ASTM D7589-09

(Test Method)Standard Test Method for Measurement of Effects of Automotive Engine Oils on Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VID Spark Ignition Engine ,

Standard Test Method for Measurement of Effects of Automotive Engine Oils on Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VID Spark Ignition Engine <sup>,</sup>

SIGNIFICANCE AND USE

Test Method—The data obtained from the use of this test method provide a comparative index of the fuel-saving capabilities of automotive engine oils under repeatable laboratory conditions. A BL has been established for this test to provide a standard against which all other oils can be compared. The BL oil is an SAE 20W-30 grade fully formulated lubricant. The test procedure was not designed to give a precise estimate of the difference between two test oils without adequate replication. The test method was developed to compare the test oil to the BL oil. Companion test methods used to evaluate engine oil performance for specification requirements are discussed in the latest revision of Specification D4485.

Use—The Sequence VID test method is useful for engine oil fuel economy specification acceptance. It is used in specifications and classifications of engine lubricating oils, such as the following:

Specification D4485.

API 1509.

SAE Classification J304.

SAE Classification J1423.

SCOPE

1.1 This test method covers an engine test procedure for the measurement of the effects of automotive engine oils on the fuel economy of passenger cars and light-duty trucks with gross vehicle weight 3856 kg or less. The tests are conducted using a specified spark-ignition engine with a displacement of 3.6 L (General Motors) on a dynamometer test stand. It applies to multi viscosity grade oils used in these applications.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exceptions—Where there is no direct equivalent such as the units for screw threads, National Pipe threads/diameters, tubing size, and single source supply equipment specifications. Additionally, Brake Fuel Consumption (BSFC) is measured in kilograms per kilowatthour.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7589 – 09

Standard Test Method for

Measurement of Effects of Automotive Engine Oils on Fuel

Economy of Passenger Cars and Light-Duty Trucks in

,

1 2

Sequence VID Spark Ignition Engine

This standard is issued under the fixed designation D7589; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method can be used by any properly equipped laboratory without outside assistance.

However, the ASTM Test Monitoring Center (TMC) provides reference oils and assessment of the

test results obtained on those oils by the laboratory (seeAnnexA1). By this means, the laboratory will

know whether their use of this test method gives results statistically similar to those obtained by other

laboratories. Furthermore, various agencies require that a laboratory utilize the TMC services in

seeking qualification of oils against specifications. For example, the American Petroleum Institute

(API) imposes such a requirement, in connection with several U.S. Army engine lubricating oil

specifications. Accordingly, this test method is written for use by laboratories that utilize the TMC

services. Laboratories that choose not to use those services may simply ignore those portions of this

test method that refer to theTMC.This test method may be modified by means of Information Letters

issued by the TMC. In addition, the TMC may issue supplementary memoranda related to this test

method. Users of this test method shall contact the TMC,Attention:Administrator, to obtain the most

recent of these information letters.

1. Scope 1.2.1 Exceptions—Where there is no direct equivalent such

as the units for screw threads, National Pipe threads/diameters,

1.1 This test method covers an engine test procedure for the

tubing size, and single source supply equipment specifications.

measurement of the effects of automotive engine oils on the

Additionally, Brake Fuel Consumption (BSFC) is measured in

fuel economy of passenger cars and light-duty trucks with

kilograms per kilowatthour.

gross vehicle weight 3856 kg or less. The tests are conducted

1.3 This standard does not purport to address all of the

using a specified spark-ignition engine with a displacement of

safety concerns, if any, associated with its use. It is the

3.6 L (General Motors) on a dynamometer test stand. It

responsibility of the user of this standard to establish appro-

applies to multi viscosity grade oils used in these applications.

priate safety and health practices and determine the applica-

1.2 The values stated in SI units are to be regarded as

bility of regulatory limitations prior to use.

standard. No other units of measurement are included in this

1.4 This test method is arranged as follows:

standard.

