ASTM D396-09

(Specification)Standard Specification for Fuel Oils

Standard Specification for Fuel Oils

ABSTRACT

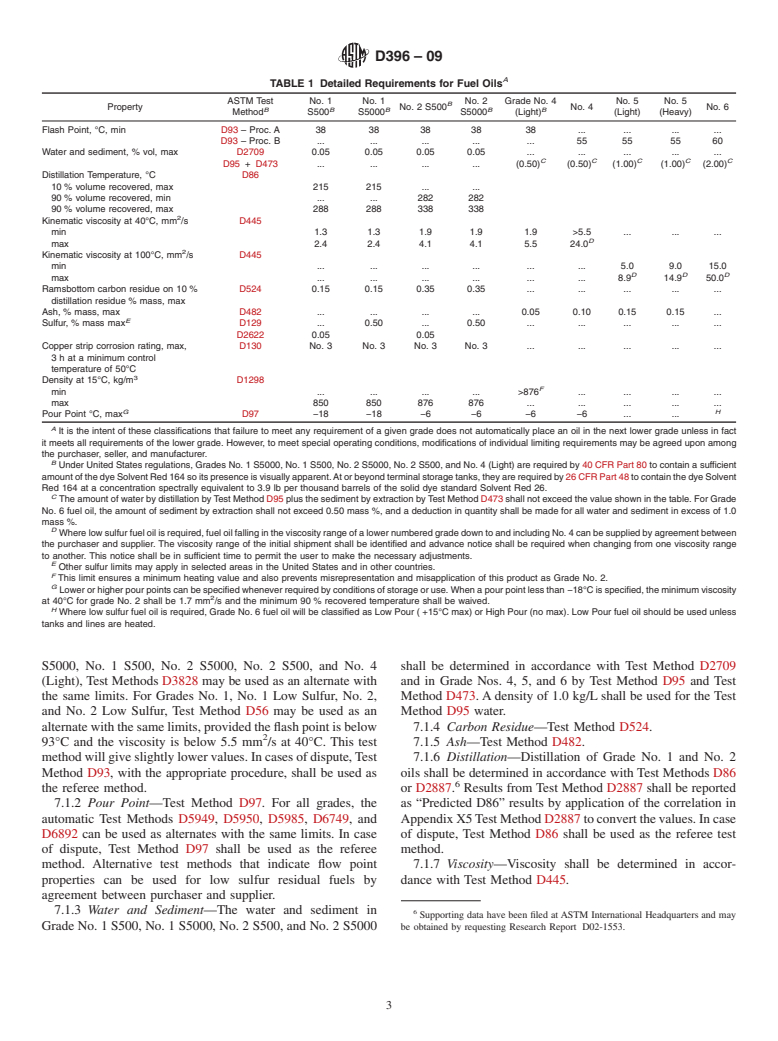

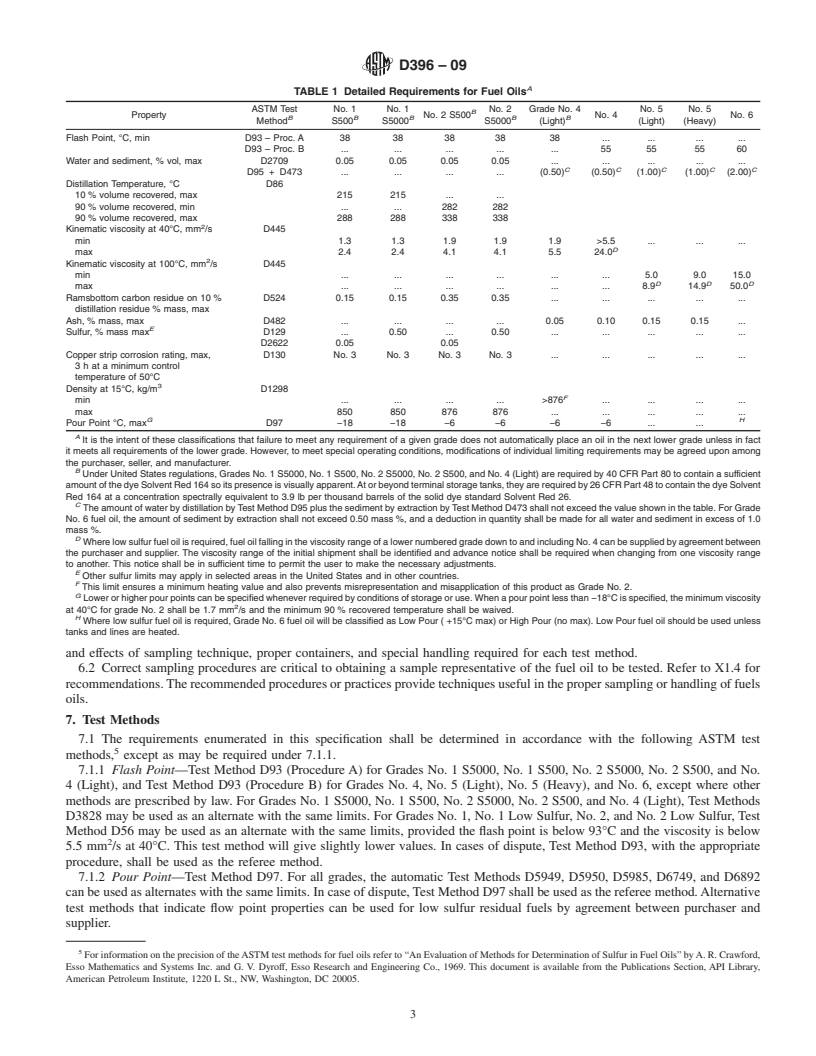

This specification covers grades of fuel oil intended for use in various types of fuel-oil-burning equipment under various climatic and operating conditions. These grades include the following: Grades No. 1 S5000, No. 1 S500, No. 2 S5000, and No. 2 S500 for use in domestic and small industrial burners; Grades No. 1 S5000 and No. 1 S500 adapted to vaporizing type burners or where storage conditions require low pour point fuel; Grades No. 4 (Light) and No. 4 (Heavy) for use in commercial/industrial burners; and Grades No. 5 (Light), No. 5 (Heavy), and No. 6 for use in industrial burners. Preheating is usually required for handling and proper atomization. The grades of fuel oil shall be homogeneous hydrocarbon oils, free from inorganic acid, and free from excessive amounts of solid or fibrous foreign matter. Grades containing residual components shall remain uniform in normal storage and not separate by gravity into light and heavy oil components outside the viscosity limits for the grade. The grades of fuel oil shall conform to the limiting requirements prescribed for: (1) flash point, (2) water and sediment, (3) physical distillation or simulated distillation, (4) kinematic viscosity, (5) Ramsbottom carbon residue, (6) ash, (7) sulfur, (8) copper strip corrosion, (9) density, and (10) pour point. The test methods for determining conformance to the specified properties are given.

SCOPE

1.1 This specification (see Note 1) covers grades of fuel oil intended for use in various types of fuel-oil-burning equipment under various climatic and operating conditions. These grades are described as follows:

1.1.1 Grades No. 1 S5000, No. 1 S500, No. 2 S5000, and No. 2 S500 are middle distillate fuels for use in domestic and small industrial burners. Grades No. 1 S5000 and No. 1 S500 are particularly adapted to vaporizing type burners or where storage conditions require low pour point fuel.

1.1.2 Grades No. 4 (Light) and No. 4 are heavy distillate fuels or middle distillate/residual fuel blends used in commercial/industrial burners equipped for this viscosity range.

1.1.3 Grades No. 5 (Light), No. 5 (Heavy), and No. 6 are residual fuels of increasing viscosity and boiling range, used in industrial burners. Preheating is usually required for handling and proper atomization.

Note 1—For information on the significance of the terminology and test methods used in this specification, see Appendix X1.

