ASTM C756-87(2011)e1

(Test Method)Standard Test Method for Cleanability of Surface Finishes

Standard Test Method for Cleanability of Surface Finishes

SIGNIFICANCE AND USE

This test method was developed to guide the user in selecting a finish coating or material that is resistant to soiling in a particular application.

The numerical values derived by this test method enables the user to rank finish coatings and materials in regard to soil retention or ease of soil removal.

SCOPE

1.1 This test method covers the numerical evaluation of the ease or difficulty of cleaning soiled surface finishes. This test method is applicable to all surface finishes not affected by water.

1.2 Values given in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C756 − 87 (Reapproved 2011)

Standard Test Method for

Cleanability of Surface Finishes

This standard is issued under the fixed designation C756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Test Method was corrected editorially in 2011

INTRODUCTION

This test provides a procedure to quantify the cleanability of acid-resistant porcelain enamel using

a fluorescent water-soluble soil in agent, a reproducible machine-wiping technique, and a means of

measuring the amount of residual soil by fluorescence.

1. Scope the solution measured. A standard reference surface is treated

inasimilarmanner.Thecleanabilityindexofthesurfaceunder

1.1 This test method covers the numerical evaluation of the

testisexpressedastheratioofthefluorescenceofthesolutions

ease or difficulty of cleaning soiled surface finishes. This test

extracted from the test surface and from the standard reference

method is applicable to all surface finishes not affected by

surface. Cleanability indexes greater than 1.0 indicate that the

water.

test surface is more difficult to clean than the standard

1.2 Values given in SI units are to be regarded as the

reference surface, while indexes less than 1.0 indicate that the

standard. Inch-pound units are provided for information only.

test surface is more easily cleanable than the standard of

1.3 This standard does not purport to address all of the

comparison.

safety concerns, if any, associated with its use. It is the

3.2 The soiling agent used consists of polyethylene glycol,

responsibility of the user of this standard to establish appro-

a black dye, and a fluorescent tracer, each of which is readily

priate safety and health practices and determine the applica-

water soluble.

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents

4.1 This test method was developed to guide the user in

2.1 ASTM Standards:

selecting a finish coating or material that is resistant to soiling

C282 Test Method for Acid Resistance of Porcelain Enam-

in a particular application.

els(Citric Acid Spot Test)

4.2 The numerical values derived by this test method

C614 Test Method forAlkali Resistance of Porcelain Enam-

enables the user to rank finish coatings and materials in regard

els

to soil retention or ease of soil removal.

3. Summary of Test Method

5. Apparatus

3.1 The test method consists of applying an exact amount of

a fluorescent water-soluble soiling agent to a specimen surface 5.1 Motor-Driven Lapping Plate, 203-mm (8-in.) diameter,

and then cleaning the surface with a reproducible machine- speed 163 r/min.

wiping technique. The soil remaining on the specimen after

5.2 Automatic Polishing Unit, 11-s cycle, adjustable to

wipingisextractedwithawatersolventandthefluorescenceof 4

48-mm (1 ⁄8-in.) stroke.

5.3 Hypodermic Syringe, glass, 2-mL capacity, without

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

needle.

and Inorganic Coatingsand is the direct responsibility of Subcommittee B08.12 on

Materials for Porcelain Enamel and Ceramic-Metal Systems.

Current edition approved April 1, 2011. Published April 2011. Originally

approved in 1973. Last previous edition approved in 2006 as C756 – 87 (2006). Suitable lapping plates are available from Buehler Ltd., 2120 Greenwood St.,

DOI: 10.1520/C0756-87R11E01. Evanston, IL60204, Struers, Inc., 20102 Progress Drive, Cleveland, OH, 44136; or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or other Metallurgical Supply Sources.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM An Olsen “S.M.” Automatic Polisher has been found suitable and is available

Standards volume information, refer to the standard’s Document Summary page on under the code name OLPOL from Struers, Inc., 20102 Progress Drive, Cleveland,

the ASTM website. OH 44136.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C756 − 87 (2011)

5.4 Repeating Pipet, 0.025 mL (25 µl) capacity. 6. Reagents and Materials

5.5 Repeating Pipet, 10-mL capacity. 6.1 Cleaning Tissues, approximately 127 by 229 mm (5 by

9 in.).

