4 There is no need to provide compensation for thermal

specimens. expansion effects on applied stress.

5.4.1.1 Quartz immersion heaters may be used.

8. Safety Precautions

5.4.1.2 Hot plate resistance hea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.