ASTM F1030-86(2014)e1

(Practice)Standard Practice for Selection of Valve Operators

Standard Practice for Selection of Valve Operators

ABSTRACT

This practice provides guidance in the selection of manual and power-actuated valve operators. The selection criteria for manual valve operators apply to handwheels and tee-wrenches. The selection criteria for power-actuated valve operators, on the other hand, apply to stem nut and handwheel driven valve operators of the electric, pneumatic, and hydraulic types.

SCOPE

1.1 This practice provides guidance in the selection of manual and power-actuated valve operators.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1030 − 86 (Reapproved 2014) An American National Standard

Standard Practice for

Selection of Valve Operators

This standard is issued under the fixed designation F1030; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The Keywords Section was editorially added in November 2014.

1. Scope 4. General Requirements

1.1 This practice provides guidance in the selection of 4.1 General requirements apply to all types of valve opera-

manual and power-actuated valve operators. tors.

1.2 The values stated in inch-pound units are to be regarded 4.2 Operating terminals shall be accessible during all ser-

as standard. The values given in parentheses are mathematical vice conditions but shall not constitute an obstruction in

conversions to SI units that are provided for information only working spaces.

and are not considered standard.

4.3 Valve controls that are not immediately identifiable as to

1.3 This standard may involve hazardous materials,

service shall be fitted with name plates.

operations, and equipment. This standard does not purport to

4.4 Valve operating stations shall be fitted with a valve

address all of the safety concerns associated with its use. It is

position indicator unless valve position is obvious for the

the responsibility of the user of this standard to establish

service intended (full open or full closed), or valve is classified

appropriate safety and health practices and determine the

damage control smaller than 1 ⁄2 in. (38.1 mm).

applicability of regulatory limitations prior to use.

4.5 Positioning of the valve by either the local or remote

actuators shall not void the ability of any other actuator to

2. Referenced Documents

position the valve.

2.1 ANSI Standards:

4.6 All valves, regardless of size, shall be readily operable

B16.5 Pipe Flanges and Flanged Fittings

by one man in a reasonable and limited time period, either

through a manual or power-actuated valve operator.

3. List of Valve Operator Types

5. Manual Valve Operators

3.1 Manual Operators:

3.1.1 Handwheels.

5.1 Material for handwheels and tee-wrenches for casualty

3.1.2 Tee-wrenches.

or damage control shall be either malleable iron, ductile iron,

or steel.

3.2 Electric Operators:

3.2.1 Stem Nut Driven.

5.2 Portable valve wrenches shall be labeled and stored near

3.2.2 Handwheel Driven.

the valve operating station. Valve operating wrenches shall fit

and turn (to open and close) deckbox operator covers.

3.3 Pneumatic Operators:

3.3.1 Stem Nut Driven.

5.3 Valves shall be located to prevent the necessity for

3.3.2 Handwheel Driven.

ratchet wrenches wherever possible. Ratchet wrenches are,

however, permitted where valve location prevents complete

3.4 Hydraulic Operators:

wrench rotation.

