ASTM D3192-09

(Test Method)Standard Test Methods for Carbon Black Evaluation in NR (Natural Rubber)

Standard Test Methods for Carbon Black Evaluation in NR (Natural Rubber)

SIGNIFICANCE AND USE

The major portion of carbon black consumed by the rubber industry is used to improve the physical properties, life expectancy, and utility of rubber products. These test methods provide a natural rubber formulation and directions for evaluating carbon black intended for use in rubber products.

These test methods may be used to characterize carbon black in terms of specific properties of the standard compound. These test methods are useful for the quality assurance of carbon black production. They may also be used for the preparation of reference compounds, to confirm the day-to-day reliability of testing operations used in the rubber industry, for the evaluation of experimental compounds, and quality control of production compounds.

SCOPE

1.1 These test methods cover the standard materials, test formulation, mixing procedure, and test methods for the evaluation and production control of carbon blacks in natural rubber (NR).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3192 − 09

StandardTest Methods for

1

Carbon Black Evaluation in NR (Natural Rubber)

This standard is issued under the fixed designation D3192; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope expectancy, and utility of rubber products. These test methods

provide a natural rubber formulation and directions for evalu-

1.1 These test methods cover the standard materials, test

ating carbon black intended for use in rubber products.

formulation, mixing procedure, and test methods for the

evaluation and production control of carbon blacks in natural 3.2 These test methods may be used to characterize carbon

rubber (NR). black in terms of specific properties of the standard compound.

These test methods are useful for the quality assurance of

1.2 The values stated in SI units are to be regarded as the

carbon black production. They may also be used for the

standard. The values in parentheses are for information only.

