ASTM G97-97(2007)

(Test Method)Standard Test Method for Laboratory Evaluation of Magnesium Sacrificial Anode Test Specimens for Underground Applications

Standard Test Method for Laboratory Evaluation of Magnesium Sacrificial Anode Test Specimens for Underground Applications

SIGNIFICANCE AND USE

This test is a guide for evaluating magnesium anodes. The degree of correlation between this test and service performance has not been fully determined.

SCOPE

1.1 This test method covers a laboratory procedure that measures the two fundamental performance properties of magnesium sacrificial anode test specimens operating in a saturated calcium sulfate, saturated magnesium hydroxide environment. The two fundamental properties are electrode (oxidation potential) and ampere hours (Ah) obtained per unit mass of specimen consumed. Magnesium anodes installed underground are usually surrounded by a backfill material that typically consists of 75 % gypsum (CaSO4·2H2O), 20 % bentonite clay, and 5 % sodium sulfate (Na2SO4). The calcium sulfate, magnesium hydroxide test electrolyte simulates the long term environment around an anode installed in the gypsum-bentonite-sodium sulfate backfill.

1.2 This test method is intended to be used for quality assurance by anode manufacturers or anode users. However, long term field performance properties may not be identical to property measurements obtained using this laboratory test.

Note 1—Refer to Terminology G 15 for terms used in this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, See Section 7 and Paragraph 8.1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G97 −97(Reapproved 2007)

Standard Test Method for

Laboratory Evaluation of Magnesium Sacrificial Anode Test

Specimens for Underground Applications

This standard is issued under the fixed designation G97; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G15 Terminology Relating to Corrosion and Corrosion Test-

ing (Withdrawn 2010)

1.1 This test method covers a laboratory procedure that

G16 Guide for Applying Statistics to Analysis of Corrosion

measures the two fundamental performance properties of

Data

magnesium sacrificial anode test specimens operating in a

2.2 American National Standard:

saturated calcium sulfate, saturated magnesium hydroxide

ANSI/NFPA 480 Storage, Handling, and Processing of

environment. The two fundamental properties are electrode

Magnesium, 1987 Edition

(oxidation potential) and ampere hours (Ah) obtained per unit

mass of specimen consumed. Magnesium anodes installed

3. Summary of Test Method

underground are usually surrounded by a backfill material that

typically consists of 75 % gypsum (CaSO ·2H O), 20 % ben- 3.1 A known direct current is passed through test cells

4 2

tonite clay, and 5 % sodium sulfate (Na SO ). The calcium connected in series. Each test cell consists of a pre-weighed

2 4

sulfate, magnesium hydroxide test electrolyte simulates the test magnesium alloy anode specimen, a steel pot container

long term environment around an anode installed in the cathode, and a known electrolyte. Test specimen oxidation

gypsum-bentonite-sodium sulfate backfill. potential is measured several times during the 14-day test and

1 h after the current is turned off at the end of the test.The total

1.2 This test method is intended to be used for quality

Ah passed through the cells are measured.At the conclusion of

assurance by anode manufacturers or anode users. However,

the test, each test specimen is cleaned and weighed. The Ah

long term field performance properties may not be identical to

obtained per unit mass of specimen lost is calculated.

property measurements obtained using this laboratory test.

NOTE 1—Refer to Terminology G15 for terms used in this test method. 4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This test is a guide for evaluating magnesium anodes.

safety concerns, if any, associated with its use. It is the

The degree of correlation between this test and service perfor-

responsibility of the user of this standard to establish appro-

mance has not been fully determined.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

5. Apparatus

precautions, See Section 7 and Paragraph 8.1.1.

5.1 The basic test equipment consists of the following:

5.1.1 Direct Current Power Source, (optional), capable of

2. Referenced Documents

delivering at least 2 mA and 12 V.

