ASTM D1681-92(1997)

(Test Method)Standard Test Method for Synthetic Anionic Active Ingredient in Detergents by Cationic Titration Procedure

Standard Test Method for Synthetic Anionic Active Ingredient in Detergents by Cationic Titration Procedure

SCOPE

1.1 Direct titration of an anionic surfactant with a standardized cationic reagent is a simple and convenient method for the quantitative determination of the content of active ingredient. The end point is detected by the transfer of a colored complex from an organic solvent phase to an aqueous phase. The relationship between anionic and cationic agents is not always stoichiometric, and for maximum accuracy the anionic type of interest should first be characterized and then used to standardize the cationic reagent. In most cases, however, the different anionic surfactants likely to be encountered react in the same proportions. That is, a cationic titrating solution standardized against a characterized anionic agent can be used to analyze other anionics of known molecular weights.

1.2 This test method is applicable to alkylaryl sulfonates and fatty alkyl sulfates. Low results are obtained with alkyl- benzene sulfonates having the alkyl chain length less than eight carbon atoms. Low results are also obtained for alkyl sulfates with the alkyl chain length of less than twelve carbon atoms. The anionic surfactants characterized in accordance with Sections 16 to 22 should be the sodium salt and not amine, ammonium, or potassium salts. In case only amine or ammonium salts are available, they should be first converted to the sodium salt before proceeding with this analysis.

1.3 The analytical procedures appear in the following order: Sections Separation of Alcohol-Soluble Matter 7 and 8 Separation of Oil-Free Sulfonate 9 and 10 Determination of Sodium Chloride (NaCl) Content 11 to 16 Characterization of Anionic Surfactant Standard: Part I. Determination of Surfactant, SO3 Content, and 17 to 19 Solution Molarity Part II. Determination of Surfactant, SO3 and Active 20 to 23 Ingredient Contents Combining Weight, and Solution Molarity Standardization of Cationic Reagent 24 to 28 Quantitative Determination of Anionic Surfactant by Cationic 29 to 32 Titration

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1681–92(Reapproved 1997)

Standard Test Method for

Synthetic Anionic Active Ingredient in Detergents by

Cationic Titration Procedure

This standard is issued under the fixed designation D 1681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 Direct titration of an anionic surfactant with a standard-

bility of regulatory limitations prior to use.

ized cationic reagent is a simple and convenient method for the

quantitative determination of the content of active ingredient.

2. Referenced Documents

Theendpointisdetffectedbythetransferofacoloredcomplex

2.1 ASTM Standards:

from an organic solvent phase to an aqueous phase. The

D 1193 Specification for Reagent Water

relationship between anionic and cationic agents is not always

stoichiometric, and for maximum accuracy the anionic type of

3. Summary of Test Method

interest should first be characterized and then used to standard-

3.1 This test method involves isolating alkylaryl sulfonate

ize the cationic reagent. In most cases, however, the different

or fatty alkyl sulfate by extraction with ethyl alcohol to remove

anionic surfactants likely to be encountered react in the same

inorganic salts, extracting the alcohol-soluble material with

proportions. That is, a cationic titrating solution standardized

petroleum ether to remove unsulfonatable matter, correcting

against a characterized anionic agent can be used to analyze

for sodium chloride present, and determining the active ingre-

other anionics of known molecular weights.

dientcombiningweight.Thecharacterizedsurfactantisusedto

1.2 This test method is applicable to alkylaryl sulfonates

standardize a cationic reagent which in turn is used to titrate

and fatty alkyl sulfates. Low results are obtained with alkyl-

similar anionic surfactants.

benzenesulfonateshavingthealkylchainlengthlessthaneight

carbon atoms. Low results are also obtained for alkyl sulfates

4. Significance and Use

with the alkyl chain length of less than twelve carbon atoms.

4.1 This test method determines anionic detergents com-

The anionic surfactants characterized in accordance with

monly found in laundry, dishwashing, and other cleaning

Sections 16-22 should be the sodium salt and not amine,

materials. Accurate determination of the anionic active sub-

ammonium, or potassium salts. In case only amine or ammo-

stance is highly important in assessing the cost and effective-

nium salts are available, they should be first converted to the

ness of such cleaning substances.

sodium salt before proceeding with this analysis.

1.3 The analytical procedures appear in the following order:

5. Interferences

Sections

5.1 With the exception of picrate, perchlorate, thiocyanate,

Separation of Alcohol-Soluble Matter 7 and 8

Separation of Oil-Free Sulfonate 9 and 10 nitrate, dichromate, and chromate, common inorganic anions

Determination of Sodium Chloride (NaCl) Content 11-16

and low molecular weight organic anions do not interfere with

Characterization of Anionic Surfactant Standard:

this analysis. However, sulfonates of xylene, cunene, or tolu-

Part I. Determination of Surfactant, SO Content, and Solution 17-19

Molarity ene interfere positively. Since the cationic titration is con-

Part II. Determination of Surfactant, SO and Active Ingredient 20-23

ducted under acidic conditions, soap does not interfere. Soap

Contents Combining Weight, and Solution Molarity

must not be present in the anionic surfactant characterized in

Standardization of Cationic Reagent 24-28

Quantitative Determination of Anionic Surfactant by Cationic 29-32

accordance with Sections 16-22.