5.6 Desiccator approximately 254 mm (10 in.) diameter.

6.2 Potassium Carbonate.

5.7 Cleaning Head, brass, 57 mm (2 ⁄4 in.), with worm-

driven hose clamp for attachment of cleaning tissues (Fig. 1). 6.3 Polyethylene Glycol, 400.

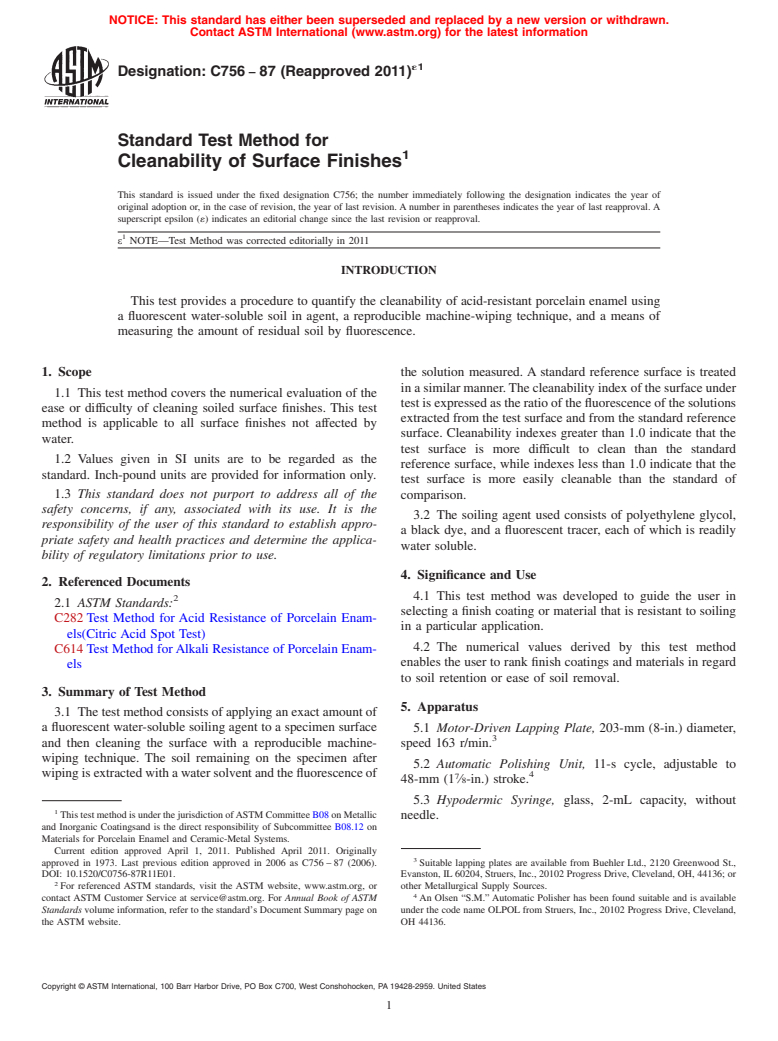

Cleaning Head, Brass Soiling Head, Brass

Metric Equivalents

AB C D E F G H

1 5 7 3 5 3 3

in. 2 ⁄4 ⁄8 ⁄8 ⁄16 1 ⁄8 ⁄4 ⁄16

(mm) (57) (16) (22) (5) (25) (16) (19) (5)

FIG. 1 Cleaning and Soiling Heads

5.8 Soiling Head, brass, 25 mm (1 in.) diameter, with 6.4 Uranine, water-soluble, USP.

25-mm (1-in.) diameter facing of polytetrafluoroethylene at- 9

6.5 Keco Acid Black, B(F101).

tached with a water-proof household cement (Fig. 1).