3.4.1 Stem Nut Driven.

3.4.2 Handwheel Driven.

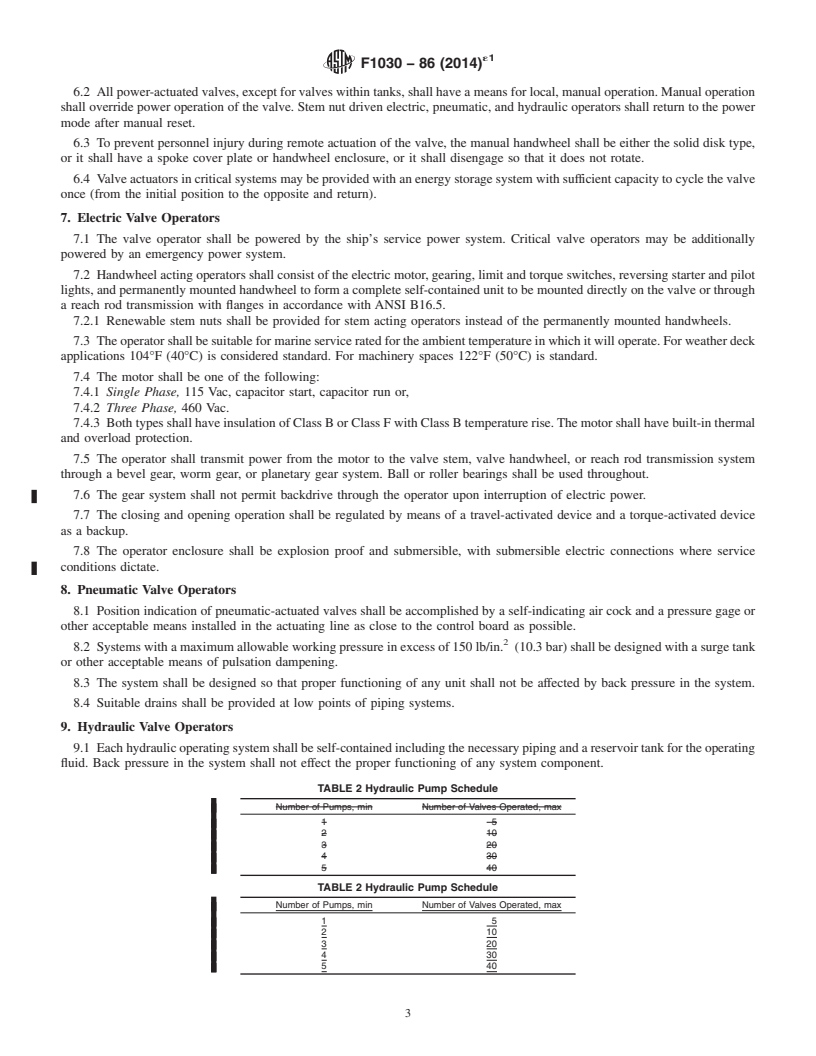

5.4 Handwheel diameter and tee-wrench handle length,

basedonthesystemtorqueattheoperatingstation,ispresented

in Table 1.

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.11 on 6. Requirements for Power-Actuated Valve Operators

Machinery and Piping Systems.

6.1 Requirements for power-actuated operators apply to

Current edition approved Nov. 1, 2014. Published November 2014. Originally

approved in 1986. Last previous edition approved in 2008 as F1030 – 86 (2008). electric, pneumatic, and hydraulic valve operators.

DOI: 10.1520/F1030-86R14E01.

6.2 All power-actuated valves, except for valves within

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. tanks, shall have a means for local, manual operation. Manual

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1030 − 86 (2014)

TABLE 1 Handwheel Diameters and Tee-Wrench Handle Lengths

throughabevelgear,wormgear,orplanetarygearsystem.Ball

Tee-Wrench or roller bearings shall be used throughout.

Handwheel

Torque, Handle

Diameter,

7.6 The gear system shall not permit backdrive through the

lbf·ft Length,

in. (mm)

in. (mm)

operator upon interruption of electric power.

7.5 10 (254) 2 (50.8)

7.7 The closing and opening operation shall be regulated by

12.3 10 (254) 3 (76.2)

17.7 10 (254) 4 (101.6) means of a travel-activated device and a torque-activated

23.3 10 (254) 5 (127.0)

device as a backup.

29.5 10 (254) 6 (152.4)

35.3 12 (304.8) 7 (177.8)

7.8 The operator enclosure shall be explosion proof and

41.3 12 (304.8) 8 (203.0)

submersible, with submersible electric connections where ser-

47.6 20 (508) 9 (228.6)

vice conditions dictate.

54.2 20 (508) 10 (254.0)

61.0 20 (508) 11 (279.4)

67.5 20 (508) 12 (304.8)

8. Pneumatic Valve Operators

80.5 20 (508) 14 (355.6)

8.1 Position indication of pneumatic-actuated valves shall

94.0 20 (508) 16 (406.4)

108.0 . . . 18 (457.2)

be accomplished by a self-indicating air cock and a pressure

128.6 . . . 21 (533.4)

gageorotheracceptablemeansinstalledintheactuatinglineas

150.0 . . . 24 (609.6)

168.8 . . . 27 (685.8) close to the control board as possible.

187.5 . . . 30 (762.0)

8.2 Systemswitha

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1030 − 86 (Reapproved 2008) F1030 − 86 (Reapproved 2014)An American National Standard

Standard Practice for

Selection of Valve Operators

This standard is issued under the fixed designation F1030; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The Keywords Section was editorially added in November 2014.