Subject Section

Introduction

Scope 1

This test method is under the jurisdiction of ASTM Committee D02 on

Referenced Documents 2

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Terminology 3

D02.B0.10 on Standards Acceleration.

Summary of Test Method 4

Current edition approved Dec. 1, 2009. Published February 2010.

Significance and Use 5

The multi-cylinder engine test sequences were originally developed by an

Apparatus 6

ASTM Committee D02 group. Subsequently, the procedures were published in an

General 6.1

ASTM special technical publication. The Sequence VIB was published as Research Test Engine Configuration 6.2

Report RR:D02-1469, dated April 8, 1999. Laboratory Ambient Conditions 6.3

Engine Speed and Torque Control 6.4

TheASTM Test Monitoring Center will update changes in this test method by

Dynamometer 6.4.1

means of Information Letters. This edition includes all information letters through

Dynamometer Torque 6.4.2

No. 09-1. Information letters may be obtained from the ASTM Test Monitoring

Engine Cooling System 6.5

Center, 6555 Penn Avenue, Pittsburgh, PA 15206-4489, Attention: Administrator.

4 External Oil System 6.6

Trademark of General Motors Corporation, 300 Renaissance Center, Detroit,

Fuel System 6.7

MI 48265.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7589 – 09

Subject Section Subject Section

Fuel Flow Measurement 6.7.2 Thermocouple and Temperature Measurement System 10.2.4

Fuel Temperature and Pressure Control to the Fuel 6.7.3 Humidity Measurement System 10.2.5

Flowmeter Other Instrumentation 10.2.6

Fuel Temperature and Pressure Control to Engine Fuel Rail 6.7.4 Test Procedure 11

Fuel Supply Pumps 6.7.5 External Oil System 11.1

Fuel Filtering 6.7.6 Flush Effectiveness Demonstration 11.2

Engine Intake Air Supply 6.8 Preparation for Oil Charge 11.3

Intake Air Humidity 6.8.1 Initial Engine Start-Up 11.4

Intake Air Filtration 6.8.2 New Engine Break-In 11.5

Intake Air Pressure Relief 6.8.3 Oil Charge for Break-In 11.5.2

Temperature Measurement 6.9

Break-In Operating Conditions 11.5.3

Thermocouple Location 6.9.5 Standard Requirements for Break-In 11.5.4

AFR Determination 6.10 Routine Test Operation 11.6

Exhaust and Exhaust Back Pressure Systems 6.11 Start-Up and Shutdown Procedures 11.6.1

Exhaust Manifolds 6.11.1 Flying Flush Oil Exchange Procedures 11.6.2

Laboratory Exhaust System 6.11.2 Test Operating Stages 11.6.3

Exhaust Back Pressure 6.11.3 Stabilization to Stage Conditions 11.6.4

Pressure Measurement and Pressure Sensor Locations 6.12 Stabilized BSFC Measurement Cycle 11.6.5

Engine Oil 6.12.2 BLB1 Oil Flush Procedure for BL Oil Before Test Run 1 11.6.6

Fuel to Fuel Flowmeter 6.12.3

BSFC Measurement of BLB1 Oil Before Test Oil 11.6.7

Fuel to Engine Fuel Rail 6.12.4 BLB2 Oil Flush Procedure for BL Oil Before Test Oil Run 2 11.6.8

Exhaust Back Pressure 6.12.5 BSFC Measurement of BLB2 Oil Before Test Oil 11.6.9

Intake Air 6.12.6 Percent Delta Calculation for BLB1 vs. BLB2 11.6.10

Intake Manifold Vacuum/Absolute Pressure 6.12.7 Test Oil Flush Procedure 11.6.11

Coolant Flow Differential Pressure 6.12.8 Test Oil Aging, Phase I 11.6.12

Crankcase Pressure 6.12.9 BSFC Measurement of Aged (Phase I) Test Oil 11.6.13

Engine Hardware and Related Apparatus 6.13 Test Oil Aging, Phase II 11.6.14

Test Engine Configuration 6.13.1 BSFC Measurement of Aged (Phase II) Test Oil 11.6.15