6.6 Ethyl Alcohol.

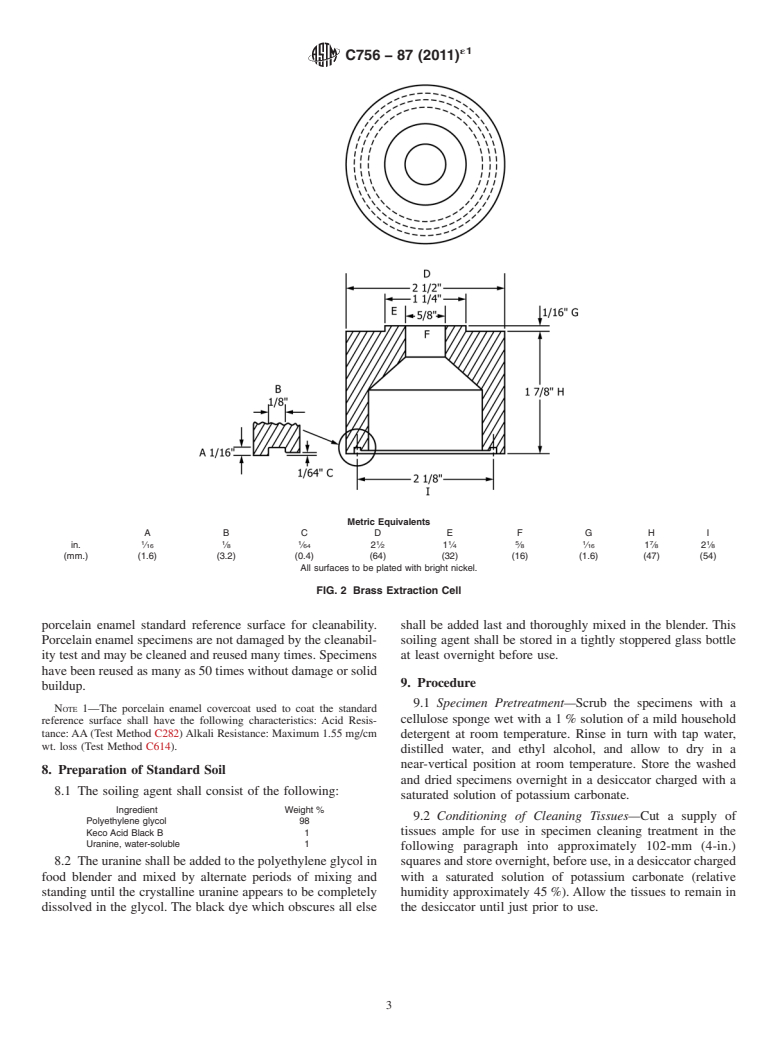

5.9 Extraction Cell, fitted with a fluorosilicone O-ring, size

5 6.7 Mild Household Detergent, liquid.

1 1

3.2 by 57 mm ( ⁄8 by 2 ⁄4 in.) (Fig. 2).

5.10 Fluorometer, for measuring the fluorescence of solu-

7. Test Specimens

tions.

7.1 The preferred specimen size is 114 mm (4 ⁄2 in.) square,

5.11 0.9NeutralDensityFilter,50.8by50.8mm(2by2in.)

but any other size or shape may be used provided it can be

glass mounted (transmission 12.5 %).

rotated on the lapping wheel and the smaller dimension is

between 102 and 127 mm (4 and 5 in.). Sharp or jagged edges

5.12 Beakers, borosilicate, 100-mL capacity.

shall be filed or honed to prevent snagging of the cleaning

tissues during the mechanical cleaning process.

O-rings must be fluorosilicone polymer; consult Precision Associates, 742 N.

Washington Ave., Minneapolis, MN 55401; Parker Seal Co., 10567 W. Jefferson

7.2 Twelvespecimensarerequiredtoevaluatethecleanabil-

Blvd., Culver City, CA 90230; & B. W. Rogers (Parker Dis.) 1000 Brookpark Rd.,

ity index, that is, six of the candidate surface, and six of a

Cleveland, OH 44109. Also see other sources in Thomas Register under SEALS:

“O” RINGS.Asuitable device for clamping the cell to a specimen is shown in Fig.

3 and Fig. 5.

Turner Fluorometer, Model 111 (Turner 111-003) available from Curtin Cel-Fibe Wipes, Type 1745 or equivalent.

Matheson Scientific, Inc., 10727 Tucker St., Beltsville, MD 20705, Sequoia-Turner Uranine is the sodium salt of fluorescein, C H O Na .