1. Scope

1.1 This practice provides guidance in the selection of manual and power-actuated valve operators.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only. mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ANSI Standard:Standards:

B16.5 Pipe Flanges and Flanged Fittings

3. List of Valve Operator Types

3.1 Manual Operators:

3.1.1 Handwheels.

3.1.2 Tee-wrenches.

3.2 Electric Operators:

3.2.1 Stem Nut Driven.

3.2.2 Handwheel Driven.

3.3 Pneumatic Operators:

3.3.1 Stem Nut Driven.

3.3.2 Handwheel Driven.

3.4 Hydraulic Operators:

3.4.1 Stem Nut Driven.

3.4.2 Handwheel Driven.

4. General Requirements

4.1 General requirements apply to all types of valve operators.

4.2 Operating terminals shall be accessible during all service conditions but shall not constitute an obstruction in working

spaces.

4.3 Valve controls that are not immediately identifiable as to service shall be fitted with name plates.

4.4 Valve operating stations shall be fitted with a valve position indicator unless valve position is obvious for the service

intended (full open or full closed), or valve is classified damage control smaller than 1 ⁄2 in. (38.1 mm).

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved Nov. 1, 2008. Published December 2008November 2014. Originally approved in 1986. Last previous edition approved in 20042008 as F1030 – 86

(2004).(2008). DOI: 10.1520/F1030-86R08.10.1520/F1030-86R14E01.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1030 − 86 (2014)

4.5 Positioning of the valve by either the local or remote actuators shall not void the ability of any other actuator to position

the valve.

4.6 All valves, regardless of size, shall be readily operable by one man in a reasonable and limited time period, either through

a manual or power-actuated valve operator.

5. Manual Valve Operators

5.1 Material for handwheels and tee-wrenches for casualty or damage control shall be either malleable iron, ductile iron, or

steel.

5.2 Portable valve wrenches shall be labeled and stored near the valve operating station. Valve operating wrenches shall fit and

turn (to open and close) deckbox operator covers.

5.3 Valves shall be located to prevent the necessity for ratchet wrenches wherever possible. Ratchet wrenches are, however,

permitted where valve location prevents complete wrench rotation.

5.4 Handwheel diameter and tee-wrench handle length, based on the system torque at the operating station, is presented in Table

1.

6. Requirements for Power-Actuated Valve Operators

6.1 Requirements for power-actuated operators apply to electric, pneumatic, and hydraulic valve operators.

TABLE 1 Handwheel Diameters and Tee-Wrench Handle Lengths

Tee-Wrench

Handwheel

Torque, Handle

Diameter,

lbf·ft Length,

in. (mm)

in. (mm)

7.5 10 (254) 2 (50.8)

12.3 10 (254) 3 (76.2)

17.7 10 (254) 4 (101.6)

23.3 10 (254) 5 (127.0)

29.5 10 (254) 6 (152.4)

35.3 12 (304.8) 7 (177.8)

41.3 12 (304.8) 8 (203.0)

47.6 20 (508) 9 (228.6)

54.2 20 (508) 10 (254.0)

61.0 20 (508) 11 (279.4)

67.5 20 (508) 12 (304.8)

80.5 20 (508) 14 (355.6)

94.0 20 (508) 16 (406.4)

108.0 . . . 18 (457.2)

128.6 . . . 21 (533.4)

150.0 . . . 24 (609.6)

168.8 . . . 27 (685.8)

187.5 . . . 30 (762.0)

225.0 . . . 36 (914.4)

TABLE 1 Handwheel Diameters and Tee-Wrench Handle Lengths

Tee-Wrench

Handwheel

Torque, Handle

Diameter,

lbf·ft Length,

in. (mm)

in. (mm)

7.5 10 (254) 2 (50.8)

12.3 10 (254) 3 (76.2)

17.7 10 (254) 4 (101.6)

23.3 10 (254) 5 (127.0)

29.5 10 (254) 6 (152.4)

35.3 12 (304.8) 7 (177.8)

41.3 12 (304.8) 8 (203.0)

47.6 20 (508) 9 (228.6)

54.2 20 (508) 10 (254.0)

61.0 20 (508) 11 (279.4)

67.5 20 (508) 12 (304.8)

80.5 20 (508) 14 (355.6)

94.0 20 (508) 16 (406.4)

108.0 . . . 18 (457.2)

128.6 . . . 21 (533.4)

150.0 . . . 24 (609.6)

168.8 . . . 27 (685.8)

187.5 . . . 30 (762.0)

225.0 . . . 36 (914.4)

´1

F1030 − 86 (2014)

6.2 All power-actuated valves, except for valves within tanks, shall have a means for local, manual operation. Manual operation

shall override power operation of the valve. Stem nut driven electric, pneumatic, and hydraulic operators shall return to the power

mode after manual reset.

6.3 To prevent personnel injury during remote actuation of the valve, the manual handwheel shall be either th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.