2.1 ASTM Standards:

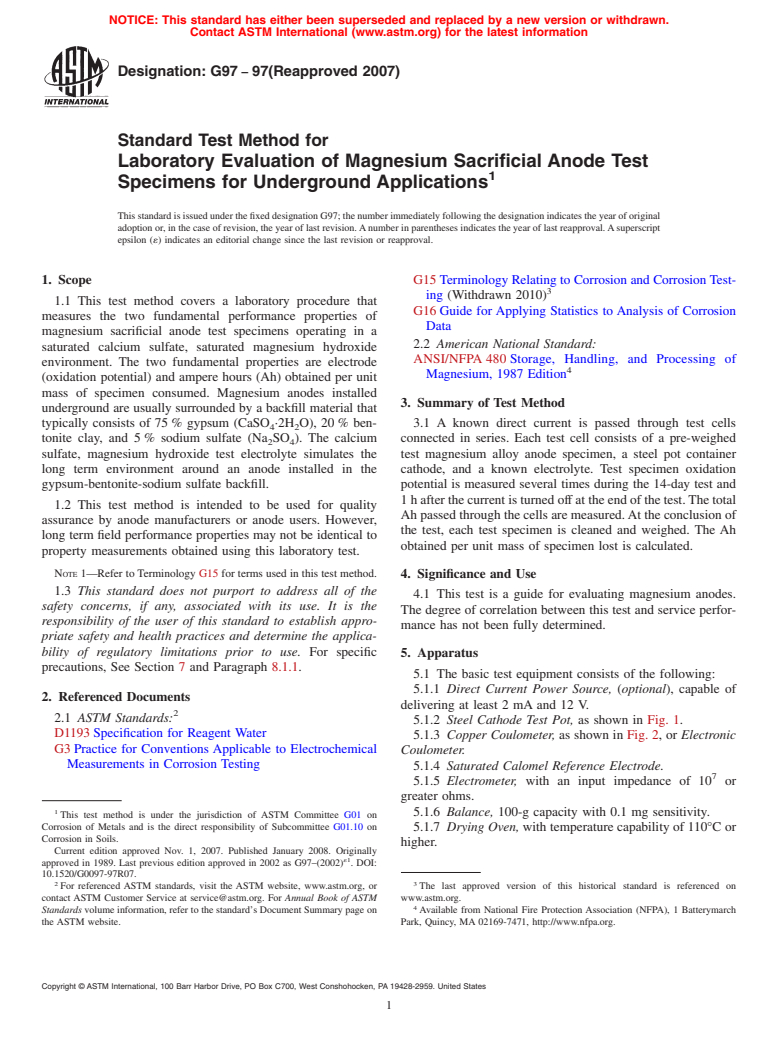

5.1.2 Steel Cathode Test Pot, as shown in Fig. 1.

D1193 Specification for Reagent Water

5.1.3 Copper Coulometer, as shown in Fig. 2,or Electronic

G3 Practice for Conventions Applicable to Electrochemical

Coulometer.

Measurements in Corrosion Testing

5.1.4 Saturated Calomel Reference Electrode.

5.1.5 Electrometer, with an input impedance of 10 or

greater ohms.

5.1.6 Balance, 100-g capacity with 0.1 mg sensitivity.

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.10 on

5.1.7 Drying Oven, with temperature capability of 110°C or

Corrosion in Soils.

higher.