ECU (Power Control Module) 6.13.2 Oil Consumption and Sampling 11.6.16

Thermostat Block-Off Adapter Plate 6.13.3 Flush Procedure for BL Oil (BLA) After Test Oil 11.6.17

Wiring Harness 6.13.4 General Test Data Logging Forms 11.6.18

Oil Pan 6.13.5 Diagnostic Review Procedures 11.6.19

Engine Water Pump Adapter Plate 6.13.6 Determination of Test Results 12

Thermostat Block-Off Plate 6.13.7 Final Test Report 13

Oil Filter Adapter Plate 6.13.8 Precision and Bias 14

Modified Throttle Body Assembly 6.13.9

Keywords 15

Fuel Rail 6.13.10 Annexes

Miscellaneous Apparatus Related to Engine Operation 6.14 The Role of the ASTM Test Monitoring Center and the Annex A1

Reagents and Materials 7 Calibration Program

Engine Oil 7.1 Detailed Specifications and Drawings of Apparatus Annex A2

Test Fuel 7.2 Oil Heater Cerrobase Refill Procedure Annex A3

Engine Coolant 7.3 Engine Part Number Listing Annex A4

Cleaning Materials 7.4 Safety Precautions Annex A5

Preparation of Apparatus 8 Report Format Annex A6

Test Stand Preparation 8.2 Statistical Equations for Mean and Standard Deviations Annex A7

Engine Preparation 9 Oil Sump Full Level Determination Consumption Annex A8

Cleaning of Engine Parts 9.3 Measurement Calibration Procedure

Engine Assembly Procedure 9.4 Fuel Injector Evaluation Annex A9

General Assembly Instructions 9.4.1 Pre-test Maintenance Checklist Annex A10

Bolt Torque Specifications 9.4.2 Blow-by Ventilation System Requirements Annex A11