20 10 5 2

Dial Model 111, Fisher Scientific Co., 711 Forbes Ave., Pittsburg, PA 15219, and Awater-soluble fabric dye used principally for nylon, silk, and wool; available

other principal cities for both. from Keystone Aniline and Chemical Co., 321 N. Loomis, Chicago, IL 60607.

´1

C756 − 87 (2011)

Metric Equivalents

AB C D E F G H I

1 1 1 1 1 5 1 7 1

in. ⁄16 ⁄8 ⁄64 2 ⁄2 1 ⁄4 ⁄8 ⁄16 1 ⁄8 2 ⁄8

(mm.) (1.6) (3.2) (0.4) (64) (32) (16) (1.6) (47) (54)

All surfaces to be plated with bright nickel.

FIG. 2 Brass Extraction Cell

porcelain enamel standard reference surface for cleanability. shall be added last and thoroughly mixed in the blender. This

Porcelain enamel specimens are not damaged by the cleanabil- soiling agent shall be stored in a tightly stoppered glass bottle

ity test and may be cleaned and reused many times. Specimens at least overnight before use.

have been reused as many as 50 times without damage or solid

9. Procedure

buildup.

9.1 Specimen Pretreatment—Scrub the specimens with a

NOTE 1—The porcelain enamel covercoat used to coat the standard

cellulose sponge wet with a 1 % solution of a mild household

reference surface shall have the following characteristics: Acid Resis-

tance:AA(Test Method C282)Alkali Resistance: Maximum 1.55 mg/cm detergent at room temperature. Rinse in turn with tap water,

wt. loss (Test Method C614).

distilled water, and ethyl alcohol, and allow to dry in a

near-vertical position at room temperature. Store the washed

8. Preparation of Standard Soil

and dried specimens overnight in a desiccator charged with a

8.1 The soiling agent shall consist of the following:

saturated solution of potassium carbonate.

Ingredient Weight %

9.2 Conditioning of Cleaning Tissues—Cut a supply of

Polyethylene glycol 98

tissues ample for use in specimen cleaning treatment in the

Keco Acid Black B 1

Uranine, water-soluble 1

following paragraph into approximately 102-mm (4-in.)

8.2 The uranine shall be added to the polyethylene glycol in squares and store overnight, before use, in a desiccator charged

food blender and mixed by alternate periods of mixing and with a saturated solution of potassium carbonate (relative

standing until the crystalline uranine appears to be completely humidity approximately 45 %). Allow the tissues to remain in

dissolved in the glycol. The black dye which obscures all else the desiccator until just prior to use.

´1

C756 − 87 (2011)

Metric Equivalents

AB C D E F G H I J K L M N

1 1 3 1 7 5 1 1 1 5 5

in. ⁄16 2 ⁄4 1 ⁄8 ⁄4 1 ⁄8 ⁄16 56 1 ⁄4 3 ⁄4 ⁄4 4 ⁄8 4 ⁄8 5

(mm) (1.6) (64) (35) (6.4) (47) (8) (127) (152) (32) (83) (6.4) (117) (117) (127)

FIG. 3 Device for Clamping Extraction Cell to Specimen

9.3 Soiling and Cleaning Treatments: 22 s (so that it will stop as well as start at the center of the

9.3.1 Lay out six specimens face up on a table. Homogenize specimen). Remove the cleaning head without sliding motion.

thesoilingagentbyup-endingseveraltimesbeforeuse.Fillthe

Repeat the cleaning operation with the second tissue-covered

hypodermic syringe with no needle attached with the soiling head,usingthesameamountofdistilledwaterandforthesame

agent by withdrawing the plunger. Expel this charge of soil

22-s period.

back into the soil bottle. Then fill the syringe again. Wipe the

9.3.3 Store the first soiled and cleaned specimen in a near

tipofthesyringewithacleaningtissueandexpelseveraldrops

vertical position in a rack while applying exactly the same

into the soil bottle. Then, without rewiping the tip, hold the

series of soiling and cleaning treatments to the five remaining

syringe vertically over a specimen and discharge one drop near

specimens.