preparation of reference compounds, to confirm the day-to-day

1.3 This standard does not purport to address all of the

reliability of testing operations used in the rubber industry, for

safety concerns, if any, associated with its use. It is the

the evaluation of experimental compounds, and quality control

responsibility of the user of this standard to establish appro-

of production compounds.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

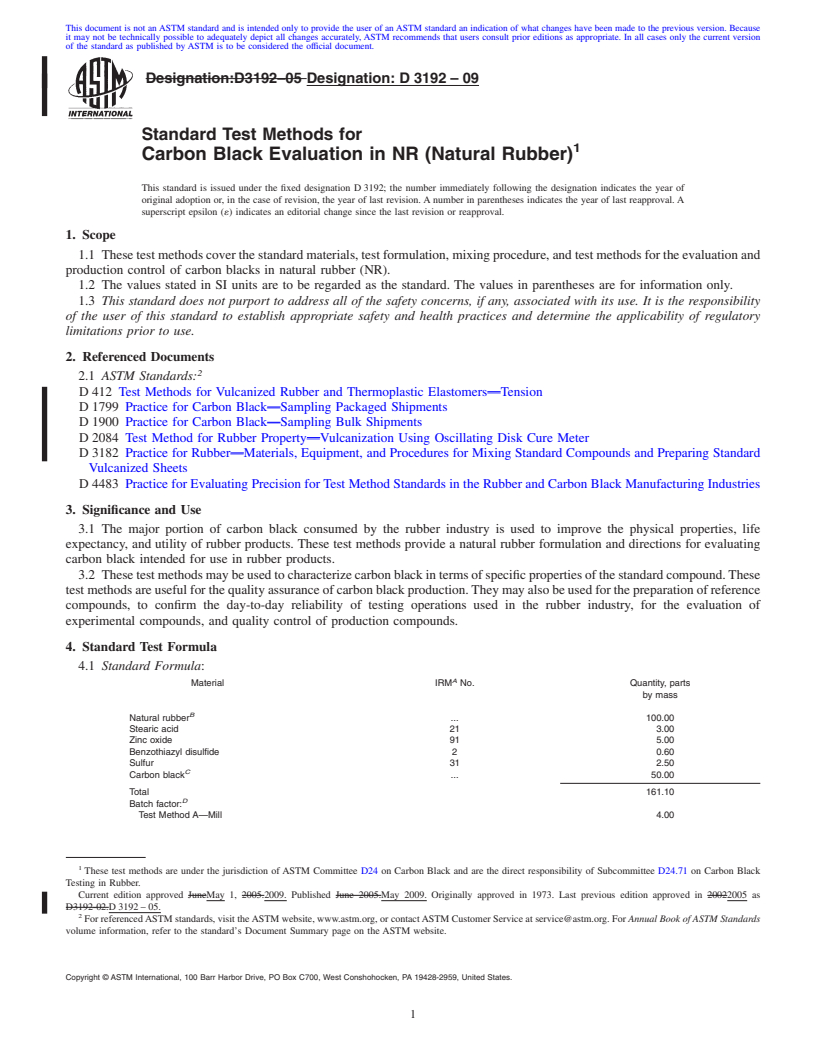

4. Standard Test Formula

4.1 Standard Formula:

2. Referenced Documents

A

Material IRM No. Quantity, parts

2

2.1 ASTM Standards:

by mass

D412 Test Methods forVulcanized Rubber andThermoplas-

B

Natural rubber . 100.00

tic Elastomers—Tension

Stearic acid 21 3.00

D1799 Practice for Carbon Black—Sampling Packaged

Zinc oxide 91 5.00

Benzothiazyl disulfide 2 0.60

Shipments

Sulfur 31 2.50

D1900 Practice for Carbon Black—Sampling Bulk Ship-

C

Carbon black . 50.00

ments

Total 161.10

D

Batch factor:

D2084 Test Method for Rubber Property—Vulcanization

Test Method A—Mill 4.00

Using Oscillating Disk Cure Meter

Test Method B—Internal Mixer 6.00

D3182 PracticeforRubber—Materials,Equipment,andPro-

Test Method C—Miniature Internal 0.40

Mixer

cedures for Mixing Standard Compounds and Preparing

_____________

Standard Vulcanized Sheets

D4483 Practice for Evaluating Precision for Test Method

A

IRM 91 is available from R. E. Carroll, Inc., 1570 North OldenAve., Trenton, NJ

Standards in the Rubber and Carbon Black Manufacturing

08638; (800) 257–9365. IRM 2, IRM 21, and IRM 31 are available from Akron

Rubber Development Lab, 2887 Gilchrist Road, Akron, OH 44305; (330)

Industries

794–6600.

B

SMR L and STR L have been found to give satisfactory performance. Other

3. Significance and Use

sources of rubber may give satisfactory results but have not been investigated by

Subcommittee D24.71. Other sources of rubber should be checked to ensure that

3.1 The major portion of carbon black consumed by the

results equivalent to SMR L are attained before using in this test method.

C

rubber industry is used to improve the physical properties, life

Use 75.00 parts by mass of carbon blacks in the N-800 and N-900 series.

D

Weigh rubber and carbon black to the nearest 1 g, sulfur and accelerator to the

nearest 0.02 g, and all other compounding materials to the nearest 0.1 g.

1

These test methods are under the jurisdiction of ASTM Committee D24 on

5. Sampling and Sample Preparation

Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon

Black Testing in Rubber.

5.1 Samples shall be taken in accordance with Practice

Current edition approved May 1, 2009. Published May 2009. Originally

D1799 or Practice D1900.

approved in 1973. Last previous edition approved in 2005 as D3192 – 05. DOI:

10.1520/D3192-09.

5.2 The carbon black shall be conditioned before weighing

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and mixing by heating for1hinan oven set at 125 6 1°C.The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

black shall be placed in an open vessel of suitable dimensions

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. so that the depth of black is no more than 10 mm during

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3192 − 09

conditioning.The black conditioned as above shall be stored in

Add the stearic acid. 1.0 2.0

a closed moisture-proof container until ready for m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3192–05 Designation:D3192–09

Standard Test Methods for

1

Carbon Black Evaluation in NR (Natural Rubber)

This standard is issued under the fixed designation D 3192; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thesetestmethodscoverthestandardmaterials,testformulation,mixingprocedure,andtestmethodsfortheevaluationand

production control of carbon blacks in natural rubber (NR).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D 1799 Practice for Carbon Black—Sampling Packaged Shipments

D 1900 Practice for Carbon Black—Sampling Bulk Shipments

D 2084 Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter

D 3182 Practice for Rubber—Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard

Vulcanized Sheets

D 4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Significance and Use

3.1 The major portion of carbon black consumed by the rubber industry is used to improve the physical properties, life

expectancy, and utility of rubber products. These test methods provide a natural rubber formulation and directions for evaluating

carbon black intended for use in rubber products.

3.2 Thesetestmethodsmaybeusedtocharacterizecarbonblackintermsofspecificpropertiesofthestandardcompound.These

testmethodsareusefulforthequalityassuranceofcarbonblackproduction.Theymayalsobeusedforthepreparationofreference

compounds, to confirm the day-to-day reliability of testing operations used in the rubber industry, for the evaluation of

experimental compounds, and quality control of production compounds.

4. Standard Test Formula

4.1 Standard Formula:

A

Material IRM No. Quantity, parts

by mass

B

Natural rubber . 100.00

Stearic acid 21 3.00

Zinc oxide 91 5.00

Benzothiazyl disulfide 2 0.60

Sulfur 31 2.50

C

Carbon black . 50.00

Total 161.10

D

Batch factor:

Test Method A—Mill 4.00

1

These test methods are under the jurisdiction of ASTM Committee D24 on Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon Black

Testing in Rubber.

