ASTM C868-02(2012)

(Test Method)Standard Test Method for Chemical Resistance of Protective Linings (Withdrawn 2015)

Standard Test Method for Chemical Resistance of Protective Linings (Withdrawn 2015)

SIGNIFICANCE AND USE

3.1 The results obtained by this test method should serve as a guide in, but not as the sole basis for, selection of a lining material for particular application. Simple chemical-resistance evaluations of the lining materials may be performed more conveniently by other pertinent methods as a prescreening test for this procedure in accordance with Test Methods C267 and D471.

SCOPE

1.1 This test method covers a procedure for evaluating the chemical resistance of a polymer-based protective lining in immersion service. The method closely approximates the service conditions, including the temperature differential between the external and internal surfaces of the equipment, which may accelerate permeation of the lining by a corrosive media.

1.2 This test may be used to simulate actual field use conditions insofar as a qualitative evaluation of the lining system after a predetermined period of exposure.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers a procedure for evaluating the chemical resistance of a polymer-based protective lining in immersion service. The method closely approximates the service conditions, including the temperature differential between the external and internal surfaces of the equipment, which may accelerate permeation of the lining by a corrosive media.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in December 2015 and replaced by Practice D6943 for Immersion Testing of Industrial Protective Coatings and Linings.1

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C868 − 02(Reapproved 2012)

Standard Test Method for

Chemical Resistance of Protective Linings

This standard is issued under the fixed designation C868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1474 Test Methods for Indentation Hardness of Organic

Coatings

1.1 This test method covers a procedure for evaluating the

D2583 Test Method for Indentation Hardness of Rigid Plas-

chemical resistance of a polymer-based protective lining in

tics by Means of a Barcol Impressor

immersion service. The method closely approximates the

D3363 Test Method for Film Hardness by Pencil Test

service conditions, including the temperature differential be-

D4417 Test Methods for Field Measurement of Surface

tween the external and internal surfaces of the equipment,

Profile of Blast Cleaned Steel

which may accelerate permeation of the lining by a corrosive

D4541 Test Method for Pull-Off Strength of Coatings Using

media.

Portable Adhesion Testers

1.2 This test may be used to simulate actual field use

D5162 Practice for Discontinuity (Holiday) Testing of Non-

conditions insofar as a qualitative evaluation of the lining

conductive Protective Coating on Metallic Substrates

system after a predetermined period of exposure.

2.2 NACE Standard:

1.3 The values stated in inch-pound units are to be regarded

NACE No. 1/SSPC-SP-5 White Metal Blast Cleaning

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3. Significance and Use

and are not considered standard.

3.1 The results obtained by this test method should serve as

1.4 This standard does not purport to address all of the

a guide in, but not as the sole basis for, selection of a lining

safety concerns, if any, associated with its use. It is the material for particular application. Simple chemical-resistance

responsibility of the user of this standard to establish appro- evaluations of the lining materials may be performed more

priate safety and health practices and determine the applica- conveniently by other pertinent methods as a prescreening test

bility of regulatory limitations prior to use. for this procedure in accordance with Test Methods C267 and

D471.

2. Referenced Documents

4. Apparatus

2.1 ASTM Standards:

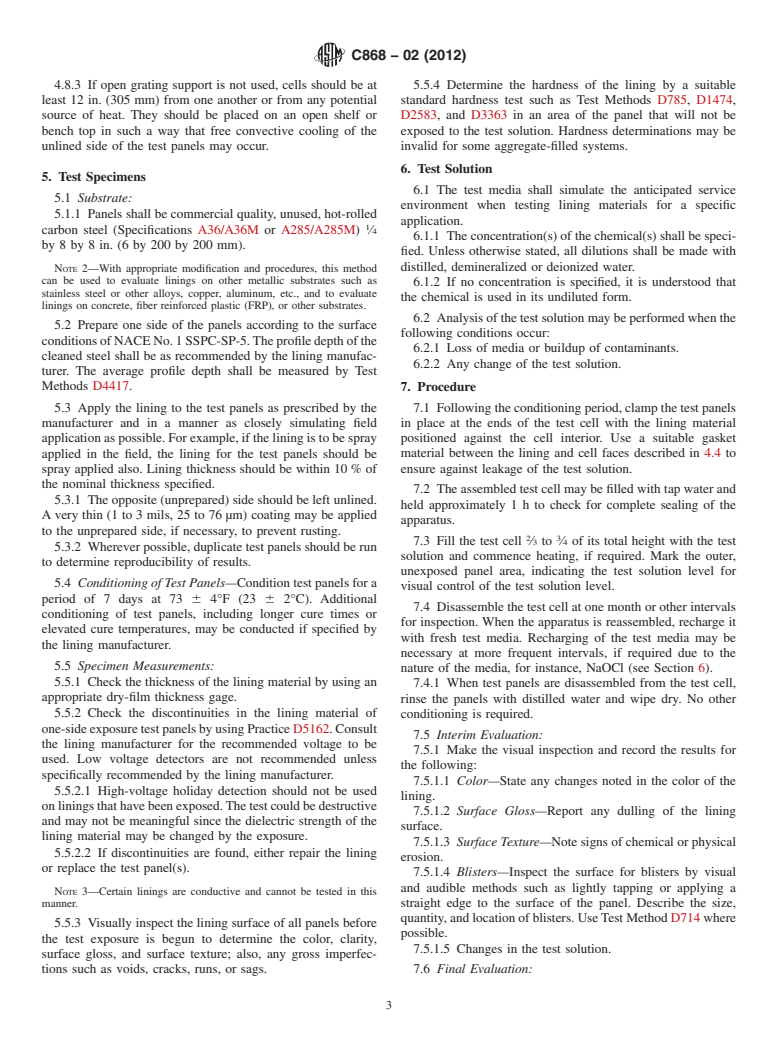

A36/A36M Specification for Carbon Structural Steel 4.1 Four-Neck Cylindrical, Borosilicate-Type Glass Test

A285/A285M Specification for Pressure Vessel Plates, Car-

Cell , similar to the unit shown in Fig. 1.

bon Steel, Low- and Intermediate-Tensile Strength 4.1.1 Whereanadditionalinletisneededforathermocouple

C267 Test Methods for Chemical Resistance of Mortars,

or thermistor to control temperature, a five-neck cell should be

Grouts,andMonolithicSurfacingsandPolymerConcretes used.

