ASTM D5052-00

(Test Method)Standard Test Method for Permeability of Leather to Water Vapor

Standard Test Method for Permeability of Leather to Water Vapor

SCOPE

1.1 This test method covers the determination of the permeability of leather to water vapor by measuring the rate at which water vapor passes through a test specimen. This test method does not apply to wet blue.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents, therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5052–00

Standard Test Method for

Permeability of Leather to Water Vapor

This standard is issued under the fixed designation D 5052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the perme-

ability of leather to water vapor by measuring the rate at which

water vapor passes through a test specimen. This test method

does not apply to wet blue.

1.2 The values stated in either inch-pound or SI units are to

be regarded separately as standard. The values stated in each

system may not be exact equivalents, therefore, each system

shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the

standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

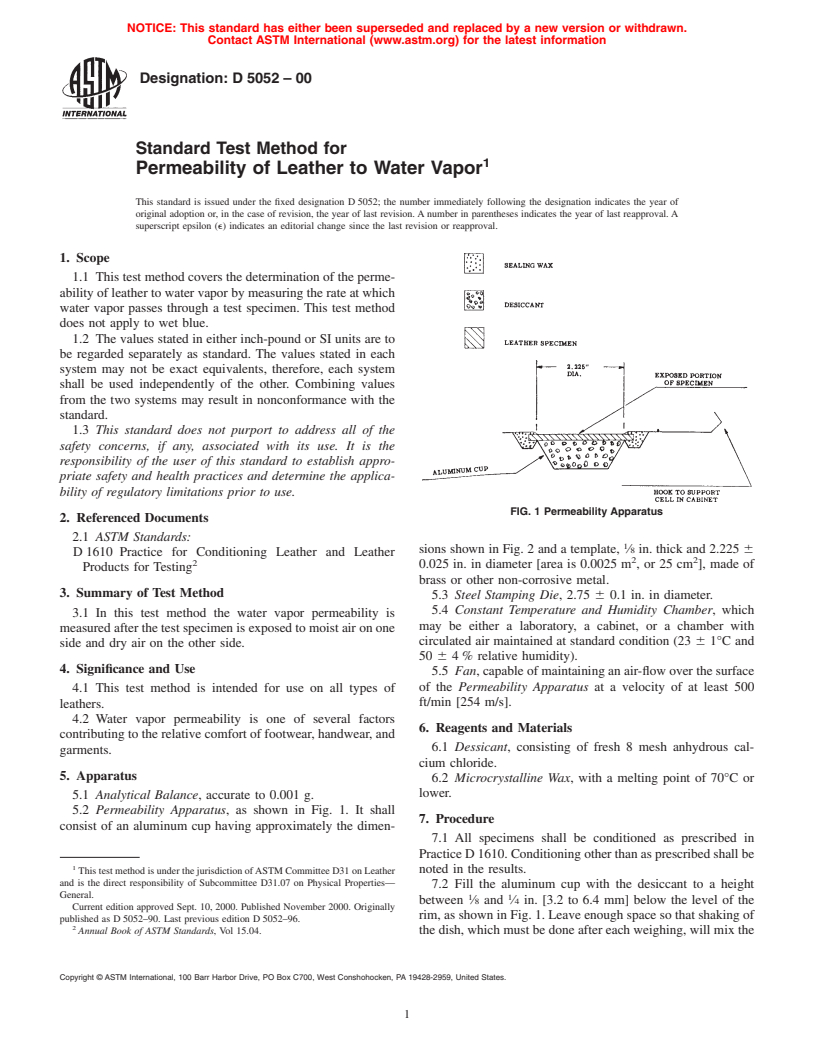

FIG. 1 Permeability Apparatus

2. Referenced Documents

2.1 ASTM Standards:

sions shown in Fig. 2 and a template, ⁄8 in. thick and 2.225 6

D 1610 Practice for Conditioning Leather and Leather

2 2

0.025 in. in diameter [area is 0.0025 m,or25cm ], made of

Products for Testing

brass or other non-corrosive metal.

3. Summary of Test Method

5.3 Steel Stamping Die, 2.75 6 0.1 in. in diameter.

5.4 Constant Temperature and Humidity Chamber, which

3.1 In this test method the water vapor permeability is

may be either a laboratory, a cabinet, or a chamber with

measured after the test specimen is exposed to moist air on one

circulated air maintained at standard condition (23 6 1°C and

side and dry air on the other side.

50 6 4 % relative humidity).

4. Significance and Use

5.5 Fan, capable of maintaining an air-flow over the surface

of the Permeability Apparatus at a velocity of at least 500

4.1 This test method is intended for use on all types of

ft/min [254 m/s].

leathers.

4.2 Water vapor permeability is one of several factors

6. Reagents and Materials

contributing to the relative comfort of footwear, handwear, and

6.1 Dessicant, consisting of fresh 8 mesh anhydrous cal-

garments.

cium chloride.

5. Apparatus

6.2 Microcrystalline Wax, with a melting point of 70°C or

lower.

5.1 Analytical Balance, accurate to 0.001 g.

5.2 Permeability Apparatus, as shown in Fig. 1. It shall

7. Procedure

consist of an aluminum cup having approximately the dimen-

7.1 All specimens shall be conditioned as prescribed in

Practice D 1610. Conditioning other than as prescribed shall be

noted in the results.

This test method is under the jurisdiction ofASTM Committee D31 on Leather

and is the direct responsibility of Subcommittee D31.07 on Physical Properties—

7.2 Fill the aluminum cup with the desiccant to a height

General.

1 1

between ⁄8 and ⁄4 in. [3.2 to 6.4 mm] below the level of the

Current edition approved Sept. 10, 2000. Published November 2000. Originally

rim, as shown in Fig. 1. Leave enough space so that shaking of

published as D 5052–90. Last previous edition D 5052–96.

Annual Book of ASTM Standards, Vol 15.04. the dish, which must be done after each weighing, will mix the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5052–00

FIG. 2 Spining Stud for Water Vapor Permeability Dish

desiccant. Place the specimen, with the grain side downward, 8. Calculation

over the desiccant and center with the cup. Place the template

8.1 Calculate the permeability to water vapor of the test

flat on the specimen and center as nearly as possible with the

specimen by one of the following equations:

cup. A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.