ASTM A389/A389M-08

(Specification)Standard Specification for Steel Castings, Alloy, Specially Heat-Treated, for Pressure-Containing Parts, Suitable for High-Temperature Service

Standard Specification for Steel Castings, Alloy, Specially Heat-Treated, for Pressure-Containing Parts, Suitable for High-Temperature Service

ABSTRACT

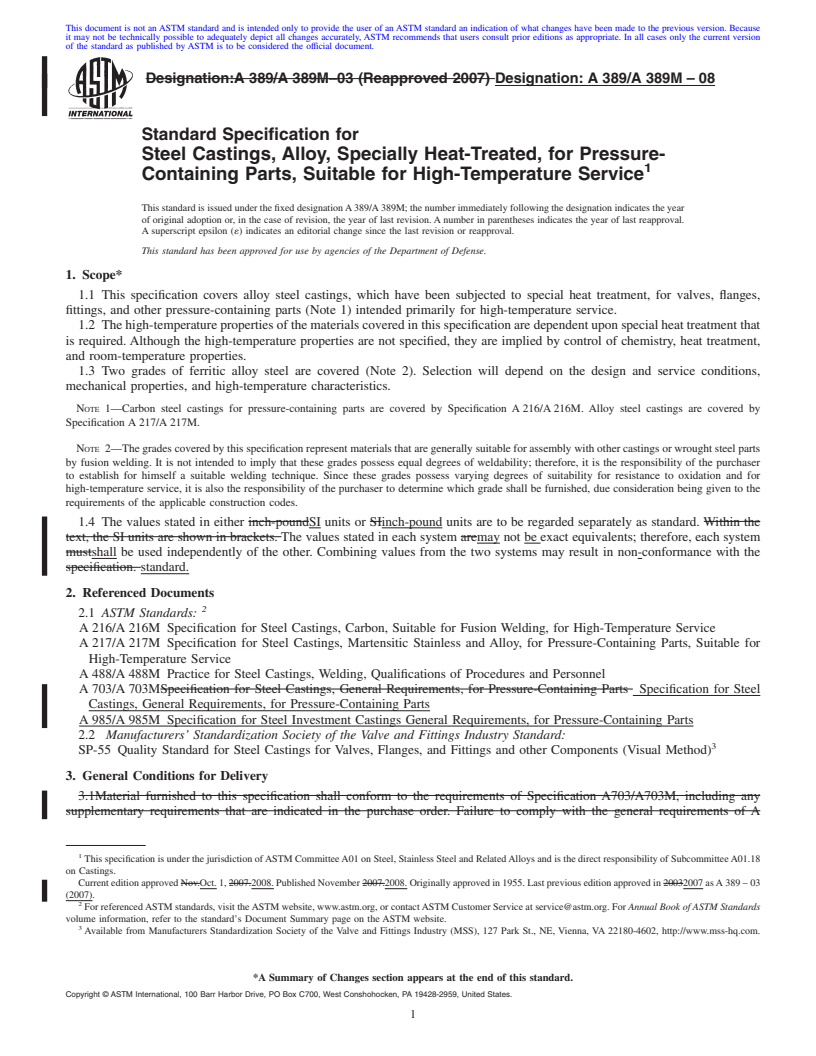

This guide specifies standard specification for alloy steel castings, which have been subjected to special heat treatment, for valves, flanges, fittings, and other pressure-containing parts intended primarily for high-temperature service. All castings shall receive a heat treatment proper to their design and chemical composition. Heat treatment shall be performed before machining except in instances when reheat treating is necessary. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, and vanadium. Steel used for the castings shall conform to the required tensile properties such as tensile strength, yield strength, and elongation. When methods involving high temperature are used in the removal of discontinuities, casting shall be preheated to at least the minimum temperatures.

SCOPE

1.1 This specification covers alloy steel castings, which have been subjected to special heat treatment, for valves, flanges, fittings, and other pressure-containing parts (Note 1) intended primarily for high-temperature service.

1.2 The high-temperature properties of the materials covered in this specification are dependent upon special heat treatment that is required. Although the high-temperature properties are not specified, they are implied by control of chemistry, heat treatment, and room-temperature properties.

1.3 Two grades of ferritic alloy steel are covered (Note 2). Selection will depend on the design and service conditions, mechanical properties, and high-temperature characteristics.

Note 1—Carbon steel castings for pressure-containing parts are covered by Specification A 216/A 216M. Alloy steel castings are covered by Specification A 217/A 217M.