Titration

6. Reagents

1.4 This standard does not purport to address all of the

6.1 Purity of Reagents—Reagent grade chemicals shall be

safety concerns, if any, associated with its use. It is the

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

This test method is under the jurisdiction ofASTM Committee D-12 on Soaps

tee onAnalytical Reagents of theAmerican Chemical Society,

andOtherDetergentsandisthedirectresponsibilityofSubcommitteeD12.12onthe

Analysis of Soaps and Synthetic Detergents.

Current edition approved May 15, 1992. Published July 1992. Originally

published as D1681 – 59 T. Last previous edition D1681 – 83. Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1681–92 (1997)

where such specifications are available. Other grades may be surfactant (Sections 20-23), continue in accordance with the

used, provided it is first ascertained that the reagent is of separation of oil-free sulfonate (Sections 9 and 10).

sufficiently high purity to permit its use without lessening the 8.6 Transferc the filtrate to a 1000-mL beaker. Wash the

accuracy of the determination. filter flask with alcohol and 10 mL of water followed by an

6.2 Unless otherwise indicated, references to water shall be alcohol wash. Evaporate the filtrate to about 400 mL and

understood to mean reagent water conforming to Specification transfer to a 1000-mL volumetric flask. Dilute with water to

D 1193. mark. Designate as Solution I and reserve for use in Part I of

the characterization of the anionic surfactant (Sections 17-19).

SEPARATION OFALCOHOL-SOLUBLE MATTER

SEPARATION OF OIL-FREE SULFONATE

7. Solvent

9. Reagents

7.1 EthylAlcohol—Freshly boiled ethyl alcohol conforming

9.1 Ethyl Alcohol—See Section 7.

to Formula No. 3A or No. 30 of the U.S. Bureau of Internal

9.2 Petroleum Ether, having a boiling point of 30 to 60°C.

Revenue. The alcohol should not be neutralized. Redistilled

alcohol must be used if alkali absorption is more than 0.2 mL

10. Procedure

of 100 mL of 0.1 N NaOH solution.

10.1 Transfer the alcohol solution quantitatively to a

1000-mLbeaker (with the 100-mLvolume marked on the side)

8. Procedure

and concentrate to 100 mL on a steam bath or hot water bath.

8.1 Weigh out a sample, to the nearest 0.01 g, to correspond

Transfer the concentrate quantitatively to a 500-mL, pear-

to surfactants with the following ranges of active ingredient

shaped separatory funnel by rinsing the beaker with 100 mLof

contents and transfer to a 600-mL beaker:

water in several portions. Add the remainder of water to the

Active Ingredient, wt % Weight of Sample, g

funnel to bring the total volume to 200 mL.

10.2 Extract the aqueous-alcoholic solution with three 50-

10 to 25 30

25 to 40 15

mL portions of petroleum ether, using additional separatory

40 to 60 10

funnels. Combine the ether extracts and wash with 3 to 50- mL

60 to 80 7

portions of 50 % aqueous ethanol. Add the aqueous ethanol

Over 80 5.5

washingstotheextractedaqueousalcoholsolution.Discardthe

8.2 Add 300 to 350 mL of hot alcohol. Cover with a watch

petroleum ether extracts. Transfer the oil-free aqueous alco-

glass and heat on the steam bath for at least 2 h, stirring

holic solution quantitatively to a 1000-mL beaker by rinsing

frequently to disperse solids and break up lumps. Have a

the separatory funnel with small portions of water. Heat the

prepared Gooch crucible or sintered glass filter inserted in the

solution in a 400-mL beaker in a water bath at 40 to 50°C in a

1000-mL vacuum flask.

hood to vent off petroleum ether fumes. When free of ether,

8.3 At the end of 2 h, remove the beaker from the bath and

transfer the oil-free salt-free solution quantitatively to a

decant the alcohol solution rapidly through the filter, retaining

1000-mLvolumetricflask.Add300mLofalcoholanddiluteto

as much as possible of the residue in the beaker.Add 50 mLof

volumewithwater.DesignateasSolutionIIandreserveforuse

hotalcoholtotheresidueinthebeaker.Heattoboilingonahot

in Part II of the characterization of the anionic surfactant

plate, breaking up any lumps of the residue. Decant the alcohol

(Sections 20-23).

through the filter as before. Repeat with another 50-mLportion

of hot alcohol.