Current edition approved JuneMay 1, 2005.2009. Published June 2005.May 2009. Originally approved in 1973. Last previous edition approved in 20022005 as

D3192-02.D 3192 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3192–09

Test Method B—Internal Mixer 6.00

Test Method C—Miniature Internal 0.40

Mixer

_____________

A

IRM91isavailablefromR.E.Carroll,Inc.,1570NorthOldenAve.,Trenton,NJ08638;(800)257–9365.IRM2,IRM21,andIRM31areavailablefromAkronRubber

Development Lab, 2887 Gilchrist Road, Akron, OH 44305; (330) 794–6600.

B

SMR L and STR L have been found to give satisfactory performance. Other sources of rubber may give satisfactory results but have not been investigated by

Subcommittee D24.71. Other sources of rubber should be checked to ensure that results equivalent to SMR L are attained before using in this test method.

C

Use 75.00 parts by mass of carbon blacks in the N-800 and N-900 series.

D

Weigh rubber and carbon black to the nearest 1 g, sulfur and accelerator to the nearest 0.02 g, and all other compounding materials to the nearest 0.1 g.

5. Sampling and Sample Preparation

5.1 Samples shall be taken in accordance with Practice D 1799 or Practice D 1900.

5.2 The carbon black shall be conditioned before weighing and mixing by heating for1hinan oven set at 125 6 1°C. The

black shall be placed in an open vessel of s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3192–05 Designation:D3192–09

Standard Test Methods for

1

Carbon Black Evaluation in NR (Natural Rubber)

This standard is issued under the fixed designation D 3192; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thesetestmethodscoverthestandardmaterials,testformulation,mixingprocedure,andtestmethodsfortheevaluationand

production control of carbon blacks in natural rubber (NR).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D 1799 Practice for Carbon Black—Sampling Packaged Shipments

D 1900 Practice for Carbon Black—Sampling Bulk Shipments

D 2084 Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter

D 3182 Practice for Rubber—Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard

Vulcanized Sheets

D 4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Significance and Use

3.1 The major portion of carbon black consumed by the rubber industry is used to improve the physical properties, life

expectancy, and utility of rubber products. These test methods provide a natural rubber formulation and directions for evaluating

carbon black intended for use in rubber products.

3.2 Thesetestmethodsmaybeusedtocharacterizecarbonblackintermsofspecificpropertiesofthestandardcompound.These

testmethodsareusefulforthequalityassuranceofcarbonblackproduction.Theymayalsobeusedforthepreparationofreference

compounds, to confirm the day-to-day reliability of testing operations used in the rubber industry, for the evaluation of

experimental compounds, and quality control of production compounds.

4. Standard Test Formula

4.1 Standard Formula:

A

Material IRM No. Quantity, parts

by mass

B

Natural rubber . 100.00

Stearic acid 21 3.00

Zinc oxide 91 5.00

Benzothiazyl disulfide 2 0.60

Sulfur 31 2.50

C

Carbon black . 50.00

Total 161.10

D

Batch factor:

Test Method A—Mill 4.00

1

These test methods are under the jurisdiction of ASTM Committee D24 on Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon Black

Testing in Rubber.

Current edition approved JuneMay 1, 2005.2009. Published June 2005.May 2009. Originally approved in 1973. Last previous edition approved in 20022005 as

D3192-02.D 3192 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3192–09

Test Method B—Internal Mixer 6.00

Test Method C—Miniature Internal 0.40

Mixer

_____________

A

IRM91isavailablefromR.E.Carroll,Inc.,1570NorthOldenAve.,Trenton,NJ08638;(800)257–9365.IRM2,IRM21,andIRM31areavailablefromAkronRubber

Development Lab, 2887 Gilchrist Road, Akron, OH 44305; (330) 794–6600.

B

SMR L and STR L have been found to give satisfactory performance. Other sources of rubber may give satisfactory results but have not been investigated by

Subcommittee D24.71. Other sources of rubber should be checked to ensure that results equivalent to SMR L are attained before using in this test method.

C

Use 75.00 parts by mass of carbon blacks in the N-800 and N-900 series.

D

Weigh rubber and carbon black to the nearest 1 g, sulfur and accelerator to the nearest 0.02 g, and all other compounding materials to the nearest 0.1 g.

5. Sampling and Sample Preparation

5.1 Samples shall be taken in accordance with Practice D 1799 or Practice D 1900.

5.2 The carbon black shall be conditioned before weighing and mixing by heating for1hinan oven set at 125 6 1°C. The

black shall be placed in an open vessel of s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.