Note 2—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser to establish for himself a suitable welding technique. Since these grades possess varying degrees of suitability for resistance to oxidation and for high-temperature service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the requirements of the applicable construction codes.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A389/A389M – 08

Standard Specification for

Steel Castings, Alloy, Specially Heat-Treated, for Pressure-

1

Containing Parts, Suitable for High-Temperature Service

This standard is issued under the fixed designationA389/A389M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers alloy steel castings, which 2.1 ASTM Standards:

have been subjected to special heat treatment, for valves, A216/A216M Specification for Steel Castings, Carbon,

flanges, fittings, and other pressure-containing parts (Note 1) Suitable for Fusion Welding, for High-Temperature Ser-

intended primarily for high-temperature service. vice

1.2 The high-temperature properties of the materials cov- A217/A217M Specification for Steel Castings, Martensitic

ered in this specification are dependent upon special heat Stainless and Alloy, for Pressure-Containing Parts, Suit-

treatment that is required. Although the high-temperature able for High-Temperature Service

properties are not specified, they are implied by control of A488/A488M Practice for Steel Castings, Welding, Quali-

chemistry, heat treatment, and room-temperature properties. fications of Procedures and Personnel

1.3 Two grades of ferritic alloy steel are covered (Note 2). A703/A703M Specification for Steel Castings, General Re-

Selection will depend on the design and service conditions, quirements, for Pressure-Containing Parts

mechanical properties, and high-temperature characteristics. A985/A985M Specification for Steel Investment Castings

General Requirements, for Pressure-Containing Parts

NOTE 1—Carbon steel castings for pressure-containing parts are cov-

2.2 Manufacturers’ Standardization Society of the Valve

ered by Specification A216/A216M. Alloy steel castings are covered by

and Fittings Industry Standard:

Specification A217/A217M.

SP-55 Quality Standard for Steel Castings for Valves,

NOTE 2—The grades covered by this specification represent materials

Flanges, and Fittings and other Components (Visual

3

that are generally suitable for assembly with other castings or wrought

Method)

steel parts by fusion welding. It is not intended to imply that these grades

possess equal degrees of weldability; therefore, it is the responsibility of

3. General Conditions for Delivery

the purchaser to establish for himself a suitable welding technique. Since

3.1 Except for steel investment castings, material furnished

these grades possess varying degrees of suitability for resistance to

to this specification shall conform to the requirements of

oxidation and for high-temperature service, it is also the responsibility of

Specification A703/A703M, including any supplementary re-

the purchaser to determine which grade shall be furnished, due consider-

ationbeinggiventotherequirementsoftheapplicableconstructioncodes.

quirements that are indicated in the purchase order. Failure to

comply with the general requirements ofA703/A703M consti-

1.4 The values stated in either SI units or inch-pound units

tutes nonconformance with the specification. In case of conflict

are to be regarded separately as standard. The values stated in

between the requirements of this specification and A703/

each system may not be exact equivalents; therefore, each

A703M, this specification shall prevail.

system shall be used independently of the other. Combining

3.2 Steel investment castings furnished to this specification

values from the two systems may result in non-conformance

shall conform to the requirements of Specification A985/

with the standard.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.18 on Castings. the ASTM website.

3

Current edition approved Oct. 1, 2008. Published November 2008. Originally AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

approved in 1955. Last previous edition approved in 2007 as A389 – 03 (2007). Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

DOI: 10.1520/A0389_A0389M-08. hq.com.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 389/A 389M–03 (Reapproved 2007) Designation: A 389/A 389M – 08

Standard Specification for

Steel Castings, Alloy, Specially Heat-Treated, for Pressure-

1

Containing Parts, Suitable for High-Temperature Service

This standard is issued under the fixed designationA389/A389M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers alloy steel castings, which have been subjected to special heat treatment, for valves, flanges,

fittings, and other pressure-containing parts (Note 1) intended primarily for high-temperature service.

1.2 The high-temperature properties of the materials covered in this specification are dependent upon special heat treatment that

is required. Although the high-temperature properties are not specified, they are implied by control of chemistry, heat treatment,

and room-temperature properties.

1.3 Two grades of ferritic alloy steel are covered (Note 2). Selection will depend on the design and service conditions,

mechanical properties, and high-temperature characteristics.

NOTE 1—Carbon steel castings for pressure-containing parts are covered by Specification A 216/A 216M. Alloy steel castings are covered by

Specification A 217/A 217M.

NOTE 2—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts

by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser

to establish for himself a suitable welding technique. Since these grades possess varying degrees of suitability for resistance to oxidation and for

high-temperature service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the

requirements of the applicable construction codes.

1.4 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A 216/A 216M Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

A 217/A 217M Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for

High-Temperature Service

A 488/A 488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A 703/A 703MSpecification for Steel Castings, General Requirements, for Pressure-Containing Parts Specification for Steel

Castings, General Requirements, for Pressure-Containing Parts

A 985/A 985M Specification for Steel Investment Castings General Requirements, for Pressure-Containing Parts

2.2 Manufacturers’ Standardization Society of the Valve and Fittings Industry Standard:

3

SP-55 Quality Standard for Steel Castings for Valves, Flanges, and Fittings and other Components (Visual Method)

3. General Conditions for Delivery

3.1Material furnished to this specification shall conform to the requirements of Specification A703/A703M, including any

supplementary requirements that are indicated in the purchase order. Failure to comply with the general requirements of A

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

CurrenteditionapprovedNov.Oct.1,2007.2008.PublishedNovember2007.2008.Originallyapprovedin1955.Lastpreviouseditionapprovedin20032007asA 389 – 03

(2007).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

*ASummary of Changes section appears at the end

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.