DETERMINATION OF SODIUM CHLORIDE (NaCl)

8.4 Evaporate the residual alcohol from the residue in the

CONTENT

beaker on the steam bath, stirring at intervals, especially near

the end. Dissolve the residue in the beaker with 10 mL of hot

11. Scope

water, heating on the steam bath until solution is effected.

11.1 Sections 12-16 cover the determination of the sodium

8.5 Dilute the water solution with 200 mL of hot alcohol,

chloride content of the surfactant in order that appropriate

bring to a boil on the steam bath, and filter. Transfer the

corrections can be made in the values obtained in the charac-

precipitate onto the filter with the aid of hot alcohol and

terization of the anionic active ingredients and the quantitative

policeman. Wash the beaker and the residue with hot alcohol

determination of an unknown anionic active ingredient.

threeorfourtimes.ForsamplesbeingpreparedforPartIofthe

characterization of anionic surfactant (Sections 17-19 ), con-

12. Apparatus

tinue as directed in 8.6. For samples being prepared for

12.1 Stirrer Motor and Small Glass Rod Stirrer.

eventual use in Part II of the characterization of anionic

12.2 Potentiometer.

12.3 Calomel Reference Electrode, saturated.

12.4 Silver Wire Electrode, 1mm in diameter by 120 mm in

Reagent Chemicals, American Chemical Society Specifications, American

length.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, The Beckman Model G pH meter, or its equivalent, has been found satisfactory

MD. for this purpose.

D1681–92 (1997)

13. Reagents and Materials 15.2.3 Add AgNO solution in 0.1-mL portions, allowing

sufficient time after each addition for the solution to reach

13.1 Acetone.

equilibrium (60 to 80 s). Measure the emf (stirrer off) at each

13.2 Ethyl Alcohol—Freshly boiled ethyl alcohol conform-

0.1-mL point.

ing to Formula No. 3Aor No. 30 of the U.S. Bureau of Internal

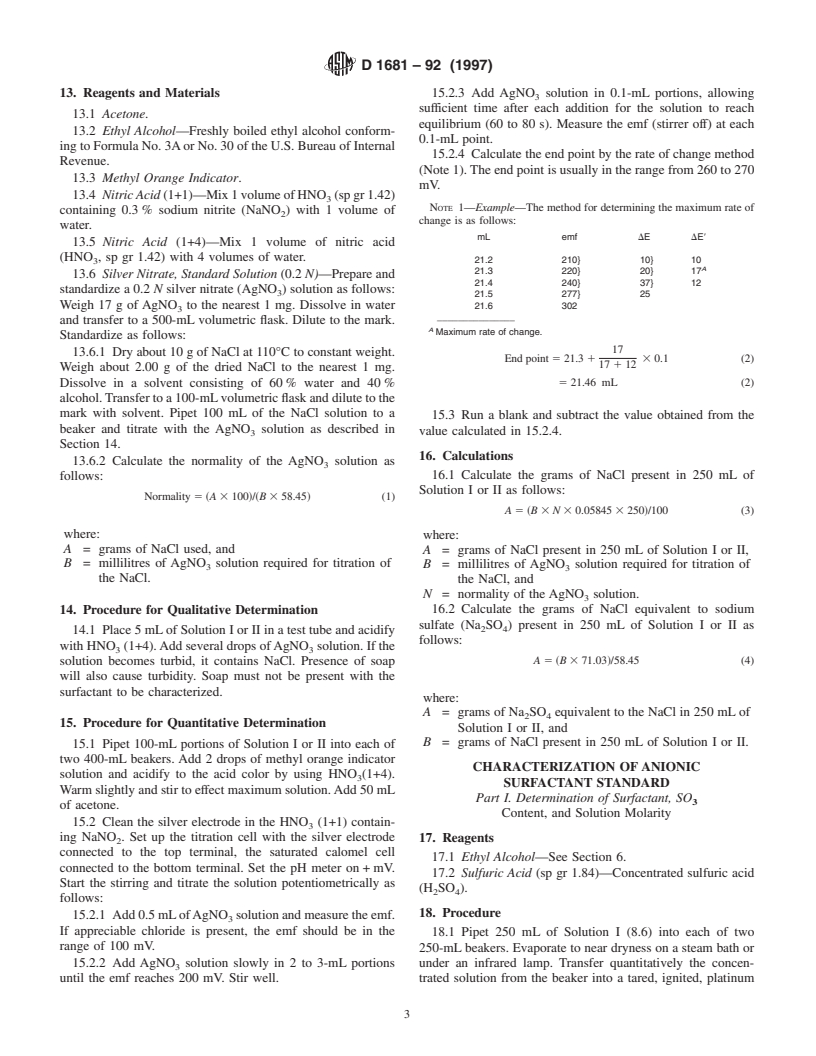

15.2.4 Calculate the end point by the rate of change method

Revenue.

