ASTM D4476/D4476M-14

(Test Method)Standard Test Method for Flexural Properties of Fiber Reinforced Pultruded Plastic Rods (Withdrawn 2022)

Standard Test Method for Flexural Properties of Fiber Reinforced Pultruded Plastic Rods (Withdrawn 2022)

SIGNIFICANCE AND USE

5.1 Flexural properties determined by this test method are especially useful for quality control and specification purposes.

5.2 The maximum axial fiber stresses occur on a line under the loading nose. The use of the semicircular cross section eliminates premature compression shear that has been noted in three-point flexure tests on full-round rods.

5.3 Flexural properties may vary with specimen depth, temperature, atmospheric conditions, and differences in rate of straining.

5.4 Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers the determination of the flexural properties of fiber-reinforced pultruded plastic rods. The specimen is a rod with a semicircular cross section, molded or cut from lengths of pultruded rods (see Fig. 1). This test method is designed for rods with a diameter of 1/2 in. or greater. Note 1—There is no known ISO equivalent to this standard.

FIG. 1 Cross Section of Test Specimen

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of the flexural properties of fiber-reinforced pultruded plastic rods. The specimen is a rod with a semicircular cross section, molded or cut from lengths of pultruded rods. This test method is designed for rods with a diameter of 1/2 in. or greater.

Formerly under the jurisdiction of Committee D20 on Plastics, this test method was withdrawn in November 2022. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4476/D4476M − 14

Standard Test Method for

Flexural Properties of Fiber Reinforced Pultruded Plastic

1

Rods

This standard is issued under the fixed designation D4476/D4476M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

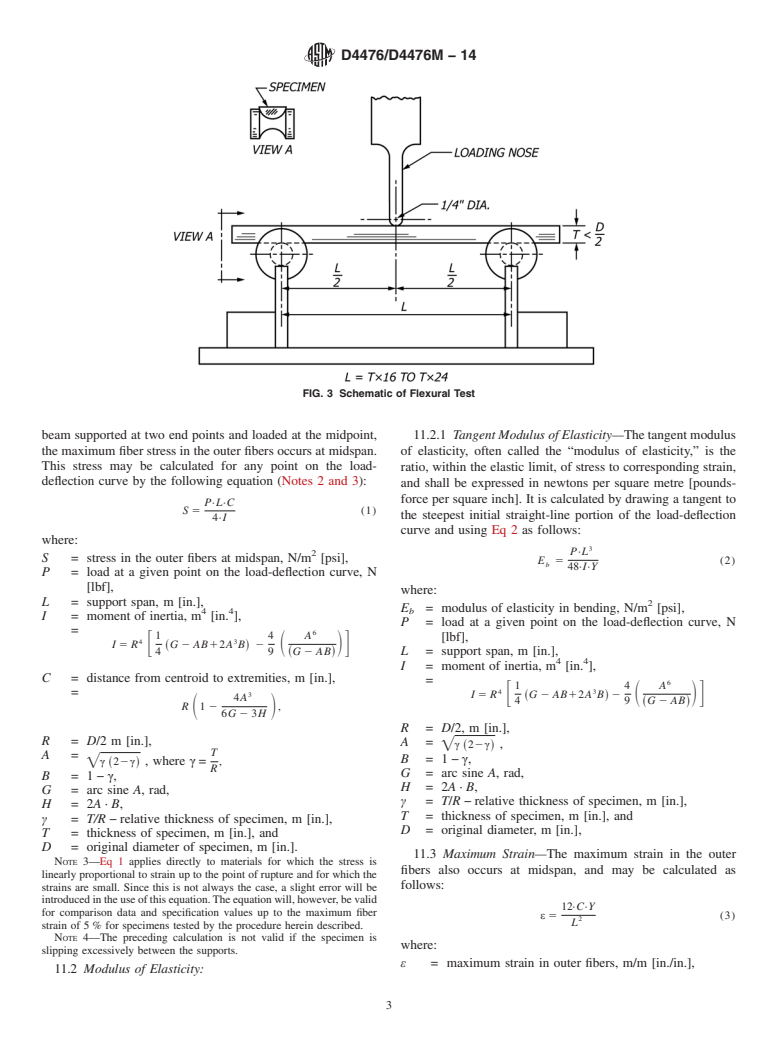

1.1 Thistestmethodcoversthedeterminationoftheflexural 4.1 Arod of semicircular construction is tested in flexure as

properties of fiber-reinforced pultruded plastic rods.The speci- a simple beam. The specimen rests on two supports and is

men is a rod with a semicircular cross section, molded or cut loaded by means of a loading nose midway between the

from lengths of pultruded rods (see Fig. 1).This test method is supports (see Fig. 3).

1

designed for rods with a diameter of ⁄2 in. or greater.

4.2 The specimen is deflected until rupture occurs in the

outer fibers, or until the maximum fiber strain of 5% is

NOTE 1—There is no known ISO equivalent to this standard.

reached, whichever occurs first.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

5. Significance and Use

each system may not be exact equivalents; therefore, each

5.1 Flexural properties determined by this test method are

system shall be used independently of the other. Combining

especiallyusefulforqualitycontrolandspecificationpurposes.

values from the two systems may result in nonconformance

with the standard.

5.2 The maximum axial fiber stresses occur on a line under

the loading nose. The use of the semicircular cross section

1.3 This standard does not purport to address all of the

eliminates premature compression shear that has been noted in

safety concerns, if any, associated with its use. It is the

three-point flexure tests on full-round rods.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.3 Flexural properties may vary with specimen depth,

bility of regulatory limitations prior to use.

temperature, atmospheric conditions, and differences in rate of

straining.

2. Referenced Documents

5.4 Before proceeding with this test method, reference

2

2.1 ASTM Standards:

shouldbemadetothespecificationofthematerialbeingtested.

D618Practice for Conditioning Plastics for Testing

Any test specimen preparation, conditioning, dimensions, or

D883Terminology Relating to Plastics

testing parameters, or combination thereof, covered in the

D3918Terminology Relating to Reinforced Plastic Pul-

materials specification shall take precedence over those men-

truded Products

tioned in this test method. If there are no material

E4Practices for Force Verification of Testing Machines

specifications, then the default conditions apply.

E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

6. Apparatus

6.1 TestingMachine—Aproperlycalibratedtestingmachine

3. Terminology

that can be operated at constant rates of crosshead motion over

3.1 For definitions of terms used in this test method, see

the range indicated, and in which the error in the load-

Terminology D883 or Definitions D3918.

measuringsystemshallnotexceed 61%ofthemaximumload

expected to be measured. It shall be equipped with a

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

deflection-measuring device. The stiffness of the testing ma-

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

chine shall be such that the total elastic deformation of the

ting Plastics.

system does not exceed 1% of the total deflection of the test

Current edition approved May 1, 2014. Published May 2014. Originally

specimen during test, or appropriate corrections shall be made.

approved in 1985. Last previous edition approved in 2009 as D4476-09. DOI:

10.1520/D4476_D4476M-14.

The load-indicating mechanism shall be essentially free of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

inertial lag at the crosshead rate used. The accuracy of the

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

testing machine shall be verified in accordance with Practices

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. E4.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4476/D4476M − 14

NOTE 2—As a general rule, support span-to-depth ratios of 16 to 1 are

satisfactory wh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.