Note 2—A more detailed description of the grades of fuel oils is given in X1.3.

1.2 This specification is for the use of purchasing agencies in formulating specifications to be included in contracts for purchases of fuel oils and for the guidance of consumers of fuel oils in the selection of the grades most suitable for their needs.

1.3 Nothing in this specification shall preclude observance of federal, state, or local regulations which can be more restrictive.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 3—The generation and dissipation of static electricity can create problems in the handling of distillate burner fuel oils. For more information on the subject, see Guide D 4865.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D396 – 09

Standard Specification for

1

Fuel Oils

This standard is issued under the fixed designation D396; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification (see Note 1) covers grades of fuel oil 2.1 ASTM Standards:

intended for use in various types of fuel-oil-burning equipment D56 Test Method for Flash Point by Tag Closed Cup Tester

under various climatic and operating conditions. These grades D86 Test Method for Distillation of Petroleum Products at

are described as follows: Atmospheric Pressure

1.1.1 Grades No. 1 S5000, No. 1 S500, No. 2 S5000, and D93 Test Methods for Flash Point by Pensky-Martens

No. 2 S500 are middle distillate fuels for use in domestic and Closed Cup Tester

small industrial burners. Grades No. 1 S5000 and No. 1 S500 D95 Test Method for Water in Petroleum Products and

are particularly adapted to vaporizing type burners or where Bituminous Materials by Distillation

storage conditions require low pour point fuel. D97 Test Method for Pour Point of Petroleum Products

1.1.2 Grades No. 4 (Light) and No. 4 are heavy distillate D129 Test Method for Sulfur in Petroleum Products (Gen-

fuels or middle distillate/residual fuel blends used in eral Bomb Method)

commercial/industrial burners equipped for this viscosity D130 Test Method for Corrosiveness to Copper from Pe-

range. troleum Products by Copper Strip Test

1.1.3 Grades No. 5 (Light), No. 5 (Heavy), and No. 6 are D445 Test Method for Kinematic Viscosity of Transparent

residual fuels of increasing viscosity and boiling range, used in and Opaque Liquids (and Calculation of Dynamic Viscos-

industrial burners. Preheating is usually required for handling ity)

and proper atomization. D473 TestMethodforSedimentinCrudeOilsandFuelOils

by the Extraction Method

NOTE 1—For information on the significance of the terminology and

D482 Test Method for Ash from Petroleum Products

test methods used in this specification, see Appendix X1.