the center of each of the six specimens. Center the first

9.4 Water Extraction of the Soil Retained—Remove the

specimen on the lapping wheel and hold it in place by means

small, often nonvisible, amounts of soil from the central

of adhesive tape across the specimen corners. Place the

portion of the soiled and cleaned specimens with 10 mL of

polytetrafluoroethylene-faced soiling head on the soil, and

distilled water in the O-ring sealed extraction cell by the

engage the spindle (Fig. 4) of the polishing unit. Operate the

following sequence of operations within 30 min after soiling;

lapping wheel and the polishing unit for 1 min to distribute the

place the first soiled and cleaned specimen, face up, in the

soil over the central portion of the specimen (Fig. 5). Remove

center of the cell clamping frame. Place a clean and dry

the soiling head and clean it with tissue for reuse. Adjust the

spindle so that it rests over the center of the soil spot. Prepare extraction cell (Fig. 2) on the center of the specimen so that the

O-ring defines the area to be extracted (Fig. 5). Clamp the cell

twocleaningheads57mm(2 ⁄4in.)diameter)bycoveringwith

fourthicknessesofcleaningtissuesclampedsmoothlyinplace. intheframewithalightpressurefromthewingnuts;introduce

10 mL of distilled water with the 10-mL repeating pipet, swirl

With the repeating pipet expel exactly 0.021 mL of distilled

water at the center of the tissue on the first cleaning head. the water in the cell momentarily and let stand for 3 min, give

the solution in the cell another swirl and pour out into a clean

9.3.2 Immediately place the cleaning head with tissue side

againstthesoiledspecimen,engagethespindle,andoperatefor and dry 100 mL beaker; transfer a portion of the extract to a

´1

C756 − 87 (2011)

Metric Equivalents

AB C

1 1

in. 10 ⁄2 ⁄4

(mm.) (254) (13) (6.4)

FIG. 4 Spindle for Polisher

FIG. 5 Equipment Used in Soiling and Cleaning Specimens

clean, dry cuvette and place the cuvette in a rack until the other 9.5 MeasurementofFluorescence—Operate the fluorometer

five extracts are ready for measurement in the fluorometer. according to the manufacturer’s instructions. Measure and

´1

C756 − 87 (2011)

record the fluorescence of a distilled water blank. Measure and 10. Calculation of a Cleanability Index

record in turn the fluorescence of the solutions extracted from

10.1 Subtract the measured fluorescence value for the dis-

the specimens.

tilled water blank from the measured fluorescence value for

each of the six test surfaces and the six standard reference

NOTE 2—If concentrated solutions give off-scale readings, a 0.9

surfaces. This will result in corrected fluorescence values for

neutral-density filter should be inserted between the fluorescing solution

the six test surfaces and for the six standard reference surfaces.

and the photomultiplier. This filter transmits only 12.5 % of the light

emitted by the solution, reducing the fluroescence readings and bringing

10.2 Calculate the average of the corrected fluorescence

them on scale. Redetermine the blank reading with the filter in place and

values for the six test surfaces and for the six standard

multiply the reduced reading by 8.0 which is 1 divided by the 12.5 %

reference surfaces.

transmission of the neutral density filter.

10.3 Calculate the coefficient of variation of the corrected

9.6 Standard Reference Surface—Apply the test procedure

fluorescence values for the six test surfaces and for the six

outlined in 7.1 through 7.5 to the Standard Reference Surfaces

standard reference surfaces.

at least once during each testing day to obtain the average

10.4 Repeat the cleanability determinations on all six speci-

fluorescence of solutions extracted from these specimens.

mens (either the test specimens or the six standard reference

specimens) if the coefficient of variation is greater than 20 %.

9.7 Preferred Methods of Equipment Cleaning:

10.5 The cleanability index is calculated as follows:

9.7.1 The successful use of the fluorimetric analytical tech-

niques employed in this procedure demands that a scrupulous

CI 5 Ft/Fr (1)

level of cleanliness be maintained throughout. An oily thumb-

where:

print on the glass cuvette containing the solution to be

CI = the cleanability index of the surface being tested,

measured may be more fluorescent than the unknown.

Ft = the average co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.