Current edition approved Nov. 1, 2007. Published January 2008. Originally

´1

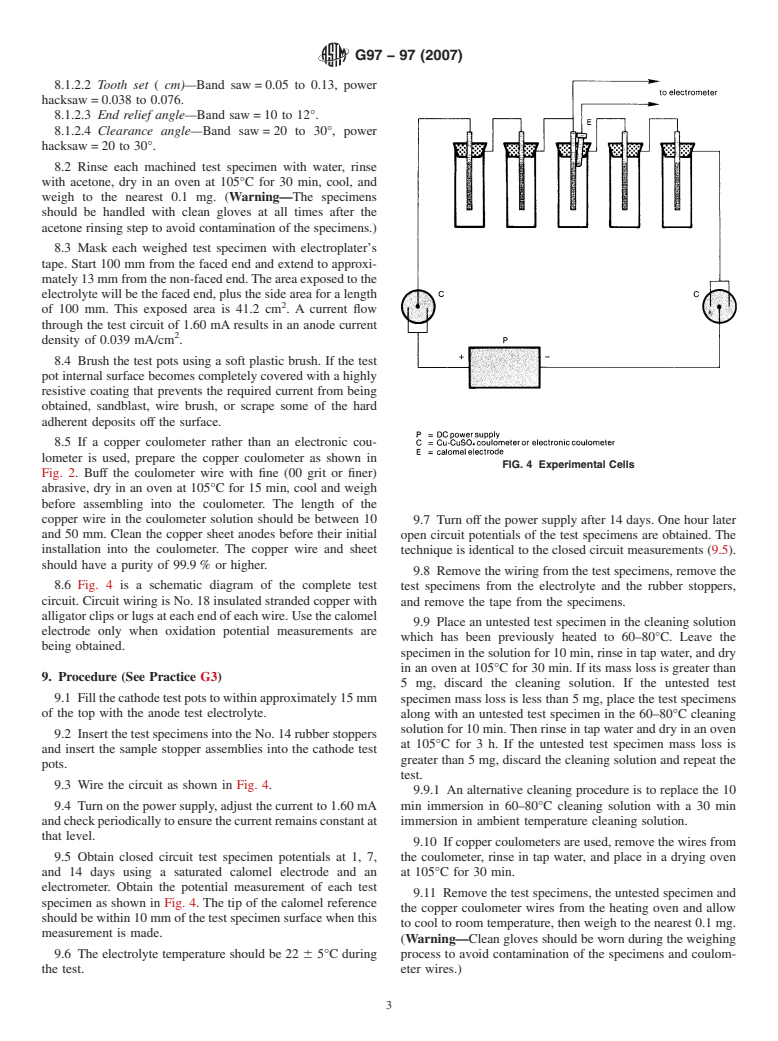

approved in 1989. Last previous edition approved in 2002 as G97–(2002) . DOI:

10.1520/G0097-97R07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Fire Protection Association (NFPA), 1 Batterymarch

the ASTM website. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G97−97 (2007)

cleaning solution. Test specimen cleaning should be done in a

ventilated laboratory hood.

7.2 Local, state, and federal regulations should be complied

with in disposing of used cleaning solution.

8. Specimen Preparation

8.1 Fig. 3 shows typical test specimen selection and prepa-

ration from a cast anode. Since all sizes and shapes of cast

anodes are not shown, the sampling is only illustrative. Test

specimens are obtained across the width of a cast anode and

approximately 13 mm from the edge. Machine each test

specimen from a sawed, 180-mm long, 16-mm square cross

section portion of the cast anode. Dry machine the square cross

section, which should be marked with a stamped identification

number, down to 12.7-mm diameter using a machining speed

of 800 r/min, a feed rate of 0.5 mm per revolution, and a depth

of cut of 1.9 mm or less. Cut the machined test specimen to a

152-mm length and machine-face one end.

8.1.1 Magnesium fines produced during cutting and ma-

chining operations can present a fire hazard. ANSI/NFPA 480

should be consulted for procedures for handling magnesium.

8.1.2 Band saws and power hacksaws with the following

characteristics are recommended for use on magnesium:

8.1.2.1 Blade pitch (teeth/cm)—Band saw = 1.6 to 2.4,

power hacksaw = 0.8 to 2.4.

FIG. 1 Detail of Test Pot

FIG. 2 Copper Coulometer

6. Reagents

6.1 Test Electrolyte, Saturated Calcium Sulfate-Magnesium

Hydroxide Solution—Add 5.0 g of reagent grade CaSO ·2H O,

4 2

0.1 g of reagent grade Mg(OH) , to 1000 mL of Type IV or

better reagent grade water (see Specification D1193).

6.2 Coulometer Solution—Add 235 g of reagent grade

CuSO ·5H O, 27 mL 98 % H SO,50cm undenatured ethyl

4 2 2 4

alcohol to 900 mL of Type IV or better reagent grade water.

6.3 Anode Cleaning Solution—Add 250 g of reagent grade

CrO to 1000 mL of Type IV or better reagent grade water.

7. Precautions

7.1 Eye protection and skin protection are required when

handling the coulometer solution and when handling the FIG. 3 Test Specimen Preparation from Cast Anode

G97−97 (2007)

8.1.2.2 Tooth set ( cm)—Band saw = 0.05 to 0.13, power

hacksaw = 0.038 to 0.076.

8.1.2.3 End relief angle—Band saw = 10 to 12°.

8.1.2.4 Clearance angle—Band saw = 20 to 30°, power

hacksaw = 20 to 30°.

8.2 Rinse each machined test specimen with water, rinse

with acetone, dry in an oven at 105°C for 30 min, cool, and

weigh to the nearest 0.1 mg. (Warning—The specimens

should be handled with clean gloves at all times after the

acetone rinsing step to avoid contamination of the specimens.)

8.3 Mask each weighed test specimen with electroplater’s

tape. Start 100 mm from the faced end and extend to approxi-

mately13mmfromthenon-facedend.Theareaexposedtothe

electrolyte will be the faced end, plus the side area for a length

of 100 mm. This exposed area is 41.2 cm . A current flow

through the test circuit of 1.60 mA results in an anode current

densit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.