D524 Test Method for Ramsbottom Carbon Residue of

NOTE 2—Amore detailed description of the grades of fuel oils is given

in X1.3. Petroleum Products

D975 Specification for Diesel Fuel Oils

1.2 This specification is for the use of purchasing agencies

D1266 Test Method for Sulfur in Petroleum Products

in formulating specifications to be included in contracts for

(Lamp Method)

purchasesoffueloilsandfortheguidanceofconsumersoffuel

D1298 Test Method for Density, Relative Density (Specific

oils in the selection of the grades most suitable for their needs.

Gravity), or API Gravity of Crude Petroleum and Liquid

1.3 Nothing in this specification shall preclude observance

Petroleum Products by Hydrometer Method

of federal, state, or local regulations which can be more

D1552 Test Method for Sulfur in Petroleum Products

restrictive.

(High-Temperature Method)

1.4 The values stated in SI units are to be regarded as

D2500 Test Method for Cloud Point of Petroleum Products

standard. No other units of measurement are included in this

D2622 Test Method for Sulfur in Petroleum Products by

standard.

Wavelength Dispersive X-ray Fluorescence Spectrometry

NOTE 3—The generation and dissipation of static electricity can create

D2709 Test Method for Water and Sediment in Middle

problems in the handling of distillate burner fuel oils. For more informa-

Distillate Fuels by Centrifuge

tion on the subject, see Guide D4865.

D2887 Test Method for Boiling Range Distribution of

Petroleum Fractions by Gas Chromatography

1

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

2

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2009. Published April 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1934. Last previous edition approved in 2008 as D396–08c. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0396-09. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D396 – 09

D3245 Test Method for Pumpability of Industrial Fuel Oils 4. General Requirements

D3828 Test Methods for Flash Point by

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D396 – 09

Standard Specification for

1

Fuel Oils

This standard is issued under the fixed designation D396; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification (see Note 1) covers grades of fuel oil intended for use in various types of fuel-oil-burning equipment

under various climatic and operating conditions. These grades are described as follows:

1.1.1 Grades No. 1 S5000, No. 1 S500, No. 2 S5000, and No. 2 S500 are middle distillate fuels for use in domestic and small

industrial burners. Grades No. 1 S5000 and No. 1 S500 are particularly adapted to vaporizing type burners or where storage

conditions require low pour point fuel.

1.1.2 Grades No. 4 (Light) and No. 4 are heavy distillate fuels or middle distillate/residual fuel blends used in commercial/

industrial burners equipped for this viscosity range.

1.1.3 Grades No. 5 (Light), No. 5 (Heavy), and No. 6 are residual fuels of increasing viscosity and boiling range, used in

industrial burners. Preheating is usually required for handling and proper atomization.

NOTE 1—For information on the significance of the terminology and test methods used in this specification, see Appendix X1.

NOTE 2—A more detailed description of the grades of fuel oils is given in X1.3.

1.2 Thisspecificationisfortheuseofpurchasingagenciesinformulatingspecificationstobeincludedincontractsforpurchases

of fuel oils and for the guidance of consumers of fuel oils in the selection of the grades most suitable for their needs.

1.3 Nothing in this specification shall preclude observance of federal, state, or local regulations which can be more restrictive.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

NOTE 3—The generation and dissipation of static electricity can create problems in the handling of distillate burner fuel oils. For more information

on the subject, see Guide D4865.

2. Referenced Documents

2

2.1 ASTM Standards:

D56 Test Method for Flash Point by Tag Closed Cup Tester

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D97 Test Method for Pour Point of Petroleum Products

D129 Test Method for Sulfur in Petroleum Products (General Bomb Method)

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D473 Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

D482 Test Method for Ash from Petroleum Products

D524 Test Method for Ramsbottom Carbon Residue of Petroleum Products

D975 Specification for Diesel Fuel Oils

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D1298 Test Method for Density, Relative Density (Specific Gravity), orAPI Gravity of Crude Petroleum and Liquid Petroleum

Products by Hydrometer Method

D1552 Test Method for Sulfur in Petroleum Products (High-Temperature Method)

1

This specification is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0 on

Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

Current edition approved April 15, 2009. Published April 2009. Originally approved in 1934. Last previous edition approved in 2008 as D396–08c. DOI:

10.1520/D0396-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D396 – 09

D2500 Test Method for Cloud Point of Petroleum Products

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2709 Test Method for Water

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.