(Note 1).The end point is usually in the range from 260 to 270

13.3 Methyl Orange Indicator.

mV.

13.4 NitricAcid(1+1)—Mix1volumeofHNO (spgr1.42)

NOTE 1—Example—The method for determining the maximum rate of

containing 0.3 % sodium nitrite (NaNO ) with 1 volume of

change is as follows:

water.

mL emf DE DE8

13.5 Nitric Acid (1+4)—Mix 1 volume of nitric acid

(HNO , sp gr 1.42) with 4 volumes of water.

21.2 210} 10} 10

A

21.3 220} 20} 17

13.6 Silver Nitrate, Standard Solution (0.2 N)—Prepare and

21.4 240} 37} 12

standardize a 0.2 N silver nitrate (AgNO ) solution as follows:

3 21.5 277} 25

Weigh 17 g of AgNO to the nearest 1 mg. Dissolve in water 21.6 302

_______________

and transfer to a 500-mL volumetric flask. Dilute to the mark.

A

Maximum rate of change.

Standardize as follows:

13.6.1 Dry about 10 g of NaCl at 110°C to constant weight.

End point 5 21.3 1 3 0.1 (2)

17 1 12

Weigh about 2.00 g of the dried NaCl to the nearest 1 mg.

5 21.46 mL (2)

Dissolve in a solvent consisting of 60 % water and 40 %

alcohol.Transfertoa100-mLvolumetricflaskanddilutetothe

mark with solvent. Pipet 100 mL of the NaCl solution to a

15.3 Run a blank and subtract the value obtained from the

beaker and titrate with the AgNO solution as described in

3 value calculated in 15.2.4.

Section 14.

16. Calculations

13.6.2 Calculate the normality of the AgNO solution as

follows: 16.1 Calculate the grams of NaCl present in 250 mL of

Solution I or II as follows:

Normality 5 ~A 3 100!/~B 3 58.45! (1)

A 5 ~B 3 N 3 0.05845 3 250!/100 (3)

where:

where:

A = grams of NaCl used, and

A = grams of NaCl present in 250 mL of Solution I or II,

B = millilitres of AgNO solution required for titration of

B = millilitres of AgNO solution required for titration of

the NaCl.

the NaCl, and

N = normality of the AgNO solution.

16.2 Calculate the grams of NaCl equivalent to sodium

14. Procedure for Qualitative Determination

sulfate (Na SO ) present in 250 mL of Solution I or II as

2 4

14.1 Place 5 mLof Solution I or II in a test tube and acidify

follows:

with HNO (1+4).Add several drops ofAgNO solution. If the

3 3

A 5 ~B 3 71.03!/58.45 (4)

solution becomes turbid, it contains NaCl. Presence of soap

will also cause turbidity. Soap must not be present with the

surfactant to be characterized.

where:

A = grams of Na SO equivalent to the NaCl in 250 mL of

2 4

15. Procedure for Quantitative Determination

Solution I or II, and

B = grams of NaCl present in 250 mL of Solution I or II.

15.1 Pipet 100-mL portions of Solution I or II into each of

two 400-mL beakers. Add 2 drops of methyl orange indicator

CHARACTERIZATION OFANIONIC

solution and acidify to the acid color by using HNO (1+4).

SURFACTANT STANDARD

Warm slightly and stir to effect maximum solution.Add 50 mL

Part I. Determination of Surfactant, SO

of acetone.

Content, and Solution Molarity

15.2 Clean the silver electrode in the HNO (1+1) contain-

ing NaNO . Set up the titration cell with the silver electrode

17. Reagents

connected to the top terminal, the saturated calomel cell

17.1 Ethyl Alcohol—See Section 6.

connected to the bottom terminal. Set the pH meter on + mV.

17.2 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

Start the stirring and titrate the solution potentiometrically as

(H SO ).

2 4

follows:

18. Procedure

15.2.1 Add0.5mLofAgNO solutionandmeasuretheemf.

If appreciable chloride is present, the emf should be in the

18.1 Pipet 250 mL of Solution I (8.6) into each of two

range of 100 mV.

250-mL beakers. Evaporate to near dryness on a steam bath or

15.2.2 Add AgNO solution slowly in 2 to 3-mL portions under an infrared lamp. Transfer quantitatively the concen-

until the emf reaches 200 mV. Stir well. trated solution from the beaker into a tared, ignited, platinum

D1681–92 (1997)

crucible. Wash the beaker with small amounts of alcohol and crucible. Wash the beaker with small amounts of alcohol and

water to ensure complete transfer to the crucible. water to ensure complete transfer to the crucible.

18.2 Evaporate the contents in the crucible to dryness on a 22.2 Evaporate the contents in the crucible to dryness on a

steam bath or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.