Sealing Compounds 9.4.3 Calculation of Test Results Annex A12

Harmonic Balancer 9.4.5 Calculation of Unweighted Baseline Shift Annex A13

Thermostat 9.4.6

Appendix

Coolant Inlet 9.4.7

Oil Filter Adapter 9.4.8 Procurement of Test Materials Appendix X1

Dipstick Tube 9.4.9

Sensors, Switches, Valves, and Positioner’s 9.4.10

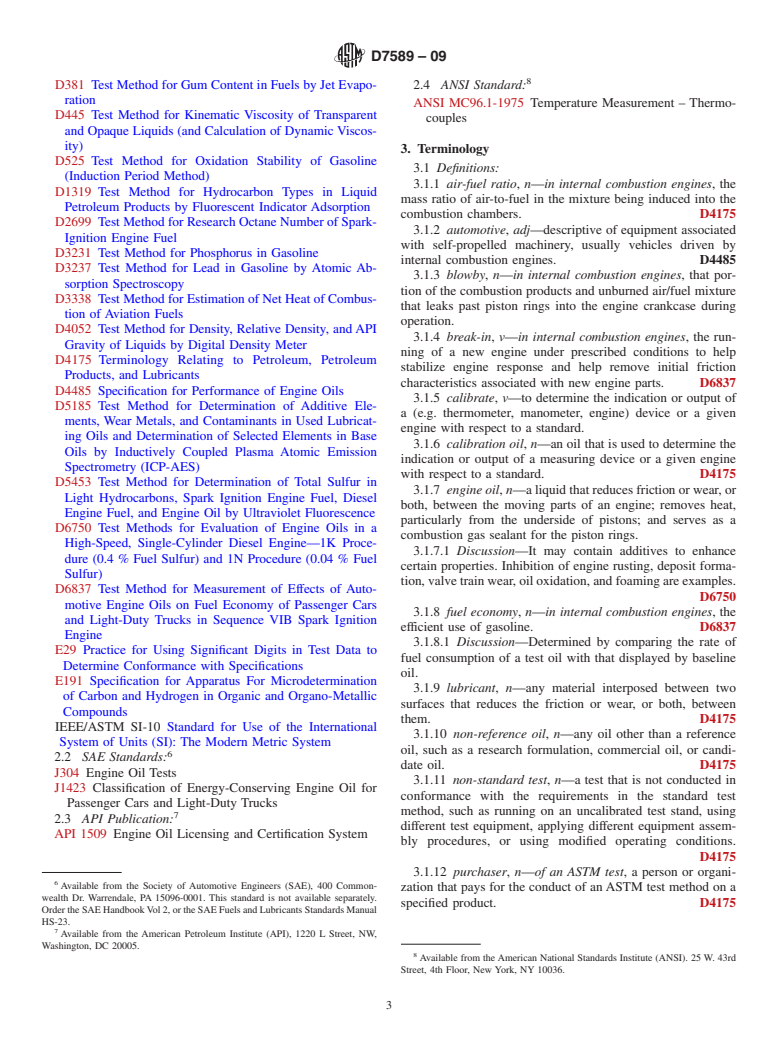

2. Referenced Documents

Ignition System 9.4.11

Fuel Injection System 9.4.12

2.1 ASTM Standards:

Intake Air System 9.4.13

D86 Test Method for Distillation of Petroleum Products at

Engine Management System 9.4.14

Atmospheric Pressure

Accessory Drive Units 9.4.15

Exhaust Manifolds 9.4.16 D235 Specification for Mineral Spirits (Petroleum Spirits)

Engine Flywheel and Guards 9.4.17

(Hydrocarbon Dry Cleaning Solvent)

Lifting of Assembled Engines 9.4.18

D240 Test Method for Heat of Combustion of Liquid

Engine Mounts 9.4.19

Non-Phased Camshaft Gears 9.4.20

Hydrocarbon Fuels by Bomb Calorimeter

Internal Coolant Orifice 9.4.21

D323 Test Method for Vapor Pressure of Petroleum Prod-

Calibration 10

ucts (Reid Method)

Stand/Engine Calibration 10.1

Procedure 10.1.1

Reporting of Reference Results 10.1.2

Analysis of Reference/Calibration Oils 10.1.3

Instrument Calibration 10.2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Engine Torque Measurement System 10.2.1

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fuel Flow Measurement System 10.2.2

Standards volume information, refer to the standard’s Document Summary page on

Coolant Flow Measurement System 10.2.3

the ASTM website.

D7589 – 09

D381 Test Method for Gum Content in Fuels by Jet Evapo- 2.4 ANSI Standard:

ration

ANSI MC96.1-1975 Temperature Measurement – Thermo-

D445 Test Method for Kinematic Viscosity of Transparent

couples

and Opaque Liquids (and Calculation of Dynamic Viscos-

ity)

3. Terminology

D525 Test Method for Oxidation Stability of Gasoline

3.1 Definitions:

(Induction Period Method)

3.1.1 air-fuel ratio, n—in internal combustion engines, the

D1319 Test Method for Hydrocarbon Types in Liquid

mass ratio of air-to-fuel in the mixture being induced into the

Petroleum Products by Fluorescent Indicator Adsorption

combustion chambers. D4175

D2699 Test Method for Research Octane Number of Spark-

3.1.2 automotive, adj—descriptive of equipment associated

Ignition Engine Fuel

with self-propelled machinery, usually vehicles driven by

D3231 Test Method for Phosphorus in Gasoline

internal combustion engines. D4485

D3237 Test Method for Lead in Gasoline by Atomic Ab-

3.1.3 blowby, n—in internal combustion engines, that por-

sorption Spectroscopy

tion of the combustion products and unburned air/fuel mixture

D3338 Test Method for Estimation of Net Heat of Combus-

that leaks past piston rings into the engine crankcase during

tion of Aviation Fuels

operation.