D471 Test Method for Rubber Property—Effect of Liquids

NOTE 1—If test solutions that are known to attack glass such as HF or

D714 Test Method for Evaluating Degree of Blistering of

caustic, a fluorocarbon or other suitable cell should be used.

Paints

4.2 Heating Equipment:

D785 Test Method for Rockwell Hardness of Plastics and

4.2.1 The corrosive media may be heated by an electrical-

Electrical Insulating Materials

resistant coil fitting inside the test cell. This is protected by a

glass immersion tube. The heater shall be controlled through

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatings. Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor,

Current edition approved Aug. 1, 2012. Published September 2012. Originally Pittsburgh, PA 15222-4656, http://www.sspc.org.

approved in 1977. Last previous edition approved in 2008 as C868 – 02 (2008). The sole source of supply of the four-neck cylindrical, borosilicate-type glass

DOI: 10.1520/C0868-02R12. test cell known to the committee at this time is DelVal Glass Inc., 1135 E. 7th St.,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Wilmington, DE. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C868 − 02 (2012)

FIG. 1 Four-Neck Cylindrical, Borosilicate-Type Glass Test Cell and Accessories

the use of a rheostat or thermostat to produce the desired attached to the ground-glass fitting in the utility opening, and

temperature 64°F (2°C). extending almost to the bottom of the test cell.

4.2.2 An electrical heating tape may be wrapped around the

4.6 Thermometer or Thermocouple, to fit the prescribed

exterior of the test cell but not around the test panels and may

thermowell, capable of registering the temperature specified

not touch the test panels.

for the test.

4.3 Reflux Water Condenser, to maintain a constant level

4.7 Mounting Equipment (Alternatives):

and concentration of the test solution.

4.7.1 Mount the test panels on the test cell with a minimum

4.4 Gaskets, of a chemically resistant material, capable of

1 3

of three carbon steel bolts, ⁄4 or ⁄8 in. (6 or 9 mm) in diameter,

withstanding the chemical environment. The gaskets shall also

using wing nuts for easy removal.

provide a tight seal between the test cell and test specimen.

4.7.2 “C” clamp fixtures or stainless steel band clamps or

Gaskets having a Shore “A” Durometer of 60 are generally

othersuitablemeanscanbeusedtomountthetestpanelstothe

adequate. The gasket material shall be selected so that it does

test cell.

not contaminate the test solution.

4.7.3 Use clamping pressures sufficient to seal the opening,

4.5 Air or Gas Bubbler—It may be necessary to include an

but not so great as to destroy the test cell or test panel or

air or gas bubbler to agitate or aerate the solution. Where

damage the test lining.

aeration is not required, a magnetic stirrer may be used to

4.8 Cell Test Area:

create agitation.

4.8.1 The cells should be maintained in an open, well

4.5.1 At solution temperatures below boiling, agitation is

ventilated area with temperature controlled to 73 6 4°F (23 6

requiredtomaintaintemperatureuniformity.Wheretheservice

2°C).

solution is considered to be aerated, air should be bubbled into

the solution. In cases where the solution will be air or oxygen 4.8.2 The preferred method to ensure the free movement of

depleted, nitrogen or other suitable inert gas should be used for air past the surfaces is to utilize grills or grating to support the

agitation. cells with several inches of clearance beneath the grating to

4.5.2 Insert a bubbler for air or other gas through the utility allow air flow past the plate surfaces. If this type of support is

opening in the test cell. The bubbler shall consist of a piece of employed, cells should be at least 6 in. (152 mm) away from

fluorocarbon or glass tubing ⁄8 in. (3 mm) in inside diameter, one another or any heat source.

C868 − 02 (2012)

4.8.3 If open grating support is not used, cells should be at 5.5.4 Determine the hardness of the lining by a suitable

least 12 in. (305 mm) from one another or from any potential standard hardness test such as Test Methods D785, D1474,

source of heat. They should be placed on an open shelf or D2583, and D3363 in an area of the panel that will not be

bench top in such a way that free convective cooling of the exposed to the test solution. Hardness determinations may be

unlined side of the test panels may occur. invalid for some aggregate-filled systems.

6. Test Solution

5. Test Specimens

6.1 The test media shall simulate the anticipated service

5.1 Substrate:

environment when testing lining materials for a specific

5.1.1 Panels shall be commercial quality, unused, hot-rolled

application.

carbon steel (Specifications A36/A36M or A285/A285M) ⁄4

6.1.1 The concentration(s) of the chemical(s) shall be speci-

by 8 by 8 in. (6 by 200 by 200 mm).

fied. Unless otherwise stated, all dilutions shall be made with

distilled, demineralized or deionized water.

NOTE 2—With appropriate modification and procedures, this method

can be used to evaluate linings on other metallic substrates such as

6.1.2 If no concentration is specified, it is understood that

stainless steel or other alloys, copper, aluminum, etc., and to evaluate

the chemical is used in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.