D4052 Test Method for Density, Relative Density, and API

3.1.4 break-in, v—in internal combustion engines, the run-

Gravity of Liquids by Digital Density Meter

ning of a new engine under prescribed conditions to help

D4175 Terminology Relating to Petroleum, Petroleum

stabilize engine response and help remove initial friction

Products, and Lubricants

characteristics associated with new engine parts. D6837

D4485 Specification for Performance of Engine Oils

3.1.5 calibrate, v—to determine the indication or output of

D5185 Test Method for Determination of Additive Ele-

a (e.g. thermometer, manometer, engine) device or a given

ments, Wear Metals, and Contaminants in Used Lubricat-

engine with respect to a standard.

ing Oils and Determination of Selected Elements in Base

3.1.6 calibration oil, n—an oil that is used to determine the

Oils by Inductively Coupled Plasma Atomic Emission

indication or output of a measuring device or a given engine

Spectrometry (ICP-AES)

with respect to a standard. D4175

D5453 Test Method for Determination of Total Sulfur in

3.1.7 engine oil, n—a liquid that reduces friction or wear, or

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

both, between the moving parts of an engine; removes heat,

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

particularly from the underside of pistons; and serves as a

D6750 Test Methods for Evaluation of Engine Oils in a

combustion gas sealant for the piston rings.

High-Speed, Single-Cylinder Diesel Engine—1K Proce-

3.1.7.1 Discussion—It may contain additives to enhance

dure (0.4 % Fuel Sulfur) and 1N Procedure (0.04 % Fuel

certain properties. Inhibition of engine rusting, deposit forma-

Sulfur)

tion,valvetrainwear,oiloxidation,andfoamingareexamples.

D6837 Test Method for Measurement of Effects of Auto-

D6750

motive Engine Oils on Fuel Economy of Passenger Cars

3.1.8 fuel economy, n—in internal combustion engines, the

and Light-Duty Trucks in Sequence VIB Spark Ignition

efficient use of gasoline. D6837

Engine

3.1.8.1 Discussion—Determined by comparing the rate of

E29 Practice for Using Significant Digits in Test Data to

fuel consumption of a test oil with that displayed by baseline

Determine Conformance with Specifications

oil.

E191 Specification for Apparatus For Microdetermination

3.1.9 lubricant, n—any material interposed between two

of Carbon and Hydrogen in Organic and Organo-Metallic

surfaces that reduces the friction or wear, or both, between

Compounds

them. D4175

IEEE/ASTM SI-10 Standard for Use of the International

3.1.10 non-reference oil, n—any oil other than a reference

System of Units (SI): The Modern Metric System

oil, such as a research formulation, commercial oil, or candi-

2.2 SAE Standards:

date oil. D4175

J304 Engine Oil Tests

3.1.11 non-standard test, n—a test that is not conducted in

J1423 Classification of Energy-Conserving Engine Oil for

conformance with the requirements in the standard test

Passenger Cars and Light-Duty Trucks

method, such as running on an uncalibrated test stand, using

2.3 API Publication:

different test equipment, applying different equipment assem-

API 1509 Engine Oil Licensing and Certification System

bly procedures, or using modified operating conditions.

D4175

3.1.12 purchaser, n—of an ASTM test, a person or organi-

Available from the Society of Automotive Engineers (SAE), 400 Common-

zation that pays for the conduct of anASTM test method on a

wealth Dr. Warrendale, PA 15096-0001. This standard is not available separately.

specified product. D4175

OrdertheSAEHandbookVol2,ortheSAEFuelsandLubricantsStandardsManual

HS-23.

Available from the American Petroleum Institute (API), 1220 L Street, NW,

Washington, DC 20005.

Available from the American National Standards Institute (ANSI). 25 W. 43rd

Street, 4th Floor, New York, NY 10036.

D7589 – 09

3.1.12.1 Discussion—The preferred term is purchaser. Dep- test oil to baseline oil, an intermediate flush with special

recatedtermsthathavebeenusedareclient,requester,sponso

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.